Austintatious

Supporter-

Posts

825 -

Joined

-

Last visited

Profile Information

-

Reg #

N305RK

-

Model

305 Rocket

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Austintatious's Achievements

-

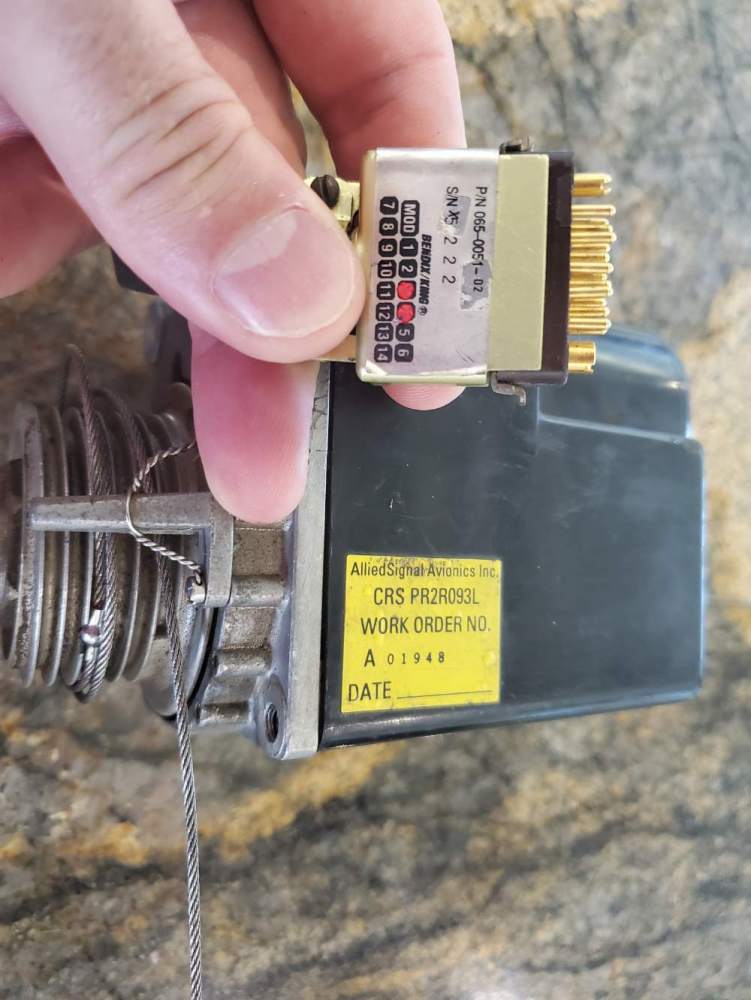

Still available Price reduced Autopilot P/N 065-0042-03 = $1300.00 + 100 for packaging and insured shipping ( I will get it to you as fast as I can for the $100.00) or free local pickup, no 100$. alt pre-select= Free, if you buy autopilot... if you buy AP and don't want this please say so. If you want Servos = 250.00 each or 700.00 for all 3 + actual shipping cost. Servo part numbers 1 x P/N 065-0051-02 2 x P/N 065-0052-14

-

Rocket visor with speeds & settings

Austintatious replied to Stetson20's topic in General Mooney Talk

I took my visors off and I dont regret it at all. First off the ones I had were prone to hitting the windshield and scratching it...When I put a new windshield on I didnt want it getting scratched. Now I have a small mesh Sunblocker with plyable edges and suction cups that I can put wherever I need it. It lives up high center windshield stuck via the suction cups, with the "frame" bent around the center post and takes up very little windown. I have the rocket speed chart on my Ipad if I need to reference it. -

More maintinance frustrations....

Austintatious replied to Austintatious's topic in General Mooney Talk

Well, I have to update this nightmare one more time as I think I have ironed out the last of the problems. I cannot remember if I had mentioned it or not, but after the annual that began all this craziness, the number 5 cylinder was running even hotter than it usually did... It has always been my hot cylinder but it was significantly hotter than it had been. I had been working with gami to narrow the gami spread. I knew that they had removed and cleaned the injectors so I figured this was the reason for the change. It was strange because the hotter temp would sort of come and go and vary with each flight. Of course we are trouble shooting and analyzing as we went... Once I had what seemed to be a decent set of data, I sent it off to gami for a tune of the injectors... and I asked them to try to make the number 5 the most rich of them all (still trying to keep the gami spread tight) to attempt to keep its temp down. I got the new injectors and worked with an A&P to install them... Upon removing the number 5 injector, we found a loose chunk of rubber floating around inside the injector... Either an old rubber seal was used or it was not put together properly...nonetheless, the piece of rubber was blocking airflow from the pressurized induction system and causing all sorts of fuel flow variability and restriction. After putting in the new injector a few months ago, the engine is running very well with a tighter gami spread and a cooler number 5 and I think I am happy and confident things are how they are supposed to be. I swear on the next annual, no one is touching anything that does not 100 percent HAVE to be touched on my airplane. So sick of mechanics breaking my plane by doing inspections. -

