Leaderboard

Popular Content

Showing content with the highest reputation on 05/23/2020 in all areas

-

After at least a year of looking around, and at least a couple years of browsing around these forums, I am excited and proud to put a N# in my MS profile Closed the deal today but won't be flying it for a few weeks while it gets cleaned and fixed up at Chandler Aviation. Began my search with 231s and ended up with 252. The serial # is in the 1000's so perhaps an encore conversion down the road?12 points

-

Thanks @kortopates @carusoam. Yep will be doing the transition training when I pick it up and get it back up to the PNW. IR will follow later this year in the bird that I will be flying - much better that way. Which leads to insurance, yes its a bit high but doable. Parker has been very helpful in that aspect. Didn't get much time to take pics after the sale. The video is from engine start by Rick who was ferrying it over to Chandler Aviation. IMG_0783.mov5 points

-

4 points

-

We use DLC coatings a lot in our designs at my day job. DLC is an extremely hard coating so it wears slower. Beyond the anti-corrosion benefits, it also lowers friction between the two parts and friction plays a big part in spalling. It does this by causing the two parts in contact to no longer be metalugically similar. Steel on steel under high contact loads has an adhesive component to the Friction because the two parts want to fuse together. This is how galling occurs. DLC on steel breaks this tendency. DLC coating isn’t cheap, and it’s tricky to only coat specific regions of a part. A camshaft lobe is only under high load on the outer base circle so this is the only region that would benefit. It would be nearly impossible to only coat those regions and so the tappets are coated instead. It would be a waste of money to coat the whole cam and coating both part provides no benefit. It would probably make things less robust. This isn’t a trouble free solution. It’s very tricky to get the coating to adhere and then to survive high temps. But, if done right it’s hard to beat. I’m about to put these DLC lifters in my A1A.4 points

-

You sound like your speaking from experience! Reminds me of a similar stunt I pulled years ago. Had a ski accident where I cracked my upper femur - no break but crack. So I was on crutches but according to my doc I went back to work too early rather than staying home to keep it elevated. I didn't keep it elevated enough at work like I should have and it wouldn't of been that hard since I had a nice office but I was too busy (stupid) meeting with the troops. I got too much swelling in the lower leg, a blood clot developed and before long the clot was breaking apart and going into my lungs making it harder to breathe, first noticeable when I was moving around on the crutches. Second stupid thing I did was chalk this up to a couple of cracked ribs. But then it progressed to the point I was having difficulty breathing in my chair sitting down. Should have went back home that morning, or really the emergency room, but waited till lunch to ask a colleague to take to the ER which was only a mile away. I could not believe I was having a heart attack but soon I became educated that I had a DVT which cause a PE with over 70% blockage to the lungs. Luckily I was super fit at the time yet I spent the next week in the ICU with all the narcotics I wanted. It was a full 6 more months till I could get my medical back. Had no clue how close I was to dying. But boy did that event alter my outlook on life as well as my attitude that a little pain just makes you stronger. Makes me think of Bernard Shaw , who sums it up well: "Wisdom is wasted on the old, and youth is wasted on the young."4 points

-

There is a lesson in this remark, that I have also thought about in the past. It reminds me of two other scenarios. 1 - about 12 years ago when I still owned my Diamond DA40 and I was on the diamond forum a lot, one fellow posted that his son's wife had died in a car crash. And they were 3 hours flight away and something like 10 hours drive. He started to prep for a flight but then realized he was just way to rattled to do a safe flight so he made a wise decision to drive. ...which even though driving is a bit easier ... it can also be dangerous when in mental distress. 2 - about 17 years ago when my father past away suddenly and tragically, wow was I rattled. I went down to DC with my uncle to clean out his apartment and take care of his affairs. I did several space-cadet dumb things. Worst was I ran a red light at a four way intersection at full speed - I mean at 50mph I drove through a moderately heavy traffic four way light in the wrong direction, and for the grace of god and good luck nothing happened. I just went sailing through, with my uncle on board and only in the middle of the intersection did I realize what happened and what I was doing and there were other cars who only began to tap their brakes going at 90 degrees to us also at full speed but luck - there was no collision - only luck. actually - a 3rd - about a week later at home - I went out on a bike ride, and I simply forgot to tighten the quick release squwer on the rear wheel - I mean I have been a bike racer since I was 17 so this is second nature to me - but I simply put the wheel on and not even a little bit tightened. Well after about 20 minutes of warm up and stood up to stomp on the pedals - and boom the wheel came half off and froze and I flipped over, crashed and broke my wrist. But I didn't break my neck or crack my skull - or get hit by a car, etc...knock on wood. Anyway - theme of these stories, and what I take from the ER doctor who did this stall spin in his cirrus, is we are only fallible humans and go easy on ourselves and sometimes if your head is not in the game, maybe find a way to get the head in the game or forgive yourself and just don't go.4 points

