Leaderboard

Popular Content

Showing content with the highest reputation since 10/03/2022 in all areas

-

Just to update all my fellow MooneySpace Family, I was the PIC of this flight. It happened quick as most emergencies do. We (my family and I) were in solid IMC at 5k when I lost almost all power very suddenly and without warning. I worked through the emergency procedures checklist but had no success. I advised ATC of my issues and started a descent to VMC about 1000’ ft below. After the emergency procedures didn’t recover the power loss, I advised I was declaring and proceeded to get vectors for the nearest field. I was about 9 miles from the nearest and I worried if I lost the engine we may not glide all the way to the field. When we broke out, I could see what I thought was an airstrip about a mile or two off the nose. ATC advised I was near a private airfield and I thought that’s what I was looking at. I informed ATC of my intentions to circle this field and make a landing. We landed safely and not a scratch on my family or the plane, thank god! Only after I landed did I find out we landed on the Consumer Reports testing facility track. It’s about 4400’ long and makes a great emergency LZ! Now to work through the process to determine what happened and what’s next. This is a sobering reminder of why to practice practice practice, constantly refresh yourself with the POH and your checklists and stay sharp! I credit my save to my flight training and the many days I spent with my CFI working through this stuff! I will continue to be a student of the game and always press myself to study, practice and stay sharp! …..your life and others depend on it!51 points

-

Hello all, I am the passenger of N231GZ - M20 Rocket Engineering conversion to turbo prop inner-cooled. I'm not a pilot so I only know a little bit. Pilot/ Physician is instrument rated for 22 years. Trained in a Mooney because it was built in Texas and could be converted by Rocket. We travel throughout Texas doing exams for the state for work injuries. Hangered in Addison field for 22 years. IFR coming home from our monthly trip to Abilene, 5 mile final 2000 ft. locked onto the ILS, engine failure. Pilot tried multiple things to restart with no success, then just "flew the airplane". Couldn't see the ground until about 400ft. and saw the street/ trees, not a very hard landing until we were lunged forward. Prop was feathered before we crashed. We now know we hit the light pole, but I think the left wing was still attached and barely on fire when we were pulled from the plane. Neither of us lost conscience, the handle fell off inside and I was unable to open the door. Someone came up to the window and we told him to pull outer latch and they got us out. I am now home with broken radius, repaired with surgery, broken facial bones will not require surgery. Pilot fractured L2 that severed nerve, had surgery and nerve will heel in 18 months but may have a drop foot, and stitches in forehead. He should be home in a few days. If he weren't such an amazing pilot with a ton of experience and God watching over us, we wouldn't have made it for sure!41 points

-

Back in late 2010 I stumbled across Mooneyspace and was amazed at the amount of valuable information available and the community atmosphere of the site. I was between airplanes at the time so I lurked for awhile without signing up, absorbing anything I could. I had owned a 231 from 1993-1996, a Bravo from 1996-2000 and then other airplanes for a few years and then another Bravo from late 2006 to early 2010. In the Spring of 2011 I was seriously looking at a 231 in Georgia so I signed up on the site , and my first post was to ask a few questions as I considered the airplane. I didn't end up buying it, but by lurking on here I had the right things to consider when I went to look at it. I didn't actually end up getting another Mooney until 2014 but in the meantime I was learning a lot on this site. Mooneyspace helped me to go from being an owner that was mainly hands-off when it came to understanding how an owner can be involved in maintenance, to really enjoying getting involved. It helped to take the mystery and intimidation away. I went from never having changed my own oil on an airplane to being very involved in a top end overhaul/Bravo conversion on an M20M that I owned from 2015-2021. Yesterday I was looking at my Mooneyspace profile and to my surprise I was a few posts short of 10,000. So I thought I would take this 10,000th post to thank everyone that has made this a very fun, informative journey. Early on, @Marauder and @carusoam were very helpful along with Clarence and many others and now so many others on here collaborate to make this the premier place for Mooney information and assistance. Here's to the next fifteen years!!40 points

