Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/2021 in all areas

-

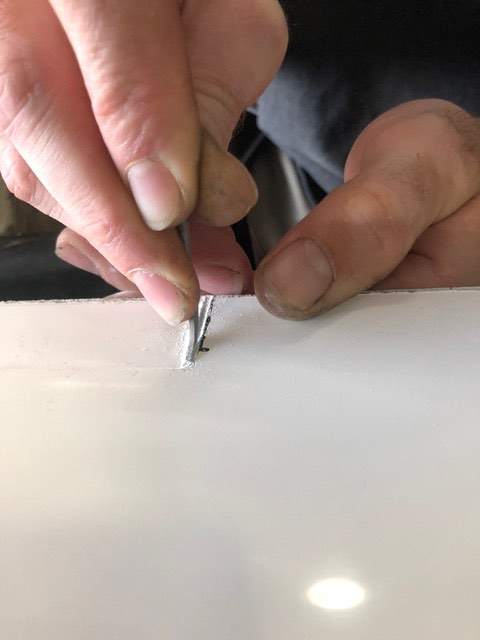

1.) I’d be a lot more concerned by what appears to be an exhaust leak blowing on your #2 bottom spark plug, and the poor installation of the EGT and CHT wiring harness. The exhaust leak would also explain your high CHT on #2 that you mentioned. 2.) Yes, the silicone gaskets will probably fix that oil leak. However, the picture of the one you posted is for a parallel valve Lycoming, your M20F has angle head valves. The picture below is the one you want, Aircraft Spruce is a much better vendor for most airplane owners: https://www.aircraftspruce.com/catalog/eppages/valvegasket05-11181-6.php 3.) That popping at low power settings isn’t uncommon at idle power. It is more fuel related than oil or exhaust.3 points

