Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/2021 in all areas

-

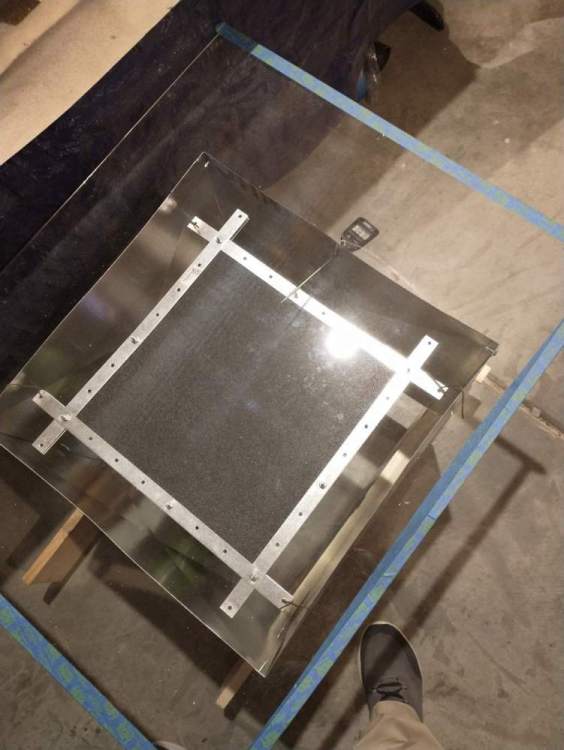

So I am currently in a very extensive annual and decided while the plane was down for a while and torn apart I might as well upgrade my Mooney from the broken plastic overhead vents to some modern eyeball vents. First idea was to order some vents from Wisconsin Aviation. After receiving those I took them in to the AP/IA to see what he thought. Unfortunately he had two conditions 1. They need to come from a company that made the vents for an airplane. They fit this description. 2. I couldn't cut the plenum to install whatever I was going to use....the instructions for the Wisconsin Aviation vents clearly stated you had to cut the plenum to install them, so no go! I had to come up with a plan B. After much thought and research I came up with the idea of thermoforming some adapter pieces out of ABS plastic to space the new vents away from the plenum. I also wanted metal eyeball vents so I ordered some from aircraft spruce. The ones I ended up with are much nicer that the plastic ones from Wisconsin Aviation. Now the hard work. First I had to build a vacuum forming table, a heating chamber, and make the appropriate form to make the parts. I used 1/8" thick ABS which created really strong parts, likely way stronger than they need to be. It took a couple attempts to get the form right and I ruined a bunch of plastic figuring out the correct amount of heat, but with some trial and error I think I got it figured out. I think they turned out well. Tomorrow I will take them in for the IA to review and if they get his blessing I'll work on getting them installed. Here are some pics of the project so far.3 points

-

As 2021 comes to a close I reflect on the previous 12mo of logbook entries. In the 2021 calendar year I tallied up 169.4 hrs in my Ovation 2. I would have flown a lot more but my Mooney was in the shop getting a new panel for 4 months. Memorable trips included a trip from PBG in upstate NY to HYI in TX and back and a trip from PBG to F45 in S FL and back. Only 1 fuel stop to and from TX. Ovation is a traveling machine! This was my first year of ownership. 100% dispatch reliability. Good stuff! My 2 favorite pics from 2021…3 points

-

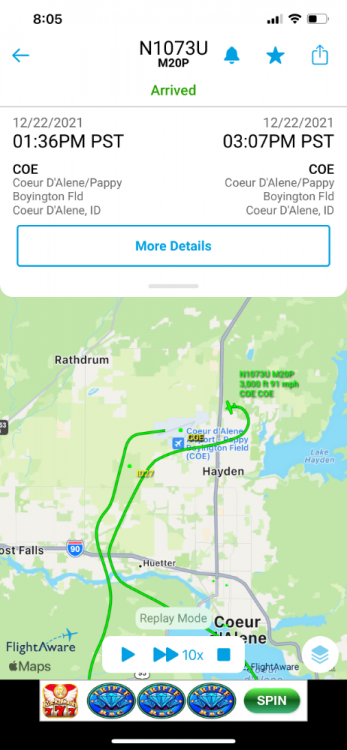

175 hours, and that was with some down time installing the IO390 in my J, which was not as simple as just an engine change. Also had some issues with the electronic mag from lycoming that caused some down time. Otherwise, it was a great year, minus the fact Covid took my best flying pal this December. Pictures are from through the year, and a few from a great trip from Coeur d Alene Idaho to San Antonio, Texas to drop of at aerocomfort.3 points

