Leaderboard

Popular Content

Showing content with the highest reputation on 07/18/2019 in all areas

-

I would like to say thank you very very much to AlexLev located in Niagara International KIAG, he was so nice to me and my family.We had a great view over the Waterfalls and wonderful food at River Works (nice place). Well, when we were start to packing bags to go back to Orlando, my daughter asked me to visit her friend in Greensville NC, so I Have to make a new flight plan, and we decided to land in JFK for fuel and spend a night, I called them and they said ok. So, we had a great experience. The costs (fee) to land was 160 bucks for 24 hs plus fuel 6.65, not bad for the great adventure, cheaper than Universal Studios in Orlando lol thank you to AlexLev and the Mooney 921W!!4 points

-

Embrace the 'Mooney Nod'. After mastering it, you will never again look at a Mooney with electric gear with anything but pity. Also, as you are lowering speed for landing, know that the gear can act like a speed brake. Unless you are in a downward death spiral from altitude, the Mooney will not exceed 120 with the gear down, so at about 125 or so, release the bar from the floor and enjoy the effect of a manual speed brake, when you hit 120, lock it in place and you'll never have the dreaded GU. On the opposite side, if your Mooney seem sluggish on climb and you just can't seem to get past 120, guess what? Let he amongst us who has never experienced this cast the first stone.4 points

-

Thank you for the comments everyone. Please understand, while new to the 20C, I am by no way admonishing the J-bar system. Still a little awkward with it but I like feeling what's going on. Maybe it's just in my mind, no pun intended, but it's comforting to feel like you're linked to the process, rather than flipping a switch and holding your breath. I'm also someone that figures "its going to happen to me first" so I was just intrigued by the simply wire and as a backup. However if flying an instrument approach, swinging ones head side to side to look out windows would not be a good thing regardless if have manual or electric gear. My checkout was with an experienced CFI, Air Force test pilot and long time vintage Mooney driver. His phrase was watch what you do, trust what you feel confirm with the light, or really just use the light more as a reminder you should have done the other two". My initial checkout with a different instructor was simply give the bar a tug aft on base to confirm it doesn't pop out. The better (more experienced) instructor taught me about the pulling the collar straight down without pushing the release button with thumb was a more confirming and indicative check. I'm sure there are opinions for and against. Personally I think the weakest part in the J-Bar chain is a complacent or inattentive brain. I will work hard to leave that failed part on the ground.4 points

-

4 points

-

For any early M20J owners out there (serial numbers 24-0001 through 24-1037, Garmin this morning approved Installation Bulletin 1954 Rev A which describes how to modify and install the roll servo lower bracket and roll servo plate so it will fit properly in those aircraft as they have internally mounted access panels. This is what I was waiting for to get my GFC-500 install completed. Can't wait to fly it!3 points

-

You see Alan, unlike Bonanzas, Mooneys have inherent value and don't need Garmin or anyone else. In fact Mooneys bring value to Garmin!3 points

-

2 points

-

2 points

-

2 points

-

Software on the GTN? https://www.garmin.com/en-US/aviationalerts/approval-of-gtn-6xx-7xx-software-version-6-62-and-flight-stream-510-software-version-2-51/2 points

-

While flying my '67C with a Vietnam-era USAF veteran pilot of C-141s then airliners, the green light didn't come on when I lowered the gear. I triple checked that the J-Bar was in the "gear down position" and locked by pulling down hard on the collar. Deferring to his many decades of seniority- I pointed at the dark green light asked him what he thought. He said "your gear are down and locked" without hesitation... A Johnson bar is a better indicator that a wire vibrating in the wind, IMHO. It it is up in the vertical position and the collar is locked, your landing gear are as down as they are going to get.2 points