-

I know a few of you are already aware of my incident on 09/30, but I've been hesitant to post anything until the insurance company made their determination re repair vs write-off. Also, having a forced landing off-airport is an awkward situation to find oneself in, and I've needed time to process the event and my responses to it before opening the topic up for discussion on an open forum. Aircraft background: M5779R is a 1985 M20K (231) with many positive aftermarket mods, including GAMIjectors, intercooler and wastegate, 3-blade McCauley prop (hot), Aspen PFD, JPI 830, Garmin 430, and Garmin ADS/B In/out transponder. The engine was rebuilt in 2016 prior to my purchase, and had less than 100 hrs SMOH when I bought it in 2018. I have flown her nearly 500 hours since then. I had a great deal of work done at annual last year, including replacement of the #6 cylinder, Prop governor overhaul, new right-side exhaust header, replacement of ALL belts and hoses, new gascolator, and multiple other smaller jobs. At the time of the incident 79R had flown 143 hours since last annual. On the date above I was flying from KABI to KDGW in a clear VFR sky to do some hunting with friends. I had stopped for fuel at Borger, TX, and was about an hour into the second leg of the flight at 12,500' when I had a sudden partial loss of power. I had been cruising at usual settings, 32" MP and 2450 RPM and 11.0 GPH (approx. 50% power setting) with a 12 knot tailwind. With the power loss my manifold pressure dropped below 20", but RPM's stayed around 2400. My first thought was that I had a fuel flow problem, so immediately switched tanks and hit the low boost switch. No change. Airspeed had dropped significantly, but the autopilot was holding my altitude and the engine was still making some power. IIRC, CHT's and TIT were fine, but the JPI was reading 20% power output and dropping. Half of my brain was trying to puzzle out the cause of the power loss, but the larger part of my brain was saying, "Look for a place to land, establish best glidespeed, try to restart the engine, and declare an emergency," over and over again. So that's what I did. I looked around at the flat eastern Colorado terrain, saw no airport; looked at my Foreflight moving map, and saw the Limon airport about 25 miles ahead of me and no other marked airfield. My airspeed was still above best glide at this point. Looking back on it now, I estimate that the time elapsed up to this point in the emergency was about 20-25 seconds. The engine was still running, so a restart was obviously not necessary; so I pushed the prop control full forward and there was no change. In fact, I noted that my RPM's were starting to climb irrespective of the position of the prop control. This was my first clue that I had an oil pressure problem. I then looked at the oil pressure gauge, and it was pegged on zero. This was the "Aha!" moment, and I went fully into my power-off landing checklist that I've had stamped in my brain since my earliest flight training. I switched off the magnetos, which caused immediate slowing of the aircraft, and of course also meant no vacuum pressure, so I began setting my attitude manually to best glide (88 KIAS). I keyed the mic and informed Denver Center I was declaring an emergency. The controller, who sounded very young, immediately experienced a 2-octave increase in his voice pitch, by which I gathered he was pretty new to this situation. I advised ATC I had lost power and was descending without power, and intended to land on either a road or an open field, unless he could vector me to an unmapped airfield closer to my position. I started at 6500' AGL, and estimated I had about 10 miles maximum glide range. There were several roads and a paved highway ahead of me, so I simply maintained my heading and descended at best glide speed. As I got closer to the ground it was apparent that the highway was far too busy with vehicle traffic to safely land on, so I decided to try for the nearest east-west gravel road, which I estimated was just within my glide range. However, it became clear quite soon that I wasn't going to get that far. As I dropped below 1000' AGL, I lowered my landing gear (I still had lots of battery power for the gear motors) and advised ATC I'd be landing in a pasture. I maintained clean configuration for airspeed, and the mains touched down a about 70 KIAS. I kept lots of backpressure on the yoke to keep the nosegear off the ground as long as possible. When I could keep the nose up any longer I started braking, but almost immediately hit a shallow cowpath and the nosegear collapsed. I skidded to a stop within about 50 yards of the cowpath. When the airplane stopped, I made sure all switches were off, unfastened my seat belt, and exited the aircraft. There was no gasoline smell, and no smoke, so I didn't hurry. I found I was less than 100 feet from the county road I'd been hoping to land on, and about 150 yards from the paved highway. All kinds of vehicles were turning onto the county road to check on the "crash scene". One kind young man offered the warmth of his car to sit in while I dealt with the necessary phone calls. ATC at Denver called within a few minutes (to see if I was alive), and of course my first outgoing call was to my wife to let her know I was down but OK. ATC got emergency services on the way and I was soon talking to the sheriff's deputy, fielding calls from the FAA and NTSB, and so forth. Eventually all the ducks were lined up as well as could be, and the deputy gave me a lift to a hotel in Limon, where my wife picked me up in her truck the next day. My insurance company has decided to sell N5779R for salvage, and I've signed the bill of sale. Unfortunately, I hadn't anticipated the rise in airplane prices this year, or I'd have re-insured her for what I could sell her for today (about $80,000 more than I paid for her!). I was not injured in the incident. I attribute this to the sound construction of Mooney aircraft, and to the thoroughness of my flight instructor(s) who drummed the engine-out landing checklist into my brain. At no time during the incident did I feel scared or panicked... I just did what I knew had to be done and flew the airplane all the way to the end of the landing rollout. Easy-peasy. I know a lot of people don't have as happy an outcome when they experience an engine failure. I realize that I was fortunate to have perfect conditions for my off-airport landing, or I might not have had as happy an outcome myself. If I had been over rough country or mountainous terrain, or flying at night, or IFR over low ceilings, my landing may have been a crash. But because I had clear visibility and plenty of flat terrain to choose a landing spot on, it was relatively uneventful. On the other hand, if it hadn't been for the cowpath that collapsed my nosegear, I would likely be having my airplane fixed right now rather than shopping for a new one. I share this experience with my fellow Mooney pilots because it may help someone else in their aeronautical decision making process or in their flight planning process. I am an avid reader/viewer of aviation-gone-bad articles and videos myself, am constantly learning from them. I hope this experience might help someone else be prepared in case of an emergency of their own. Postscript on the engine failure: when I landed, the entire belly of the airplane was covered with engine oil. I did not remove the cowling then and there, as more than one helpful idiot has suggested I should have done (including the guy from NTSB that called me 20 minutes after my airplane came to a stop in the pasture) but when the salvage crew got it to a nice clean shop and pulled the cowling they found no sign of a catastrophic oil line failure, etc. What they DID find was an oil breather tube covered with oil, and a splatter pattern in the compartment suggesting that an oil passage blockage had occurred somewhere in the engine resulting in the sump oil being blown out the breather tube. There was still about 3 quarts of oil in the sump, and the crankshaft still turned, so my delay in shutting down the engine apparently did not seize it up. I was just informed yesterday by the insurance adjuster that the engine is going to be torn down and inspected as part of the salvage process, and he will keep me informed as to the location of the blockage. FAA and NTSB have both signed off on the incident as an engine failure, and I have not been cited for pilot error. So that is something of a comfort. Postscript on aircraft damage: in addition to the collapsed nosegear, the right main gear was damaged (framework within the wing bent). Two of the 3 prop blades struck the ground and were severely bent, which of course necessitates and engine tear-down and inspection. The engine mounts were not damaged, but there was some deflection of the airframe back of the firewall which the insurance adjuster estimated would require significant repair costs. At this time I still don't know what damage to the engine and/or turbo may have occurred to cause the power failure. So I'll be airplane shopping now. I love the 231/252 platform for a lot of reasons, and I am strongly tempted stick close to home in this respect. Jimmy Garrison at GMax (formerly All American) says he has a lot of options in that area if I'm willing to be patient, and can stomach the high current prices. But I'm somewhat concerned about the growing scarcity of parts for Mooneys, as the factory continues to not make them. So I may stray farther afield into the land of Bonanzas, Cessnas, or Pipers. I guess we shall see. PPS 12/19/21: I posted the following last week farther down in the thread, but I am copying and pasting it here to save folks having to scroll down. I received an unofficial report on the engine postmortem. The engine crew looked first at the turbo, expecting to find the exhaust to be full of oil, indicating the failure was in the turbo (as the loss in manifold pressure suggested). However, there was no oil. The turbo had seized, but that would be expected with almost any loss of oil pressure. The crankshaft had not seized, and still turned easily… they found there was about 3 quarts of oil still in the crankcase. The culprit proved to be a broken exhaust valve in the #4 cylinder, which fell into the cylinder and punched a hole in the top of the piston. I w@s surprised to hear that, as I heard nothing that sounded like any engine cylinder eating a valve I’ve ever heard before (in automotive and small engine applications). The engine guys suggested I might have had enough power to keep the engine going a bit longer, as it was still making some power… but if I had done so, and tried stretching it the 25 miles between the point of failure and the Limon airport, other nastier things might have happened, such as an engine fire. All in all, I think what was basically an uneventful power-off landing in a field was the preferred option, as opposed to a high-speed and high-angle descent in a burning airplane into a fresh crater.2 points

