Leaderboard

Popular Content

Showing content with the highest reputation on 12/26/2020 in all areas

-

Subtitle: They said my crankshaft was subject to an AD and had to be replaced. I said it didn't. History: Owners prior to me hung a factory reman O-360-A1D on the Mooney M20G in the very early 2000's. It flew for around 2,500 hours without the case ever being opened. Recent: I finally decided to have the engine overhauled. It was still running fine, but a cavalcade of circumstances such as time for annual, desire for EDM900, Penn Yan offering a 10% discount, and a willing banker all made the decision a no brainer. And if nobody has a brain, it's me. So off to Penn Yan the engine went. The case was cracked open for the first time since Lycoming bolted it shut, and the crank went to some shop in the midwest for inspection/overhaul/whatever they do to cranks. A few weeks after sending the engine, I get a call from Penn Yan. The shop out west had red-tagged my crank due to it being subject to a life-limiting AD per Lycoming. Before contacting me, Penn Yan had already discussed the issue with Lycoming to possibly provide me with some relief, since supposedly Lycoming had offered discounts or something to people affected by the AD back when the AD was fresh on the books. Turns out, Lycoming had to issue the AD twice, since additional cranks were flagged after the initial AD was released. But since the AD was quite old by now, Lycoming had no interest in helping me in any way shape or form - and if I understood the Penn Yan man correctly over the thud of my jaw hitting the floor, a new Lycoming crankshaft could run around $17,000. He suggested I contact Lycoming directly. I wondered what I could accomplish that world-renowned Penn Yan couldn't, and he said it wouldn't hurt. So first I did some research on the AD. As it turns out, my crankshaft serial number definitely WAS on the AD list. But interestingly enough, my engine wasn't. In reading the AD, compliance is accomplished as follows: Look at the list of affected engines. IF your engine is not on the list, you're not affected and go fly. If your engine IS on the list, then you search the crankcase serial numbers. If you find your serial number, you get to replace your crank. A little more research revealed that to my untrained eye, EVERY engine on the AD list utilized a counter-weighted crankshaft. Not only is the O-360A1D not listed as an affected engine, the O-360A1D does not use a counter-weighted crankshaft. So with this info, it was time to contact Lycoming. Lycoming has a special department that ignores investigates these things. Penn Yan had given me the email address of the head of this department, so I emailed him for further information on my plight, and was there any way Lycoming could help me out (I'd refer to it as a "hat in hand, please please please" letter). After several days of no response, I called the number of this department and spoke with an underling that worked for the guy I had emailed. I spoke of my email and my plight, and the underling seemed as perplexed as me as to why my serial number was on the list. He promised (PROMISED!) he would look further and someone would get back to me in two days (I pressed him for a deadline, as my rebuild was already way over schedule due to this incident). Well two and three and maybe four days passed with no word. So I decided to forgo the "please please please" attitude and put on some boxing gloves. I wrote a second email to Mr. "You're bothering me" at Lycoming and landed a few punches. Thankfully I CC'd my contact at Penn Yan, just so they'd know I was still working it from my end. Here's the body of the email: My engine overhaul has been delayed a week while awaiting a response from you. I'd like an answer from Lycoming as to how I've been flying behind a crankshaft well beyond a life-limited AD, and how Lycoming did not know they had put it in my engine. Perhaps it's a question better asked of the FAA, but I'd prefer to hear from Lycoming first. I need my engine back and it needs a crankshaft, and I need this process to move forward. As I said, thankfully I CC'd my contact at Penn Yan who apparently got such a kick out of my, let's call it "brashness", that he forwarded it up the chain to the top dawgs at Penn Yan. The top dawgs at Penn Yan felt inclined to alert the top dawgs at Lycoming, and a day or so later my Penn Yan contact called me to say that Lycoming had decided that my crankshaft was not part of the AD after all. He also congratulated me on the size of my... let's call it "brashness". All in all it was nearly a two week delay in the rebuilt, but thankfully Penn Yan had my back throughout. I'm still waiting for an explanation from Lycoming, or maybe that's a question better asked of the FAA...9 points

