Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/2021 in all areas

-

This is of course RV antifreeze, it’s cheap and usually Walmart or any RV store or West Marine has it, one big advantage of it is that it’s not toxic as it’s meant to treat drinking water systems, car anti-freeze however is usually toxic and tastes sweet so it can kill any dogs or other animals that happen to drink it, it’s also more expensive.3 points

-

If you put it in an un-heated hangar, get a kerosene heater, the ones that look like a jet engine, and use it to warm up the hangar and melt the ice. Most of the ice comes from snow, dew and frost, which will be greatly reduced in a hangar. It is possible that the heat from the Tanis will keep the hangar slightly above freezing. Back in the 80s when I used to fly daily in the winter with the airplane on the ramp, out of Denver, I would use a brush to get the snow and frost off and if there was any ice, I would give it a sharp bump with the side of my fist, this would flex the skin enough to crack the ice so it could be brushed off. It never damaged the skin or the paint. One other word of advice, when parked on the ramp in the winter, always leave one prop blade pointing down. This lets the water drain out when the spinner gets full of snow and then melts during the day . If it can't drain out, it will form a solid block of ice in the spinner that you cannot easily see that will shake the engine severely when you start it.3 points

-

Today I am IFR near KTHA. I hear a Bonanza call Memphis Center for clearance off of KSYI. They give him the clearance with void time and "squawk 5603". A few minutes later the Bonanza calls back Bonanza: Memphis Center, Bonanza 444XX request? Memphis: Go ahead Bonanza: We are having some trouble with our transponder. Do you have another code without an 8 in the second digit? Memphis: I don't think I can change your "squawk" until you are airborne....oh actually your "squawk" is 5603 Bonanza: Oh ok, that works Me (being a smarta**): There is no 8 or 9 digit on a transponder anyway Unidentified aircraft: It's a Bonanza, they're special. They got everything. Memphis Center attempts to transmit, but cracks up in laughter.2 points

-

What seems to be a pretty good map of fly-in community/airports in the entire US except Hi, and a few international locations, too. https://www.google.com/maps/d/viewer?mid=1iZzR4PzTHJ-jXhNByere6X7qyYE&ll=37.148305086213206%2C-100.69936074092027&z=32 points

-

2 points

-

Yes, here is the reference. I am very good friends with Ben Bernstein who is one of the authors and he helped co-author my Ice is NOT Nice series. Cober, S., Bernstein, B., Jeck, R., Hill, E., Isaac, G., Riley, J., & Shah, A. (2009). Data and analysis for the development of an engineering standard for supercooled large drop conditions. US Department of Transportation.2 points

-

Followup: mechanic said the continental battery failed the “caps” test and wouldn’t take a charge. All is good with a new battery. After plugging in my battery minder with the new battery the lights seemed wrong. I then had the epiphany: my extension cord to the Battery Minder had come unplugged allowing the battery to die. This was on the heals of 4 months in the paint shop which really drained the battery.2 points

