Leaderboard

Popular Content

Showing content with the highest reputation since 11/14/2025 in all areas

-

Back in late 2010 I stumbled across Mooneyspace and was amazed at the amount of valuable information available and the community atmosphere of the site. I was between airplanes at the time so I lurked for awhile without signing up, absorbing anything I could. I had owned a 231 from 1993-1996, a Bravo from 1996-2000 and then other airplanes for a few years and then another Bravo from late 2006 to early 2010. In the Spring of 2011 I was seriously looking at a 231 in Georgia so I signed up on the site , and my first post was to ask a few questions as I considered the airplane. I didn't end up buying it, but by lurking on here I had the right things to consider when I went to look at it. I didn't actually end up getting another Mooney until 2014 but in the meantime I was learning a lot on this site. Mooneyspace helped me to go from being an owner that was mainly hands-off when it came to understanding how an owner can be involved in maintenance, to really enjoying getting involved. It helped to take the mystery and intimidation away. I went from never having changed my own oil on an airplane to being very involved in a top end overhaul/Bravo conversion on an M20M that I owned from 2015-2021. Yesterday I was looking at my Mooneyspace profile and to my surprise I was a few posts short of 10,000. So I thought I would take this 10,000th post to thank everyone that has made this a very fun, informative journey. Early on, @Marauder and @carusoam were very helpful along with Clarence and many others and now so many others on here collaborate to make this the premier place for Mooney information and assistance. Here's to the next fifteen years!!40 points

-

In about 3 years I will have been a MooneySpace member for half my life.16 points

-

15 points

-

14 points

-

13 points

-

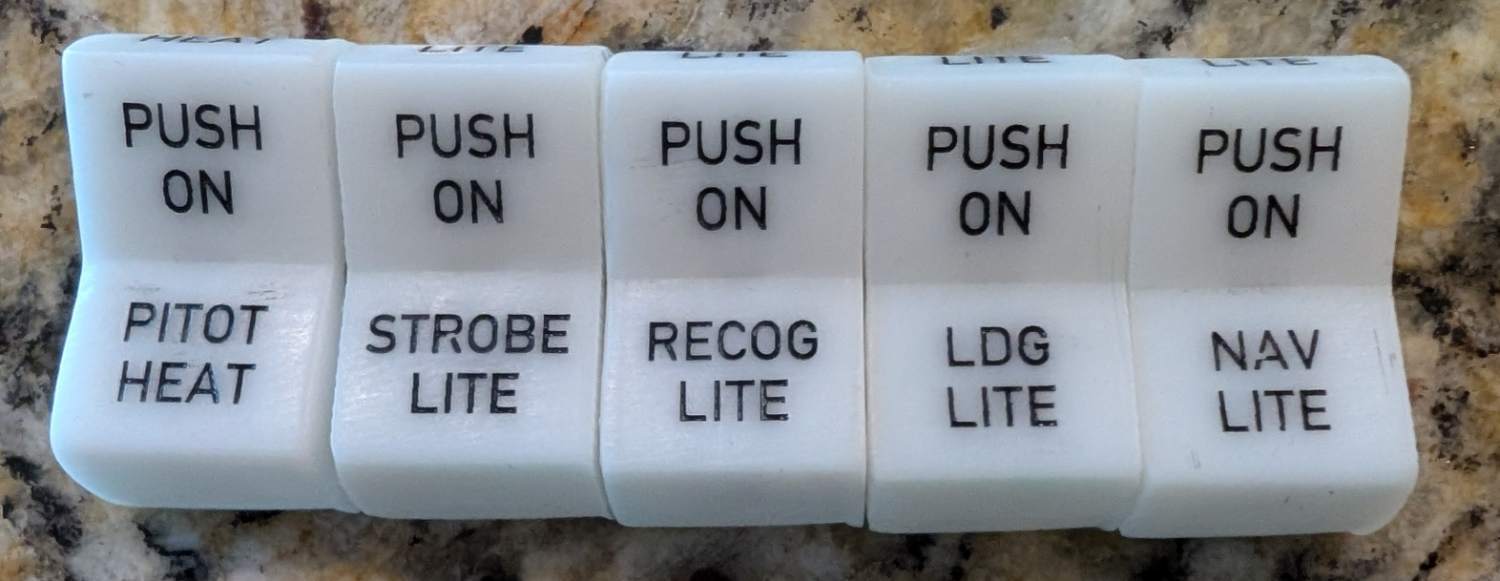

I'm halfway through my A&P program and I like sheetmetal so I decided to do a very minor owner produced part project. My 201 yoke switch covers (blanks) needed a refresh so I thought I'd just do a quick strip and repaint. Once I stripped them I wasn't happy with the condition of the old aluminum so decided to fabricate new ones. I tried .051" 2024T3 as well as .064" 2024T3 and 7075T6....I think I like the 7075 best. First photo below show the old switch covers as installed. And the other two photos compare the old stripped covers (left) to the new covers that are almost ready for paint (still need a little more hand sanding). I'll etch primer tomorrow and hopefully paint Sunday. Will post final pictures when I can.13 points