-

We don't know what the future holds in avionics. While the G3X is a very capable glass display, its interface capabilities are rather limited. The interface of the G500TXi has more flexible capabilities for future developments. Those capabilities do come at a price, though. The TXi is more expensive than the G3X. For me, even though the G3X wasn't available when I did my installation, I'd have still gone with the G500 TXi. Since I wasn't going to upgrade to a turbine airplane, I decided that I would go all in for the best that Garmin had to offer. With the TXi, GTN 750 and 650 there is overlapping of data, but I find I can make use of all of it by putting different data in the various data fields on the different products. Unlike the G1000 where upgrades are either expensive or unavailable, I took advantage of the ability to upgrade my system from the GTN 750 and 650 to the Xi versions. It was simply an exchange and system upgrade. The connectors were the same. The upgrade from the G500 to the G500 TXi was a little more extensive, but only took a couple of days and a new left panel to adjust for the increase size of the TXi. Garmin also gave a discount for the upgrade if the display was returned. In regard to the G5 vs the GI275, the G5 has some additional data displayed, but the GI275 has a brighter display. That wasn't enough for me to want to upgrade to the 275. I'm very happy with the G5. A lot of people go with the GNC 255 in lieu of the GTN 650 as a second radio. I like the flexibility of having the second GPS. So, if you want to be a minimalist, go with 2 G5s. If you want a little more, then go for 2 GI275s; little more then the G3X. And finally, for the top of the line, go for the G500 TXi.2 points

-

Another related word. In my experience as a municipal defense counsel and hearing officer (I have presided over licensure suspension proceedings under the Air Quality Act - e.g., emissions testing facilities), the way this sort of thing would probably come up is where someone gets a license, then basically does no work for an extended period of time. Then, let's say the license-holder does a job, the aircraft owner is dissatisfied, gets injured, or causes damage attributable to the work (or someone claimed that it was, anyway), and the FAA gets notified and is asked to review the license or does that unprompted. The thing is, barring that scenario, it could well be that this question has never been addressed in a formal opinion. But another basic principle of law in general is that the legislature or admin agency: (i) knows what it's doing; and (ii) choses language deliberately. So, applying that principle here, if the FAA had wanted to impose a minimum hourly requirement, it would have done so. In my experience, that's an argument that a hearing officer or, say, a U.S. District Judge is going to accept absent settled common law--or an agency decision or advisory letter--to the contrary. Hope that makes sense. Joel2 points

