Leaderboard

Popular Content

Showing content with the highest reputation on 01/12/2022 in all areas

-

I think discussing who is to blame (if me or the shop) at this point has been already covered. I'm using AOPA services to guide me in possible solutions/compensations, but my main concern is getting the aircraft fixed and ready to fly again. Just as more context info, I requested the shop to do a prebuy and following that a annual inspection. The point was to due all the "inspection" part of the annual as part of the prebuy, and complete whatever was remaining (for instance wheel bearing service due or service the spark plugs) after the purchase. In the annual inspection report they stated: "Finish Annual inspection after Pre-Purchase." And also, at least verbally, they confirmed that during prebuy they opened or the inspection panels. Anyway, it could be as @JWJR mentioned, maybe the annual was done by a different mechanich, and that's why it came up. Also, I agree with @LANCECASPER that I have to value that they were honest in declaring the corrosion and also in saying that they are not able to repair it. So, at the end, they are not gaining anything with this. Also, they are helping me get the quotes from Don Maxwell and dugosh.com. Ando also they offered to help with the ferry permit. I'm not mad at them, nor I want to take advantage of the situation. I just want to try to come to an agreement that is fair. In my view, it is not fair for me to absorb all the cost of this. Anyway, if at the end there is no agreement and no legal way of getting a compensation of this, I will just move the page forward, enjoy the new aircraft, be 15k poorer but feeling confident with a safe airplane.8 points

-

I got a bunch of emails from my students about this accident. It was largely driven by Dan Gryder's video. He has no doubt icing caused this accident. I don't know this guy and he evidently has a huge following. But, this guy doesn’t know what he’s talking about…please don’t follow him. He plays the ATIS at the time of departure which says the temperature is +7°C and then he says immediately after that, “…taking off into freezing drizzle.” Huh? First, you can’t have freezing drizzle at the surface with that warm of a temperature and second, there’s nothing in that ATIS that says anything about freezing drizzle or even precipitation. He then goes onto say that it gets colder as you go up. Yes, eventually it does get colder, but not at the altitudes the pilot was flying…it was actually getting warmer. Evidently this guy has never heard about temperature inversions. Ugh! That’s why so many pilots get really screwed up when it comes to making weather decisions since they listen to guys like this. This video has gotten almost 50,000 views already…just insane. If you want an accurate analysis, please visit my blog and read this post.6 points

-

5 points

-

Funny how your explanation prompted a memory. My older child was about 7 when she came home from school with a note from the teacher saying she wasn’t paying attention in class. She had a regular pediatrician scheduled for that week and I mentioned her attention issue. He looked in her ears and said her attention issue was caused by the fact she couldn’t hear. Before sending her off to an ENT, he asked if I could try flushing her ears with one of those pharmacy kits. Every night for the next several days I rinsed out her ears. On the 4th night out came these huge plugs of wax - from both ears. She looked at me and said “Daddy, I can hear!” Now if I can only find a kit for Tinnitus! Sent from my iPhone using Tapatalk Pro4 points

-

I’m working with a friend on a 310. He bought some used engines. He asked me to do a compression check on one. One of the cylinders only made 10 Lbs. I told him he should pull the cylinder and fix it. He didn’t want to do that, so I said “put the cylinder TDC on the compression Stroke, fill it full of oil, gently pull the prop to force the oil through the rings.” He did it with MMO. We ran it the next day and did another compression check and it was at 65 Lbs. The oil must have loosened the rings that were probably rusted in place. The engine runs fine BTW.4 points

-

As of today pilot out of surgery in normal room and eating a little apple sauce. Recovery looks good right now.4 points

-

It was released and includes: Changes made from version 7.30 to 8.00: Added support for Smart Glide Added ability to simultaneously arm flight director VNAV along with GP or GS mode Added additional data to SD card flight data logging Added notification of missing/undetected battery Added menu option to diagnostic page to access AFCS diagnostic log Added support for LP+V CDI scale Improved AFCS operation with blocked pitot tube Adjusted appearance of dual cue flight director General improvements to system operation Includes GMC 507 software version 3.10 Includes GSA 28 software version 4.90/2.20 Includes GMU 11 software version 2.10 Includes GAD 13 software version 2.10 Includes GAD 29B software version 3.40 Includes GAD 29D software version 2.103 points