-

Hey all! My name is Philip, and I fly Dassault Falcon jets and run a mobile A&P business based out of the upper Midwest. I picked up a unique little E model Mooney as another service rig for the business, so figured I'd join and get involved with this awesome community! This E model is unique because one of the past owners put a lot into making it just like a mini-J model. It has every offered speed mod, a beautifully done original 201 paint scheme, electric gear, one piece belly, wingtips, speed brakes, and much more. The most interesting part is that it received a single aircraft approval STC for a Lycoming IO-360-C1D6 engine, which uses a 6.3 and 8th order counterweight on the crankshaft, just like the J model engines (A1B6D & A3B6D). Finishing it off, the engine is mated with a round-tip J model propeller and spinner. I've been a long-time viewer of this group, and the content here has helped tremendously when working on client's aircraft. I'm glad to now be a part of this group and hopefully I'll be able to contribute even just a fraction of the value and knowledge that is held within this community!12 points

-

Flew my Mooney for my 3rd flight without transition CFI (takair). Brought my wife up with me. We just did a short flight, for her to get used to the plane, and weather was looming so we went back and landed. Probably my best landing ever. I could barely feel my mains touch and rode them all the way out, gently touching the nose wheel down. "Are you feeling this awesome wheelie?!?" I was laughing out loud and so excited. My wife just shook her head. A landing that would've made my instructor proud. But alas, he was not there, as he has kicked me out of the transition training nest. I guess I should start instrument training soon then11 points

-

10 points

-

9 points

-

9 points

-

For those interested 43-9 was just revised allowing A&Ps to sign off on 8130s for parts and repairs. In the past some shops and IAs would not accept an 8130 with an A&P sign off because the AC only mentioned Repair Stations Now that has changed (attached below) The AC is probably deeper than most any owner wants to read but IF you have a shop not accepting an A&P 8130 you might refer them here The AC really does have (starting on page 3) a real good synopsis of who and what records are required by the owner and A&P. AC_43-9D Maint Records.pdf8 points

-

Your experience bears absolutely no resemblance to my experience when intentionally opened the door in flight to retrieve a seatbelt tail, but then I was much slower. In the summer, I frequently open the door right after touchdown with none of the violent oscillations you describe. How does a door swing open 2-3 feet into a 175mph slipstream? Seems like that defies physics. And then there’s the “drag and partial stall”…none of this seems plausible.7 points

-

7 points

-

Hi all, After a long upgrade process, my 1980 M20J is finally back in the air with a completely new panel. Here’s the clean factual list of everything that is now installed in the aircraft: Primary Flight Display / Backup Garmin G3X Touch (PFD/MFD) Garmin G5 backup (EADI/EHSI) Remote GPS antennas for both the G3X and the G5 Navigation / Communication Garmin GTN 650Xi (NAV/COM 1 + GPS) with FlightStream 510 Garmin GNC 255 (COM 2 + VOR/LOC/ILS) Garmin GMA 245R remote audio panel SIRS Navigator Compass Autopilot Garmin GFC 500 with: AutoTrim Yaw Damper Smart Glide dedicated button Engine & Sensors Full Garmin EIS integration GAP-26 Angle of Attack via GAD 26 New blue annunciator light for the electric fuel pump, now wired into the annunciator panel ADS-B / Weather / Traffic Garmin GTX 330ES retained (ADS-B OUT) Garmin GDL 50R (ADS-B IN) ADL-150B (Iridium weather) – displayed on the G3X Additional Avionics L3 WX-500 Stormscope (direct to GTN650Xi) LHS-200-C radio altimeter (audio) DME retained Panel Work One-piece custom metal panel Removal of KI-87 ADF Complete rewiring Updated breaker table Happy to answer questions about the install or config details if useful to anyone here. Before the avionics retrofit:7 points

