Leaderboard

Popular Content

Showing content with the highest reputation on 03/05/2020 in all areas

-

I just got back from my annual with @AGL Aviation and I could not be more impressed. On time, on budget and Lynn and Tamara are just the best. They got to the bottom of my chronic poor heat problem, and Lynn figured out that my rudder trim was out of spec. He straightened that out, which straightened the plane out and I’m pretty sure I picked up a knot or two in cruise. And as a special bonus, I got to meet @Bob_Belville in person and see his plane.10 points

-

See, this is the kind of discussion I was looking for. I'm not looking to be "right". I just want to know the why. In my opinion, it's a "standard part", as defined here :https://www.faa.gov/aircraft/safety/programs/sups/standard_parts/media/62fr9923.txt I've always been one to not just follow the leader. I want to know the "why's". as a kid, at church, all the Sunday School teachers called me "desert island kid". Because I always wanted to know, if you were born on a desert island, your parents died, and you were never exposed to the Bible - would you go to heaven or hell when you died. And why.7 points

-

A log entry will cover many situations. My all-time favorite was found in the airframe log of a Cessna T210. It read in its entirety, and I quote, “replaced left wing with serviceable unit.”5 points

-

And so the plot thickens here using your definition. A wheelen PAR 46 LED bulb for tractors sold off Amazon is certified to SAE J1113-42 Class 5 EMI. So now we have a regulated body and nationally identified standards. Good go? https://www.amazon.com/Whelen-PAR-46-Super-LED-Steady-8-DEGREE/dp/B009LQG64S/ref=sr_1_2?keywords=whelen+led+par&qid=1583421733&sr=8-25 points

-

I know it’s been quite a while “in the works” stage, but I’m making progress. The first lower cowling stuck in the mold last week, so looking to next week for the first lower cowling to be finished. All the other molds are made and ready to produce parts. David5 points

-

@hypertech, great to see you and your nice Ovation this week! Glad you had a good experience here. @AGL Aviation is sponsoring the 2 breakfasts at our Mid /Atlantic Formation Clinic @KHKY May 15-17. They did the same last year and spent 2 days with us. Lynn had tools and parts with him just in case. The Maces' daughter Adrienne starts flying lessons Friday. She might be a pilot before she's licensed driver! She's learning in a C172 but is spending a lot of time sitting in their M20C which should be flying next week!5 points

-

USB is absolutely an industry standard. Like most standards, there is a standards body and a repository for the documentation. You can find it here: https://www.usb.org/documents I think that article has some misconceptions about what a standard is and misses the point. - signed, an EE who spent a lot of his career as a voting member of a number of standards working groups, including IEEE 802.16, IEEE 802.11 (WiFi), and 3GPP LTE (Cell phones).5 points

-

How is adding a USB charger a major alteration? Just a quick minor mod sign off from an A&P would seem to do it. No 337, no STC, no TSO, no PMA. All legal. Whether the A&P would feel comfortable using his certificate to do that is a different issue. -Robert4 points

-

There are those that may not buy another plane but utilize funds to finish commercial rating and cfi to ensure more people get checked out in Mooney’s and possibly make a run at flying for the airlines. That way more people learn about Mooney’s from the CFI that loved flying Mooney’s and gets to attend college fairs and tell the students at them to go buy Mooney’s or that person gets another Mooney !4 points

-

All you need is an a&p willing to sign it off as a minor mod. -Robert4 points

-

3 points

-

Partly. I talked to the CAV folks, who are very nice and very helpful by the way. TKS FIKI requires the full panoply of items. Dual batteries, dual alternators, dual pumps, dual windshield pumps and a TKS prop system. If you had a hot prop they would remove it. Now would an airplane with a TKS system without dual everything and a hot prop be just as effective? As long as everything works, most likely. I've flown a lot of very effective hot props. The reality is in one case you are looking for a "parachute" and in another you are looking to expand the legal dispatch envelope.3 points

-

A sudden and unexpected gust of that magnitude would be quite a handful in a much larger airframe. In a Mooney, it would be near horrendous and I thought you did well to maintain control. Thanks for sharing and a lesson for us all.3 points