-

Data logging engine monitor Savvy Analysis subscription MooneySpace @kortopates (Paul K) That is a powerful combination and one I'm thankful for every single time my Mooney flies. An affordable version of a Formula 1 crew.6 points

-

Sure Skip, A sinusoidal oscillation in EGT of frequency .75 cycle(s) per minute with an amplitude of 40º F ± 10º peak-to-peak. Correlation is high, but not 100%. When we see it we advise borescoping the valve. When caught early enough, we've have had very good results lapping the valve in situ to correct the issue. The trick is to catch it early enough with a hot spot before being burnt.5 points

-

10 degrees isn’t enough magnitude to trip our algorithm. But don’t hesitate to open an analysis ticket and I’ll take a real look next week for you and let you know. Sent from my iPhone using Tapatalk4 points

-

3 points

-

A clean-burning LNG powered Mooney. I like it! Of course even after you get the vacuum insulated fuel tanks FAA certified (...) the LNG inside is still boiling away at a stable -130C at 100 psi. (Just to pick a point on the LNG phase state diagram). Even with fabulous insulation the wing skins are likely to be very cold. Encounter rain and the wing will be iced over instantly. Self-induced SLD, so to speak. Maybe a set of TKS panels can be modified to seep natural gas vapor past combo VG/igniters and spread flames over the wing skins to deice them. And augment thrust. High temperature paint will be needed. Should be spectacular at night and you won’t need position lights. When parked on the ramp the vented gaseous methane can be used for engine preheat or to run a BBQ grill for real $100 burgers.3 points

-

Great question, and I was wondering the same thing... Has anyone else thought about this? The tank on each wing in a E/F/J/K holds ~32 gallons usable... so you’re telling me that if I have 35% fuel remaining in that wing tank, I might lose my engine if I bank up a little? Would the ferry pilot have regained his engine if he’d just switched tanks when the engine started to stumble? (My guess is yes). Man... having to ditch an aircraft for fuel starvation when you’ve got 20+ gallons on board, in an airplane with 64 gallon tanks; just seems all wrong.3 points