-

I tend to agree with most of what Mike Busch says, only pull a cylinder if it’s really warranted. Some places when they see 59 psi they pull it, sometimes even when it’s higher. Even on continental engines, where they clearly have a service letter that says it could be as low as about 42 psi and still be passing. on my own personal engine it was 52 psi and hissing out of the exhaust. We’re scoping it showed a heat stress valve. I was tempted to lap it in place and I probably could’ve done that, but I had a feeling the valve guide was shot which is why the valve burned… that turned out to be true so a new valve guide and valve got it fixed. But I only pulled it because it was necessary3 points

-

You aren't going to like this . . . but here goes: It's already been mentioned multiple times by those that work on Mooneys every day that a pre-buy is very unlikely to catch this unless unless by chance you would have known to have specifically asked them to look for it, which few people would have. I wouldn't have before this post on a Mooney this recent. All of us on this forum are learning at your expense. Going forward if someone wants to pay the hours required for this to be part of their pre-buy inspection at least it's out there for everyone to consider. Here's the part you aren't going to like: In thinking about this over the last few days, the easiest thing in the world for that shop to have done would have been to ignore what they found if they felt that they should have caught it during the pre-buy. They didn't feel that they should have caught it but they still did have the integrity to tell you about it. Their life would have been easier for the next week or two if they hadn't told you. That wouldn't have been ethical but I'm sure it's been done at one point somewhere. It's not like they were trying to get the job for the repair. They don't even feel comfortable doing it. Knowledge is power. Knowing sooner is better. Yeah it would have been better to have known before closing, for sure. But at some point if it goes too long, it may have totaled the airplane. Would the next annual have caught it? Hard to say. Would any annual in the next five have caught it? Did any of the last five annuals catch it? So i would definitely give the shop some credit for informing you on what they found during the longer, more thorough annual inspection. Rather than having anger, regret, remorse at this point I would work on channeling that toward at least some gratitude that they told you about it and just concentrate on moving toward a solution. Try to work out something fair for both of you. Also not sure why you would need a ferry permit since it's still in annual until the end of February.3 points

-

You just need a Xi navigator with the upgraded software, and a flight display (G3X, G5, G275, G500/600 ect) with the correct software updates. The updates mentioned above added G5s and G3Xs to the list of approved flight displays. The panel mounted button is an option but not required. Without it you can activate smart glide by holding the Direct to button for 2 seconds or the emergency touch button in the menu.2 points

-

Ah, I see. You are using the standard lapse rate instead of using the actual temps aloft (or forecast temps aloft). Not sure I understand why you'd do that. But what happens if the environmental lapse rate is greater than the standard? Then you've calculated the freezing level to be much higher than it actually is. No thanks. But, you do you. I'd rather use the actual/forecast temps aloft and make a much more informed decision. In this accident, the actual lapse rate was not 2°C/1000 feet, it was negative as I describe in this post. That put the freezing level above 9,000 feet MSL (likely near 11,000 feet). I teach all of my students, never, ever use the standard lapse rate for any meteorological decisions. The only time it's acceptable to use is to calculate the departure from standard for those POH/AFM performance tables.2 points

-

Hi Greg, There seems to have been a lot of people (based on the comments he received) that didn't go as far as you did with this...that is, believe there could be a temperature inversion. Just quite a shame that so many of his followers are being misled. No, I don't have any good sites to use that provides a truly historical model-based Skew-T. NASA did have one, but it seemed to stop working many years ago. At some point I will likely provide one on my site, but that's several years off (hopefully before I retire in about 7 years).2 points

-

2 points

-

Title says it all. I would like to think I was so smooth on the controls she could sleep like a baby… Sent from my iPhone using Tapatalk2 points

-

Circling back around on this at colder temps. OAT does obviously affect output, but not as much as I thought (may be of interest to @Ragsf15e). At OATs in the single digits, output was still very robust. All of the settings felt quite hot and were more than adequate to keep me comfortable while wearing a T-shirt and lightweight fleece. OAT 7°F 25LOP Max heater output 172.7° 100ROP Max heater output 157.2° Peak Max heater output 174°. My little 200hp bird really tries to overachieve in these chilly temps despite a governor that’s holding 50rpm shy of redline.2 points

-

So blame the customer instead of the prebuy shop. Who conveniently found the corrosion a couple days after the plane changed hands. They couldn’t possibly find it until they did. MSC pedigree. Ok…2 points