-

14 CFR § 65.83 - Recent experience requirements: "A certificated mechanic may not exercise the privileges of his certificate and rating unless, within the preceding 24 months - (a) The Administrator has found that he is able to do that work; or (b) He has, for at least 6 months - (1) Served as a mechanic under his certificate and rating; (2) Technically supervised other mechanics; (3) Supervised, in an executive capacity, the maintenance or alteration of aircraft; or (4) Been engaged in any combination of paragraph (b) (1), (2), or (3) of this section." *** With the proviso that I am not herein offering a rendered legal opinion to anyone reading this post, but merely making general observations for our discussion and leisure purposes, my reading of the section is as follows--beginning with some basic canons of construction. First - any statute or regulation must be read as a coherent whole. Second - courts default to a plain language reading unless that would produce an absurd or unjust result. Third - courts defer to admin agencies where their expertise in interpreting and applying a highly technical reg is appropriate/needed--only one possibility here that matters for our discussion. Applying those canons: Note the use of 'or' in two places. The first instance, between (a) and (b), means the Administrator could waive the requirements in (b). The second instance is what we care about. Its placement means that any of 1-4 is sufficient; the conjunctive 'and' would mean all would be needed. Applying the canons as I ordinarily would, paragraph (b)(1) contains no hourly requirement at all by itself or by reference to the other provisions. That said, I'll fire up Westlaw when I get a chance and see if there are any FAA admin decisions or courts being asked to weigh in on an appeal (if allowed) on how the meaning of 'served as a mechanic' has been interpreted by the Administrator or a hearing officer (I sat as a hearing officer for the local environment department for > 10 years). In the meantime, here are a few opinions skirting this issue that I found on the FAA website. They seem to be focused on the substance rather than duration of qualifying experience, in ways that I don't think resolve the issue. That said, again a plain language reading of the reg seems to impose no specific hourly requirement. Joel Carpenter_2012_Legal_Interpretation.pdf DaSilva-CommuteAir_2015_Legal_Interpretation.pdf Pohl_2008_Legal_Interpretation.pdf2 points

-

2 points

-

You ain’t LEDing unless you is pimping your ride. This is with them set to the max setting. I have a set of whites as well. Whites come in a variety of K values ranging from 4000K to 6500K. They are cheap enough that if you don’t like the ambiance you can pick up a different set. For older Mooney’s, I found a PWM controller does a great job of giving a wide range of dimming. Where some of these installations go astray is if they are powered on one end and run is long enough, they will be brighter on one side than the other. You can split them in two and wire each leg. Sent from my iPad using Tapatalk Pro2 points

-

Volk Field is an ANG base in Wisconsin. Westfield is about 50 miles east of Volk Field.2 points

-

Out in the sticks = a very rural area Fly in the mud over my house = they flew very low, close to the ground Tail number = registration number (like a license plate on a car), painted on or near the tail of the plane. The gist of the story is that planes would fly very low over his house, going from the military base to practice shooting and bombing, often flying so low that he could read the small markings painted on the planes. Volk and Westfield are placenames, I would guess somewhere not in America (but I could be wrong). "Volk" sounds quite germanic to me.2 points

-

I’ve posted this several times, It’s as much to do with the pilot as anything, have you walked the field, do you know where the holes etc are? This guy has a very Uber expensive painted RV8, look at the tailwheel fairing, maybe an inch, two max of clearance? He and I fly off of the same airfield, which is sort of a rough grass field, not bad, but not a golf course either. There is a whole laundry list of better off airport aircraft than a Mooney, but if your careful just like this guy with his RV, you’ll be OK, but your margins for error is a lot tighter than say a C-1822 points

-

Thanks Andy! I did notice that there is a nut missing from one of the studs for the exhaust manifold. I’ll see if I can get a nut and tighten that back down. I’m thinking that’s why there is an exhaust leak in that spot. As far as the popping, that makes sense. I know when on the ground for a while on a hot day, the engine will “hiccup” slightly as in a drop in RPM for a half second or so due to fuel vaporization. Goes away when increasing MP. Looks like some new seals and a nut are in order!1 point