-

You can talk to your local prop shop about getting a hot prop. They should have the product and the STC for it. As far as I know there is no STC for an alcohol windshield only. It is usually part of a TKS package. There is no FIKI with a hot prop for Mooney's, only inadvertent protection. To have FIKI you must have a TKS feed on the prop and even then it is only for the long bodies. In reality in 30,000 hours of flying including daily runs to Lake Tahoe for 6 years I have yet to find icing that stuck to the windshield all the way to landing. Even on measly little single engine Cessna's. You can usually get enough defroster heat and enough temp rise down low to clear the windshield. A hot prop would be a good idea if you are a regular IFR traveler. At least you can keep thrust on it while you look for a way out which often times is a climb.3 points

-

This is simple, just ask the person signing your annual inspections if what you want is good enough for them, if the answer is yes, your good to go until a IA change, or selling, then it could be an issue. Mechanics and IA's are able And required to make these types of decisions, even if 2 disagree , its their signature. If I was your IA I would suggest no to installing a non certified panel mounted USB. Why? A few problems I see are load needs, internal issues, radio/nav issues, fire hazard, materials, does it burn up inflight and toxic smoke will pour out, these are all unknowns, that I feel are to high of a risk for an aircraft installation. my IA .023 points

-

The 1st image is not legal. The second image would be legal in a certified aircraft. I could run an inverter off my cigarette lighter, plug in a powestrip, and run all sorts of stuff (nevermind the breaker might pop). That mess is totally legal. Why?3 points

-

I installed one in my Citabria. It was an easy install and only took a couple of hours or so. I paid my mechanic $75 to inspect and sign off. The unit works fine. The AOA seems to be accurate, though I don’t think it adds much value in the Citabria. I will probably put one in my Mooney for another backup AI. The AI is excellent, it reacts quickly and accurately to extreme attitudes. Lee3 points

-

If your IA will sign off on it install as a minor mod install it. This a minor mod only. After installation make sure you don't have any interference with radios and move on. If you experience interference try another brand or add a noise filter to the power lead to the USB port. JMHO3 points

-

If your aircraft came with a cigarette lighter from the factory like mine did, simply plug one of the usb chargers from dollar general that cost 5.99 into it. If it bothers your radios then try a different brand. I use one all the time to power my tablet and phone. It is perfectly legal if it is not permanently installed. Mark3 points

-

Personally I moved on just seeing the GB and clever marketing by 130 SMOH LOWER 220 SMOH TOP TSIO360GB1 Recognize the misuse of SMOH - there is no such thing as SMOH Lower or top. Neither reset the clock for the engines TSMOH. It would be more correct and honest to say Lower was IRAN'd 130 hrs ago and whatever cylinder work was done 220 hrs ago - but engine time since last overhaul hasn't changed by either of these repairs separately or together. A major overhaul has a legal definition. The real point though is that the owner didn't want to spend the $ for proper OH and you probably have no idea how thorough the repairs where done but someone is trying to tell you the work is equivalent to a Major overhaul - but its not!2 points

-

as my wise mechanic once said, "if this thing fails on you at 10,000 feet, you would have paid any amount of money to replace"2 points

-

Paul's 100% right IMHO. I had a largely problem-free 1500+ hours with a Merlyn-equipped LB. Lots of good planes out there, and buying from a reputable dealer/broker whose business depends on reputation well past this sale is wise.2 points

