Leaderboard

Popular Content

Showing content with the highest reputation on 03/23/2020 in all areas

-

I have lived through some hard times in aviation sales in my 25 years in the business and while I don't necessarily want to face another one, I know that I probably will before I retire. This one may be a little different. After 9/11, the market came roaring back. I am expecting this one may be similar. The recession of 2008 was rough but we still sold planes, albeit at reduced prices. I don't see prices falling too much for at least a year on this one, and that is IF we fall into a recession as a result. The one thing we have with this blip is the whole 'social distancing' thing and how it relates to airline travel. I wonder if there might be a little bump in GA to fill the travel needs of those who have the means and the ability to purchase an aircraft.8 points

-

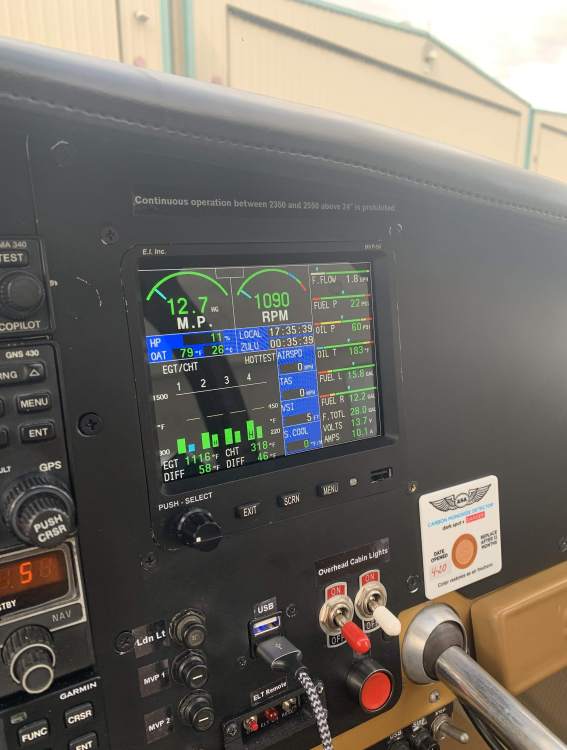

I have few hundred hours in this Mooney already so insurance wise I’m good. As far as CO2 monitor I still have and use the Foreflight’s Sentry with crazy loud audible alarm and works very well, plan on continuing to use just for that. More pics to come soon, Did about 6-7 touch n go’s and 3 high speed taxi’s done, on last taxi I got a bit too excited and ended up taking off. Just stayed in pattern in case something went wrong. Very pleased!4 points

-

As long as they are avoiding crowds and staying 6' from people they meet, all is good. Right?3 points

-

3 points

-

Whoever does your install, make sure that they use the expensive Aspen shielded ethernet cable between the EA-100 and the Aspen PFD. Some shops have cut corners on these and some of the non-shielded cables have worked, but some have not. Now with the MAX upgrade some of the non-shielded cables are kicking the Autopilot off-line. Better to do it right the first time.3 points

-

But the medical manufacturing that I am in is apparently not on the critical infrastructure list. While our products from this plant have no connection to fighting the current [or any] infection, the product that we make is keeping patients alive and out of the ER, saving space for virus sufferers. So we have decided ourselves that we are "critical."3 points

-

If you can do this without requiring anyone else to be working... then go for it.3 points

-

At annual last year, my new IA adjusted the nose wheel doors, leaving a God-awful thump with shaking of the yoke and a severe twitch in the pedals. And he was proud of the work he did. He is not doing my annual right now . . . . A quick trip to Cole Aviation and now my gear opens and closes the smoothest it has ever done in my almost 14 years of ownership. I used to like the comforting thump as they locked in the Up position, and the lesser thump as they locked into Down, but.now there is virtually no feeling at all, just the sound of the electric motor starting and stopping.3 points

-

While not a Mooney, I can atest to Adams. i did their paint correction in 2017, this is over 2 years later and all I do is a Gary Dean wash and Adams detail spray. This also includes 6 track days: I’ve done no paint correction since I did the original acrylic paint sealant. Adams have great products... yes that is a swirl free surface on a 2011 Camaro - factory paint too in most areas! if your curious as to how it looks overall: https://www.camaro5.com/forums/showpost.php?p=10611579&postcount=2590 -Don3 points