Need advice / sharing my concerns with someone

Austintatious replied to redbaron1982's topic in General Mooney Talk

Really? $2500.00 for 2 days isn't a lot of money? If we are talking 8 hr days that is 16 hours @ $156.25 an hour. That is a $300,000 dollar a year salary. That is top 5% wage earnings in the USA.... I dont think it is unreasonable to expect to pay 2500.00 for a PPI, but I also think it is a chunk of money... I could fly my airplane for about 15 hours for that amount of money. And if in said PPI they cant be bothered to look for serious show stoppers like spar corrosion, engine issues, structural damage.... then the 2500 is little more than a ripoff. Seems simple to me... start with the big expensive to fix stuff... check that out thoroughly before you move on to writing up that the carpet is wrinkled in the back. -

On a rocket with an insured value of 200k, we just paid 4100.00

-

Deltahawk DHK 200 and 235hp Variants

Austintatious replied to Rotorhead's topic in General Mooney Talk

That was for a Velocity V twin... which have already been put onto a flying (experimental) aircraft. -

Deltahawk DHK 200 and 235hp Variants

Austintatious replied to Rotorhead's topic in General Mooney Talk

Woa there buddy... that last part isnt true at all.. Maybe for race boats... but the majority of Outboard engines spend VERY little time at WOT.... I have 3- 300 HP Mercs on my boat and I typically cruise it around 4500 RPM... this translates to like 50% power or something like that... Fuel burn wise they will go as high as 90 GPH between all 3 of them... but when I cruise I am burning 35 GPH. BTW, you looked at how much those OB's weigh in comparison to an aircraft engine? WAAAAAAAAY too heavy. -

Deltahawk DHK 200 and 235hp Variants

Austintatious replied to Rotorhead's topic in General Mooney Talk

I heard from Deltahawk directly 100-110K.. but that was for a firewall forward package (not for a mooney) -

Yea, sure, if you up the MP then run LOP to get the same power you are correct... but it simply cannot be done with my power plant. The TIT will not allow it, perhaps because I am a TSIO and not TNed. So the only way I can run LOP is at lower altitudes and the same MP/RPM I would run ROP, which means less power and thus slower flying... Believe me, If I could do this I would, I certainly love saving gas.

-

Wombat, I thought I might give you some info to think about from a fellow rocket operator... In fact, I have 2. First off, You could absolutely hurt your engine, specifically the turbo at fuel flows less than 24 GPH... or even 18 GPH... You are not automatically safe based on a fuel flow. I have given up on LOP operations for the TSIO520NB. I know Mike Bush runs LOP but his engines are different even though they are TSIO520s. For starter they dont have the same big ol turbo charger that the rocket does but instead 2 smaller. I have had so many adjustments from gami, to get anymore I would have to start paying Extra... and it seems every time an adjustment is made, it never has the intended effect. I have replaced rubber seals each time and have pulled my hair out to get to a gami spread of about .6 and still the engine gets to rough running before getting truly established in LOP operation. And I expect that to change just because of how "finicky" these fuel systems are. The slightest changes can have big effects on the cylinder balance... for instance the last time I had an annual done and they removed the injectors for cleaning, everything went WAY out of wack. And the real kicker is that anything higher than about 9000 feet, you cant keep the TIT within limits if you go lean, and still I am into rough running. So, what do I do? I run 29/22 at about 16.5GPH... this puts the TIT at about 1550 and the hottest CHT (#5) at 360-370 and I will do about 147 IAS. This will put me around 200 KTAS at FL180 depending on temp. I can also run 31/22 @ 18.5GPH and keep everything in the green while doing about 5-7 knots faster, but I do not feel it is worth it. In short, I feel that just pulling the power back in ROP operation saves as much fuel as messing with LOP. I would be much further ahead if I had never even started down this road of attempting to get to a point of running LOP. Especially considering that LOP cost a LOT of speed which you may not be wise to do if you are fighting a headwind. Cheers.