-

As I mentioned in another post, after AirVenture was canceled for 2020, I decided to trade its cost for the cost of the GTN 750 and GTN 650 upgrade. While Sarasota Avionics in Florida has an upgrade program, they weren't a possibility here on the West Coast. I called around quite a bit and finally found an organization that was more than willing to do the exchange upgrade, Pacific Coast Avionics in Aurora, Oregon. It turns out that they had provided one of the best bids for my GFC 500 autopilot upgrade, but they had so much business that I was going to have to wait 6 months for them to do it, so I went with Accurate Aero in Minden, Nevada. I got what I thought was a fair bid from Pacific Coast. They said they could do the job in about 3 hours including all the paperwork and could start the job in about 2 weeks. That meant that I could leave early in the morning, fly up, get the work done, and fly back, all in the same day. I didn't want to stay overnight at any motel. So, armed with face mask, Clorox wipes, gloves, and hand sanitizer I flew up on May 15th, the one good day between storm systems in Oregon and California at the time. Due to headwinds the trip took 3 hours. but with gas at $2.99 the cost wasn't that much. It was good to get back in the air and exercise the plane, which had been sitting idle for awhile. Once there, the plane was quickly pulled into a new hangar. Chad was the only one working in the hangar, and he took me to a private room where I set up to spend a few hours working on the Gleim FIRC. Even though I renew my CFI through giving Wings Programs, I like to stay up with what is going on in the industry by taking their course yearly. It takes a lot longer than the required 16 hours, but I have found the course to be useful. I told Chad that it bothered me that my G5 altitude always varied from the G500 TXi altitude by more the 60 feet, and he said that he could fix it, but that it would take an additional hour. I told him to go ahead and do it. Being a PIA, periodically I"d go to the hangar to see how things were going. During one of those times I asked him when my units had arrived from Garmin. He said that wasn't necessary since they "keep the units in stock". That took me by surprise. How many organizations can keep high priced avionics like that in stock? Although the installation is "plug and play" and the units have their own configuration modules to make for easy exchange, there were still some settings that needed to be changed. Chad made the changes, calibrated the air data computer to correct the altitude deviations I had discussed, and finished up by mid afternoon. Fuel was expensive at Aurora so I flew the 10 miles over to Mulino State to get fuel at almost $1.50 a gallon cheaper. From there I filed through Garmin Pilot, picked up the clearance in the air, and headed home. Everything worked perfectly, as expected on the way home. Pacific Coast was excellent to deal with and I highly recommend them. The units are faster, have better resolution (although I can't really tell), have better software upgrade capability, and I have a new 2 year warranty. The software is a little different from the basic GTNs with a database icon showing up on turn on that could make database updates a little easier for some. All in all a very good day. Finally, I think I am done upgrading (how often have I said that). Well, maybe if Garmin comes up with a good autoland system for the Mooney....3 points

-

Technically a skid is not cross controlled... as cross controlling literally means aileron one direction, rudder In the opposite (crossed controls), vice a skid where the rudder and Aileron are in the same direction. you can easily wrap up the aircraft in a base to final turn with lets say left wing down, left rudder, then cross controlling by leaving the rudder in but rolling to the right.... that plus backstick pressure to pass through the critical AoA could result in a snap roll left. Which would be considered cross controlling, although from a skid entry. I get your drift- we are trying to say the same thing- he wasn’t in coordinated flight- and that, in some capacity, led to the spin in (most likely). edit: I see where the disconnect is- the reason for spin entry in both circumstances is a cross controlling action + stalling- hence you saying “cross control” (which makes sense)... a skidded turn tends to be the “lead-in element” of said spin- that’s where I’ve crossed the wires- as a skid itself isn’t a cross controlling action. It’s what the pilot does as the aircraft wraps up that is the cross control. So yeah- all that to say- we’re saying the same thing3 points