-

UPDATE: Today we removed the forward belly panels from LHS and RHS. Here's what we discovered: The piano hinges on both sides were fastened with an assortment of mostly #4 screws on both sides, of various lengths, all but one with a pointy end, and only three used Tinnerman nuts. My co-pilot found six Tnuts unassociated with screws on the left side in the miscellaneous agglomeration of quasi-gritty and used ta be sticky substance formerly known as lubricant as she cleaned the area. Oddly, the Tnuts on the LHS had loosened. This indicates that either the wrong type of screws were used or the Tnuts lost their grip somehow. Plan of action: order new type-B screws with Tnuts and replace them all on LHS and RSH during next weekend's social-distancing at the airport. Regular preflight now to include jiggling the nose gear doors to make sure they haven't worked loose. Thanks to everyone for the guidance. -Fred3 points

-

Since you've got the winch, the airplane, and the slope, I'd give it a test. But I'd put a scale between the winch hook and the plane. That way you can see how much force it takes to move the plane back into the hangar. You might be surprised how little the force is and be comfortable with it. Or it might be more than expected. Let us know how it goes.3 points

-

The invoice is in, waiting payment. I have taken care of Eric for his time and expenses of course in the interim. Mooney has approved it as far as I know. you tend to miss a lot as a troll, dear friend. The Mooney specific trainer employed by Mooney Pros, Inc., Eric R, happens to also own one of the most respected Mooney Service centers and is very tuned into proper maintenance of not only the aircraft but as a vetted Mooney CFI, knows how to train.2 points

-

The Aspen cable is double shielded. There is shielding around each of the twisted pairs AND shielding around the whole cable just inside the external insulation. Most shielded Cat5 or Cat6 cable I've seen is only shielded around all twisted pairs, not individual twisted pairs.2 points

-

1450 on an engine that has a TBO of 2000 is higher time but i wouldnt exactly call it really high. Also this is an engine that regularly gets taken to 3000 to 3500 since they are bulletproof. As for avionics, they add up really quick. To install an stec 60 today in an m20c cost around 30 grand. The new avionics rack on the side set him back at least 16 to 18k. I rarely see HSI's on older mooneys. Id go call a couple of shops and see what itll cost you to get a panel set up exactly to your needs that includes AP, GPS, Audiopanel, ADSB, new coms and an engine monitor. I will be surprised if you can get a number under 40k.2 points

-

I can assure you the hose and nozzle hasn't touched the wing as long as I've owned the plane. But the right wing was opened up for a full strip and reseal, which ended up including a repair of the spar cap as well. Through all that process, the paint on the wing was the least of my concerns. It's the original 30+ year paint on those wings, so I'm sure they've seen plenty of abuse over the years. Someday, she'll get new paint, but until then...2 points

-

2 points

-

Flight Chops, Matt Guthmiller, Kermit Weeks, Lewdix Aviation, MzeroA, P1D, Aviation 101, Angle of Attack, Baron Pilot, Mikey McBryan (From Ice Pilots; Has a great series on restoring a D-Day DC-3 just in time for the anniversary), Just Plane Silly, Martin Pauly, Steveo1Kinevo, The Flying Reporter (UK pilot). If you want a good weather channel to watch try Meteorology Lab/Tim Vasquez (breaks down the weather every day around the country with special emphasis in Texas since he is from here). I don't always watch all of these. But these are one's I have watched and am currently subscribed to. If they do something that catches my interest I will watch them.2 points

-

We’re all concerned about a possible collapse of the economy, many of us are 70+ and have never seen anything of this magnitude, hopefully it won’t become a depression, praying for all those whose livelihood has been impaired, be well and safe everyone2 points

-

In the old days... avionics could be expected to wear out over time. Bearings, gyros, bellows, etc, all moving parts that wear out. Solid state electronics are not quite the same. They can certainly fail, but they don't "wear". An electronic part either works or it doesn't. And it's just as likely to break on the first day as on the 10,000th day. So for me it's all about the cost savings. Which for my panel, have been considerable.2 points