-

Mooney Rocket - partnership offered in JAX area

Austintatious replied to Stetson20's topic in Aircraft Classifieds

I like the panel. -

These came out of a M20k Mooney and I purchased all of it. I had intended to put it into my aircraft, but I messed up and didn't catch that it is a 24v unit. While I feel like an idiot, to my defense, the avionic shop missed this too... and well, long story short, I'm losing a lot of money here as I paid a lot of labor fees for them troubleshooting... about $1000.00 to have this unit bench tested, which it passed. So I am confident it is a working unit, it just wont work in my aircraft. Autopilot, 3 servos and Alt pre select = $2000.00 + 100.00 packing+Shipping+insurance Autopilot P/N 065-0042-03 = 1500.00 + 100 for packaging and insured shipping( I will get it to you as fast as I can for the $100.00) or free local pickup. alt pre-select= Free, if you buy autopilot... if you buy AP and don't want this please say so. If you want Servos = 300.00 each or 750.00 for all 3 + actual shipping cost. Servo part numbers 1 is a P/N 065-0051-02 2 are P/N 065-0052-14 Sorry, tried everything and cant get the pics to be upright.

-

More maintinance frustrations....

Austintatious replied to Austintatious's topic in General Mooney Talk

Yea, The above story got even worse... I discovered that the instrument lights they were supposed to fix (and claimed they did and charged me for it) still do not work.. So I still have 3 instruments that have no lighting and cannot fly in the dark. I don't even know what to do now as it requires removing my instrument panel to fix the lights. I didn't bother posting about it because I am completely dejected about the whole thing. In 4 years my situation is going to change and I will be abandoning certified aircraft for experimental, this is no longer tenable being at the mercy of bad maintenance. Hope you have a better experience. -

What you wrote in section 3 is so underrated.... ""I would only say that it's less drastic than it sounds because you can travel the same distance in a year using less time. Less time means less wear and tear on components. This and the fuel savings slightly offset the higher costs making them more but not as much more."" This is so true, and when you look at what a Lancair 4 does it becomes very obvious. Sleeker and faster is better

-

More maintinance frustrations....

Austintatious replied to Austintatious's topic in General Mooney Talk

OK, I'm going to give a final update on how this all played out. I got a call day before yesterday from the avionics shop... with a "quote".... I put quote in parenthesis because As the lady went down the list of line items, I knew 2 things... one being that most of the things she was listing had already been completed on the airplane and 2 that the prices she was spitting out where not even close to what had been discussed. She finished with a "quote" of 20,000.00 .... Needless to say, I was floored. I wont get into all the details, but I will say that there was clearly a communication problem. I had requested several times to know how much these things were costing and could not get an answer. And in some cases, such as the Dsub connector being upside down, I had flat out been told 1200.00 but was now looking at a 2800.00 charge. I also learned that the shops minimum labor charge for ANY line item was 4 hours... This was obvious when They tried to charge me 8 hours at 1400.00 to take the top left panel loose and re connect the OAT spade connector, which the shop that broke the ASI left loose and to put in a new digital clock in the same panel. The actual clock cost 350.00. Anyhow, over about 35 min in person we went down through all the line items. It was an experience and Apparently I was ignorant that aviation maintenance operates in a "blank check" manner... I was told in so many polite words that I was quibbling over small amounts of money while flying a $750k airplane. As it turned out $9500.00 of the 20k was for a replacement Autopilot computer, which I never was even told about until this day, they pulled that unit back out of the airplane and Between that and the other items we discussed, the total was brought down to 6700 + tax which covered the following work 1- Reconnect OAT 2- install new clock 3- Check Airspeed switch for any signs of overheating (as reported by previous shop) 4- Correct the ASI issue, which consisted of replacing it with a customer supplied ASI which needed to be tested/certified 5- Re connect "light bar" for the KI256 ADI, How it got disconnected I have no idea. 6- Troubleshoot Autopilot including bench testing Computer ( about 2500.00 worth which I did not contest) I will say that the shop was mostly open to my protest and admitted some of the issues were on their end and vowed to do better and did work with me towards compromise on the bill. I acknowledge that I could have done differently and I vow to in the future by doing the following 1. Set a CLEAR and WRITTEN expectation of being given a quote on any work BEFORE it is performed so that I may consider the situation and make a decision and authorize the work in writing. This protects both parties. 2. Set clear and WRITTEN dollar limits for which I am to be contacted before proceeding beyond on items that are difficult to quote precisely. 3. When I drop the AC off at the shop, do a run through WITH A TECH to determine what equipment is operational or INOP so that if the shop breaks something there is no wiggling out of it.... This all started with the ASI at the other shop and at this shop the GEM stopped working on their watch. That being said, this experience has me even more certain that going experimental is in my future.