-

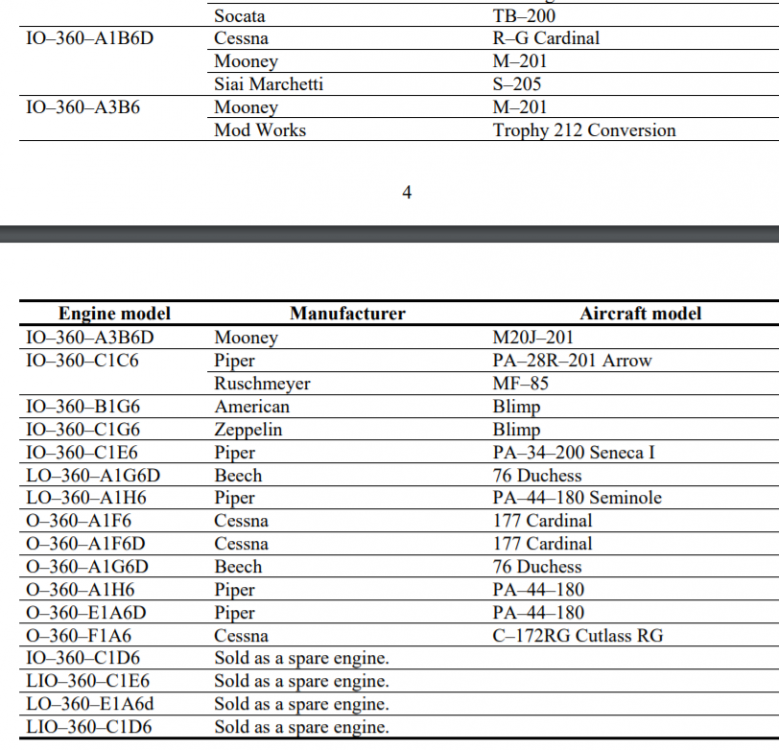

EDIT: In re-reading your comment, I realize now that I didn't completely answer your question below. In a nutshell: whether my engine was listed or not, my crankshaft WAS listed and is therefore required to be replaced. My argument is that the crankshaft in the O-360A1D was not like the other crankshafts in the AD, the fact that the O-360A1D was not listed supports my position, and therefore my crankshaft was erroneously included in the AD. Only Lycoming knows the reasons why, and they're not talking. You're exactly right, and that's why none of the annual inspections caught the crankshaft AD. The O-360-A1D engine was not on the AD list, so no one looked further at the crank serial #. However, once the crank was sent for overhaul in Kansas, the overhaul shop checked the crank serial # against the AD list and there it was. So if there were no O-360-A1D's listed, how in the world can a crank inside an O-360-A1D be on the list? My assumption is that my crank's serial # was listed by mistake or by typo, since no O-360-A1D's were affected by the AD. Compounding Lycoming's position is that they're documented as being the one that installed this crank in the engine. The crank overhaul shop only had the serial # to go on, and they rightfully flagged it. Lycoming knew the crank shouldn't be part of the AD, else they would have contacted one of the previous owners (all friends of mine) at the time the AD came out. I guess it was just too much for them to admit they made a paperwork mistake, and they were willing to let me pay the price. Or maybe there was a batch of incorrect cranks included, some of which were replaced at great expense to other owners and Lycoming didn't want to open that floodgate of liability. I can speculate all day, that's why I'd like an explanation from Lycoming. I'm sure it's much more boring that anything I can conjure up. Here's a partial engine list including all of the O-360 engines (assuming I pulled the correct AD). Notice that the O-360-A1D is not listed:3 points

-

My wife, kiddo, and I flew down to Cartersville(KVPC I think) Georgia outside of Atlanta and were forced to tie down outside. It rained real well on Christmas Eve and then got below freezing. I didn't think anything of it until we got in the plane today and fired up. Immediately you could tell something was off. It was very confusing since shutting down a few days before everything was perfectly smooth. I thought maybe the FBO towed it around and damaged the prop, but we were in the same parking spot as before. I shut down a few times and restarted thinking maybe it was only running on three cylinders. The whole time I'm trying to remain cool in front of my wife and kid but clearly knowing something's not right. The first clue that I had was the prop slinging water on the ground as it was idling. I got out of the cabin a couple times with the engine off to try and see, maybe it was an engine mount failure. But it finally registered with me to check the inside of the spinner. Sure enough, there it was. A large amount of ice. I never pay attention to the orientation that the prop stops since with the three blades, it is somewhat random. But going forward I'll definitely be watching this should we find ourselves tying down outside again.2 points

-

I think it's funny that they have two different versions. Like anyone in the market for a jet pack would have a budget constraint or the self restraint to not get the higher thrust, higher endurance, and cooler jetpack.2 points