-

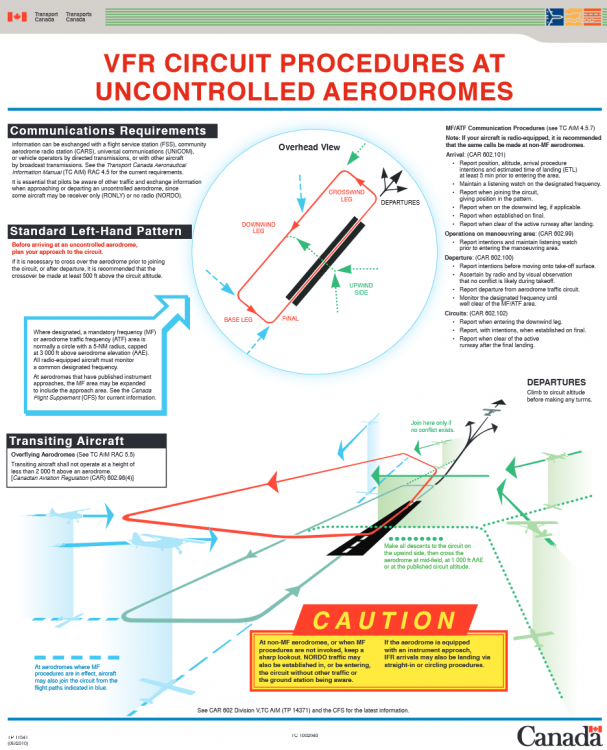

AC90-66B is a good document and provides recommendations, but it really fails to recognize what happens at most US airports. Transport Canada has a good doc on the realities of what I see at most airports. https://www.tc.gc.ca/en/services/aviation/documents/TP11541E-Accessible_VFR_procedures_at_uncontrolled_aerodromes_EN.pdf Its common to see straight in final and down wind entry. Is less common to see a base entry, but its still seen often. And rarer yet is the upwind pattern entry2 points

-

2 points

-

I recently saw a swift getting an annual inspection and noticed something that I thought was a cool idea and dirt simple. A wire rod that attached to the gear door extending forward to just forward of the leading edge and then bent upward to be above and perpendicular to the leading edge when landing gear is extended. When gear is retracted it's parallel to the wing about 1/2" below it. Much more informative than a green light that is connected to a switch that holds the J-Bar. Just look left and right and if see that wire sticking up, you know your mains are down and locked. I jokingly said, "hey lets do that to the 20C!!" He took me serious, told me it would require 337 and FAA approval and a bunch of other things he told me. I'm thinking, really? for a wire and two screws? Then he does his best to act serious and angry, but the smirk gave him away..... "now look you're a new Mooney owner so I will cut you some slack this one time, but you fail to see the huge reason why you can't do such a thing. You have a Mooney for cripe sake, a paragon of speed and efficiency, you do that it will be 1/2 kt slower and kill the clean aesthetics and that my boy is Mooney Blasphemy. Now wash your mouth Philips XC, say ten hail Lycomings, put $5 my poor box and your grounded from the Mooney for ten days, and oh, give me the keys I'll exercise her for you". Geez you'd think I wanted to bolt a big mirror on it. :-) So of course at annual I'm going to have to come up with something else I want to do, just to get him going. Any suggestions? Maybe review mirrors or turn signals? Hope no one minded the levity. However, the wire is a simple and effective indicator.1 point

-

You will have a challenging time pulling a cylinder with the rear baffle seal in place. Odds that you get frustrated and bend or break something increase a great deal. You can measure the cam lift, but that only tells you the cam lift. The failure mode starts with the cam follower. As it degrades it stops rotating and then the cam lobe begins to spall. The up shot is that a wiped cam never caused an engine to catastrophically fail...just a slow degradation in performance with metal showing at oil change.1 point

-

Pull the plugs which you can do under owner maintenance. Clean/rotate and replace. Report back.1 point

-

@aviatoreb Erik... Your Description matches a fouled plug on that cylinder... The fuel is only getting partially burned in the cylinder... The rest burning in the exhaust... Hence the elevated EGT on that cylinder... Slow flight, and low power settings can cause the fouling... extra care in leaning probably helps to avoid the situation... Got the JPI data? Great download experiment to identify exactly which plug it is... Run-up data should expose the fouled plug... Normally Aspirated PP thoughts only, not a mechanic... Best regards, -a-1 point