-

Above is a cut from Gert's above post where he finds the original specs for the Mooney discs. Below I have tagged on an article by Bill O'Brian (deceased) the guru of GA maintenance for many years with the FAA on OPP Owner Produced Parts and what has to be done. If you go to Question 6 and his answer - one needs to confirm that the part being made conforms to its approved design of which it seems that Gert has a copy. I would think that there would be no issue if the owner "participated" in the design process (as required) by sending a letter to Gert specifying that new donuts be made to the original design specs he has and then retaining a copy of the letter for the aircraft records and (as noted in Bill O'Brian's letter) the owner makes a log book entry saying he/she has supplied an OPP part for installation on his/her airplane only. The A&P also needs to inspect the part (as noted in Bill's letter) and sign off the installation. (read the below letter) This is no different than getting a mixture control made by McFarlane to OPP design and having the A&P install it. And, as he has been doing it for a number of years on Beech airplanes with apparently no issues at this point I see no problems. If it had been 6 months ago I probably would have gone through him for mine. HERE IS ANOTHER THOUGHT I HAVE NOT SEEN PROPOSED YET FOR US WITH MOONEY BEING SHUT DOWN- In question 8 in Bill's letter he talks about FOIA request for the design sheets for parts not available from defunct companies. Maybe we need to pursue this avenue for parts we can't readily get anymore. Answer 8: For aircraft that the manufacturer is no longer supporting the continuing airworthiness of, the owner or operator can petition the FAA Aircraft Certification Directorate under the Freedom of Information Act for the data on how the part was made. Interesting article by Bill O'Brien who is an Airworthiness Aviation Safety Inspector in FAA's Flight Standards Service. (BELOW)by Bill O'BrienAlong with the pilot shortage and the mechanic shortage, there is also a parts shortage that plagues the general aviation industry. Because supply and demand are out of balance the cost of new and used parts seem to increase every day. Let's examine the reasons why this is so.First, we have an old fleet. The average general aviation (GA) single engine airplane is approximately 32 years old. The average age of GA multi-engine reciprocating aircraft is close to 27 years old. The average age for the turbine powered multi-engine propeller driven aircraft average out around 19 years of age. So because of long term wear and tear the demand for replacement parts and large sub-assemblies is much greater today than it was even 10 years ago.The second reason is our general aviation fleet has been well maintained over the years. So well maintained in fact, the average GA aircraft with a mid-time engine and decent avionics has appreciated to two or three times its original purchase price and is still climbing. Yet even in that land of many zeros the older aircraft are still substantially lower in price than the cost of a brand new aircraft with similar performance numbers and equipment. So the value of older aircraft in good shape are proven investments that over time have beaten the DOW JONES average. So we have an economic imperative on the part of the owners to keep maintaining older aircraft in flying condition which increases the demand for replacement parts.The third reason is the increasing production costs to make a part. Today aircraft manufacturers are not making makes and models of aircraft in the same quantity they made them back in the Seventies. So the production runs for parts are not as frequent and not as many parts are produced. In addition, it is not cost effective for a manufacturer to make a lot of parts even if the unit price for each part is out of this world because taxes on maintaining a large inventory of parts would eat all of the profits. This low parts production keeps the supply of replacement parts low.The fourth reason is that some manufacturers would prefer that their older makes and model aircraft-made a million years ago-would quietly disappear from the aircraft registry. This retroactive birth control on the part of the manufacturers may seem not to make any sense until you look at aircraft market dynamics of creating demand and reducing costs. First, each older aircraft that is no longer in service creates a demand for a new, more expensive aircraft to take its place. Second, despite some tort claim relief granted to GA manufacturers in the early Nineties, the fewer older aircraft there are in service, the manufacturers of those aircraft enjoy reduced overall liability claims and ever decreasing continuing airworthiness responsibilities.So how are we going to maintain these older aircraft with an ever dwindling parts supply when Part 21, section 21.303 Replacement and modification of parts, requires us to use the Parts Manufactured Approval (PMA) parts on a type certificated product? Well, the same rule grants four exemptions to the PMA requirement.1. You can use parts produced under a type or production certificate such as a Piper, Cessna, or Mooney produced part;2. A owner or operator produced part to maintain or alter their own product;3. Parts produced under a Technical Standard Order (TSO) such as radios, life vests and rafts, and GPS; or,4. A standard aviation part such as fasteners, washers, or safety wire.Before I segue into the subject of "owner produced parts" as called out in section 21.303, which is the purpose of this article. I would like to create a small uproar with this statement: "FAA Airframe and Powerplant rated mechanics can maintain, repair, and modify parts, but they cannot make a brand new part and call it a repair." Before you accuse me of losing dendrites by the minute, check out section 65.81 General privileges and limitations. The section talks about maintenance, preventive maintenance, and alterations, but not the manufacturing of parts. Nor is it an implied privilege in Part 65, because Part 21 section 21.303 says "no person" may make a replacement part for a type certificated (TC) product unless that person has a PMA, etc.While I