-

2 points

-

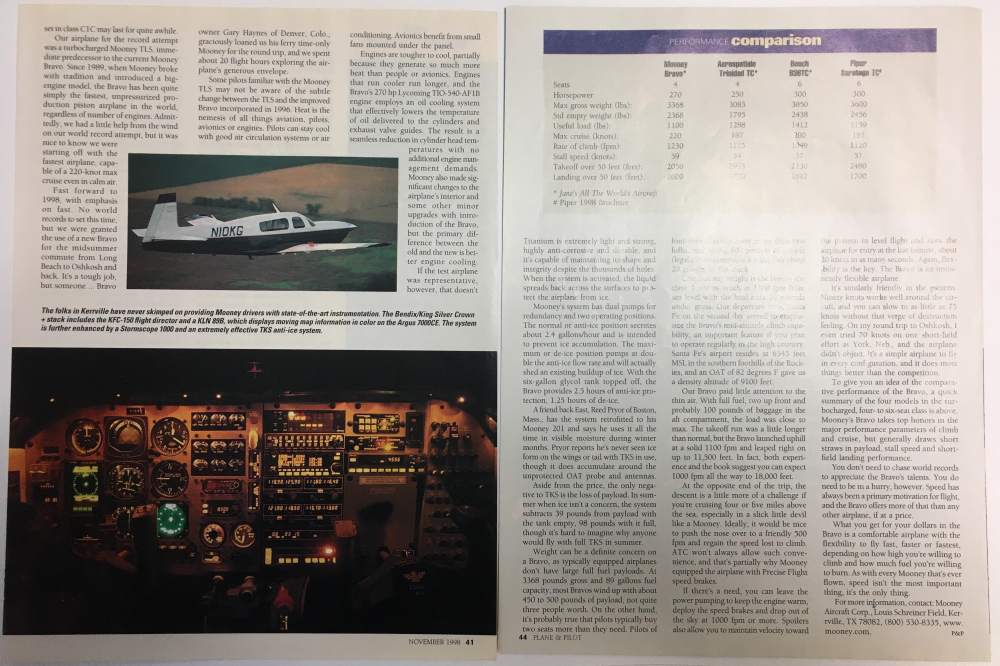

2020: 221.4 hours and 27 instrument approaches in the Bravo 3 transcontinental round-trip flights 2021: Fly the North Atlantic Route to visit family in Germany2 points

-

1 point

-

Most LNG tanks are operated at 1 bar. 14 PSI. Most are insulated with fiberglass, not a vacuum barrier like a Dewar flask. BTW I have a dewar in my garage from when I used to work on the stuff all the time. It could use a suck down. It holds 25L I usually buy 5L of LN2 at a time. It used to last for about 2 months, now it only lasts for about 2 weeks. This is an open top Dewar and operates at ambient pressure. I seal the top with a Styrofoam coffee cup. The liquid stays at 77K at ambient pressure. So even with a poor vacuum the boil off rate is quite slow. If you fill a Styrofoam coffee cup with LN2, it will take about an hour for it to all boil off. If you put a coffee cup lid on it, it will last twice as long. You can hold the cup in your hand and it isn't cold at all. Seeing that I'm on the subject, Stupid LN2 trick: Make a support structure out of stiff wire to suspend a metal shot glass over the top of a Styrofoam cup. Fill the shot glass with LN2. you will notice a milky white liquid condensing on the outside of the shot glass and dripping into the coffee cup. That is liquid oxygen! It condenses above LN2 temperature. Wait till all the LN2 boils off, refill if you like, but when you are done sneak up on the coffee cup with a bar- b- que starter. It is better if you do this with a welding glove on. Light the lip of the cup on fire. The cup will disappear in front of your eyes in a bright flash of light. FYI LNG = Liquid Natural Gas LN2 = Liquid Nitrogen1 point

-

@Parker_Woodruff My insurance guy has me convinced I need a Seneca...so that's been the focus for now.1 point

-

Looks like it did, $165. https://www.yosemiteaviation.com/our-fleet1 point

-

I know that Tony at Airborrn Aviation at KMPI bought an "F" intended to go in the rental fleet. When I moved out of CA, they were still prepping it. Don't know whether it ever made it or not.1 point

-

This time there is video. Remember there were at least two other sightings this year where he was busting LAX bravo airspace. This time enough courtesy to fly in a GA practice area? https://www.foxla.com/video/8841131 point