-

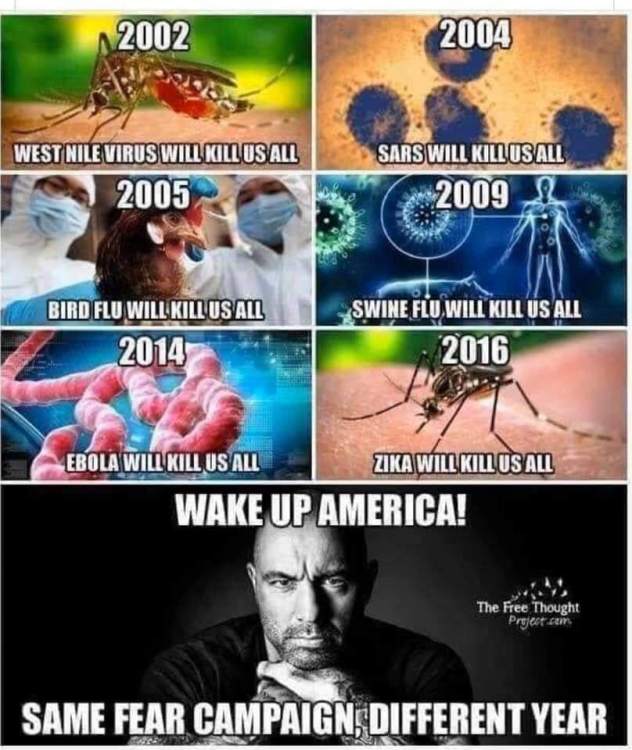

The difference is that there is a lot of people in this world with international media access that would love to ruin the current robust economy to put their own political party back in power. Their efforts are successful, so I would expect the hype to continue until the threat has long diminished.2 points

-

Yeah, everything @Oldguy said. I obviously don't know anything about this particular airplane, but there are things in the story that are concerning. It's a bit unusual that one of the GB engines gets overhauled without being upgrade to an LB engine. The engine work times are curious as well. A TOP is done and then 90 hours later the Bottom is done? Now the airplane is for sale so soon after major engine work. All of these could be indicative of an owner who isn't spending to properly maintain the airplane. That would make me wonder what else the owner isn't spending on, or what other maintenance is being deferred. Regardless, I would expect the asking price on an 231 with a GB engine to be... attractive. *PP only, not a Mooney broker or Jimmy Garrison2 points

-

You got there before I did. I've been trying to steer it that way lol. There's a LOT of parts that meet the definitions set forth in that AC.2 points

-

I met a couple of FAA accident investigators that strongly disagreed with the phrase “Mooneys carry ice well.” Be careful with that. I bought a FIKI plane. One you go FIKI, you never go back...I do spent more time running it during the monthly tests than I do in actual icing, though.2 points

-

FWIW some planes came with prop-only TKS systems (eg. Socata TB20/21). I'm told that with singles the TKS fluid from the prop usually does a good job deicing the windshield. With twins not so much, so you need either a heated one, or separate sprayers.2 points

-

Well, unfortunately you can’t get a 231 with FIKI TKS. There are a couple with inadvertent. Many have the hot prop though, which carusoam explained well, it gives you the choice of keeping the engine on the airframe.2 points

-

Here we go a trolling... I have a hangar neighbor a few hangars down with a beautiful RV that has lots of "non-certified" also not PMA/TSO's electronics/avionics in it. I have another friend around the corner with a Glasair (another pristine plane) with all kinds of "non-certified" also not PMA/TSO's electronics/avionics in it. Somehow the two of them manage to fly around without falling out of the sky or their radios quitting at the most inopportune moment causing a huge safety of flight issue. Yes, I know that my Mooney is not an experimental and thus requires certified or PMA/TSO parts in it per regulations and I knew that when I bought it. However, the argument that putting "non-certified" electronics in it can/will cause a safety of flight issue when there are experimentals flying around with those exact same electronics is disingenuous. Required by regulation? Sure. A safety factor? I have a hard time swallowing that when there are so many flying examples to the contrary. I should check with my neighbors and see which usb power ports they have installed. My guess is probably something like one of these. https://www.aircraftspruce.com/catalog/elpages/easmartdualusb.php?clickkey=156696 https://www.aircraftspruce.com/catalog/pspages/usb-adapter.php?clickkey=1566962 points

-

I like to argue, lol. I don't care if I'm right or wrong, I just like to know why. Most people, when you ask them things, say essentially "because I say so". That's never been good enough for me. I need to update my location. I'm actually in Glendale next door now. I keep my plane at DVT.2 points