write this I can remember 25 pounds ago and when I had hair, I worked in the real world and I specialized in making engine baffles for Lycoming engines. Before someone accuses me of bureaucratic ventriloquism which is roughly translated as "talking out of both sides of my mouth." My weak defense is, I made the parts because I thought I could." It never dawned on me that I could not legally make a part. Some of you may be astounded that I make this confession freely. It's no big thing because I know the statue of limitations has run out years ago and a jury of my peers would never look me in the eye and convict me.So here is our problem that we must solve. Since mechanics cannot legally make parts for aircraft and aircraft need replacement parts, how are we going to keep the fleet flying? If we cannot find PMA, TSO, standard, or production holder replacement parts, we are left to make the part under the owner-produced option under section 21.303(b)(2). However, we must remember that the part is for the owner/operator's aircraft only and is not manufactured for sale to other TC aircraft.To get through confusing regulatory policy with our pride intact, let's try the question and answer routine. (Note: This policy is taken from FAA 's AGC-200 policy memorandum to AFS-300 on the definition of "Owner-Produced Parts" dated August 5, 1993)Question 1: Does the owner have to manufacture the part him or herself in order to meet the intent of the rule?Answer 1: No, the owner does not have to make the part him or herself. However to be considered a producer of the part he/she must have participated in controlling the design, manufacturer, or quality of the part such as:1. provide the manufacturer with the design or performance data from which to make the part, or2. provide the manufacturer with the materials to make the part, or3. provide the manufacturer with fabrication processes or assembly methods to make the part, or4. provide the quality control procedures to make the part, or5. personally supervised the manufacturer of the part.Question 2: Can the owner contract out for the manufacture of the part and still have a part that is considered "owner-produced?"Answer 2: Yes, as long as the owner participated in one of the five functions listed in Answer 1.Question 3: Can the owner contract out the manufacture of the part to a non-certificated person and still have a part that is considered "owner-produced?"Answer 3: Yes, as long as the owner participated in one of the five functions listed in Answer 1.Question 4: If a mechanic manufactured parts for an owner, is he/she considered in violation of section 21.303(b)(2)?Answer 4: The answer would be no, if it was found that the owner participated in controlling the design, manufacture, or quality of the part. The mechanic would be considered the producer and would not be in violation of section 21.303(a). On the other hand, if the owner did not play a part in controlling the design, manufacture, or quality of the part, the mechanic runs a good chance of being in violation of section 21.303 (b)(2).Question 5: What kind of advice can you give on how a mechanic can avoid even the appearance of violating section 21.303(b)(2)?Answer 5: First, a mechanic should never make a logbook or maintenance entry saying that he/she made a part under his certificate number. This foopah will send up a flare and get you undue attention from your local FAA inspector, which you could do without. However, the mechanic can say on the work order that he helped manufacture an owner-produced part under section 21.303 (b)(2).Second, the owner or operator should be encouraged to make a log book entry that is similar to section 43.9 maintenance entry that states: The part is identified as an owner produced part under section 21.303 (b)(2). The part was manufactured in accordance with approved data. The owner/operator's participation in the manufacturer of the part is identified, such as quality control. The owner must declare that the part is airworthy and sign and date the entry.Question 6: Is there anything else a mechanic must do?Answer 6: The mechanic must ensure that the owner-produced part meets form, fit, and function, and, within reasonable limits, ensure that the part does meet its approved type design (e.g. like looking at the approved data used to make the part). Then the mechanic installs the part on the aircraft, makes an operational check if applicable, and signs off the required section 43.9 maintenance entry.Question 7: What is the owner responsible for and what is the mechanic responsible for concerning owner-produced parts?Answer 7: The owner is responsible for the part meeting type design and being in a condition for safe operation. The mechanic is responsible for the installation of the owner-produced part being correct and airworthy and for a maintenance record of the installation of the part made.Question 8: How does the owner or operator get the approved data to make a part if the manufacturer and other sources are no longer in business?Answer 8: For aircraft that the manufacturer is no longer supporting the continuing airworthiness of, the owner or operator can petition the FAA Aircraft Certification Directorate under the Freedom of Information Act for the data on how the part was made. Or the owner or operator can reverse engineer the part and have the data approved under a FAA field approval or, if it is a really complicated part, have the data approved by a FAA engineer or FAA Designated Engineering Representative.Question 9: What happens to the owner-produced part on the aircraft if the original owner sells the aircraft?Answer 9: Unless the part is no longer airworthy, the original owner-produced part stays on the aircraft.I hope that I spread some light on the murky subject of owner-produced parts, so the next time instead of saying to the owner of an broke aircraft: "Sure, 'I' can make that part," you will now say "Sure, 'WE' can make that part."--------------------------------------------------------------------------------Bill O'Brien is an Airworthiness Aviation Safety Inspector in FAA's Flight Standards Service. This article also appeared in the Aircraft Maintenance Technology magazine.3 points