-

1 point

-

As Skip said make sure to check the prop control and that it is getting full travel. I had an instance where the cable had slipped in the clamps and no longer allowed the governor to hit the stop resulting in not getting to 2,700rpm. The reading on the 900 "should be" accurate as it is taking its reading from the mag, not a cable like the factory tach. While you're at it pull the factory tach and the other gauges you don't need anymore now that you have the 900, it is primary. All you need to pull the factory tach is a cap that gets screwed on and safety wired. $32.50 from AS. https://www.aircraftspruce.com/catalog/inpages/tachcap.php?clickkey=13626 Also as Rob said get that idle down closer to 500. Between 500-700 but as close to 500 as you can get it and still have it run smoothly. The higher your idle the longer your landings. Just be aware that the first few will be different with a low rpm if you are used to the extra power, you have to be more careful to keep from planting it on the runway. The nice thing is that you will need much less runway to land with the lower idle. Also as Rob said it will idle different after warm up and a trip around the pattern so do that and them make your fine tuning adjustments.1 point

-

Not to be a paid factory shill here, but if you go to the factory engine, all those A.D. mandatory replacement crankshaft, and all of the cylinders everything else get tossed out, they don’t charge extra for that. Big-name engine shop overhauls are cheaper, but when you have to replace the crank are you spec for new cylinders and new cam and lifters, often it is more. And you do not get a roller cam with those options . There’s a story of a guy on here who went to aero engines of Winchester, and the case and the crank were bad. And by the time he was done he was in it for $50,000. Now he has a rebuilt used crank repaired case flat tappet engine for that money. Not bad engine per se, But upside down in it for sure. Just carefully evaluate the condition of your core, and if you’re going to get slammed for a new case or a new crank or a bunch of other stuff, make sure all that is baked in before you open it up. Because once it opens up at the engine shop, you eat all of it1 point

-

Does doing a one wheel landing require less rudder input than a crab and kick landing. And other things I figured out is on a strong crosswind I add planned drift into my set up. It's a boat thing.1 point

-

Wow. Caveat emptor. I had Gulf Coast Avionics do my "official" LED upgrade a little over 3 years ago. Excellent service; cost was $1800 but that included some additional work on the radio, which now looks and feels like new.1 point

-

I'm happy to be corrected on this but as far as I have been able to tell, the only difference between wing low and crab and kick is the amount of time spent cross-controlled. With pure crab and kick, you are delaying it until immediately before touchdown, but you are still going to kind kind in rudder and drop aileron to prevent drift after touching the pavement. In both cases, doing it correctly means your momentum is forward relative to the runway and not drifting. One wheel at a time is a result, not a goal. On a slippery runway, the goal is going to be to touch down and go to full crosswind taxi correction as quickly as possible.1 point

-

I wonder if it’s regional or equipment differences that explain the difference. My 90 day flight aware data only shows 3 flights, but looking at my logbook, I’ve flown about 30 times during that time. Perhaps it’s because I’m using 978 instead of 1090 for my ads-b out solution?1 point

-

1 point

-

I had my L3 installed in September 2016 and had a lot of issues with loss of WiFi ...in fact, I was losing communication with every single flight....L3 was of little help, they told me several people have had this same issue....finally I found a brand new PMA voltage regulator on eBay for $200...I installed it and in 20 tach hours I have only had loss of WiFi 3 times...all three times was departing KMTN (not my home field) and power cycling got it back immediately. I consider this a great success. Prior to changing the VR voltage would go from 13.7 to 15.1v and was never steady...the new Zeftronics model holds a steady 14.0v changing a VR on an M20J is about the easiest job imaginable...plug and play! And it so easy to get to the VR on the copilot side ...2 small bolts and it’s out1 point

-

I have an S-Tec 30 and it's a big help. It's coupled to the Avidyne IFD440, so it actually will fly random location holds and anything else I can plug into the amazing 440. On the other hand, I have a friend with an IFR-capable Symphony SA-160 (basically a certified version of the Glastar) and he'd like to add an S-Tec to it, since S-Tec is one of the few autopilots STC'd for his somewhat rare aircraft. I don't know the details, but the deeper he delves into installing a used S-Tec the more frustrated he becomes. Seems S-Tec has made installing a used box in a different airplane a very expensive paperwork endeavor, I suppose to drive you toward buying new. Which to me puts them in the same walled-garden mentality as Apple and Garmin.1 point