-

7 points

-

We should strive for perfection. I think this poll shows it is hard the achieve. Designers also strive for perfection, but the regulations and design standards recognize human and machine fallibility. I think this poll also shows that there are some nice redundancies built into our machines and checklists. Miss a pitot cover on walk around, hopefully we see it on takeoff roll. Miss it there and training takes over…we hope. Miss a gust lock on preflight, hopefully catch it on the control sweep. This one gets tougher if you get airborne, so it’s important to not let errors stack up. There is a risk when we add modifications and our own protective measures without thinking failure modes. I’ve seen a number of well intentioned safety devices or design ideas that end up being more hazardous than the one they intend to prevent. Let’s all have a happy and safe Thanksgiving. Try not to rush, try to check things twice. Strive for that perfect flight. In the words of Rob Holland, Fly Good, Don’t Suck.7 points

-

In the "how have you improved your process" category, the last thing I do before climbing into the airplane is go stand 20-30 feet off the nose and give everything a last big picture look. I caught a low tire once that had looked fine in the hangar so it catches more than the obvious stuff with flags and such.7 points

-

Just an update for everyone - it looks like after a few days of working with my hosting company they FINALLY a) admitted this was a problem with their top level DNS servers and b) they managed to fix the issues. I am not sure what exactly was wrong but it was something with the SOA (start of authority) DNS records for the domain and something that is outside of my control. So users that were not able to access the site with certain ISPs (Verizon and CenturyLink are ones I am aware of) should now be able to find our site again. This also fixed the email delivery issues we were having with Yahoo (and their subsidiaries like AOL and SBCGlobal) and Apple as far as I can tell looking at logs over the past 12 hours the emails seem to be going through now. If you do have any issues I would appreciate you letting me know by shooting me a message here at @mooniac58 Thank you for your patience! Craig7 points

-

7 points

-

7 points

-

What is hard to see in Tyler’s picture is that the stab rigging was off by over 2 degrees. He never had full up trim which was actually closer to TO trim. Needless to say takeoff trim was very heavy and it was very difficult to get enough trim to land consistently. The elevator position varies depending on the vintage of Mooney. Older ones have only the bungee springs that yield a more upward position in takeoff. This J has a down bias spring, on top of the bungee springs, that provides constant down pressure. Full rigging requires removal of that spring and then reinstallation. Later models removed the bungee and have other mechanisms including bob weights. It is super critical that shops understand the mechanism. Just putting index marks on the torque tube when taking it apart to do work on the trim servo or tail is not good enough. The trim stops and trim indication are in front of the plane. As shown in this thread, it can be miss indexed to a hazardous level. Any post flights should be treated with caution. I wish the FAA still had the old service difficulty system that most mechanics read. They still have it, but it is not highly visible like it used to be. Thanks again for the kind words Tyler, but it is your integration into the entire ownership process that resulted in finding this. I feel the previous owner suffered through a poorly rigged airplane.7 points

-

Thirty-five years ago I was an engineering manager at a telecom equipment manufacturer. The CEO decided to fire the VP of Manufacturing and gave the job to the VP of Engineering - my boss. In turn, my boss anointed me warehouse supervisor. Some weeks earlier, I had ordered a birthday present for my wife and had it sent to the company so she wouldn't know about it. UPS said it was delivered, but the warehouse crew swore they never received it. Now, I was suddenly and unexpectedly their boss. I got everyone together on the warehouse floor and said that the first order of business was to find my wife's birthday present. After the shock wore off, it only took fifteen minutes to find it where it had fallen behind some other boxes.6 points

-

I think I've heard of more gear collapses due to lock block or other J-bar failures than I have electric actuator failures that led to damage. I think Skip is on the nose that the most likely failure mechanism is the pilot.6 points

-

The biggest failure mechanism isn't the actuator -- it's the pilot. Just look at all the gear ups. And, it's not that people are stupid or careless -- a lot of very experienced pilots have gotten distracted and missed the gear. I used to be in a club in San Jose that had a manual gear M20C that managed to get bellied in twice.6 points