-

An O2 sensor is going to have a very short life in a leaded environment1 point

-

There was a full paragraph of specific details that immediately followed that statement. I'm just giving feedback, which is, as previously described by others, a normal part of the process in developing technical papers. It's a productive process that improves your work if you use it. I'm not livid with anybody because there's nothing to be livid about. Figure numbers are important for quite a few numbers of reasons, and they're pretty painless to add. Most word processing programs will automatically caption and number figures because it's a commonly used feature. As an example of the case in point, in paragraph 15 you say "Look at the RED BOX for 75% load." Next to that paragraph is a figure that says "65% Power". Where is the figure for "75% load"? There's a figure that says "75% Power" on it much further up in the document, but it's not clear whether that's what you're referring to or whether there is a "75% load" figure elsewhere. Power and load are often not the same thing, so relying on the text which continually refers to load percentages to find graphs that are labelled with power percentages adds another potential layer of confusion. Figure numbers makes identifying and locating figures far easier for the reader and referring to them far easier for anybody with questions. Likewise labelling axes and adding units when quantities are displayed make it clear what you are trying to convey. You say certain figures (referenced by the paragraphs in which they are intoduced, which is unfortunately somewhat ambiguous), are precision figures by which one can make precise measurements. Unfortunately, the axes aren't labelled and the quantities do not have units specified, so while one already experienced in the area may be able to infer what was intended, one can never quite be sure because the information is missing. Adding labels and units is fairly painless, removes the ambiguity, clarifies what you intended to convey, and makes the information more useful for readers. The red box figures that were previously published in Sport Aviation were shown together there as a single figure in order to show how the box shrinks and disappears with a reduction in power, and the ambiguity in the horizontal axes was explained in the accompanying text. In this case the figures are separated and the explanation is not included, so the lack of labels, units, and explanation for the horizontal axes becomes a bit of a mystery. I suspect some readers will think that you are abusing the copyright system. You imply a sort of license agreement in paragraph 45 and while the terms are not unlike those used in some free software licenses, attempting to apply them to a written work may be construed by some as attempting to circumvent existing federal laws on such things as Fair Use and other rights. This may be particularly problematic since your document contains figures for which you very clearly do not own the copyright, so it appears that you may be intending to apply unusual licensing terms (and especially broader licensing terms by offering free distribution) to those items that it is not clear that you own the rights, and may not be in the interest of the owners of those copyrights. Usually use of an item copyrighted by others is handled with a disclaimer of "Figures x, y, and z Copyright Fizzbucket Corporation and Used with Permission", or simply by reproducing it yourself as an original expression of the figure, or some other recognized method, but in this case there is no indication of permission from the existing copyright holders. On the contrary you assert copyright claims on every page and original figure, and also with assertion of a specific license agreement that you wish to control all of the content in ways that are a bit unusual. The easiest work-arounds are usually to indicate that you have obtained permission for use (and in this case also permission to assert your license terms on their work), or just to create new versions of the same charts. Many of us have been there before, and I got called out for making a public presentation with new data plotted over somebody else's original chart after having used the same chart internally for months prior...somebody noticed right away, and I'd been using it long enough internally that it just didn't occur to me at the time that I needed to update it before presenting it publicly. It was a fairly easy error to correct, though. I wasn't offering free licensing of the other person's work, though, which is a complication here. You're free to use or ignore or disdain or whatever you want to do with this advice. I offer it only as constructive criticism. I suggest contacting an Intellectual Property attorney for details on copyright assertion, licensing terms, and attribution and permission for use of other's work.1 point

-

1 point

-

1 point

-

My previous hangarmate was a Super Viking restored by the hangar owner. Beautiful airplane, but hasn’t moved in years. I’m restoring a 64 Pitts Special right now with wood wings. Generally speaking the wings are in good shape, but the plane was indoors. Glue joints appear good, with some exceptions, and a trend. One location had collected water in storage AND the wood and glue was not sealed. The original damage was in 1972 and hidden by whoever repaired it. It would have caught up to me or someone else in a dramatic way. The only reason I found it was because I pulled the leading edges due to a bad feeling……. Other areas are where there was movement of the wood and joint…..and again exposure. Ultimately, a wood airplane, especially an old one, should not be kept outside. Moisture is definitely not good for them, but UV, heat and very dry also takes its toll on glue joints and the wood. The complication is the difficulty in inspecting them….and even a small amount of moisture can collect in places that can’t drain. This is just another complication in the shortage of affordable hangars…1 point