-

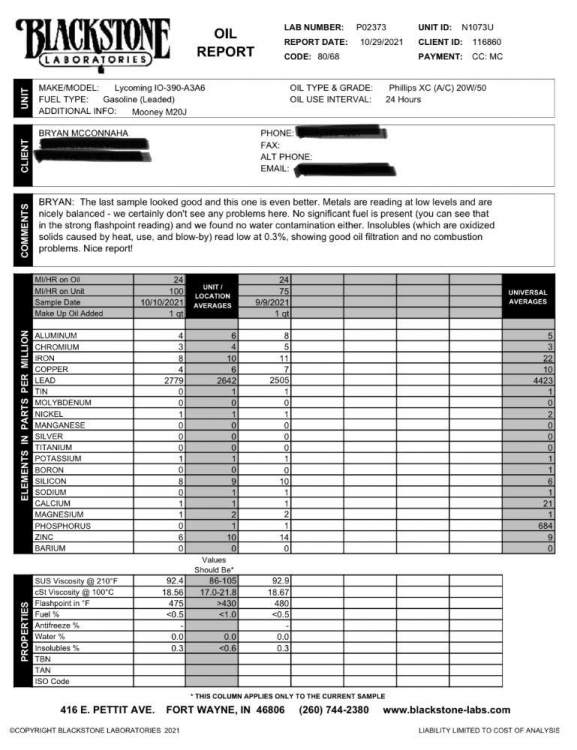

What I am searching for is a low time and relatively fresh overhaul ovation or bravo. Fiki and a garmin GTN750 are preferred. If you have such a beast, PM me. I’m going to build an add on barnstormers and trade a plane and I’ll get a link to it posted here in the classifieds. To summarize: 1990 m20J- 2000TT- 115 hours since factory reman IO390/factory new top prop. Done this year Engine mount overhauled, new metal baffles, new engine control cables, new exhaust. Oil cooler overhauled. Surefly magneto on the left side. Maggie ignition wires. Stunning brand new aerocomfort executive interior. Avidyne IFD550. Lynx NGT9000 transponder, PS engineering 450B. Century 2000 autopilot. Whelen nav/strobe combo, all synced together. Whelen landing light. Reiff turbo preheater. New precise flight electric speed brakes. August annual from advanced aviation (mooney service center) Couple photos attached, more photos and better photos once I get an add up. Still working out pricing. Paint is a 7, maybe better, interior 10, mechanical is 10. No fuel leaks. Thorough and complete logs. Sad to part ways with what has taken most of my time/energy and money recently, but I think I want a FIKI bird.1 point

-

Yeah, just haven’t seen any studies on this. Seems to be entirely in the “gut feeling” territory. As A64 mentioned above, a 10w50 and a 100 straight weight have the same viscosity when hot, and should have the same viscosity at engine shutdown. I *think* the argument is purely about residual oil, but I also think that residual oil adherence will have as much to do with dirt and sludge and the condition of internal components as it has to do with viscosity.1 point

-

Lacking any instructions from tower, the only choice to make after turning towards the airport is whether to turn left or right to join the published missed approach course. I suppose I could see someone getting that wrong in the heat of the moment if they hadn't reviewed it during briefing. It's hard to imagine anyone getting the initial turn towards the airport wrong, since you're required to be looking in that direction anyway...1 point

-

Yep - Celsius for Canada on this trip. Back to Fahrenheit next week, we hope! The hairdryer idea is a brilliant suggestion - since this is a trip to visit family (vs being at our home airport), I’m sure our in-laws would let us borrow their hair dryer (maybe not their Dyson hair dryer though -haha) Hair dryer, extension cord, and a spray bottle of windshield fluid or RV antifreeze. I think we have a plan! thanks!1 point

-

Presume your talking Celsius when you say “below zero”. If temps are are just around freezing, it won’t take a lot of energy to bring a small unheated hangar to an adequate temp to melt ice. If you have power, an 1875W hairdryer can be had for under $20. Remove an inner access panel from the underside of each wing and heat the interior of each wing structure. Tail can be done in short order from the outside.1 point

-

I emailed Mark Scheuer and he confirmed that on a PMA450B, the phone should pair with BT1 and the iPad running ForeFlight with BT2 to avoid clipping of ForeFlight voice alerts. Of course, the pilot audio must have both BT1 and BT2 selected. Skip1 point

-

This is a thing that I’ve always had trouble getting my head around too. My assumption has been that they’re talking about residual oil that will remain on engine components for hours or days after shutdown, where there is a theoretical difference between cold thin residual oil and cold thick residual oil.1 point

-

Couldn't read CRAFT because of his own hand writing smudging the 6 as an 8. For sure! Had this happen some years ago with some dude in a Bonanza @Alan Fox thinking he's going faster.1 point

-

1 point

-

My experience is limited with the Ovation. I owned a 310hp STC version for about a year and a half. It is a great airplane at 10,000 and at that altitude and below is as fast as a Bravo and almost as fast as an Acclaim. If you fly it at those altitudes it is the airplane for you. Personally I was not impressed with the one I owned above 10,000, but keep in mind I was pre-conditioned. Previous Mooneys I had owned were a 231, two Bravos and an Encore, all turbocharged. I bought it because I was in love with the panel that the previous owner had re-done, and it had a service ceiling of 20,000. How could it be that much different than the other Mooneys I had owned with service ceilings in the mid 20's? But after a few trips where I really would have liked to be up in the teens, but in the summer in Texas it just wasn't happening at the climb rate I was getting, I decided to move back to a turbocharged Mooney. Ovations outsold every other Mooney since it was introduced in 1994, with over 500 produced, so it is the 1st choice of a lot of people1 point