-

A lot of good comments above but I just wanted to add another to emphasize the correct recovery technique when ever getting so slow in the pattern. The pilot began with the correct recovery in lowering the nose and the NTSB report has it as well but its a bit buried in the many bullets: Its critical to recognize pitch is immediate and lowering the nose will instantly regain flying speed, it doesn't matter whether the wings are level either at this point Notice as well that power isn't even mentioned as that may not even be necessary. The plane supposedly making its base to final turn when this happened and ideally it would have been at ~500 AGL - plenty of altitude not to yet panic. But once the pilot realizes they won't make the runway then certainly adding power is necessary, but it shouldn't need full power after lowering the nose, not even a lot of power, and there is no evidence that recovery was delayed to the point of a wing drop - quite the opposite. But what the pilot reported after he lowered the nose and after adding power is that: "The airplane then “violently” pitched up and to the left." Any increase in power needs to be matched with right rudder otherwise the plane will roll to the left uncoordinated from all of 5 turning tendencies we all learned as Private Pilots (Torque, P-Factor, Gyroscopic Precession, Spiraling Slipstream and Adverse Yaw - or lack of rudder while turning). It pretty much requires full or near full power to get the aircraft to pitch up like that violently when trimmed for landing as we're all familiar with when doing a go around and advancing full power. So plain and simple the pilot had to over react with the power and wasn't prepared for the out of trim forces that ensued. Over use of power has been mentioned a couple times above but I just wanted to emphasize the correct reaction is to lower the nose immediately; power is a secondary consideration not the immediate one; especially at 500' AGL I wasn't able to review the ADS-B ground track data to see if he might of been really low on that base to final turn but might have spawned adding so much power but in the narrative the pilot stated he thought he was about 500 AGL (per his handheld GPS) in the turn that shows excellent situational awareness IMO. But he also stated that on the down wind he had gear down, 1 notch of flaps, prop forward at 70 mph which we all know couldn't be true. The pilot was not a new pilot, but a VFR Private pilot with near 1500 TT and 376 hrs in type, flying with his wife passengers. I am thankful and amazed that both he and his wife survived with only minor injuries with only a Lap Belts!! It a testament that he never gave up. I hope if he fly's again, and I hope he does, that he never does so again without shoulder harnesses. I personally do not fly in any aircraft without them because most aren't so lucky.6 points

-

The trim-rigging issue was eventually resolved by my local mechanic, who measured a 4.5-degree off-trim condition. This is significant, because on landing with two people on board the trim was fully at the trim-up stop, and during takeoff it was obviously far outside the takeoff trim band. I therefore want to highlight the importance of checking the correct trim rigging whenever work is performed on the system, especially when installing a GFC 500 autopilot, as was the case for my aircraft. Following this incident, I completed an occurrence report form — for whatever it’s worth, at least the Spanish authority has been informed. Improperly rigged rigging (trim indication in the take-off band): After proper rigging:6 points

-

Hey! thanks for inviting me down memory lane with you fine people… it was y2k when I acquired a very worn in M20C… it fit like a glove, especially with baby seats in the back… stumbled upon MS while looking for a replacement… M20Js were an easy choice, Missiles were next on the list, Ovation was a stretch goal… ending up with a Standing Ovation… took the help of MSers to get there…. one day I was helping a new guy define differences between an Eagle and Ovation, a few months later he was giving me a ride in the coolest Screamin’ eagle ever..! Shortly after that, my plane suddenly needed a prop replacement… our friend @Cris (rip) helped me with a few contacts… and get some flying time… Getting to meet as many MSers as possible makes my day. And confuses my family…. one of those times.. meeting up with @Mitch at the mapa tent in kosh…. Where Lemonade is a tradition! ’dad, how do you know that guy?’…. MS! I started here with a member number just over 100… and read every post generated. not hard, there weren’t very many posts to read even day… as we near 20 years of MS… I hope to get that 50,000th post before then… Happy Saturday! Best regards, -a-6 points

-

I replaced mywindows in my first Mooney years ago. I say this with the most compassion, If THIS is a roadblock you are way out of your comfort level and need to get assistance. Removing the old plexi is the easy part in the process.6 points

-

Yes. The newer spec is MIL-PRF-5606H, but it's the same thing. If you are changing the brake fluid, you might consider Royco 782. It's a newer synthetic MIL-PRF-83282 fluid that won't congeal with age like 5606 which is a mineral oil. It is fully compatible with 5606, so you don't have to flush the system.6 points