-

I am confused. If the following you posted is correct, then what does getting anything from Lycoming even matter? "In readingthe AD, compliance is accomplished as follows: Look at the list of affected engines. IF your engine is not on the list, you're not affected and go fly." If YOUR engine wasn't on the list, it seems you were good to go from the start, and Penn Yan should have known that. The crank shop, NOT having the engine info, was merely responding to the crank serial number. Or, am I missing a key point??1 point

-

Around Seattle, I know of one school renting out a M20J: Galvin Flying. $213 club rate $234 retail rate. Great school btw.1 point

-

I’m glad that you got Lycoming to agree that your crank is OK, but ADs are federal law. If it is listed on the AD, I think you need Lycoming to get the AD amended to be totally legal.1 point

-

Thanks for the update David. Hope this pull together for you on this project. Still waiting on the sidelines. Sent from my iPad using Tapatalk Pro1 point

-

Fly commercial to and from training clients without a mask on, you know, like back in the old days.1 point

-

If you knew how much stuff they crammed into that GI275, your opinion might change...as it did mine when i thought similarly. Over the last several months, I’ve had a complete change of heart...from wanting to go down the BK 230 route (to avoid having to pull my ESI500 with all the options, among other reasons) to the GFC500 with a GI275. I must’ve gotten a really great deal, as my 275 was - installed - around $4100’ish, along with a pretty generous trade on my L-3 ESI500. Installation started Wednesday this week. My shop has done a few dozen 275 installs already, and has been so impressed with its capabilities, they’ve dubbed it “G500TXi in a tube”. Only had a chance to fly behind a couple of them installed in a Saratoga recently. I found a little bit of a learning curve with them...push-and-hold menus selection, etc. and some other functions that take some getting used to, but I hope that once your install is done, you reach the conclusion that it’s money well-spent and they meet your expectations, as I’m sure they will mine.1 point

-

there are very few shops like this. I convinced my PA30 turbo twin comanche client to convert his Slick mag airplane to a hybrid Bendix S21 / Electroair setup. Man its nice. About 20 hours after the work, the left engine, left mag wont shut off with the switch. It has a special capacitor that is very easily overtorqued, which breaks it, and renders the P-lead ground inoperable. (much like the Rochester CHT probe for factory Mooney gauges). I advised the client to take the top cover off the mag and see if the P-lead wire is broken or disconnected from the tab inside. He took those directions wrong and took out the screws that separate both halves of the mag. gears showing. its screwed. I called Aircraft Magneto Service, who sold us the overhauled mags, and spoke with Cliff, who Ive called before, and knows mags like he knows his own birthday. He said "send it in". I replied my client wants to fly soon, and can I put it back together.. He said I'll pay the freight.....send it in. Dont F with it, we will do it right. Anyways, 48hr later, we have a tracking number, and an invoice. It comes tomorrow early AM. On the invoice they have 100$ for repair of bendix magneto, $125.24 for a new capacitor, and 96$ for overnight freight back to MD. (plus the 90$ overnight freight there). so a sum total of $322.19. And a final line at the bottom. "warranty". -$322.19. they ate the whole cost of this, and im certain its my fault. So, when you need a magneto fixed, and fixed right, and stood behind. Call Aircraft Magneto Service.1 point

-

VAT (which I guess is the closest equivalent of a sales tax) in Poland is 23%... 19% in Germany, I think. @jetdriven - I like the new logo.1 point

-

This brings up a point I’ve wondered about - how low becomes an unporting problem - in any phase of flight? 12 gal? 12 gal even at the end of the flight arriving at the pattern?1 point