-

Nooo... Not Auto Antifreeze (as in the FAA reference).... Just the windshield cleaner, or the stuff @BravoWhiskey posted the picture of. I use that in our cabin every year and available at any auto shop. If you don't see it when you walk in the door, ask them for "Mobile Home" or "RV" antifreeze (vs. straight auto radiator antifreeze). One other thought if you do still have ice and need to spray. If you can, get whatever you use really warm. I know that may not be real easy, but maybe keep it in the car right in front of the heater and only put smaller amounts in the spray bottle to do smaller sections. ADDED: And the point of wiping the wing off falls in with the FAA document. The sprays we're talking about have not been tested at altitude and at the temps you may encounter. Dry or not. So you don't want the stuff locking up any moving parts. Also why you need to confirm everything moves and is dry while you're in the hangar. Once you're out, it's like any other day on the ramp with all it's winter pitfalls.1 point

-

Back in the day, I got a metal Hudson sprayer and soldered a 500W heater in it. I would fill it with 25% car antifreeze. I could boil the water in about 10 minutes. I would heat it up at home, then plug it back in at the airport for a few minutes. It would take the ice right off. I would clean off as much as I could with brush and rag and then hit it with the hot antifreeze. I could usually get it all clean in 15 minutes or so.1 point

-

Several days in an unheated hangar and there a chance what's on it will come off, it will at least prevent more from accumulating. As @N201MKTurbo said, bumping the ice with your fist cracks it and it will fall off. From the picture, it looks like you are at Buttonville, you could probably get Million Air to spray it with Type 1, but I'm sure that wouldn't be cheap.1 point

-

It doesn't seem so - looks perfect. And the paint color itself is so similar to the dye color that there is no discoloration that I can see.1 point

-

I’m thinking a trunkload of windshield deicer from the local auto parts store might do the trick. Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

With some APs… you may be lucky to use the old servos when updating to the same manufacturer’s new autopilot… Chances are… you may prefer new servos as well… from a performance and reliability viewpoint… Battling worn and old servos isn’t an easy thing to accomplish… unless you share the field with a really good AP shop… And OH costs for servos isn’t very favorable either… Best regards, -a-1 point

-

Only because you have a mono audio panel. With a stereo audio panel it can be in stereo.1 point

-

I got the plans from the archives here and took them to a cnc machine and in short order I had 3 inch extensions that my mechanic installed at annual1 point

-

Showing a little inexperience here Anthony , This turn coordinator , has a rate gyro output for an autopilot... Cant just replace it , if the plane has an autopilot..1 point

-

1 point

-

Good Mag expertise is getting harder to find… There may be a few recommendations around here. Or you can ask… People like to have their mags OH’d out of sync with each other… on 500hr service schedules… This keeps OH challenges from occurring at the same time, and wear issues occurring at the same time later down the road… The capacitors and plastic gears caused a few common challenges… -a-1 point

-

There have been conversions from A3B6 to A3B6D that have been field overhauls. IIRC, that does not include the replacement with roller tappets, but not 100% sure FWIW, if the A3B6 serial number ends with an "E", it is roller tappet motor.1 point

-

I still have the receipts from when the previous owner of my '86J converted from a factory A3B6D to a rebuilt A3B6 at Dugosh in TX, it was about $50k in 2012.1 point

-

Lycoming will give you a discount for a D core on a rebuilt A3B6. There is no way to "convert" an engine as there are a great many internal differences -- it's not just the accessory case. Lycoming told me that the IO-360-A3B6D was built in lesser numbers than other IO-360 variants and shares fewer common parts. Lycoming would like to accelerate the retirements so that's what's behind the lower cost to get an A3B6 from the factory. Skip1 point