-

There are a few days in a lifetime that are especially memorable. In my case it would be my birthday, Shirley's Birthday, the day we met 41½ years ago, and the day I closed on N9148W, 31 years and 12½ thousand flight hours ago today. Little did I know at the time the life changing event that would be. Before I bought it, I was in awe of anyone who owned an airplane, and anyone who owned a Mooney TLS had to be in a different league than me. I remember sitting in the airplane that day and thinking, "what have I done?" Will I even be able to learn how to fly this thing? It was intimidating. I had, Suzanne, Top Gun's pilot and a flight instructor, fly with me down to San Antonio where I took the Flight Safety Mooney M20M Course. After the course, I was still uncomfortable and had, Paul Arrambide, my flight instructor fly back with me to San Diego, where I showed my family what I had done. My Mother had not a few reservations. A PPP the following March in Fresno, where I flew with Jerry Johnson and met my soon to be mentor instructor, Robert Goldin, who fortuitously lived close by me, changed the direction of my life. Who ever heard of someone changing from a Real Estate Developer into a Flight Instructor? I did it. Real Estate became a sideline and Aviation took front and center. It still does. It's a passion and never gets boring. Along the way I've met hundreds and hundreds of people who became my students and later my friends. I've met many top educators in the aviation field. Most of them were dedicated teachers. What an experience it has been and continues to be. After all this time, buying my airplane was one of the best decisions I have ever made. It's a special day indeed.38 points

-

It was 12 February, 1973, my Dad brought 47U home from Willmar Air Service to a 1/2-mile long grass strip (2Y5) in Northern Iowa. With Mom in the right seat, they enjoyed 35 years of flying the Mooney all over the country. Getting up there in years, in 2008 he gave up his medical and I brought 47U out to California, just north of Sacramento. I learned to fly in a Tri-Pacer (on the farm strip) and owned a Cherokee 160 for 20 years. But, 47U is my forever plane, just like it was Dad’s. Photo below, my Mom and Dad on a trip to the Dallas area to visit her sister.35 points

-

I called Anthony tonight , and all is well... He has put down the keyboard and ventured out to smell the roses for a little while.... No problems , or issues , just didnt want to commit the huge amount of time , that he has been for all these years.... He will be back , e v e n t u a l l y ..... Carry on....32 points

-

Just to update everyone, Upon inspection with the FAA Inspector and A&P/IA, they found that the internal baffles had broken off inside the muffler. The FAA Inspector and IA noticed heat marks and deformation on the inlet pipes going into the muffler housing indicating that the exhaust gases couldn't flow smoothly out of the exhaust and became trapped. They determined that the piece of the exhaust baffles had become lodged and obstructed almost all of the exhaust exit hole in the muffler, thus causing the immediate reduction in power and inability for the engine to run properly or make any power to maintain flight. They did say that they had seen this once before on a different aircraft and normally when a muffler fails the pieces simply blow out the tailpipe. I guess I got very unlucky that mine got stuck. I was very lucky however, that i had such a great spot to make an emergency landing!! We got a new muffler overnighted and made the necessary repairs yesterday. The FAA approved all of the work and all the ground runs showed that the problem was corrected. I was able to take off yesterday afternoon with the plane and fly it back to my local field. I played it safe and made the trip at a high altitude so I had options should any issues arise on the way back. I will say that the FAA Inspector was amazing and did a great job. He never approached with the attitude that he was out to get me and if anything, he was extremely understanding and compassionate to the issues. He reiterated several times that I did the right thing and made safe decisions to result in this positive outcome. He said this is why we have emergency procedures and pilots should never hesitate to use them! Then he said, Never let your pride get in the way of your safety! Thanks all for the kind words above and thanks for reading. Stay safe and fly Smart- Matt32 points

-

As many of you are aware over the last couple months and escalating today in an epic nature the site has been invaded by spam bots. It reached a level that was no longer manageable so I have set all new accounts to requiring manual approval. IF YOU JUST REGISTERED A NEW ACCOUNT: Please contact me using the "Contact Us" link at the bottom of the site requesting approval. Make sure to include your username on the site as I won't know you by your real name and your emails might not match. This might take up to 24 hours so please be patient. Going forward these are the changes I am proposing: All new accounts will be created as a "basic member" that cannot create content but can browse the forums. All current members will become "verified" members. No action or fee required to keep using the site as you already are. To become a new "verified member" you will have a couple options. For instant and easy access you will pay a small fee. Probably a one time $3.00 fee something like that and your account will be verified for life, no additional payments required. A free alternative and slower method will be available where the new user can email me a copy of their ID and something like a utility bill to prove they are who they say they are. As part of this I have upgraded the forum software to include their "commerce" package which will enable the site to automatically take payments for a number of things like membership fees, selling items, etc. I have been considering this for a while since it will automate the current donation system that requires me to manually upgrade accounts after donations which can take time and is prone to errors (such as PayPal emails not matching user emails and me not being able to find accounts to upgrade). So in the near future I expect to change the current "donate $10 or more to remove ads and get Supporter level access for a year" to something more like a $25 per year auto-renewal membership that is completely managed within your member area of the site. While going from $10 to $25 seems drastic, I need to pick a single amount for all users and $25 is actually what the average donation is now from the past 12 months. Also consider that the minimum donation has been the same $10 minimum since 2008 (hard to believe I have been operating this site for 17 years!) and I have been considering raising it to $15 or $20 for a while now. Note that all current Supporter level members will remain as such until it has been 12 months since their last manual donation. I hope this all makes sense. Please feel free to post your comments below. I might not get to reading them all so if you have something really important to tell me please use the in-site messaging system. Thank you all for your patience as we dealt with the floods of spam over the past couple months. It was frustrating for all of us I know. Craig30 points