-

Replacing these should be elementary as indicated above. I would be more concerned about where the loss occurred. If they failed when removed or reinstalled, and not "lost", replacement should be routine. It's when they're lost and floating around the belly of an aircraft among components that don't react well with things like this.. These are one of the most common things I found while cleaning bellies, I was a stickler for "debris free under the floor" and often presented the client with a bag of such that "people behind me" had missed during their work. The older and more sloppy maintained aircraft can get pretty scary when dug real deep into. Fly Safe Bob Weber webairconsulting.com2 points

-

Great looking panel,,,,,, I'm jealous. However, I've been following this thread and you have given me the inspiration that I need. Thanks.2 points

-

Just finished reading the wonderful book "Understanding Air France 447" by Bill Palmer. It not only supported what I previously knew, I also learned a couple more things about Airbus control laws (one in particular that is poor - only IMHO. Really good book and highly recommended … especially for our Mooney pilots that happen to have real jobs flying airplanes, too. Note 1) Oh, I do take a slight exception to my profession being called "eggheads" as I typically don't refer to pilots as "trained monkeys'" or "the nut holding the wheel/stick/yoke" … at least in a public, permanently stored record. Yes, I am a pilot, too. Note 2) The book refers several times to the airplane as being "deeply stalled". I've never heard of an airplane being "shallowly stalled" or "lightly stalled". If the author is trying to say the airplane was in a "deep stall", there is a definition for that, and AF447 was never in a deep stall (it was always recoverable (with enough altitude). With an AOA of 45-60 degrees, the wing was definitely fully stalled. @GeeBee or anyone else that would like to add to my knowledge/experience base (I'll never stop listening or learning), my email is fly-in-home@att.net or solutions@blueontop.com (which just goes to fly-in-home@att.net Thanks, Ron2 points

-

My cell is 210-872-1110. Best way to contact me is email. jimmy@allamericanaircraft.com or jimmy@gmaxamericanaircraft.com2 points

-

2 points

-

Good design practice would dictate that a backup system should not share critical components with the system it is backing up. Mooney violates this in that the mechanical system is identical for the electric and emergency extension means. So, the failure modes protected against are electrical only. Cessna singles have a similar issue in that the normal and emergency systems both require hydraulic fluid so a leak will make neither available. I always marveled at the utility and simplicity of the Piper Cherokees. For the gear, there are no up-locks — hydraulic pressure holds the gear up. Pretty much any failure results in the gear extending. There are a lot of other things about the Cherokee design that are well thought out. If they were just faster... Skip2 points

-

2 points

-

This entire project is going to take me around 60 hours. -Buy enough products to do 4 SUVs. I’ve run out a couple of times. -Get the good polish rags and wash them nightly, they need to be clean. -Have lots of light. -Wear eye protection and face protection especially when working under the aircraft. So far the best system I’ve come up with is clean the area you think you can do that day, then work the clay bar, cut and polish in sections. If your going to do the ceramic coating, apply that after you have a large section of the plane polished, if you can wait until the entire airplane is polished the do the coating. We’ve been flying 2AD, so I’ve tried to get the areas that get the dirtiest, ie gear doors and belly ceramic coated first. Once coated, those areas clean up MUCH easier. Just except the fact that you’ll end up do a section twice.2 points

-

I had what M20Doc described as all different sizes of sheet metal screws installed in the nose gear door hinges. From sheet metal screw sizes ranging from 6 to 10 I elected to go the machine screw route with nut plates. Yes it was a pain to do all of the positions in nut plates (with countersunk rivets) but I now have number 8 machine screws in all positions and as you know the nut plates are self locking so they are now very secure. Prior I was finding loose sheet metal screws almost every post flight. And yes I found no Tinnerman nuts on the back side of my sheet metal screws holding the nose gear door hinges to airframe. A&P, IA, DAR2 points

-

Sometimes the weather makes the decision of whether and when to fly easy, as the attached shows. I was at Daytona the front was moving slowly, and the mission was just an IFR practice flight. I punted to live and fly another day. Sent from my iPhone using Tapatalk2 points

-

Fixed it. I'll refrain from posting pictures of my panel, but suffice it to say, all of it was either used or trade-in or clearance sales. I bought my Aspen and EA100 used from different sources on Barnstormers. No need to send them back to Aspen. It took me about a year to amass all the parts and pieces for my panel. But I took my time and made sure I had all the parts before the installation started on anything. The total cost of my panel upgrade was about 40% of what it would have cost to just pull it into the avionics shop and purchase the same.2 points