-

I investigated this recently too. It looks like less than 40 were made during or after 1997. An experience broker estimates that less than 10% (older than 1997) have been converted. My conclusion was you've gotta have deep pockets to buy a newer one, get lucky or go with the D mag engine. I'm curious what it takes to convert the D mag engine if you buy one with a run out engine and plan to overhaul. Will Lycoming still do it at a reasonable cost, etc.1 point

-

OK for those who are interested, M20Doc saved the day. I sent this info to my mechanic and he confirmed my serial number is among those authorized through an FAA/ PMA cable MacFarland can make so BINGO, new cable ordered for $708.00! My mechanic now feels comfortable installing it so we are golden.1 point

-

I installed in my M20J in anticipation of getting a Surefly installed on the left side. My only complaints are: 1. Sometimes (maybe once or twice) I forget to turn on the right mag until I get out to run-ups. 2. The mag switches are too "soft" meaning that it's too easy to flip them off and on. I installed mine right where the original key switch was located which is directly under my digital clock. On one occasion, in turbulence, while starting my timer for a practice instrument approach, my hand accidentally turned off one of the mag switches. 3. Once (and only once, so far) I forgot to turn them off. Advantages: 1. You don't have the bendix 100 hours AD grounding checks anymore. 2. Cleaner Look -- feels cool to use a push button start 3. You have a solid feel for which mag is on and off during mag checks.1 point

-

According to the IPC, S/N 24-3374 and above were built with A3B6. EDIT: That serial number range is for 1996, 1997, 1998 (last year built)1 point

-

I have a couple of comments to add to the excellent advice given already given always pre prime before you need it. So prior to entering visible moisture but while flying I start a ten minute timer and turn the TKS system on low. If I’m not wet out in ten minutes then we are a no go for icing conditions. I alternate which tks pump I’m using every single time I switch on the Tks system so I know the pumps are both working I almost always tanker or carry replacement fluid in the baggage compartment. One gallon for three hour or less flights and five gallons for longer flights. I don’t want to be skimping with tks usage because I’m worried about not having enough. I’ve seen the price as high as $80 a gallon when flying cross country i carry a two gallon plastic garden pressure sprayer which I use to device on the ramp with using my own tks fluid I’ve been quoted thousands of dollars to get a Comercial deice especially in Canada where deice is done for airliners Just be descrete and get it done quickly and with out talking about it some airports only want deice done at special deice fluid recovery pads which is how we get to a thousand dollar deice service I have had a tks system failure while airborne a fitting let go. The airplane had ice very fast it is really important to fly a flight plane with an icing out in this case I was at 12,000 feet I declared an emergency request lower and deviations left and right to avoid visible moisture while I was inside class b airspace the controller gave me exactly what I asked for and I was able to descend through the ice to a warmer altitude the plane will always go down! For this reason I always file for as high an altitude as possible as early as I can for just this reason . Dress warm as my ovation cabin heat stops working at minus thirty but I also don’t get ice either I hold altitude longer above ice so that ATC doesn’t bring me down into an ice layer and then motor me sixty miles to the airport this is common and I’ve had some tough radio exchanges with approach on this issue if you have not already changed your wing landing lights to led then do so before you fly in known ice my led landing lights are the only place I can easily so how much ice the tks system is dealing with I have been flying along fine for an hour with no ice build up and intermittent tks to keep it that way as I approached a blacker uglier bit of weather I turn on tks and within two minutes the light covers had more than an inch of ice. The tks system was working and the plane was fine but these conditions are very dangerous I would not have known if I had incandescent lights which generate enough heat to keep ice off I descended to warmer air and life was good the Faa has an excellent library on icing read it learn how freezing rain is charted and do not fly when it’s forcast it can overwhelm a tks system sld or super cooled liquid drops1 point

-

For those who don't understand the jargon used in this post (like me): SLD = Supercooled Large Drops I work for the National Organization for the Advancement of Acronyms. I'm fighting a one-person battle to try and change an agency culture that overuses jargon at the expense of understanding by the public that we strive to serve.1 point

-

Nope. Today's servos have microprocessors in them and the autopilot relies on constant communication with the servos. Only the servos that are in the Garmin STC will work.1 point