-

You can confirm just about all parts in the Illuistrated Parts Catalog for the J model, which is available online for free. Specific parts may depend on the serial number of your aircraft, but generally J models are PAR46, if it is in the nose cowl.1 point

-

My concern for a Viking would be the same concern I had for my Mooneymite: how long does wood glue last; how long does it maintain its strength? No one seems to know for sure.1 point

-

It's hardly BellancaSpace, but this is a good read: https://airfactsjournal.com/2021/12/owning-and-flying-a-bellanca-viking/1 point

-

I’ll note that my 231 is terrible at producing cabin heat with the cowl flaps full open, just ok with the cowl flaps in “trail”, and will cook you out of the airplane (excluding your frozen toes) with cowl flaps closed with the heat lever full open. I’ll also open the defroster valve to spread the heat around a little more when it’s really cold out. Cowl flaps are the biggest variable in maximum heat output for me with ROP/LOP and lower power settings (descending) being contributing factors. Ensuring the overhead and “knee” fresh air vents aren’t leaking substantially is also on my pre winter checklist.1 point

-

1 point

-

Definitely get your A&P, but I can tell you it’s not gravy. It can be fun but it can also be the most stressful thing in your life. Don’t take it lightly. Be serious and methodical in all that you do. Pay attention to minute details. There’s a reason why the A&P field is dwindling, it’s not easy work. David1 point

-

I just replaced existing incandescent bulbs with red LEDs, but left a couple on the left side figuring I might need to read a chart or something. I’ve never needed to do that and will swap out all the incandescent bulbs next time I remove the glare shield.1 point

-

I agree that G1000 was modern in 2003, but that was a few years ago... I’m familiar with the G1000 and have flown behind one many times- i just didn’t buy one. I actually seriously considered a couple of G1000 Ovations when I bought my plane and decided not to do it specifically for the reasons I’ve mentioned. Frankly; I would have preferred the lower panel but I didn’t want to be trapped with that system and no clear upgrade path when it becomes obsolete. It sounds like you love your G1000 and your G1000 loves you. That’s great. I’m very happy for you. That still doesn’t make it modern or upgradable. Sorry I stuck a nerve with that statement.1 point

-

Follow -up Report : A big thanks for the schematic & those that chimed in ! The problem was a bad connection on the pitot heat switch that apparently also sends current to the PFD & MFD. Thankfully, the immediate solution is to use the E-bus until sorting it out.1 point

-

Bruce is originally from Minnesota. Seemed like I ordered a lot of 3M stuff to do my interior [emoji1787] I think the white pieces were trimmed pieces of his side panels. The 3M “Velcro” he used needs to be flat to get the best adherence to the counter piece of the sidewall. The wider white pieces allowed the full Velcro to lay flat on it. He then used a double sided 3M tape to stick it on the tubing and then tie wraps to ensure it doesn’t pull off if you remove the side panels. I will say one thing. The screw-less approach is the way to go. My side panels have been off numerous times since they were installed for the CiES sender install, new avionics and just to check on the condition of the tubing. And oh yeah, when I replaced all of the RG-58 with RG-400. Here is another picture of them attached. What Bruce did to make sure the strips lined up correctly was to leave the side panel piece on the tubing and remove the covering tape once he had the fit correct. Sent from my iPad using Tapatalk Pro1 point

-

Yeah, we were discussing that in earlier posts--but you're right that it's an issue. Bottom line for me is getting the A&P cert for convenience and savings re: approving my own work, and everything else is gravy.1 point

-

I love mine! We used click bond nutplates and countersunk machine screws to attach them so that they'll be easier to service. Sent from my LM-V405 using Tapatalk1 point

-

I'm joining the Aveo club too. I can't say I am a fan of the way Mooney riveted the original wingtips on, but we followed the same pattern and when its repainted it will look fine. I hope the LED's do last 10,000 hours, because the whole wingtip will have to be removed to replace the lights. The joggle in the fibreglass was a bit short, we had to file away the gel coat another 1/8" to match the training edge of the wing. While we were at it, we cleaned up the wingtip rib and painted it white. The aileron is off for fitting of the Encore weights and balancing. The quality is excellent, the overall fit is good, easy compared with some of the other fibreglass wingtips I have fitted to Cessnas and Pipers. And the wiring pigtail could be 6" longer to make it easier to connect. Aerodon1 point