-

1 point

-

A price that isn't sideways might be a good idea. Nice looking Mooney, good luck with the sale.1 point

-

I’m pretty sure the Feds won’t let you use STC data as approved data for your own STC. intellectual property and all.1 point

-

1 point

-

1 point

-

I'm closing this thread as it was originally posted incorrectly in the Safety section. As a reminder to all, this section is a sanctuary so we can collectively analyze safety issues that we face as Mooney pilots. Feelings, emotional responses, vauge guesses, etc. do not help determine root causes. NTSB reports, safety bulletins, FAA advisories, etc. are to be used as source documentation during analysis. Thank you for helping be part of the Safety conversation and if you have questions, please send them my way. It takes all of us working diligently to increase awareness of safety issues in GA Fly Safe, Safety Forum Mod1 point

-

Pretty close for electric gear. Not to discount some of the mechanical advantage and overlock. At least in the ITT actuator and probably the dukes for an F model. There is a brake in the back of the motor actuator. When power is not applied, then the brake is holding the armature of the motor. This keeps the gear from "chattering" down. which was a problem for some of the earlier electric gear. Power is applied during the gear sequence to release the brake. This is done via the 4 pole ford tractor solenoid. The 4th pole is 12v. used to release the brake. Normally you need 2 wires to a motor to make it go forward and reverse by switching polarity. Always worriesome when you see 4 wires to a motor and you expect 2. So 2 grounds. 1 for the motor, one for the brake.1 point

-

Candela is the brightness of the beam, you can get nearly infinite candela with a narrow enough beam thus my comment about a beam pattern,. Lumens is the total light put out, same lumens for a narrower beam is higher candela this is why you see taxi lights with much lower candela for the same lumens. As far as I'm aware the best in-the-lab LEDs today get 200 lumens per watt. Assuming that Whelen is using those(hint: they aren't) with the about 45 watts that light draws they could hit 9,000 lumens. In reality those 2 lights seem to be fairly close on specs. I'd guess the Whelen has the edge on reflector design, but until a third party does a shoot-out there's not really a good way to see which one would 'win'.1 point

-

It's part of the line that Whelen got when they purchased LoPresti. It looks to be this one(with a little more specs): https://flywat.com/collections/led-landing-taxi-recognition-lights/products/parmetheus-plus-46-series-led-landing-and-taxi-light Although as usual there are no lumens or beam pattern specs listed.1 point

-

All the reasons you listed are why I wanted the rocket. Power when I want it, Efficiency when I want it. A good engine monitor is on my list... In the meantime I will be running ROP and nice and cool on the TIT.1 point

-

There are Mooneys all over DVT, my home field (a bunch of the peeps are here on MS). One day while driving amongst the hangars on the way to mine, I see *my* airplane taxiing from the fuel pump back to the north hangars...wtf!?!?! Then I notice the tail number is slightly different...d'oh. I went over and met the guy, and his airplane is also a '77 J only about 25 serial numbers before mine. Nearly the exact same paint job. He's owned it for something like 25 years. Interestingly, his came from the factory with no step...we were comparing a few things that are same/different. Definitely cool when stuff like that happens.1 point

-

Had to think about that. The .06” dimension means the axle is more forward. By adding the washer, it essentially compresses the shocks more and causes the axle to move aft more. Essentially it trails more and makes it more stable during that point where the nose is light. It’s as if there is more weight on the nose wheel....so it trails more.1 point

-

I did when I bought my plane, the guys at All-American had all the logs scanned and they e-mailed them to me. I had an IA friend of mine review them with me. I keep a working e-copy of all my logs current on Google Docs these days1 point