-

What are aviation EMI/RFI requirements? I earlier quoted AC 20-62 which says that electronic components "do not adversely affect the performance of the equipment or article into or onto which they are installed", and pretty much anything sold has to meet FCC Part 15 for unintentional radiation (which, we've recently discovered, some very expensive TSO'd panel equipment doesn't meet). Can you cite a spec for "aviation EMI/RFI requirements"? Almost no standards do that. Standards typically define a function and characteristics, and it is up to the implementer to decide how to meet the requirements. Very often a test/verification body exists to confirm that a particular item meets the standard, but not always. e.g., a bolt might have to have certain tensile strength and corrosion resistance. A typical standard won't say how to do that or what material/alloy/etc., to use, because that stifles competition and innovation. It is up to the standard definition to completely capture the actual requirements and characteristics, but how those characteristics are met are up to the implementer/manufacturer. e.g., the specs for most "light bulbs" don't say that they have to be incandescent or how they're implemented, but, for example, how much light of what color should be emitted and what the electrical interface needs to look like. Many lighting standards originally written for incandescent bulbs are met and exceeded by LEDs, which is an example of a new technology coming to market that improves things. If the standard had specified "put a tungsten filament here and coil it this many times and string it this way", you'd have a lot of identical bulbs and no chance to improve the technology. The vast majority of standards are written explicitly to avoid that trap by only capturing the minimum requirements to meet the task that needs to be done, and leaving the door open for smaller/faster/cheaper/better ways to meet the requirements. In aviation TSOs are essentially standard specifications for particular equipment or functions. We already know that lots of different manufacturers find all kinds of different ways to meet some of them, e.g., there is a TSO that describes what a transponder needs to do, and there are lots of different implementations of transponders. Including "exactly how to make every part" is usually avoided by standards bodies. That's the manufacturer's proprietary information.2 points

-

I found myself cancelling a number of trips because there “could” be ice. Basically any cloud in the sky when it was cold. So I sold my J and bought a FIKI Encore. I rarely use it but I sure like having it.2 points

-

This isn't about wanting to do it (I already bought a couple guardian avionics chargers - which, btw, aren't TSOd or PMA either lol) but about why. So far, no one has posted any regulation that says all parts used on an aircraft have to be TSO, PMA, or on a type certificate. That's what this conversation is about2 points