-

\G3X Version 9.0 is also released including Smart Glide. Changes made from version 8.64 to 9.00: Add support for Smart Glide Add Emergency page and optional EMERG button in data bar Add ability to simultaneously arm flight director VNAV along with GP or GS mode Add support for FIS-B Center Weather Advisories and Graphical AIRMET Add display of GTN Xi series navigator VNAV TOD/BOD positions on map Add fuel flow/quantity labels to EFIS/Airdata ARINC 429 output format Add support for GTX 3x5D diversity transponders Add ability to schedule fuel tank reminder based on fuel quantity used Add support for displaying fuel quantity and flow values in units of lbs or kg Add ability to enable/disable fuel calculator automatic reset of fuel-used quantity in normal mode Add ability to record engine cycles Add ability to touch PFD AOA field to temporarily mute audio alert Add support for LP+V CDI scale Add display of density altitude on PFD when on the ground Add CAS message to indicate ADS-B transmit inhibited by pilot Add CAS messages to indicate ESP inhibited Add menu option to autopilot config page to access AFCS diagnostic log Add additional data field options Improve map display of TFR, NOTAM, and obstacle data Improve AFCS operation with blocked pitot tube Improve heading display when true direction is selected Improve altitude display when adjusting baro setting or below sea level Improve synthetic vision Pathways display Improve data log file processing Improve audio alerting Improve COM radio data processing Improve transponder interface Improve functionality of GSU 25 backup RS-232 connection Improve ARINC 429 label output Improve GNX 375 GPS data processing Improve Connext data processing Change ESP to inhibit protection when a miscompare is detected Adjust appearance of dual cue flight director Correct display of winds aloft magnitude for FIS-B sources General improvements to system operation Includes update to G5 software version 8.00 Includes update to GAD13 software version 2.10 Includes update to GAD27 software version 2.70 Includes update to GAD29 software version 3.40 Includes update to GAD29C/D software version 2.10 Includes update to GAD29C/D boot block software version 2.00 Includes update to GDL5x software version 2.15 Includes update to GEA24 software version 3.90 Includes update to GMA245 software version 2.80 Includes update to GMC507 software version 3.10 Includes update to GMU11 software version 2.10 Includes update to GPS20A GPS software version 2.10 Includes updates to GSA28 software version 4.90/2.20 Includes update to GSU25/B software version 4.30 Includes update to GSU25C/D software version 2.70 Includes update to GSU73 software version 3.80 Includes update to GSU73 IGRF database version 1.04 (Base Year 2020) Includes update to timezone database version 28.00 Includes G5 boot block software version 2.20 Includes GAD13 boot block software version 2.00 Includes GAD27 boot block software version 2.30 Includes GAD29 boot block software version 3.10 Includes GDL39 software version 4.91 Includes GEA24 boot block software version 2.20 Includes GI260 software version 2.80 Includes GI260 boot block software version 2.20 Includes GMA245 audio software version 2.20 Includes GMA245 Bluetooth software version 2.00 Includes GMA245 boot block software version 2.30 Includes GMC507 boot block software version 2.30 Includes GMU11 boot block software version 2.00 Includes GPS20A software version 2.40 Includes GPS20A boot block software version 2.10 Includes GSA28 boot block software version 2.20/2.10 Includes GSU25/B boot block software version 2.20 Includes GSU25C/D boot block software version 2.00 Includes GTR20/200 software version 3.30 Includes GTR20/200 boot block software version 2.30 22010A_ASDN.pdf2 points

-

You should ask old Dan about his own crash. Bet you he would say it was caused by a microburst. Sent from my iPhone using Tapatalk Pro2 points

-

If she's still taking psychostimulant medication and/or plans to continue, that's pretty much an automatic disqualifying medication for any class medical. I think I recall seeing that in the FAA guidance for AME's somewhere. The diagnosis of ADHD should not by itself automatically be disqualifying (unless the condition is actually impairing enough to prevent flying), so If she stops it or plans to stop medication in the future, I don't think that would technically result in her requiring special issuances forever. Those are reserved for people with "psychosis, bipolar disorder, repeated acts of self-harm or severe personality disorders" IIRC. On the other hand, I could totally see an AME interpreting it that way, but hopefully not all of them. And, of course, the disclaimer is I'm not an AME, but I know we have couple here somewhere?2 points

-

Here is a flush mount horizontal picture. Sent from my iPhone using Tapatalk Pro2 points

-

The pilot is an acquaintance of mine and belongs to the same flying group I do in LA. He has facial injuries requiring surgery yesterday but recovery should go well No info on what caused the crash I know the area well as I have flown out of there for over 50 years. Interesting airport history especially back half a century ago. He and the police officers are very lucky Quick decisions by the officers saved his life.2 points