-

1 point

-

Google Piper Painter! See if that’s something you are willing to do. My Dad is based on a 2800ft grass strip. This summer I landed at a local airport because I did not personally walk the strip. It’s your gear, prop, and engine. -Matt1 point

-

No doubt. I think all told including books, tools, testing, etc., my A&P program was probably about $20k or so. As an aircraft owner I've already made that up in spades just by reduced delays and aggravation by being able to do things myself. The money doesn't really come into it from that perspective. Totally worth it.1 point

-

Grass in and of itself is not a problem, as the previous posters wrote; I am based at a grass airfield with my M20K. The key thing, as others have pointed out, it is an actual airfield, maintained and looked after, not a grass field someone happened to decide to land a plane on. That's what Maules are for1 point

-

Improved grass airstrips are one thing, but I would never attempt landing at anything not well-maintained for the purpose of landing planes. Sent from my Pixel 3a using Tapatalk1 point

-

1 point

-

1 point

-

I like beer!! Send me a message if you have any other questions, I'll be happy to help where I can.1 point

-

I too had one depart over Ohio somewhere, if you find it, please send back to me. The issue is water gets behind the seal and then at freezing altitude pops off. When I reglued the new one, made sure to seal properly. Gave me a startle as when I looked out that side, looked like there was a big hole in the wing. I am highly doubtful Mooney will order more.......we are going to be on our own for these parts and I suspect a lot more as time goes on. I have found the gauge online, or at least something that looks the same for like $11.29 each, I need/want to replace the one on the other side as it is really cloudy. I am going to order one and see if I can make it work. will advise.1 point

-

GTN750 with GTN650. I find Time to TOD (Top of Decent) coupled with VSR - Vertical Speed Required, makes descents (when using VNAV) pretty easy to time without having to do mental math. Put top left user field "Time to TOD" and top right user field "VSR" (or vice versa). I've also enjoyed the Visual approach field that comes up around airports; makes it easy to throw in a visual for a long straight in approach and easy to see a perpendicular extended base leg. I watched a Garmin webinar showing a pilot add the Procedures page or Approach page to one of the lower user fields to quickly select an approach. I've added this briefly when I'm working on approaches so that I can quickly add approach after approach. I'd like to get my location of ETA to next waypoint squared away...would make position reporting easier and since I just got my instrument rating I'm still working on where to get each piece of info and what's the most efficient way to set the avionics up for me. Of course I have more of the standard flight data shown routinely in the GTN 650 default nav page. So I've been using this for standard flight info (TRK, DTK, ETA, etc) Marc.1 point

-

Depends on how many screens you have that can display information but among my favorites are: Groundspeed Distance to destination Distance to next fix Vertical speed required (if I don't have an autopilot that does VNAV) ETE to destination. We have dual GTN650's. We leave one set to the Flightplan page and one set to the Map page. Because of that, we have the field on the far right, just below the standby frequency window, set to page buttons that take us directly to the FP/Map page respectively. That way, if we navigate away from our usual page for some reason (find a nearest for example, or loading an approach) we can get back to the usual page with a single touch.1 point

-

This is what happens 9 months after a Mooney and a Cessna share a hangar.1 point

-

The TCDS for your engine (1E10, see Note 7) will specify the approved ignition systems for that engine. Lycoming can approve, and has, additional ignition systems, so you can install any "approved" accessory via the engine TCDS, approvals from Lycoming, or accessories specifically STC'ed for that engine, which also provides "approval". Naturally the only electronic ignition Lycoming has approved, to my knowledge, is the EIS. Anything else without approval will be a major alteration. Sometimes even "approved" items are treated as major alterations (e.g., many STC's are treated as major alterations), but the STC provides the "approved data" for the alteration which makes the 337 form pretty straightfoward. Without such approved data a major alteration would require sufficient independent data, e.g., from a DER, to support a field approval via a 337. AC 23-27 doesn't really provide an easy means to circumvent that process for major alterations. Edit: BTW, I don't think you've ruffled any feathers. It's a good question and I think sometimes people give up on exploring such possibilities too easily.1 point

-

Actually the definition of major alterations makes it a major alteration. FAR 43 Appendix A (a)(2)(iii) Installation of an accessory which is not approved for the engine. That's a major alteration.1 point