-

I let @carusoam take me to lunch just so I could get a lot of likes here on Mooneyspace. Ladies and gentlemen, the ambassador of Mooneyspace Mr Anthony Caruso: He’s ignoring me cause he’s probably busy checking Mooneyspace! PS, I heard Anthony managed to get re-current in his airplane for the first time in years!30 points

-

Years ago I was flying home and while planning my flight realized there was a 70knt tailwind at 25k, directly on my tail. Pretty hard to pass up in a plane capable.. I was alone, had the nice blue silicone mask with a microphone, so I filed for 25k and off I went. I was cruising along and I looked down in my lap and saw this little black disk. At the time the plane I was flying was an ultra with the precise flight conservers, and I thought the disk looked like the adjustment dial on the outside of the unit. After a few seconds of fiddling with it, I realized I was trying to put it back together, but it wasn’t apart…. By the grace of god I realized that what I was doing made no sense whatsoever and I engaged the vertical descent for 1400fpm and still to this day do not recall the next two or three minutes. What I do recall is being level at 8,000 ft with atc calling me asking intentions. I hit replay on the g1000 and listened to me responding to them and taking instruction. I did not sound like myself, but I was responding. I do not remember any of this… After my wits were about me again I looked down and realized my arm had gotten wrapped around the o2 hose going to my mask and had inadvertently pulled the grommet out of the front of my mask at 25,000ft. The disk was the grommet, and if one was completely cogent, would never had mistaken it for anything else. I don’t know how long it had been pulled out, or how long it took me to notice something was wrong. The flight recorder only goes back about 2.5 minutes on a constant loop, so that’s all I could listen to. I don’t know how long the entire event lasted, but I did realize how close I came to being a bad story. There is certainly more elevated risk at those altitudes, and one must be very vigilant, aware and have some routine to check yourself very regularly. I personally stay 19k or below if I am alone, and will only go to 25k with someone else and if we pick up enough time to really make a difference. This isn’t my recommendation or suggestion, it’s merely a personal minimum in my Mooney, or any non pressurized airplane. Things can deteriorate much quicker than you would like to believe… Last thought on this story… I was embarrassed by this. I felt foolish, like my arrogance and confidence led me to a bad choice that could have killed me. I finally opened up and told the story to a pilot friend of mine and he told me I should share, because perhaps someone could benefit from hearing my mistake. I sure hope it does, because I still feel foolish.27 points