-

Here is an older AOPA article that I have highlighted several paragraphs for your perusal- All aircraft parts must carry some type of verifiable FAA approval. One of the concepts that's new to first-time owners is the concept of FAA-approved parts. No other vehicle we operate has such a requirement. If our car develops a problem, we can get the parts we need at the dealer or local auto parts store. Or we can adapt another part, make our own, or choose not to take care of the problem. In aviation, however, safety and reliability are such overriding concerns that all aircraft parts must carry some type of verifiable FAA approval, and usually we must keep the approval documentation for all the parts currently installed on the airplane in the aircraft maintenance records. Even "non-functioning" parts, such as upholstery and carpeting, require approval for fire resistance before we can install them legally in an aircraft. Unapproved parts are a clear and present danger in aviation. They are attractive to some buyers because they cost less, or are available when an approved part may not be. However, these parts have not been manufactured or tested according to minimum FAA standards. That means they may not perform as well or as long as the same FAA-approved part and that should be a serious safety concern for everyone. Some sources of unapproved parts are the military, which often sells parts as surplus; parts being illegally "recycled" after they have reached or exceeded their approved life limits; parts intentionally made by unapproved manufacturers and sold to unsuspecting buyers; and auto parts and non-aviation quality hardware installed on aircraft. Shops that specialize in vintage and antique aircraft commonly find auto parts and hardware installed on aircraft. Even if the item functions adequately, it's not legal and the aircraft cannot be approved for return to service after an annual inspection. When an aircraft technician installs a part on an FAA-certified product, he or she must meet five standards, or requirements. One, the part must have FAA approval and that approval must be documented and kept in the aircraft maintenance records. Two, the part must be the proper part for that installation. Three, the part must be installed correctly. Four, the part must be function-tested to ensure that it works properly. And five, the maintenance records must be completed, showing the work accomplished, the function test performed, and that a properly certificated person or facility approved the work for return to service. The FAA parts approval process is one of the prime contributors to both the high level of safety and the high cost of aviation. The FAA has several ways that a part may receive approval for installation on an aircraft. It may be approved by the original manufacturer; it may be approved under a Parts Manufacturers Approval (PMA) by an after-market manufacturer; it may be approved as part of an Supplemental Type Certificate (STC) by an after-market manufacturer; it may be approved by meeting the requirements of a Technical Standard Order (TSO) by an after-market manufacturer; it may be approved by an FAA Field Approval (FAA Form 337); or it may have a "blanket" approval by virtue of meeting some accepted industry standard, such as a "MIL spec" or MS. The FAA approves parts installed by the original manufacturer when it builds the aircraft under the manufacturer's Type and/or Production Certificate, and these parts are eligible for both original and replacement installation. When we order a replacement part from the original manufacturer, it comes with certification documentation that verifies it's FAA-approved. The documentation might also include a part number and, sometimes, a serial number. Hence the approval of the of the Balkamp lighter It comes under the original TC An after-market parts manufacturer can apply to the FAA for a PMA to manufacture and sell parts for FAA-certificated products. To apply for a PMA, the manufacturer must tell the FAA specifically on what products the part is to be installed. It must give the FAA the name and address of the facility that will build the parts, and the drawings and specifications that show the part's configuration, dimensions, materials, the tests that will define its structural strength, and test reports and computations necessary to show that the part meets FAA regulations. Once the FAA grants a PMA, the part must carry a number and possibly a serial number, as well as the proper documentation to verify that it's FAA-approved under a PMA and is legal to be installed on the appropriate product. Anything manufactured and offered for sale to be installed on a certified airplane by a 3rd party has to have a PMA (or other approval basis, TSO, STC, etc) This shows that the part and the manufacturer have been looked at and approved by the FAA Generally, a PMA part replaces a factory original. To upgrade or enhance an airplane with products and kits not available from the original manufacturer or PMA source, such as a larger engine, floats, skis, and the like, we need to seek an after-market firm that has earned an STC approval. An STC alters the aircraft's original type certificate and is therefore a major alteration to the aircraft. A person wishing to apply for an STC must show the FAA that the altered product meets all applicable airworthiness requirements. If the aircraft was originally certificated under FAR Part 23, it must continue to meet all of the requirements of Part 23 after the STC is installed. Parts included in the STC will be FAA-approved as part of that STC and can be used under that approval only. If the parts manufacturer wants the part to be approved for use other than with the STC, it must receive a PMA for the part. Some aeronautical products are approved under a TSO. Common TSO parts include seat belts, avionics, and emergency locator transmitters (ELTs). A TSO is a minimum set of FAA performance standards for a product, and to earn it a manufacturer builds its product to meet them and verifies this by testing the product. The TSO means the part itself is FAA approved, but it implies no FAA approval for installing the part on any specific aircraft. Installing a TSO'd part in a specific process is done under another process. A part or component may be approved under an FAA Field Approval (FAA Form 337). I own a 1946 Taylorcraft with wood wing spars. When rebuilding the aircraft I found that the old spars didn't meet my standards, so I made new spars and submitted the proper documentation to the FAA for approval to install them. The FAA gave the spars a field approval on a Form 337, which is part of the aircraft's permanent records, along with a logbook entry for the installation. This process can be used for a wide variety of parts and is especially useful on older aircraft where replacement parts are no longer available. A wide variety of parts generally classified as hardware are approved by what the FAA refers to as "established industry or U.S. specifications." Most items of aircraft hardware are identified by their specification number or trade name. Threaded fasteners and rivets are usually identified by AN (Air Force-Navy), NAS (National Aircraft Standard), or MS (Military Standard, or MIL spec) numbers. This is where our "STANDARD PARTS" come in. As mentioned above a GE 4509 light bulb is made to an industry standard design (size, shape, incandescent filament , watt draw, everything about it is spelled out in an industry standard publication (SAE is a typical publication). There is no "industry standard DESIGN" for any USB socket! Nothing spells out what plastic to use or what wire size or what the contacts are to be made out of. THAT is what and industry standard does. AN bolts. MS fasteners or AN orings all have an industry standard to match, Space qualified components are approved. Unapproved parts are a serious safety concern, and they present a problem that's difficult to resolve. I've attended unapproved parts programs where parts were displayed that appear to be acceptable in every way - but are really bogus. It's extremely difficult, if not impossible, for an aircraft technician to identify an expertly manufactured, marked, and documented bogus part. One partial solution is to purchase parts only from reputable sources. The FAA is currently considering requiring FAA certification for parts suppliers. This would increase the cost of parts somewhat, but it would also increase the level of safety by making it more difficult for unapproved parts to make their way into the system. The requirement for FAA approval of aircraft parts and the system to accomplish that does increase the cost of flying, but it increases the safety of flying even more.2 points