-

I talked to @Hans in Denver yesterday. Meet the nicest folks on MS.2 points

-

SWTA is not in San Marcos, they moved to Smithville a few years back. But yes the people I had look at the brakes were just asked to bleed the brakes since they were soft. There definitely was air in the system, so that was one issue. My fault for being too specific - I should have said look over the brakes. Brian Kendrick (who is usually in San Marcos) stopped by and looked at it last Friday and within a minute he caught the backwards pad. I had asked him to look at it from day one but he finally had a day open up.2 points

-

Similar thing, low voltage, happened to me leaving KORL. The TWR asked if I wanted to declare and I told them yes without even thinking about it. I was at pattern altitude when it happened. I turned cross wind flew the pattern and landed without incident to a parade of fire trucks. Some minor paperwork, one ring lug and an hour later I was on my way. One note though, I did get a little distracted on final still trying to diagnose the problem instead of focusing on flying the plane and the landing.2 points

-

2 points

-

I think we worry too much about this sort of stuff. I fly, land, taxi to the pump, shut down, fill up, start up, taxi to the hangar, shut down and put the airplane away. I see absolutely no harm in that except for highly theoretical conjecture unsupported by any actual data. Skip2 points

-

1 point

-

If you have o GTN Xi, the software is free. The avionics shop may charge their time for installation. Skip1 point

-

Somewhere over the years someone installed a circuit breaker type switch as an avionics master in my 64D. I would have to dig back through the log books or stick my head up under the panel to see what the amperage is but it is one of these. https://www.aircraftspruce.com/catalog/elpages/pbcircuitbrkr2.php Note that they do not have FAA approval but were OEM in certain planes, not sure that the Mooney is one of them, a conversation to have with your AP/IA.1 point

-

Mike Busch And Savvy Aviation recommend the ring flush because it does absolutely no harm to the engine. Pulling a cylinder is an invasive procedure that is not recommended by Mike Busch and Savvy unless absolutely necessary because of the possibility of a MIF (Maintenance Induced Failure). I find it interesting that even though most people here respect Savvy Aviation and Mike Busch, there are so many who are so willing to shoot down their recommendation to do a ring flush as a first step, before resorting to the more error-prone cylinder removal. And 2 years after doing this procedure, my #4 cylinder keeps chugging along happily with a clean bottom spark plug, so it definitely worked for me.1 point

-

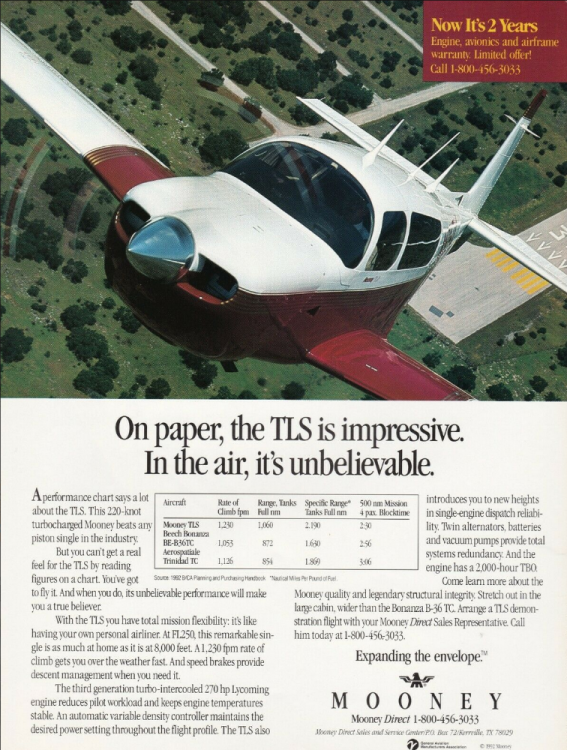

I wish I could, Fred. I googled Mooney advertisements and found that and remembered seeing it in Flying magazine or something. That picture was the highest resolution I could get off the interwebs.1 point

-

Thanks!! Happy to be meeting such a helpful group! The response has been fabulous.1 point

-

1 point

-

Some people have more time than money, and enjoy the challenge of keeping old stuff working. After resealing the boots and changing hoses, my Brittain with Alt hold and Pitch control now works fine for flying VFR1 point

-

I think one of the biggest myths is that there is a Mooney model, or any plane for that matter, that is better than a Bravo. Just saying.1 point