-

26 points

-

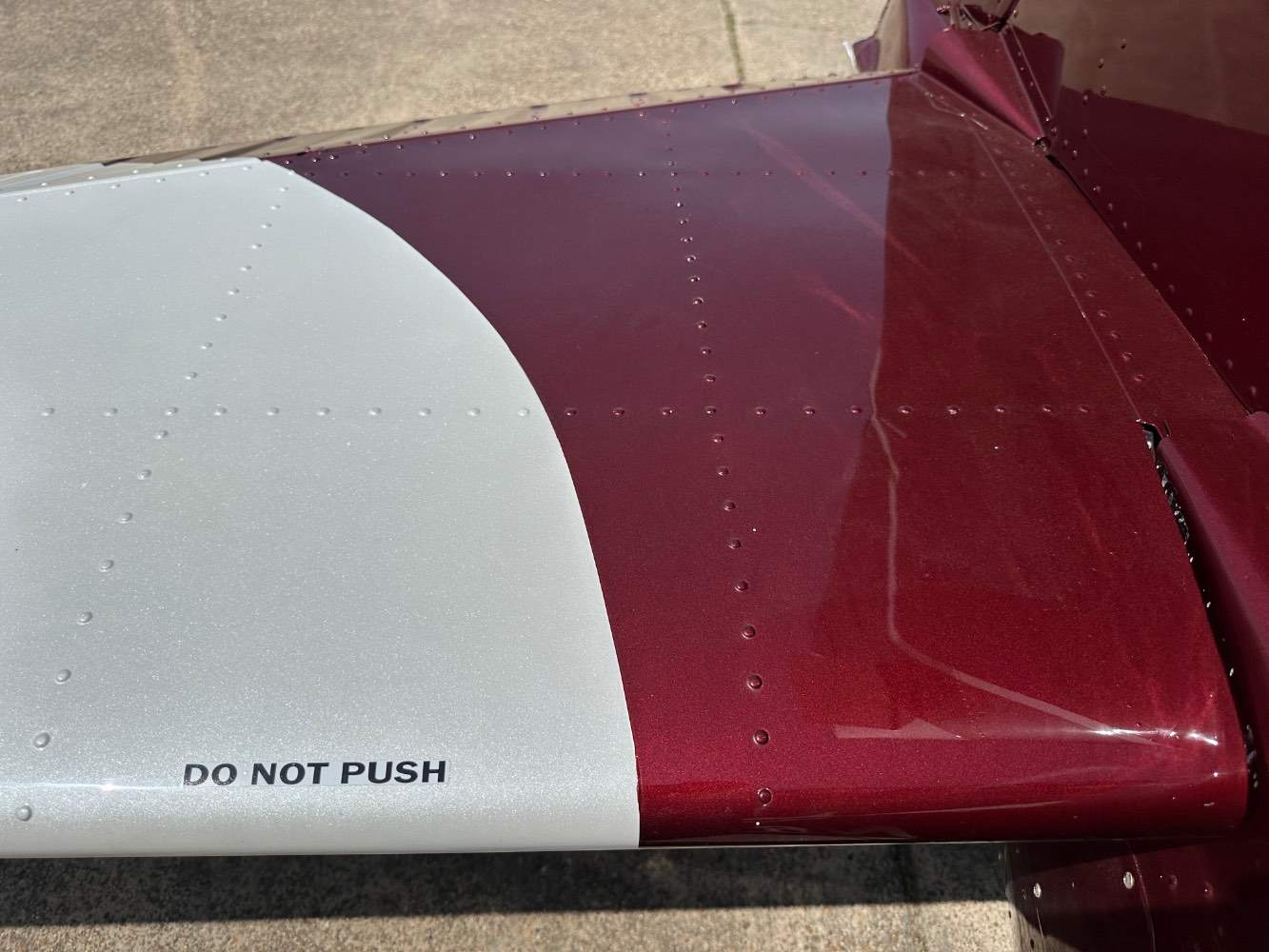

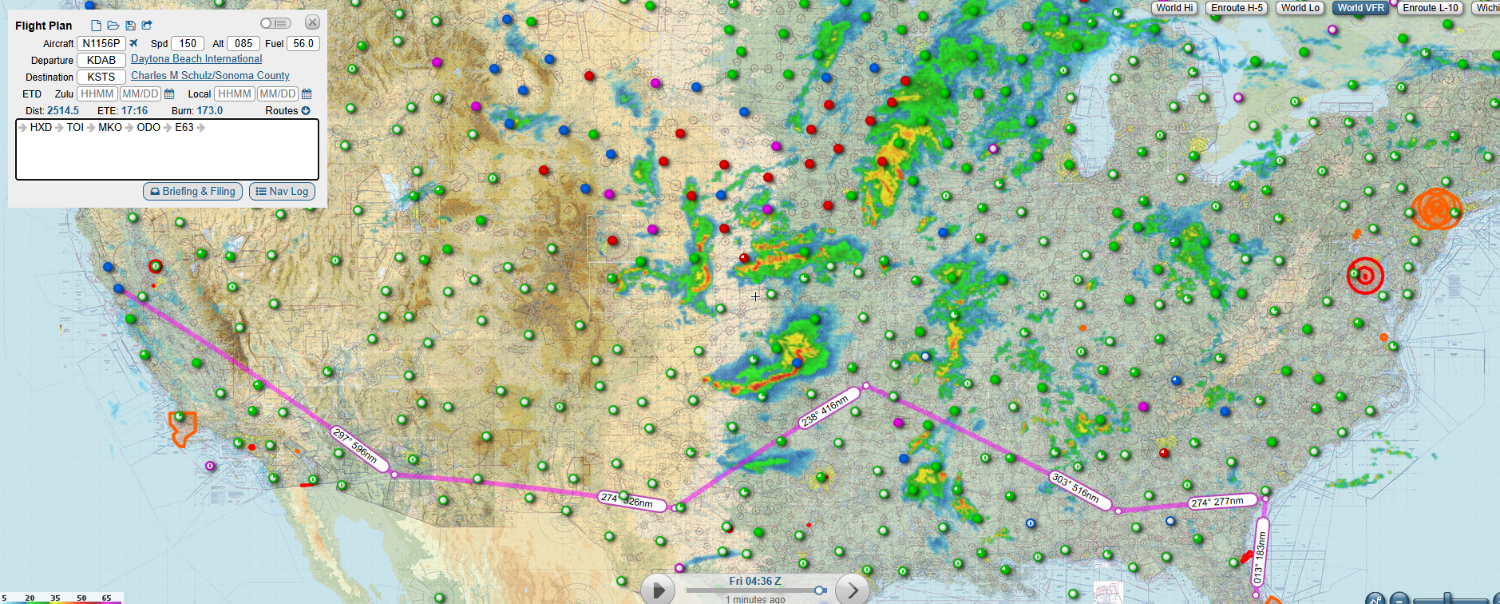

Strap in. I bring you a story of adventure, peril, and a bit of “there I was” with my recent purchase of M20J sn 24-1167, currently N1156P (Soon to be N707LT) You saw it for sale here: A seldom used M20J of a few 1810 hours. 0 time OH engine and prop, new paint, engine mount, tires and tubes. Original interior an panel. Looking for a new home from Fl. And I bought. Sure, a few questions, but it is a good deal so yada, yada, she is mine. Fast forward. We all have jobs. When do you have time? Not now, or now, but NOW! Time to fetch the new find from FL to CA. Overnight, delayed flights, lost luggage, finally land Orlando. Rent car. Drive to Daytona (DAB). Meet airplane and confirm I have not been catfished – it exists and isn’t a fantasy (of 6 figures tossed for fan mail) Wait for an hour for gas (because it is a training base for Embry-Riddle after all). Pay pre-purchase inspection bill (shout out to Daytona Air Service – great people), and become #12 in line for T/O. A moment: ME: 13,000 hr pilot. Current 121 B737, 135 current G650/G4. But first time ALONE in an airplane in 3 decades. I taught in these airplanes: How hard can it be? Well, my friends, neighbors and colleagues, your skills and patience will be tested. Especially in a new airplane over 2,400 nm cross county with the three time FLARE rule: one at 737 height, once at Gulfstream height, and once at “OMG this is LOW” height. After multiple landings, it wasn’t pretty, but no bent metal. I will be calling a local CFI. Short story: DAB-HXD-TOI-MKO-ODO-E63-STS. 2400 nm, 2 days. 9 hours first day, 8 the second. REALLY comfortable factory seats (thank God). Super-grateful for iPad and Sentry+ And a great deal of super-IFR/VFR skills involved. Let me explain. I used skyvector.com to choose the route. I chose cheap fuel spots. It was a fantasy because MA nature had other ideas. Day 1 was just up to meet a friend in HXB and landing was embarrassing. But I didn’t hurt anyone or bend metal. Day 2: Up at em and head West! But 400nm long line of TRW up the East Texas side through LA and AR. So I land short in TOI. Nice FBO, quick gas. New plan. UP North around the TRW and come back down towards Midland right? OK: lots of TRW, dip, dodge and weave at 8,000’ in the “not forecast