-

2 points

-

Here is an update, I wedged the parts in where they would go and evaluated whether the vents had enough articulation to hit me in the face - which is where I prefer the air to go when I'm using overhead vents. In the front seats it looks like I could get them to hit me in the chin. The back seats however only the chest. I'm going to consider how to implement N201MKturbo's suggestion and introduce an angle to the part so they can be aimed more effectively. Below is a picture of how they look just setting in place with the current part. Unfortunately I'm just working with the tools a guy in construction would have and not any cnc equipment, so I have to really think through how to make a part that isn't symmetrical. I'm thinking I may screw the mold to another piece of wood so I can cut the bottom in my miter saw, then add more wood to the cut side and reform again with the grinder/flapdisk.2 points

-

2 points

-

If the airplane will spend all of its time in warm weather climates, then there is some argument that a straight weight 100 will better protect against corrosion because it takes longer to drip off engine components. This has been mentioned by Busch and Aviation Consumer, among others - but I don’t believe it’s much more than a gut feeling. I haven’t seen any studies proving this. If you occasionally fly to cooler climates, just fill with multi weight and be done with it. I used to do the straight weight thing, but I was always stressed when seasons changed. I had one particular trip where my destination forecast temps were dropping, and would be way outside operating temperature for Aeroshell W100 with no preheat available. I had to do a middle-of-the-night oil change with quart bottles I bought from the FBO counter. That was the first time I did Phillips XC and I haven’t gone back to straight weight since.2 points

-

That’s my set up! Love it. I don’t know but it’s unexectantly fun starting the engine by pressing a button. yeah - what other people said - it’s easier to forget to flick the switches to off after shut down - very important. And I would add - check again before you ever touch the prop. e2 points

-

I think there’s a similar thread here, but you should contact @Bob Weber, he is very good at troubleshooting these over the phone. His phone number ison MS if you search.2 points

-

Only 60 hours this year in the Mooney, but 500 hours in other aircraft (172/208/PA44/CRJ9 sim)2 points

-

2 points

-

If you didn’t get what you wanted for Christmas…this is a great treat to add to your plane. once you buy it, you will get to use this great tool for every landing. please keep in mind with every marginal and poor landing you have you shorten the useful life of your landing gear components and sealing of the in wing fuel tanks. Even consider that it could help you avoid a gear up event with the “check your gear” call out. you can minimize installation expense if you run the interconnecting cable during your annual when panels are removed. with LHS i grease over 90% of my landings…Ito me this couldn’t be accomplished without it. My testimony is without any compensation…I have no connection to the company I just feel it offers such value for fellow M20 owners2 points

-

It really depends on how much you fly. If you're flying daily, you can run any oil and be just fine. If you're letting the plane sit for long periods of time (say, more than a week between flights on a regular basis) then an anticorrosion additive package is your friend. Camguard is all about preventing corrosion in airplanes that sit.2 points

-

Have you guys looked at one of your own patterns on adsb just to make sure the speeds match up? I’m just saying that sometimes adsb gets sketchy near the ground. I try to fly 100mph dw, 90mph xwind, 80mph final in my F… with winds and adsb issues (especially if the adsb is relying on atc radar), the speeds may look way different.2 points

-

It seems strange that he would be flying too slow. Most people with low time in type tend to fly too fast, not too slow. There has been times when I was flying patterns that I would just leave the gear down. I don't see that much difference at the low speeds. I usually climb to 500 feet or the end of the runway, which ever comes first, with the gear down anyway. If I forget to put the gear up (see post on stupid pilot tricks) I don't notice it until I trim for cruise (Why is my plane so slow? Oh crap, they let me fly planes?). I make fun of myself a bit on here, but those who have never made a mistake, just haven't flown enough. Let's just try to keep it to the non fatal ones.2 points