-

Paul's mention of an escrow service is very good advice. When we bought our E last year, the transaction was done through an escrow service and I was SUPER impressed and pleased with their responsiveness, professionalism, and knowledge. I am not in any way affiliated with them, but here's the contact info for the escrow agent we used and a screenshot of an early letter they sent (which describes the fee - as of March 2019 - and their services). In our case, the fee was $550 (split between buyer and seller) and it included a title search, FAA registration filing, and the whole shebang. Worth every penny! EDIT - to clarify that neither I nor the seller are anywhere near Oklahoma...this was all done remotely and was very smooth.3 points

-

3 points

-

3 points

-

The most disappointing thing about reaching the end of the Mooney line... It comes too quickly... We have lost MSers Mooney owners for various reasons... (true MSers never leave... even after they no longer have a Mooney.) A fifth seat... A need for more speed... (looking for a turbine solution) A need to haul more stuff... (2X UL) But before you you go, remember... Long bodies have a fifth seat option... A TN’d Acclaim is a pretty fast, awesome ride... Some LBs have a UL over 1.1k#s... with loaded panels.... Young kids don’t carry much stuff.... Old kids don’t stay around very long... Plenty of room for the kids and their stuff in a LB. many people use an LB for quite a while before moving up the ladder.... The LB serves as a great stepping stone up from the M20C... Remember to Be nice to the third child... remind them how you had to give up the sports car for them.... PP thoughts only, not a plane sales guy... Best regards, -a-2 points

-

When our KFC pitch servo died, we sent it and the servo mount to Autopilots Central. They wanted $3500 to fix it. A brand spanking new servo for the GFC is $1750 for the certified version.2 points

-

There's no requirement that the materials be identical, just that the part has the same characteristics to return the aircraft to "at least equal" to the original or properly altered condition. Note that exceeding original or properly altered condition is allowed. It doesn't have to be the same. I share the concerns on these parts, though. How the owner is participating in production via the requirements is not clear. How the installer can determine that the part will perform as well as the original also isn't clear.2 points

-

I'm also in the EDM700 upgrade stage and we just took out the 700, to make room for the 730 to go in the same location. And, like you, we found that the wires are just a bit too short...at least at first glance. The 730 (like your 830) unit is shorter in length, than the 700, by 3-4 inches. And that small difference in depth may require us to extend our wire harness also, unless we find a bundle tied deeper in the panel. I'm hopeful about that, because it seems odd that the first installers would make the harness that "precise" when it seems that everything else behind the panel has about a yard of extra wire all bundled and zip tied... BTW, a shout out to our MSer @Jeev from whom I ordered the 730...great and responsive support! I was prepared the order the 700>730 upgrade from either Chief or AS...and then I found out about him - glad I did.2 points

-

It’s a noticeable improvement by front seat passengers too. The arm between front and rear seat from center of axis isn’t too much. My costs were almost the same as Niko’s. I also had the vacuum system removed and an RCA-2600 installed in lieu of the TC. Originally I was not going to do the YD, but messaging with @Bobs50 convinced me it was worth it. Particularly in the models without rudder trim, the yaw servo effectively gives you an auto rudder trim function from 800AGL in the way up to 200AGL on the way down. In the medium body (200HP) models the YD servo is strong enough to maintain right rudder pressure all the way up during climb In fact the avionics shop tried over and over to convince me not to do it- said it is only useful in the V tails for their Dutch roll characteristics. The original plan was to pre-wire for that servo in case I’d want it in the future. It was 3AMU to do it during the install and 5AMU to come back and do it later - so I decided to get it done. So, in summary, it is a (valuable) worthwhile addition and I’d highly recommend it for Mooney models without independent rudder trim.2 points

-

Most people that try the yaw damper say its worthwhile. the ones that haven't tried it tend to say it doesn't make it worthwhile for the price. I took the former's advise and just went with it. In my opinion, its well worth it. The GFC500 handles turbulence very well, and with the yaw damper it makes it noticeably better. the fact that the yaw damper can be on without the autopilot being on is another nice addition.2 points

-

it takes Boolean logic, Kavanough Maps, and some kind of Smith chart to use the search function, so I'm told.2 points

-

Congratulations! You'll be much happier with a 252 and yes, you are fully eligible to do the Encore upgrade as I have done.2 points

-

Per JPI, you are allowed to lengthen it as long as you use the yellow JPI wire. I had to do that to mine when I rearranged my panel and didn’t want to spend the $300. Works great, big pain the ass.2 points

-

Short answer is yes it can be installed but you need an A&P to sign it off and make a log book entry, as tools are required. You may be able to install it under an A&P's supervision if you can find one willing.2 points

-

As much as the opposing party would like this state of chaos to continue til the election, the people are sick and tired of it! Besides, where are all the sick people? From what I hear on the news, they should be everywhere! I can't find them anywhere!2 points