-

Could be true; I have no idea of the total installed cost comparisons between STEC and the others. My angst stems from what seems to be the current prevailing view that a sub $100K aircraft needs the latest GTNs and a fully coupled $30K A/P to be considered worthy. No, my buggy whip STEC won't couple to the glide-slope, or fly random location holds, but those features aren't worth the coin to me. I'm just constantly surprised at the number of people that seem to think they're mandatory, and feel the need denigrate perfectly functional 'old' tech.1 point

-

I think "recommend" is perhaps a little strong. LW-16702 is required by AD for certain engines with smaller faced tappets. Lycoming "approves" the use in all it's engines. (SI 1409C) Aeroshell and now Phillips make oil with the additive in it approved by the FAA as meeting the AD so you don't have to mix it if you have an engine that requires it.1 point

-

1 point

-

I fly in the same area you do. My typical trip is KRHV to KTRK. Every couple weeks, year round. I flew the trip today. And other trips in the West and coast to coast. I owned a J for 5 years. While owning it, I got tired of cancelling trips because I could not guarantee not touching a cloud below freezing. When I upgraded FIKI was on the top of my list. Now that I have a FIKI Encore, I am very happy with my choice. It allows me to depart when I don't think there is icing but I cannot be 100% sure. It allows me to continue a flight where in my J I would have had to divert. I probably use it 2 to 3 times a year in actual. I probably launch 4 trips a year now that I would not if I did not have FIKI. That does not sound like a lot of trips affected, but it makes a big difference in confidence level in launching a trip. So now days it is more the 100 kt mountain top wind observation and not the icing that makes me cancel. Weather forecasts are not perfect. Freezing level forecasts are not perfect. It is not uncommon to see freezing level a couple thousand feet below forecast. And when that happens, you can be squeezed between MEA and the freezing level. FIKI takes the anxiety out of those scenarios.1 point

-

In case anyone was wondering what other avionics companies Moog has... https://www.moog.com/products/avionic-instruments.html Typically, in the US... a corporation will buy up smaller companies to add to their product and services catalog... They usually advertise this increase to their skill list... Unfortunately, adding finance and sales people isn’t in the acquisition plan... Good luck Stec! Best regards, -a-1 point

-

Anthony, I think that the 100 means 100/130 (green) not no lead. The lead was understood until the 100LL was introduced. Skip1 point

-

FlightAware does indeed use FAA flight plan data as well as several other sources including a network of over 25,000 receiver sites. FlightAware Data Sources1 point

-

1 point

-

I don't know where that posting is, but one way to pay for a Mooney is through flight instructing. I've earned a lot more than the cost of my airplane doing that, helping other people, and having a lot of fun doing it.1 point

-

I gave Captain Dickson a line check in the 737NG years ago. He is an excellent pilot and his evaluation of the Max will be thorough and thoughtful. It is nice to have a real stick as the Administrator.1 point

-

I agree. That's the way it should be with certified aircraft, right? The person doing the final certification flights should not be a company pilot. Now here's my fantasy. They should also strap in every MBA from Boeing on who had a role in the original rush-out and corner cutting in the back and simulate an MCAS trim runaway event. Stream real time video of the terrified executives to those who registered objections to the decision to avoid redundant AOA sensors. Use it in orientation sessions to educate new management employees about why it was such a major foul-up. If only.1 point

-

Actually, that makes sense. Back in the late 80s/early 90s, when the M20J MSE was released, they also had a stripped down version for flight schools for Instrument/Commercial training. It was the M20J AT- for Advanced Trainer.1 point

-

A simple google search netted these 6 in less than 5 minutes.... M20J - $189 an hour http://www.pinnacleacademy.com/rates/ M20C - $139 an hour http://duboisaviation.com/id1.html M20J - $179 Club Rate http://www.flynfi.com/View/Mooney-M20J-N54ER M20K - $248 an hour https://www.advantage-aviation.com/rental-aircraft/ M20E - $185 an hour http://www.wyndflight.com/rentals.php M20F - $170 an hour http://www.wvfc.org/aircraft Cheers, Brian1 point