-

Might want to read this….hint: all mechanic aren’t equal. https://www.aopa.org/news-and-media/all-news/2014/october/22/aircraft-maintenance-major-vs-minor-alterations-part-21 point

-

It looks like it's CallAir B-1. See: http://www.callairmuseum.org/B-1.html1 point

-

1 point

-

When I had a mechanical gyro (DG) driving the heading bug of my STEC 60-2, I had a failure like you described. Turned out to be a failure inside of the DG. You can look at the back of the HSI and see the connector. Maybe you will get lucky and find it came off. Sent from my iPad using Tapatalk Pro1 point

-

I agree and for a dual GI275 (and everything else) we were less than the $44,100.00 USD estimate.1 point

-

For those who don't understand the jargon used in this post (like me): SLD = Supercooled Large Drops I work for the National Organization for the Advancement of Acronyms. I'm fighting a one-person battle to try and change an agency culture that overuses jargon at the expense of understanding by the public that we strive to serve.1 point

-

With very regular use and oil changes, they should go to TBO and beyond. Cam and lifter corrosion (then destruction) is the Achilles heel. Any significant down time can start that time bomb... It got me in my previous overhaul, although I got a bit over 2100 hours SMOH before I lost a cam lobe so it didn't owe me much more. I opted for the centrilube STC mod when I overhauled and hope that helps. I fly regularly as well, and use Camguard. I wish the DLC lifters were available when I overhauled as they likely fix the issue. For a 300 mile trip, I agree a J is a better choice unless you find an under-valued K. As an experienced owner, I would rather buy an appropriately priced Mooney with a higher time engine (ie discounted) and plan to overhaul to my specs on my timeline. Buying a low time engine these days is still a crap-shoot IMO, so I'd rather take care of it myself. YMMV Sent from my LM-V405 using Tapatalk1 point

-

I understand completely about not always filling it up. Glad to hear that the totalizer is spot on. If that's the case then just "add" the amount of fuel that you put in by using that function on the the totalizer. I've used Hoskins, Shadin and JPI totalizers on Mooneys over the last 30 years and found them to be very accurate and useful, but good record keeping is essential. They are not the only tool, but one important tool we have for fuel management. The tank that you refer to - i agree, the totalizer wouldn't account for that. But a much more important point - it should have remained completely empty at the rate it was leaking, since it was not airworthy with fuel in it according to the maintenance manual. Paul in Willmar and Edison in Fort Lauderdale have both mentioned that many times people have to ferry their airplanes to them using one tank for that reason.1 point

-

I had the exact same thing happen to me in flight school, Piper 161, it just was never able to climb and made only 2200rpm on the go. I did a 180 and asked the town if I could land downwind "winds calm" on the parallel runway and they approved. Mags check out before and after the flight. I reported the issues in detail and the school did there do diligence and had it checked out by a A&P. Two days later the plane crash near Orlando with two CFI's building time, both walked away clean.1 point

-

100.9 for me. Barely over my 100 hour goal. Not too shabby for mostly weekend flying due to the real job.1 point

-

Nice work. You will find that an angle would be better. The vents won’t swivel enough to point the air where you want it. I did the same thing, but put the Wemac’s on a piece of sheet metal with fabric glued to it. They don’t swivel far enough. They need to be angled toward the passenger’s head.1 point

-

I have it and like it a lot. Its simple and does the trick. At first I forgot to turn off the mags a couple times, but since I've added it to the checklist, it hasn't been an issue.1 point

-

~40 hours so far, though did take a cool trip across 1/4 the US! Nice shot from El Paso1 point

-

1 point

-

1 point

-

A lot of people report about 1 Qt/6 hours or so. Mine does about 1 Qt/7 hours typically.1 point

-

Yes, this is just part of laser element characteristics. When flying straight & level in an IMC layer that is 'near' freezing, it can hit a target such as cooled water droplets ice crystals and report it back. The procedure for those who fly IMC regularly, is to either ignore it or disable the audio using the "Switched" input on the audio panel and add a note to their landing checklist to enable it.1 point