-

@PT20J’s explanation is simple and dead on. What is your xwind landing technique? I was taught to slip from about 1/4 mile final and fly each wheel onto the runway. I find that “crab and kick” method is more comfortable for passengers but it does little to develop the pilot’s ability to manage roll and yaw independently to hold centerline…which is exactly what one must do on a xwind takeoff. The centerline is the ball until the plane airborne. It can be counterintuitive as it is not typical in normal flight to increase right aileron while pulling the nose left with rudder but that can certainly be needed on a crosswind takeoff.1 point

-

Not CFI If you're not used to strong crosswinds, 3 things can happen: The plane yaws upwind - can suddenly increase when the nosewheel lifts The plane slides laterally downwind - can suddenly increase when the plane gets light The plane banks downwind - can happen with gusts When all 3 happen it can be pretty confusing if you've not experienced it before. I recall practicing crosswind takeoffs in training--as the plane got light, it started sliding downwind, and I mentally could not keep my foot on the downwind rudder. At the same moment, the nosewheel comes off the ground, which accentuates the weathervaning, so the plane REALLY turned upwind. It was like a mental block, once the plane started sliding downwind, I just could not stop myself from stepping on the upwind pedal, and it took some practice to train that out of me. Keeping upwind aileron puts more weight and grip on the upwind tire, which decreases the amount of sliding, but it will always happen some either before or after lifting off.1 point

-

While it is easy to assume that someone is just being a jerk, there could be all kinds of other explanations. At an uncontrolled airport, it’s possible to be transmitting but not receiving and be completely unaware of it. Or it can be the reverse. My embarrassing incident being that “jerk” was the time I spent an hour at my home airport brushing up my taildragger crosswind skills by doing touch and goes on every available runway, including two grass ones, in the Fleet Canuck that belonged to our local classic aircraft club. I made all of the right radio calls as I switched from runway to runway having a grand old time. The only other aircraft in the pattern was sticking with the main runway and I kept him informed of all my changes and ensured I did not conflict with his pattern. On my last circuit another aircraft called inbound for the circuit. The other aircraft in the circuit responded with the active runway and added “watch out for a Canuck doing NORDO circuits on the grass.” After I taxied in and shut down, I discovered that I had connected my headset to the passenger side of the portable intercom, which someone had installed upside down on the aft bulkhead. It looked like I was connected to the correct side, I could hear everyone else, and I assumed I was transmitting because I could hear myself on the sidetone. Turns out I was just talking to myself on the intercom. I am not sure I would want to hear what that other pilot must have been saying about me!1 point

-

One of the most sacred aviation rules in the book of Steingar. If I see or hear something I don't like while approaching an airport, I go elsewhere. Too easy to wind up dead in an airplane. If it's my home field I'll go look at fields or clouds for a few minutes. Like @skydvrboy said, lots and lots of things can happen in the landing pattern. One of the reasons my airplane is always dirtied up before I enter the downwind. Of course, another piece of wisdom from the Book of Steingar, if everyone around you is an asshole then maybe the asshole is you.1 point

-

this situation occurred exactly to me at ksac where ATP does a lot of slower 172 training.Because of the speed difference tower gave the right of way to the lower in my case cessna and ordered me to slow it up and a 360 for spacing which i complied reducing power,speed brakes out and dirtingup as much as possible.Plus these are student pilots like I once was...1 point

-

The problem with all these solutions is they lock the controls but don't prevent the forces that act on the control surfaces which then transit through all the hardware between the surface and the associated controls. I use the seatbelt if left outside but luckily I am hangarred at home. With my Cessna I had 2 long pieces of very stiff hose with a cut along their length which I would bridge the ailerons to the flaps to anchor them together. Worked very well1 point

-

You don't need to fly both, a simple paper exercise is all you need to compare the two... When I did the exercise, Mooney seemed like a niche plane. I was concerned that if I couldn't afford to fly over the long term, could I possibly sell it again without losing my shirt. I performed a PPI on the Arrow, lucky for me, it failed. So I bought what I really wanted an M20C... 15 years later the factory was back in business and then out again. Somebody invented the Internet. M20Cs are common and are easy to buy and sell. MooneySpace was created and revised. Interest rates are at an all time low. Support from the factory is alive. Support from the community is tremendous. Support from the engine manufacturers is excellent. Who wouldn't want to buy a Mooney and hangout here? Best regards, -a-1 point