East of the Texas Line”. Oh, but low clouds/vis underneath you for about 4 states. Thanks. Not ready to takle a non-turbo airplane over the Rockies/Sierras so Southern route is still the key. The FlightAware forecast: LIES: 4+20 if dipping and weaving around the most hearty of cells who didn’t want to be found – but they were there (like Artesians for those of a certain age). MKO: My first time self-fueling up in a while. I ran the truck in the old days: this self-service stuff is new, but I figured it out. Then, well, we are on the back side of the TRW, so let’s head for the original destination: ODO. Multiple overcasts, with MOA’s: NO, you can’t go right for weather but you can go as much LEFT as you want. Why would any military agency in their right mind want to fly in THIS? OK, you want it, you got it! I’ll go around and you in your T-38, F-16, F-18 can cry for help later. Actually feel sorry for the newbies trying to navigate this. Why the Hell would anyone head to Midland in their right mind? Because dear friends, I go there A LOT. Well, to MAF. But now I’m in a light plane headed to ODO. There are MOA’s to avoid, overcast with some good thumpers I’m trying not to get underneath. It’s quite the show. And by landing, it’s 9 hours of flight. And the young line man looks at me on landing and asks, “Want a hangar?” Oh yeah, the MOTHER of all TRW has parked itself South of MDW tops +510 so Yes please! I just bought this pure-skinned angel and don't want her BEATEN TO DEATH BY HAIL PLEASE. (Heck, she make it this far) This AM (4/24): I am up at 630, breakfast, UBER to airport, and there is my plane fueled and ready. Only real IFR to break through layer to E63: Gila bend. 3+45 I was there. Spoke to a really nice lady who was in her C-182RG just out foolin’ around for the day. You know what? It’s 623 nm to STS from here: I can do it. Damn Skippy. Across the American Southwest. Great controllers through Joshua, LAX, Lemore, and OAK. 4+23, 40.2 gal 4+23 later landed in STS. I now have my commute vehicle. Needs some radios. But the mechanics, interior and exterior are fine. Good deal. Glad to be a part of the Mooney community and have a literal 2 day cross-country machine. So friends and family of the Mooneyspace, I welcome you comments, contributions and patronage at my FBO's in OAK and STS. Dang: What a machine AL built!25 points