-

I believe you are right and I am also pretty certain (but can't say 100%) that Rocket Eng did nothing for the Missile. I do know they did nothing for the Rocket. So you can interpret that way anyway you want. Mod'ed owners will claim the FAA thought it was perfectly save to add all that extra weight to the gear, in contrast to the Mooney which some and myself would interpret as being more engineering conservative and perhaps thorough. But I have noticed everyone interprets it their own way so I won't even try to justify any interpretation. I can share a data point. I new one owner of an older Mooney. We shared the passion of Mooney adventure travel flying to many international destinations. In his early J, he always traveled long range with 2 couples and about the equivalent of 1 carry on roller bag per person. Yes, he was hundreds of pounds over weight! I always worried about him having a traffic pattern accident or landing incident or takeoff accident. We did some dirt field destinations together. But he was a smart guy (engineer) and a careful pilot; other than not respecting the regs concerning his plane limitations. But he never got into trouble from that and died happily in his sleep. I am not judging, but I could never take unsuspecting passengers like that and expose them unknowingly to that risk. Besides I also would hate to risk my estate to the lawsuit that would undoubtedly transpire when some lawyer figured that out. You know that will be the "cause" even if it was truly for something unrelated. NTSB findings are not admissible in court by design - perhaps civil court they are. Anyway my solution was always to get the legal increased gross weight before ever taking off overgross with a pax; lack of confidence in the airframe was never the issue for me but concern over liability I found very frightening. Sent from my iPhone using Tapatalk1 point

-

Back in the eighties I was working on my plane and had the car parked behind the wing. After a few hours I thought I should start the engine to charge the battery. I was listening to the car radio. I reached in the window and turned the key. It started right up, it was in gear! The car drove under the wing lifting the wing about two feet. Does the car insurance cover this? NO! Does the airplane insurance cover this? NO! So, at the airport, always park your car behind someone Else’s airplane!1 point

-

I sure don't mean this to sound scary or critical, but I really encourage my clients to start slowly from no more than 65% power where you can't hurt a thing and become familiar with setting up LOP precisely. As you get to know how your engine operates LOP, you'll get very proficient at setting up and be able to use proxies like TIT and MAP after you know the relationship between TIT and your richest cyl EGT peaking. But at 75% you need to be a full 50F LOP or you have one or more cylinders operating in the redbox. I have been in many clients Bravo's helping them with this stuff and seen a lot of Bravo data and not been able to see a Bravo operate that deeply LOP. 65 to just under 70% is the maximum I have seen when everything is perfect. Nor have I seen a Bravo get anywhere near 0.5 GPH gami spread with stock injectors which equates to resulting in the leanest cylinders flaming out before the richest are adequately LOP in higher power settings. Normal is > 1.0 GPH. All of this is to merely say, just start out at lower unharmful power settings and due your due diligence collecting the data before advancing to higher power temperatures. Additionally, IMO TIT over 1600F is not good for the longevity of your exhaust components and the Bravo is one of the more vulnerable exhaust systems. I personally limit my TIT to 1580F to give me a little buffer before I need to do anything. To get you started check out the Savvy Test profile here and start collecting your data. http://content.savvyanalysis.com/static/pdf/SavvyAnalysisFlightTestProfiles.pdf1 point

-

1 point

-

I believe I was parked next to you right by the fence near the exit gate. Was there at KIAG over the 4th of July weekend until the 9th.1 point

-

He certainly doesn’t need a second inspection. The “inspection” part is complete and payment is due - so nobody should be considering paying for another inspection. Just for resolving the remaining unresolved discrepancies per the inspection. What you need to understand is once the inspection is done, the IA is obligated by the regs to provide the inspection log book entry. If he can’t sign it off as airworthy he is obligated to sign it off with a list of discrepancies which can be resolved by any A&P. The IA knows this and he also knows if Santos calls the FSDO about him refusing an inspection logbook entry then his FSDO PMI will be promptly calling him. An inspection can not be undone, it can only end in one of the two ways discussed above with either an airworthy return to service signature or a list of discrepancies. The list is his easy way out, especially now that he has a second opinion A&P saying it's fine. Other than discussing M-0 Diff compression inspection with him, I wouldn't waste anymore time on him. Sent from my iPhone using Tapatalk1 point