-

1 point

-

I wouldn't trust them for exact numbers but pretty close. But, we don't know the exact wind at that moment and particularly at that altitude. Could be that winds above tree line were brisk and you can add 5-20 knots to that estimated airspeed. However, it is still pretty apparent that the airplane wasn't flying on the fast side of the spectrum.1 point

-

I had a fair amount of trouble with calibration of the system. Ultimately it took 5 test flights. Alpha Systems was very supportive. They lent me a test set to confirm all the wiring and pneumatic connections were good. That helped greatly as I then knew that getting the vane angle set was the remaining issue. Once the proper vane angle is found the calibration took us (definitely take a second pilot along!) perhaps 30 minutes. I chose to have the system use 4 configurations: Flaps up, gear up Flaps up, gear down Half flaps, gear down Full flaps, gear down That means eight configuration entries (plus 4 more for the optional Vs x 1.1 settings) for calibration.1 point

-

A few days of deployment to go…. Where all of the panels get unfolded/rolled out/expanded into position…. Go JWST! -a-1 point

-

1 point

-

The authority for operation of the airplane is the Owners Manual (POH/AFM starting in 1976) specified in the TCDS. If no procedure is listed for a maneuver required by the ACS then the Airplane Flying Handbook generic procedures could be used. I would not arrive for a commercial practical test without the proper Owners Manual. Skip1 point

-

Jeez, I see why we all get corrosion in the engine… all our planes have been down 6 months at a time for avionics and other maintenance!1 point

-

I flew 80 hrs a bit beloW my average 100h per year. below few pictures of Marseille (2nd biggest city in France after Paris) where i leave in south of France. Controllers of Marseille airport are very cool and let us fly in security along the coast line below 1000ft, Then at 1650ft along protected area of calanques to Cassis and La ciotta Philip1 point

-

1 point

-

OK go ahead and rub it in. Put extra tanks in and go to the main land. Add hrs that way. @120 hrs here but now down for new Dynon panel thru Jan. New Pics? OH wait this is an airplane forum and not the classic car forum but I guess if I have a 56 year old airplane I needed a 35 year old car to match it in the hangar :-) Today's new equipment is so mundane1 point

-

1 point

-

160 hours, was down for three weeks getting a GFC500 installed. Better than the total hours was getting my instrument ticket.1 point

-

1 point

-

1 point

-

It may be a little steep. Just for reference, I have recently installed a GNC 355. It was $8640.88 including labor. I am currently in line to have a GFC500 as well as a G5 attitude indicator to drive the autopilot. I have been quoted $3638.46 for the G5 which includes labor and $12010.34 for the GFC 500 (3 axis including trim) that does not include labor, I don't believe. So for something comparable to what you are doing I have spent so far around $24,000 and change. That does not include labor for the autopilot but I seriously don't think it would be $20,000 in labor to install the autopilot (at least I hope not). So maybe this helps you with a reference.... This is all US dollars.1 point

-

I am a Chemical Engineer with an advanced degree having worked 32 years for Dow Chemical which was the largest manufacturer of chlorinated organic chemicals in the world. I know from real life experiences how incompatible these materials are with aluminum. I have to speak up when somebody acting as an expert “corrects”me and makes a bad recommendation that will likely cause harm. Methylene chloride will get into the cracks and joints and over time decompose to minute amounts of hydrochloric acid which will damage the passive protective oxide layer on the aluminum causing exfolation of the aluminum in the crack or joint. Raymond J eluded to caution when talking about cleaning preparation for tank lining above. I have also felt that some people painting aircraft have not been aware of the hazard here and have used chlorinated solvents to strip the paint aircraft. This type of corrosion will not show up immediately but years later the results can be exfolation damage showing up in the cracks and crevises especially in the overlapping joints and rivets. Yes these solvents are volitale but they can become trapped or mixed with grease, dirt or other materials so don’t just assume the evaporate cleanly like they might in a laboratory beaker. Do we really understand all the causes of corrosion on our airplanes that we are scraping everyday? This is just one.1 point

-

But thanks to you sharing the info and the power of MooneySpace one of our comrades might end up finding it on the first attempt. Thank you!1 point