-

I had a mission to fly on Dec 26 from KGVL Gainesville, GA to KMKL (Jackson, TN). 267 miles. I have a known ice airplane. Looking at the forecast, MKL was above minimum, above personal minimums but would require an approach. The airport was in light snow that would end later in the day by the time of my arrival. Cloud cover forecast on Aviationweather.gov showed bases at 900' tops FL320. Freezing level near the surface. There was SLD icing above 13,000. Light to moderate icing below. After considering all things I canceled. Here was my thinking. I don't mind flying in forecast icing if I can bail out to warmer temps below and maintain MEA. I flew from BWI (actually KMTN) to GVL a week earlier and took a route down over RDU and CAE to do just that. Highest MEA was 3000', forecast to be above freezing. ATC wanted to route me out over western VA and NC but I told them unless I got what I wanted and filed I would divert to RIC. They granted me my wish. I was 2.5 hours solid IMC but had no worse than light icing. In this case on the 26th, I had no out. I could not descend into a non icing environment nor could I quickly exit it to the south as HSV (Huntsville, AL) had similar issues. The real range of a known ice Mooney is 1.5 hours. That is the amount of time you have running the TKS at max. Thus you must have no-ice conditions max within 45 minutes of entering, because that is the amount of time to get in, decide you are over your head and get out. You have to make your decision for turn back or turn out within 45 minutes of entering otherwise you are committed to the remaining time if you don't have "above MEA no-ice conditions below" and you have to be pretty darn sure about those conditions. I also could find no PIREPS on icing other than a Baron on the edge of the wx area over AR to the west reporting light icing at 9000. A look at flightaware.com (pirep by absence) revealed no aircraft below 10,000 feet and below 250 knots in the intended operational area. Equally so, a call to KMKL revealed no operations inbound, snow of unknown depth on the ramp and questionable runway conditions. Cancel. Finally a flight aware flight popped that met my requirement. A small commuter flight called "Southern Airways", departed ATL for MKL. Operating a known ice Cessna Caravan. It made Chattanooga where it executed a 180 and returned to ATL. A discussion with the MKL agent the next day (when I completed the mission) revealed he bailed when he TKS system was at max just to remain airborne. I made the right call. I post all this just to give you an idea of my personal decision making process, especially if you have a known ice airplane or are new to IFR flying. It is not enough to have a capable airplane, it is knowing what the real capability is and it's limits. Equally so, yes you can approach to 200' and 1/2 mile but can you stop on the runway? Can you taxi in and park? Always leave yourself an out. 625 points