-

I had hopped out so brakes weren’t an option (for me at least …). It was flat ground, but there was a strong wind and the rear hinged canopy was up like a sail (F-15). It was on a run up area in Kuwait. The plane was rolling backwards towards the dirt. My whole piloting life flashed through my mind and I pictured my impending death at my commanders hands when his jet ended up in the sand. I would have thrown my body under a tire to stop it if I thought it would work. Thank god we bombed the crap out of that place in the Gulf War and the concrete debris was still there 15 years later. I ran off the ramp, grabbed a huge piece of 3” thick concrete debris with the Herculean strength of desperation and got it under a rear tire just before it would have gone off the pavement. I braced it with my whole body. The tire partially rolled up, then settled back down. Most of the back of the jet was hanging over the edge as if I had backed it in. My wso was still in his seat the whole time yelling that it was rolling. It wasn’t until after that we both remembered he has an emergency accumulator brake handle right in front of him. There but for the grace of god go I…6 points

-

I bought a well-equipped 1978 J in 1986 for $40K. Mods were minimal: I put an Airtex interior in it and cleaned up the interior plastic and installed a 4 place intercom and replaced a transponder and an ADF. To keep costs down I did most of the maintenance myself supervised by Vern Miller at RHV in San Jose CA. Vern heartily embraced owner assisted maintenance and was a great teacher. Weekends were always interesting at Vern's hangar as there would be a lot of owners there working on their planes under Vern's tutelage. Several were Silicon Valley execs of companies you've heard of who worked on their planes not out of financial necessity, but as a form or relaxation and decompression from the stress or leading tech companies. My wife and I flew the J for 700 hours and I sold it to Ken Shoupe ( Ken started All American Aircraft Sales which he later sold to Jimmy Garrison) with bad paint and a runout engine seven years later in1993 for ----- $40K. Those were the days. I have learned so much from this site that there is no way I can ever repay it all!6 points

-

At the risk of beating a dead horse... Over 40 posts in this thread about how we're going to deal with the specific, unlikely case of a LiPo battery fire. But not a single follow up on emergency descent technique, which is important in any kind of fire, and in some other emergency situations as well. Pilots - including me - are generally terrible at risk management. We invest disproportionate time, money, and energy into the things that are least likely to kill us, while generally ignoring the things that are most likely. It's just the nature of humans, I guess.6 points

-

6 points

-

6 points

-

Just watched this. Here's one of the comments on Reddit: My first thought was the car driver might have died. Pilot should have avoided car better, even at risk to themselves. I am concerned that was their point, though. BMW of the skies. “I’ll just land on one of the peasants.” I for one believe that it is our duty to not aim for other people when we are in trouble, even if it costs us our lives. Some smiling face on a Florida billboard is going to make a $hit ton of money off this one. Luckily, the driver of the car escaped decapitation by inches. This makes me sick.5 points

-

Today's flight was my first flight of the year in my Mooney. It was glorious! I've been down for numerous health issues (removing and replacing a worn part, removing some other sick parts all together) starting last December, and the airplane was down for parts past the start of the runway rebuild project here at GKT. I kept both of us in flyable storage throughout. Me in the books and on X-plane, my baby in a climate controlled hangar with an engine dehydrator and dehydrator plugs for good measure. The runway opened a couple of weeks ago. I got a flight review in a 172 last week so I'd be legal to do the hour of post-maintenance orbits over and around the field solo. I exercised just about everything and collected enough data to confirm the engine, airplane and avionics are operating 4.0. After the GAMI sweeps I captured a couple of screen shots of the performance ROP and LOP at 30/2200, my preferred power setting. It was a good day.5 points

-

11/30/2010 - my 15 year anniversary was just 2 days ago! Maybe I'll have an extra dessert tonight in celebration Nah I have to work on that useful load5 points

-

5 points

-

Everyone needs to go back a few steps anytime they get distracted on preflight and also do a walkaround, at a distance, of the entire aircraft. Phone call interrupt your preflight? Go back a bit and do a walkaround. Prop strikes Tow bars and FBO traffic cones are *such* common claims. Old Republic (the insurance underwriter) even has branded "Tow Bar Removed?" embroidered keychain straps.5 points

-

Well, Starlink just made the decision very easy. We have Starlink at home, just received an email telling us because we do, we get a mini for free and when using roaming, 1/2 price on the monthly fee. No requirements for anything other than the low use $5/ mth fee and can roam whenever and for however long we choose. Terms are the mini is a rental at no cost so I won’t own the unit. I rather like this format, should allow for future upgrade at an overall lower cost than buying initially.5 points