-

I had a fair amount of trouble with calibration of the system. Ultimately it took 5 test flights. Alpha Systems was very supportive. They lent me a test set to confirm all the wiring and pneumatic connections were good. That helped greatly as I then knew that getting the vane angle set was the remaining issue. Once the proper vane angle is found the calibration took us (definitely take a second pilot along!) perhaps 30 minutes. I chose to have the system use 4 configurations: Flaps up, gear up Flaps up, gear down Half flaps, gear down Full flaps, gear down That means eight configuration entries (plus 4 more for the optional Vs x 1.1 settings) for calibration.1 point

-

The Lark, Darter and Quail as well as the Meyers 200D (Commander 200) were built in the Albany Ga plant by Aero Commander, they were all purchased to be manufactured and for whatever reason none were successful. The 114 Commander was also built and Certified there, maybe the 112 also? Only aircraft that ever was successful from that plant was the Thrush Crop Duster. The yellow Ag plane in this picture is not a Thrush, I don't know what it is, if anyone does I’d like to hear what it is. I believe they all have at least some steel tubing and all have a reputation of being overbuilt if somewhat heavy.1 point

-

The fact that that particular sealant system is known to not leak and you had figured out a way to reseal it definitely makes that an option. Since you've already had it apart, you can weigh that against the likelihood/difficulty of having to take it apart again and maybe doing something different. I'm wondering if you can use the traditional sealants on the inspection covers and maybe urethane fill where you put the skin back on, but it's interesting to have multiple potential paths. The fact that you have time on your side is excellent as well. Cool project, I'm always interested to see your updates.1 point

-

I got the plane cheap, and my labor is even cheaper. Just got my pilots license last year. I have my a&p and recently got my ia. Never worked in ga so this is quite the adventure for me. I have met some amazing people along the way. A guy that works at a well reqarded shop as a structure guy has been giving me invaluable tips along the way. One day she will fly. I thing 2-3 yrs, still have my day job. Glenn1 point

-

I was able to get a wing from a plane a few numbers newer than mine. Swapping it is a pain but the quotes I got for spar replacement was more than what I paid for the plane. I cleaned out the proseal in my tanks but I put in the fuel tank bladder STC so as to never do this job again. Bladders would get you out of getting off all that old sealant.1 point

-

I've told this story here before...I've had this issue since I first got my plane. First, I sent the prop in for reseal and they accidentally overhauled it (but only charged me for a reseal since it was their mistake) but it still leaked...sent it back and they resealed it for free,....still leaked! I lived with it as I had become educated by then about the problems with Aeroshell 6. I bought some Aeroshell 5 and at last annual had my A&P/IA add the Aeroshell 5 (mixing Aeroshell 5 and 6 is now OK per a recent Hartzell SB; excerpt below). Yeah, it still leaks, but not nearly as much. My plan is to keep 'topping off' with Aeroshell 5 at each annual and hope it improves even more. Meanwhile I just live with wiping down the prop1 point

-

1 point

-

the oldest roller case is 2005, so I dont think many cases are that old. I got two of them, both new cases. I also have a core engine 2006 roller case in my shop. A field overhauler can build that too.1 point

-

I literally just completed what has been a over 2 year project replacing my single drive dual mag in my 78J. The engine swap didnt take that long but the time it has taken to do the extras did, including EI engine monitors, SureFly electronic ignition, etc, and its been flying about 150 hrs during this whole project. I can tell you a rebuilt Zero time engine from Lycoming is worth every penny, enough so that when I TBO this engine out I would very strongly consider doing it again and forgo the overhaul route. The difference in cost between overhaul and reman is instantly made up in the increased value of the plane which now has a zero time engine in it. Additionally, most of the components on my reman were new because Lycoming has not received many of the A3B6's back in cores. So many benefits IMHO to going the reman route verses overhaul...the biggest and only downside is the upfront cost of the extra $7500ish. I could go on about a reman vs overhaul but it just went really well in my experience, especially considering what my end goal was. Fuel economy is also a great benefit with electronic ignition, another reason to deep 6 the A3B6D, along with simply starts, hot or cold...all the time! I digress....1 point