-

The issue is if the non aviation approved 'auxiliary USB power socket' introduces EMI/RFI into the nav/comm system. The device in the OPs post may, or may not, cause an interference issue. Practically speaking, I'd rather NOT buy an unknown part, pay an A&P to install and complete whatever paperwork he deems required, and THEN find out the device does, in fact, cause interference. Much easier to buy a USB adaptor that plugs into the existing cigar lighter socket. No A&P or approval required. If there's an interference issue, just plug in another brand. Rinse and repeat as required; the things are low cost. I was lucky. The PO of my plane had already found one that plugged in and doesn't cause interference2 points

-

Perusing the invoice for my panel overhaul from an FAA repair station, I see a lot of line items from Mouser, Newark Electronics, and O'Reilly Auto. A number of permanently installed items in my airplane use batteries, supplied by such stalwart aviation legends as Energizer, Ever Ready, etc. Many ACK ELTs run on D cell batteries sourced from the aviation aisle at Wal-Mart. As has been discussed here in the past, electrical parts are legendary for not really having strict requirements, including wire terminals, butt splices, light sockets, bulbs, etc., etc. AC 20-62E says discrete electrical components may be used if "it is determined that they meet their published performance specifications and do not adversely affect the performance of the equipment or article into or onto which they are installed." This is for part substitutions into existing equipment for repair purposes. You're suggesting installation of a new gizmo as a minor modification since this does not meet the criteria of a major modification. I was noting that the 12V "Socket-Cigarette Lighter" that were installed by the repair station during my panel overhaul (4 of them) do not appear to have any PMA or TSO and were sourced from Deklin Technologies, who produce all kinds of things specifically for aircraft but who do not seem to have any PMA authorizations or TSOs on their equipment, at least not that they claim on their site or in their literature. They don't seem to appear in the FAA PMA database, either. Their AIU-900 autopilot interface does not appear to have any PMA or TSO or any other qualifications, nor do their GPS annunciators. In their installation manuals they cite AC 20-62E Par 11a and say it is the installer's responsibility to determine airworthiness. There does not seem to be a clearly defined line between the discrete and component parts defined in AC 20-62E 11b, the kits described in 11a of the same document, or even how big or complex a "kit" can be. Clearly things not listed as examples in 11b, such as cable ends, connectors, etc., are typically not PMA/TSO/STC/TLC/XYZ or whatever, so it is not a comprehensive example list. I think the part you're looking at falls in there somewhere, and whether it's a kit or a component or what it is may be debatable in itself. Regardless, there appears to be a path to installation like what Deklin describes in their installation manuals for "kit" installations, i.e., your installer inspects and tests it and makes a determination. USB is an industry standard, so maybe it's a standard part and can therefore be installed under AC 20-62E 4.f. As usual I think the bottom line is that whatever your A&P and IA are comfortable with supercedes anybody else's opinion.2 points

-

Balvenie Double Wood is my favorite for 25 years. At first, there was a 12y old single malt and now 17.2 points