-

1 point

-

Sounds like it was a crash on takeoff from Whiteman Airport in LA. There are some YT videos of with the ATC recordings. FWIW my experience was LAPD in the ER (at least 20 years ago) was that they were highly professional, diligent, and conscientious of avoiding the perception of abuse or discrimination. I was always impressed with my interactions with them, especially now that I have some perspective working with PD's outside of LA.1 point

-

I'm tracking. The Bravo is a great plane and I sold mine because I needed more UL and Mooney keeps dragging their feet on a GW STC for the long bodies. The turbo is great for Rockies and high DA flying, but the XC speed difference in a Bravo in the low FLs and an Ovation at 10k isn't that much. Take all my comments with a grain of salt. I quit Mooney and now fly a Lancair ES with the IO-550N. I did my yearly trip TX-CO last week and flew it between 8,500-11,500 and it does 177 TAS LOP burning 12.5 gph. It did that trip within 10 min of my Bravo and burned 50 gal vs the Bravo's 72 gal. To be fair, for high alt and mountain flying, I'd still prefer a turbo. But since I do that 1-2 per year, the NA IO-550N is a beast and I can do without the turbo. I can see why the Ovation dudes do the N conversion. Sent from my Pixel 4a using Tapatalk1 point

-

It all depends. If you have definite indication of generation failure such as field breaker pops you might be ok depending on flight conditions. An electrical failure with no other indications is usually a predicate to electrical fire and smoke. The fact that you have an electrical system means there is an additional source of ignition on the airplane. How it fails is determinate on if it is an emergency or not. A fault on the hot bus for instance can be very serious and often gives few indications.1 point

-

If you look at the electrical drawing for your serial number, you will see it shows a 5A fuse near the battery master. And it looks like two additional circuits branch off after the clock, one to FF memory, the other to overhead cabin lights. Are those working? Then your clock has failed. Aerodon1 point

-

Paul's airplane is at KBJC, and he's not (yet) an instructor. I'd like to help, but I'm not really the right guy for this. I've got about 30 hours' dual given in the right seat of K models, but only giving instrument instruction, flight reviews, etc. to pilots who have already received transition training and have plenty of turbo Mooney time. My airplane is NA, and as much as I understand the principles of turbo engine management, I wouldn't trust transition training to any instructor who doesn't have significant left-seat turbo time.1 point

-

See if Paul answers. He keeps his K at Centennial, I believe. He hasn't been here much lately, but is on F-book. @gsxrpilot1 point

-

When I told an old DPE friend that I'd bought a Mooney she said, "You have to do a little snake dance to get down into one, but they're pretty good airplanes."1 point

-

Biggest Mooney myth.......being sucked out of a Mooney when the door pops open in flight !!1 point

-

In a manner of speaking it’s not a Myth. Many years ago my Father sold his C-210 and bought a Mooney, compared to a C-210 a Mooney is small, and difficult to get into, Cessna has a big door, front seaters get in, position their seats and the back seaters get directly in climbing over nothing. It’s a whole lot harder to get into and out of a Mooney, it’s a little like my Miata, plenty of room once your in, but getting in and out is more difficult. Personally I find the nose gear well restrictive, if it were a tailwheel it would have so much more room, be faster too1 point

-

How about the huge myth that Mooney owners are C.B.s? Oh, wait....1 point

-

Steve, The double puck Brakes, which is in a separate Mooney drawing, is the reason for requiring the new gear doors. The drawing is not available on the internet. But it also calls for the new trusses because the double puck brakes require a larger brake torque plate that attaches to the gear trusses. You’re right though, the SB makes no reference to the brake system drawing that adds the double puck brakes that became standard with the newer Bravo’s and all long bodies and M20K Encore’s going forward. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Here is an update, I wedged the parts in where they would go and evaluated whether the vents had enough articulation to hit me in the face - which is where I prefer the air to go when I'm using overhead vents. In the front seats it looks like I could get them to hit me in the chin. The back seats however only the chest. I'm going to consider how to implement N201MKturbo's suggestion and introduce an angle to the part so they can be aimed more effectively. Below is a picture of how they look just setting in place with the current part. Unfortunately I'm just working with the tools a guy in construction would have and not any cnc equipment, so I have to really think through how to make a part that isn't symmetrical. I'm thinking I may screw the mold to another piece of wood so I can cut the bottom in my miter saw, then add more wood to the cut side and reform again with the grinder/flapdisk.1 point