-

I'm with @KSMooniac on this. The only thing certain about the release of anything new and STC'd for our Mooneys, or any certificated airplane, it that it will take a lot longer than forecast. I'm of the opinion that the autopilot is the most important piece here. For example, if Dynon had announced the release of a full featured 2 or 3 axis autopilot today, and said stay tuned for a glass panel coming in the future, but for now you can drive the autopilot with your steam gauges/GPS. They'd have sold 100 of them by the end of today. As it is, I'm not interested unless it fully drives my KFC150 today, or until the autopilot is approved/released.1 point

-

A friend of mine bought a home with a 60 x 60 hangar attached to it. Since he's single, he spent "several thousand" on a BigAss Fan for the hangar instead of furniture for the house.1 point

-

Took my wife and daughter down to Nut Tree (KVCB, Vacaville, CA) for brunch at Fenton's Creamery this morning. The little one rode up front for the first time, and had SO MANY questions about the airplane once we were home (What was that black knob for? What does the orange button do (CO alarm)? What are all the other buttons for? On and on and on until bedtime). She's been telling us she's going to be a pilot when she grows up since before I took my discovery flight. The only downside at all about our flight today was that it was 95º out. That made for a sweaty time on the ground while we got loaded in and through the run-up. It might be time to look into one of those ice-chest-based coolers I've seen mentioned.1 point

-

The best AC is a turbo. Passing 10k on the way to 17k the ride smooths out and the temps cool down. At altitude the OAC is below 0. All is good until time to come down. My vote is TKS.1 point

-

It's a fair question because landing gear is a critical system to understand and different airplanes have different systems. Some have mechanical up locks, some are held up only by hydraulic pressure. The Mooney electric gear doesn't have up locks per se. The electric worm drive/ball screw actuator is an irreversible mechanism (the motor can move the gear, but the gear cannot turn the motor) and holds the gear up. Skip1 point

-

Avoid the 1999's since they have the Moritz gauges which are troublesome. Serial #258 is the first 1999 and the first Moritz equipped Bravo. Moritz Bravos continued up until the G1000, and are serial numbers 0257-0317, 0319-0325, 0327.1 point

-

I do expect the whole package to be about $5K or less. Aerovonics looks interesting, but I have doubts as to whether they can certify both the instrument and the autopilot interface, remain at their stated price point, and remain in business. If they pull that off, awesome! I wouldn't be surprised if Garmin bets against them by pricing the new solution closer to King's stated target price if not above. Something that can keep my KFC150 going for the moment and then later drive a GFC 500 and serve as a backup to the G3X Touch, complete with miscompare monitoring, that's priced reasonably, is something I will plunk my money down for immediately. Of course, I'll still be crossing my fingers that my KI-256 lasts until Q2 next year which is the soonest I'll be able to get into the shop for an upgrade! You mean the GMU11 magnetometer? Pretty sure that's included with the G5 HSI, which is why it costs more than the G5 AI.1 point

-

Flew my Mooney to St. Paul Downtown airport yesterday. The EAA had their B17 and B25 here for the weekend giving rides and ground tours. The terminal building was built by the WPA in the mid-1930’s and was used by Northwest Airlines. The large Quonset hangar behind the B25 was built in WWII and used to modify aircraft, including Doolittle’s B25’s. Lot’s of great history.1 point

-

Well i finally got a chance to mess with the airplane yesterday. Got the oil pressure back to normal by replacing the spring and ball inside the oil pressure regulator. Check all oil hoses for clogs and found nothing, removed the thermostatic bypass valve and clean it, there was some carbon inside it but not much.Functionally checked the valve by putting it in boiling water and it worked like it supposed to. Clean it really good again to get rid of all the water and re installed. Did a leak check. Ran the engine @ 2000 RPM did all checks to get the oil flowing and then i let it run at 1000 RPM for 20 minutes and i was really please with the result. Here’s some pictures. Hope this helps someone now or in the future. New spring on the left. New ball on the right Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

I would have your mechanic inspect it. Pull the intake coupling off and inspect the compressor wheel. Feel it for smooth rotation and end play. Use a borescope up the tail pipe to inspect the turbine wheel. Inspect the turbine housing for cracks. This should all be done at annual anyway. If all is OK, Then I would say if it ain't broke, don't fix it. It should make it to TBO.1 point