-

Typically the buyer pays for the ferry pilot and fuel to move the plane to your preferred shop for the pre-buy. As the buyer, try to make is super easy for the seller to agree to your choice of shop for the pre-buy. That usually includes... Look the plane over as closely as you can yourself. Get another experienced Mooney owner to look it over with you. Go over the logs and even get the pre-buy shop to go over the logs before taking the plane to them. (You'll pay something for this service) Pay for a title search. Come to an agreement on the purchase price of the plane assuming it is as advertised, and airworthy. Sign a purchase contract that stipulates these terms. Give the seller a deposit of between 10% and $5K for a sub $100K airplane. (Or use escrow.) Let the seller chose the ferry pilot and you will pay all expenses of the ferry pilot, fuel, etc. to get the airplane to the shop for the pre-buy. This all shows the seller you are serious about buying the airplane and are going in with your eyes open. It should also ensure you've done all the due diligence possible before laying out cash for the deposit, ferry, and pre-buy.2 points

-

I guess it depends if you want to embrace the entire iPad role in aviation. The Aera 760 seems to limited to E6B kind of functionality or maybe a better way to put it is more of a duplication of our panel GPSs rather than adding real new capabilities. My panel is G500, GTN750, GTN650, GTX-345 with FS-510 as well as XM weather and music. I could be wrong since Garmin doesn't publish a user manual on the Aera 760 and I am not a user of it like Don. But when I refer to the new capabilities provided by iPads these days, as a Garmin Pilot user, where I beleive the iPad shines, I am referring to complete performance modeling (fuel and time) for my pre-flight planning at home, as well a ability to file flight plans, get a weather briefing and review official weather products. I can even activate and close VFR flight plans from my ipad on the runway, and GP has taken over the role of being my on-line backed up in the cloud Pilot logbook and record of endorsements given and received. And then the one big thing no matter how much you might love an Aera is the database concierge service on the iPad which make it so easy to update all my panel databases wireless over the iPad. I know the Aera does bread crumbs or saves flight track info, but with the iPad I can no only go over the recent track, it saves every track along with the entry in my online logbook. I also use checklist capabilities along with performance capabilities for many different models I work in which I would expect the Aera does as well, but I doubt the Aera is as useful for preflight planning and filing flights plans like the iPad is, let alone provide the log book functions and update your databases. So realistically, i don't think you can call this a either or decision. Even with our nice panel, you'll need the iPad regardless with GP or Foreflight even if you only use it for the database concierge service and then it comes down to whether you also wan to add in the Aera 760 too. Like Don, I also supplement my iPad GP with a GDL-39D so I have onboard weather and traffic on my iPad when instructing plus its last line of backups in my plane in case of a total electrical failure.2 points

-

I was talking with my wife about this crash yesterday. I was talking about how a stall/spin in the pattern is almost guaranteed to not be survivable. She asked "So what do you do?" I said "Don't get too slow, don't over bank/load up the wing in a bank, stay coordinated." I'm still looking for that perfect flight where I didn't either make some kind of a mistake or have something I wish I had done just a little better. Fortunately none of the mistakes have had serious consequences. I do have some things I put into the "Never let it happen" category as the pilot. A stall in the pattern is in the "Never let it happen" category. I can recover from a lot of things in the pattern either by making adjustments or going around, too high/too fast/overshoot final, those are recoverable. A stall in the pattern, not so much.2 points

-

On my trips to Northen Europe I avoid stopping at Narsarsuaq, fuel is expensive and not always available. When travelling to Madrid LEMD I go via Santa Maria LPAZ. In the old days before GPS I home in into the LPAZ NDB, LORAN C just barely worked at the time. Be ware that the LPAZ routing requires HF. People at Santa Maria (Portugal territory) are very friendly.2 points

-

Actually, no, I wouldn’t recommend that. I think this answer is going to be in line with Skips and Carusaum, even though they didn’t say it exactly... if in doubt, go for a hot start first. You give that one good shot. If that doesn’t work, follow Skips advice for flooding it to know where you’re at and do a flood start. You only get one shot at a hot start, and once you prime, you can’t go back. You can always flood it. @Marauderhad a good story of a tailpipe fire after a flooded start. Now that’s pretty rare, but enough for me to give hot start a chance. Honestly hot starts probably work 99% for me. The question of 3-5 minutes idle then shutdown would be tough, but I’d probably try hot start first. If in doubt...2 points

-

As indicated by his “pilot attitude indicator”, it tells you how cool/grumpy your look on makings2 points