-

2 points

-

I like to only include true consumables (fuel & oil) in my variable cost to fly the plane. Everything else goes into fixed costs. That way I can tell my wife, I'm already spending $3,000 a month just to own the plane and it only costs $40/hr to fly it, so we might as well fly it every chance we get!2 points

-

In order to take a C to an E your going to need to do the following. Find a IO-360, preferably a IO-360A1B6 (or have your O rebuilt by penyan) and get the lasar 200 HP Conversion STC Find a M20J 201 top and bottom cowl, left and right cowl flaps, engine baffling and duz cowl firewall mount support. Locate a Hartzell Top Prop kit for a M20J or contact hartzell and explain your ordering for a M20C with a M20J firewall forward. This will require at least 1 STC and 2 337s, I think I have access to the data for the cowl and top prop for an E but only for a -A1A which means it has the "No cont. ops. above 24″ btwn. 2350 and 2550 rpm" limitation. This also will require completely splitting the skins from the firewall so that you can replace the cowl attach points, I recommend also doing a J sloped windscreen. It goes without saying unless you are of the type to get your hands dirty and can locate a friendly A&P this is not a project for the faint of heart. It is also worth keeping in mind, this will not increase the gross weight limit of your C.2 points

-

OMG, so sad for your sweet little Echo. That was a really nice Mooney.2 points

-

A&P Dave, before he flew west, installed the fuel flow transducer in our C using an elbow and three pieces of hose, not two pieces. Photos of that are on MS someplace. Instructions from From the JPI "Frequently Asked Questions" on their web site say: 1. Make sure the transducer is horizontal with the wires up. 2. Be sure there is no bend in the line closer than 6 inches before or after the transducer. 3. Do not use aluminum fittings. 4. For carbureted engines, if the transducer is higher than the carburetor, put an anti-siphon loop in the line that peaks higher than the transducer. We installed it slightly lower than the carb for this reason. 5. Mounting the transducer between the electric boost pump and mechanical pump is not recommended. 6. Do not hard mount the transducer to the engine. Vibration may damage the internal parts and cause erratic readings. 7. Do not use teflon thread tape. The big issue with this is that the teflon tape can produce threads that when mobilized, and jam in the fuel system or in the fuel flow transducer turbine. I'm not an A&P, just an involved and curious owner and PP. Good luck!2 points

-

I saw this posted on BeechTalk and looked up the N number on FA. I couldn’t bring myself to dig for ATC recordings because I saw the path and track log. So sad, a very capable aircraft and the owner was an MMOPA member so it would “seem” conscientious. But it shows that Mother Nature doesn’t care what you know or fly, you are not invincible. I am learning a lot about ADM and recently @Yooper Rocketman penned a great thread about his recent no-go decision from his home airport to Las Vegas. Between his thread and reading about the other pilot who was in this crash, I’ve learned a lot. Tom was NOT the pilot of this airplane.2 points

-

Audio panel officially wired in, only things left on it is the marker beacon antenna because we aren't sure how you'd pin a fat coax cable into such a small pin. Wiring to be cleaned up and organized tonight then the shelf goes in. Absolutely LOVE the new overhead LED lights, installed red and white color switches, both can be dimmer or mixed. Pics show red, white and mixed. MVP-50P audio output alert tones also in audio panel and works. IMG_3191.MOV IMG_3195.MOV2 points

-

Guess that was one of those high pressure days where FL260 is below the 25,000 foot MSL limitation. (wink, wink)2 points

-

@carusoam, thanks. I dont have any more pics sorry. Agree about the GA. Like I said, hindsight, i probably should have just went around when I felt the first big gust that was a lot more than what they were calling for. I had the plane with flaps in and on normal approach/speed when it hit and outloud even said I should go around because the plane and speed weren't set up for that type of gust if there could be more. Fortunately the damage was very minor and could probably have been bent back into place but I decided to replace the door. Lesson learned.2 points

-

Where else do you get expert advice, from a leading Mooney maintenance guy, for such a great price...? Go MS! Go Clarence! Best regards, -a-2 points

-

2 points

-

2 points