-

1 point

-

You’ll encounter less people on your flight than the thousands that are going for hikes or walks these days. Shocking how many neighbors are out and about! -Matt1 point

-

That's not how it works for engine cylinders. You want things (cylinder/Piston/case) to heat up and cool down at the same rate, also the cross hatching is important to the design. The bigger things are, the more it matters. Not an gineer, but have heated things with a torch.1 point

-

The federal government has a list of critical infrastructure areas. CISA List Aviation including repair, operations, fuel and flight schools are specifically listed. Obviously you should practice all due care with social distancing and sanitation. But solo flight and even flight training appear to be permitted.1 point

-

1 point

-

1 point

-

Great pirep for Mr. Weber! Thanks for posting the details. Best regards, -a-1 point

-

I don’t think that’s true so I am a little lost. In a 68C (I have a 67) the buzzer is behind the panel and tied directly to the light through relays tied to power, controlled by the switch. you would either have to send power through the Dynon module which they don’t want you to do, come up with a different way to feed the buzzer, or come up with a different way to feed the indicator. my design keeps the existing press to test and horn as well. a new panel laser cut and powder coated is around 250 from lasar. I’m happy to share my file once it’s finalized.1 point

-

Great work, @Denver98. Looks like a huge improvement since I saw this plane at 84R. (Still have never actually met Paul in person!)1 point

-

1 point

-

I’ve NEVER PAID someone to change a tire for me. Guess this dumb Yooper has a few skills of value. Tom1 point

-

Like most iPhone apps, it's just super easy to use. I've seen the site you mention, and yes, I think you can mostly get the same information from there. But the app just makes it easy to enter an origin and destination, a departure time and arrival time, and in a few seconds you'll have a series of graphs spaced along your route at appropriate time intervals. It's easy to use on the phone and I can even take a quick look while sitting in the cockpit just before take off, to get one last quick look. The website just gave too much information and too many options. There is a cost for it, I don't remember what it was. But it's a one time thing and compared to what we spend on this activity, it's nothing.1 point

-

Nice all, it’s amazing the breadth of knowledge on this board. Impressive diagnostic @Bob Weber from such a distance! Thank you all. My installer found the problem, it was a diode that had gone bad that was related to my TXi install. Works like it should now. Thank again everyone for the tips!1 point

-

1 point

-

In reality, Tinnerman nuts should be used with TYPE B screws NOT standard sheet metal screws, It has to do with the pitch diameter of the screws. Here's what they look like- https://www.aircraftspruce.com/catalog/hapages/trusstypeb.php While sheet metal screws (the sharp pointy ones) can be made to work, they really aren't the correct screws Also in observing your picture it looks like there is worn out metal above the missing screw hole. You might need some sheet metal work in that area. Something to think about for the next annual might be to inspect, clean and repaint the nose gear push/pull rods. They look a little the worse for wear in the picture. If you remove them you will have to reset the entire gear over center torque NOT just the nose gear setting.1 point

-

1 point

-

Kramali, you have so much Mooney experience... (amongst a whole bunch of other birds) Are you sure you will be happy with an ordinary (work with me here for a second) M20K? Since the M20K has developed over decades... it went from a 231 to a 252 then Encore...and spawned things like the 262 and Rocket... Might you want to search the whole list of Ks before starting at the beginning? Economically, it may make sense to buy one fully updated than to start on the first step and climb each rung... over time... I’d love to buy a new plane from the factory... just for the experience! PP thoughts only, not a plane sales guy yet... Best regards, -a-1 point

-

It’s pretty hard to argue the safety of a parachute.That is indisputable. Not that anyone asked, but here is my two cents.... My dad is an attorney and dove a mercury marquis for 30 years. Most of his clients were farmers and he drove in the fields for years, and never got his car stuck. One day he told me he was going to buy a pickup truck, and I suggested four wheel drive. He told me he didn’t need four wheel drive, because he had been driving a two wheel drive for all those years without a problem. I said, but in a truck, you will make different decisions. He didn’t agree and bought a two wheel drive. He has been stuck six times in three years. A parachute cannot possibly be a bad thing to have as an option... Unless, it causes you to make decisions you would otherwise not make.1 point

-

Post any plane at any price, and we'll pick your deal apart. That's a mooneyspace guarantee.1 point

-

1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)