-

2 points

-

It’s all about experience... Take notes as you go, Matt! Often... really cold starts... are below <20F 100LL doesn’t evaporate very well...at all... Cold starts... <40F pre-heat is suggested... Extra prime is warranted... Because 100LL evaporates slooowly... ordinary starts... minimum prime is used... makes sure Fuel is getting to the engine... 100LL evaporates well... warm starts...just like an ordinary start... using extra caution to not over prime (don’t prime at all) Engine was running to taxi.... Is a warm start... but the fuel system is empty because you just pulled the mixture... (put the fuel back) Hot start... The CHTs have Been run up around 400+°F while doing pattern work, and you hear the fuel boiling in the injection system from under the cowl... (100LL evaporates too well when hot, and The bubbles push the liquid down the tube... into the cylinders when not asked for...) If you don’t hear the fuel boiling... probably not a hot start... a good long descent from altitude... Probably not a hot start... Plane has been sitting long enough to get comfortably refueled... probably not a hot start... You ate lunch Since you landed... not a hot start... Doing lots of pattern work on a hot summer day... needing to refuel... CHTs are high, injector system is boiling, you open the oil door on the cowl Just to let hot air out... You jammed 10gal per side in and run to get back in the seat... expect it to be your lucky day... do the hot start! When you can’t figure it out... flood it... do the flooded start before the battery croaks... Remember when changing Mixture settings while starting the engine... you can hear each compression stroke... don’t be too Fast.... PP thoughts to consider... Best regards, -a-2 points

-

Greetings Spacers: I closed my family medical practice at the end of last year. I was going to practice overseas but Covid squashed those plans. So, I'm just going to do FAA medicals until I've gone west, (and maybe even after that if I can figure out a way!). I'm based in the Seattle area (Edmonds, wa to be exact) but I'm willing to do exams when I'm visitng friends and relatives in other locations. If a gaggle of you get together and want to do a medical day I can fly into your airport and knock out a bunch. It'll probably cover the cost of fuel! At any rate, if you are so moved to have me poke and prod, give a call or email. Henry Hochberg, M.D. N355RZ@KPAE Appointments: 425-686-2510 Email: FAADrHochberg@gmail.com1 point

-

Do you want to fly your airplane from your own hangar without the hassles of renting, but just can’t quite justify the full expense? That’s my situation. Or maybe you already own an aircraft, but don’t fly as much as you’d like because it just costs so much that it’s tough to swing. Maybe having a partner would help? Either way, let’s see if sharing the costs might make sense.I’m a CFII/MEI with SEL/SES/MEL/MES privileges. I’d like to have access to an IFR-certified aircraft with a safe range of at least 600 nm or so. There are any number of efficient piston singles that will do the trick, and a vintage Mooney would be perfect for me. I’d prefer the aircraft be based around Houston. I’ve shared ownership before, and know that there are a variety of ways to make that work for all concerned. What works for you? Let’s talk...!1 point

-

As "cheap" as that sounds- $18k on a "toy" for someone who is 28 years old is a TALL ask. I still have college debt, credit cards, etc. I haven't made my mind up on what I want to do.1 point

-

Ive had this mental exercise and my end result was a 1976-1978 straight-tail, Hershey-bar wing Piper PA-32-300 Lance. Big cabin. Some parts commonality with the venerable Cherokee (cheaper than Beech) and the best part and big swinger in my book- Lycoming 540. Basically a -360 with two more jugs. The thought of Continentals tickle my wallet in ways I cant fathom. From what I read is they do 145-155KTAS at 11-13gph, 6 seats, 2x baggage compartments. Certainly not as fast as a Bo, but if it fits, it ships1 point

-

1 point

-

Impossible to tell. Both sides can claim the high ground with no way to prove either view. Irregardless of claims of absolute proof, we’ll never know what would have happened if we treated this like every other disease that comes along. Too bad there are sides.... I guess it comes down to those who value freedom vs those who value security. There are those who can take care of themselves and those who need someone to take care of them.1 point

-

@ukrsindicat@yahoo.com Use the key but just barely insert it into the cylinder and see if it will turn while jiggling it around. Before I changed mine out last year I could open LOCKED door by jiggling the door handle and I could watch the cylinder turn enough to open the door. The body of the lock assembly was worn pretty bad1 point

-

@Ross Taylor I don't think there was an adjustment to keep the "hook" (top of door) from going over the top of the cabin. Sounds like it may have gotten bent some how1 point

-

Same thing, said in a different way... Thermo-couple wires are made from two different metals... So... extending the wires takes using the same two different wire materials... The wires are color coded... their insulation is colored. Don’t mix up the wires...you will get useless data from your JPI as a reward... If the shut-down continues... you can always ask EI for advice on extending the JPI wires... Technically possible for you to get it done... just a big pain (Like Andy said!) Best regards, -a-1 point

-

Interesting, I don’t use the electric pump at all on my hot starts.1 point

-

The best setup possible IMO: PAR200B Audio Panel Comm GNX375 ADSB WAAS GPS GNC255 Nav/Comm Get another G5 and get rid of both CDI's. JPI900 inbetween the 6 pack and the Radio stack and get rid of the old engine instruments. Full new panel with everything properly organized. 2 USB chargers1 point

-

Yes I used CTC on my last hub inspection and mentioned them on a couple other threads on the subject . There tech did the most thorough inspection of any I have used. Ramp elves handled the RR on the spinner.1 point