-

Personally I don’t like keeping tow bar attached when not in use. I understand why some do it, and tow bar used as a chock seems okay. But my habit is when the tow bar is on it’s in my hand and when not in my hand it’s off will save a LOT of damage. It’s happened to a local pilot. I also have the habit of putting my tow bar, cowl plugs and pitot cover in the back where the pilot can see them. I’ve looked over my shoulder to verify them more than once. Reassuring to see them before the key goes in the ignition. ** the above are my habits and not trying to convince anyone else what they should or shouldn’t be doing.5 points

-

That is an early J that has been for sale since the minute the owner finished it in 2023. He started out selling it himself at well over $300,000. I think he thought he was going to make a killing on it. Now it's with a broker for a lot less, but still higher than any other early J has ever sold for. After 2-1/2 years the market has spoken. No one else has felt it's worth that. I would hate to be the only one who did. The first step is take the emotion out of it and disregard all of the new paint, nice interior and new panel. Have someone who is a Mooney expert and objective go through the logbooks with a fine tooth comb. If it passes that then negotiate the price you're willing to pay, put a deposit down and then have someone objective do a pre-buy, with the seller paying for all airworthy items found and see where it goes from there.5 points

-

5 points

-

Wow same here . . . 48 must be a popular age to start looking at Mooneyspace. . . with the exception of @Parker_Woodruff who found Mooneyspace when he was 12 . . lol5 points

-

Congrats on that milestone and on owning some fantastic Mooney aircraft. I have had a much different voyage over the years on Mooneyspace over the many many years aboard. I have ruffled many feathers here including you Lance, but have enjoyed the ride largely because of quality people such as yourself on the site. I hope you achieve another 10k. Scott5 points

-

This is sad. Props to @LANCECASPER and @donkaye, MCFI for being very cautious with him in the original first flight thread. Yall were spot on. I think, as a whole, people flying vintage airplanes, we become a little desensitized to mechanical problems bc they are so frequent. Whether it’s a pesky problem or a serious one, sometimes they are difficult to differentiate for most pilots. That’s why I stick around here. I’ve got to be in the drivers seat of knowledge and information bc too much is on the line for the hobby I love. It’s not without risk and every tiny detail could be the difference of home for dinner or an NTSB report.5 points

-

5 points

-

When doing pattern work with full stop landings: 1. Take off with approach flaps. Apply about 5 pounds of back pressure on the yoke. (Bob Krommer's "The Mooney Pull". The plane will fly off the ground when it's ready to fly. 2. In the crosswind and 100 feet below pattern altitude put the gear down. This applies the "brakes" to keep the plane from accelerating once at pattern altitude. 3. Reduce power to maintain 90 knots on downwind (Gear and Approach Flaps). By putting the gear down first before power reduction saves having to do an additional power change to maintain speed had the power been reduce first. 90 knots is a comfortable speed to maintain an appropriate distance from the runway on downwind. Without putting the gear down first a very low power setting would be required to maintain a speed below flap speed below 110 knots. Also, using this speed keeps the airplane from getting ahead of the pilot and provides for easy transition to base leg. 4. At 3° from the aim point reduce power to about 12" nominally, turn base while trimming up and adding full flaps simultaneously. By setting the nose of the airplane at 3° down the addition of the flaps will automatically cause the plane to slow to 80 knots thereby simplifying pilot workload. 5. Turn final early enough to keep the bank angle at standard rate and adjust power to main 75 knots nominally at mid-weight. Control speed with elevator and altitude with power. This is antithetical to the Jacobson Flare method. Behind the power curve it is safer to do so because pitch provides an immediate response, while power provides a delayed response. While I appreciate Jacobson's attempt to mechanically fly the airplane to a landing, even though some may use it successfully, there is a reason it has not caught on in the 40 years he has been advocating for it. Even using his method there is still an art to his last 4 seconds to flare at the proper rate to touch down with the proper amount of energy remaining. The rate of simultaneous power reduction and flare is basically the same as taught conventionally. The bottom line to "Why not reduce power to slow down and then only add gear and flaps app when commencing the final descent for landing on downwind?" is to maintain a consistent and simplistic approach to landing without letting the airplane "get ahead" of the pilot.5 points

-

I flew to Courchevel airport with a friend of mine today in his C150. It's nuts. The runway length is 1762 feet and has an 18.6% incline after the first 25 yards or so. You need training and certification to land there and my friend's was due to expire in a few days, so we went for two landings and a coffee. He promised to take me in my Mooney once I get the propeller back, so I'm a bit nervous, but excited. Anyway, check this out: (Runway is to the left, sloping up the hill...) Here it is cropped....5 points