-

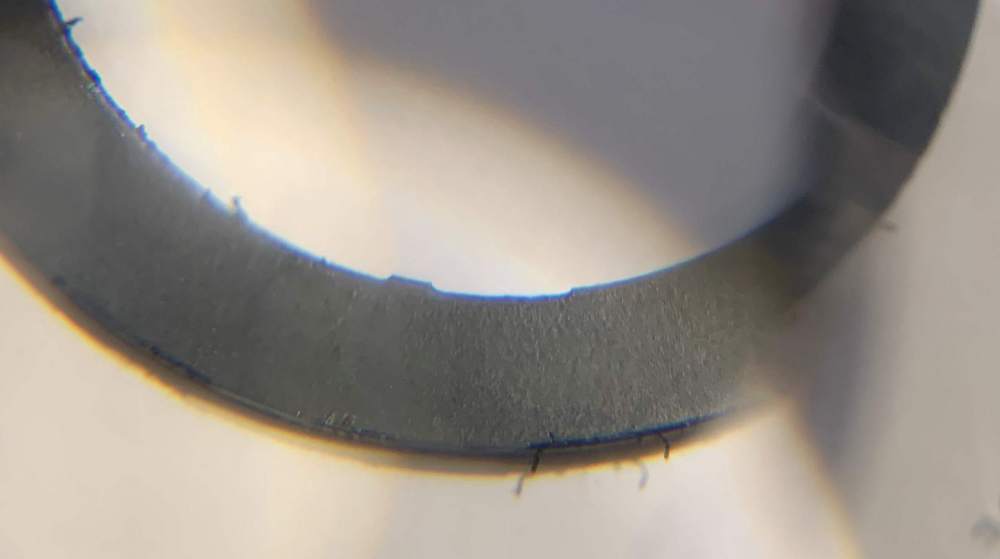

For those following the saga... Our "overnight" gasket actually took two days to arrive due to UPS delays in Louisville, but I did receive it yesterday. Out of the bag, it measures 2" O.D. by 1.5" I.D. by about 1/16" thickness. Weight is 0.05oz on my kitchen scale, but that's the limit of the scale's resolution so that's not a very reliable number. I gently tugged on the inner and outer edges all the way around and found no cuts or defects. Looking through a magnifier, you can see the material isn't what I'd call "pristine": it has some light fraying along the cut lines, and the surface is not perfectly smooth; but this is not different from anything I remember with previous good gaskets. I dropped it in a clean mason jar with about a cup of 100LL drained from our left tank (the one that didn't get emptied by the leak). Will report back here on what it looks like in a few days.1 point

-

Yes it is one of these "never let it happen", there is no way to recover from base & final spins (unlike recovering from departure & go-around), main emphasis is being able to recognise and act early or better never get there in the first place, First issue is distraction and second is loss of visual references when flying low (if you bank/pitch 45deg at 500agl all you see is ground or sky not the line in between), it is hard to train anyone for these at 3000ft agl, the only defense in the pattern is mainly about "watch pitch & bank & speed" but this will fail sometime under pressure One can try throwing few approach where student fly pattern by fixating his eyes on fictitious traffic on the runway numbers or somewhere else on the left window (not looking over the nose or watching speed) while RHS is monitoring speed & pitch & bank & traffic, it is an eye opening experience on spatial disorientation and loss of speed & attitude and may explain why we pilots fall out of the air in a blue sky days Also flying with other slow & fast traffic with distraction in the pattern is not something chutes can solve... RIP airman https://assets.publishing.service.gov.uk/media/5b7422c040f0b60c3b7848fe/Cirrus_SR22_N844MS_09-18.pdf1 point

-

Yep, I looked at the day of and there was essentially no wind at the field or at 3000' altitude. A prefect CAVU day!1 point

-

One advantage of the iPad is that with your subscription you can authorize 2 devices. If my iPad dies in flight I can pull my iPhone out and get back all of the chart, approach and weather information needed to complete the flight.1 point

-

My thoughts exactly. We all did stupid things as student pilots (and I continue to do stupid things on a regular basis) but fortunately most of us flew forgiving trainers during that stage in our piloting career. I don’t get learning to fly in a Cirrus. I’m making my son do all his primary flight training in a 172 instead of our Ovation for exactly this reason (and the robustness of the 172 gear system is much more suited for his “carrier landings.”)1 point

-

I considered going with roller lifters and and exchange, but after looking into the DLC coated lifters I chose to go that direction with a new Camshaft. Unfortunately my A3B6D engine was removed on 1/31 and shortly after all of my components were sent out to specialty shops the Pandemic hit. Due to unexpected delays at specialty shops and COVID-19 slowing everything down it took a while for all of my engine components to finally come back back in one place. Planning on beginning installation tomorrow morning1 point