-

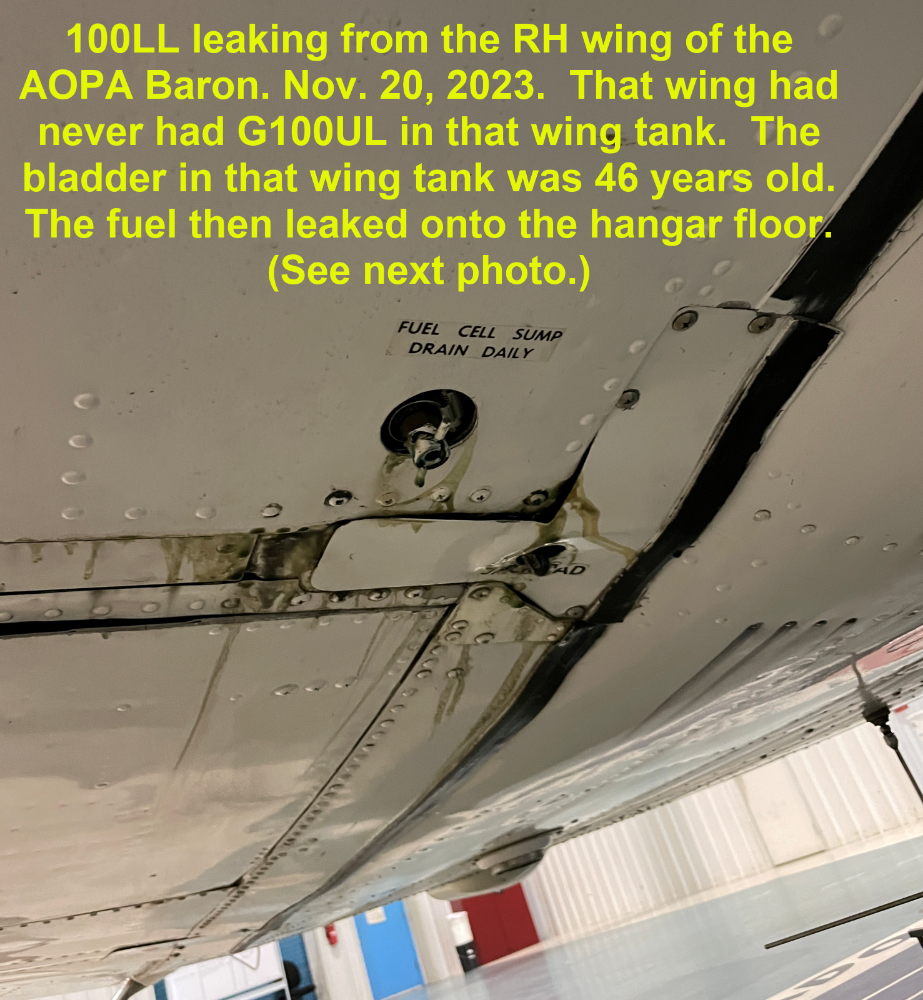

Very much appreciate the discussion and the feedback, here. Please allow me to provide a response to some of the messages. 1) I am a big Mooney fan. Flew a 67 Mooney Super 21 for nearly 2,000 hours. Commuted to and from law school in Norman, Ok. to the family Ranch (100miles each way) on a daily basis for 3 years. 2) Part I - - Some aviation fuel chemistry history: A- During WWII fuels with very large amounts of aromatics were adopted. Arguably, the Air War would have been much more costly in terms of losses for the fighter aircraft without the introduction of aromatics to aviation gasoline. The fuel approved for D-Day was "100/150" - - and used a lot of different aromatic components; B- In the ranking of the levels of "aggressiveness" as solvents, the ranking starts (most severe) with benzene. Then add a single CH3 group and you get toluene. Yes. Paint stripper you buy at the paint store. C- Add a second Ch3 group and you get xylenes (three isomers - ortho, meta, & para) Xylenes are significantly less aggressive as a "paint stripper" than is toluene. <== THAT is important. Keep that in mind. D- Many fuel bladders were developed during WWII and are labeled "approved for aromatics" or something similar. If you look closely at some of the P-51s and other planes at Oshkosh, you will see a placard that states "approved for aromatic fuels." Part II - - Post WWII. A- We had "Green" 100/130 with LOTS and lots of lead. And even purple 115/145 (with lots of aromatics) At the end of the piston airline and going into the late 1970s and 1980s, the ASTM folks decided to drop the lead content and created BLUE 100Low Lead. Still lots of lead. But much less than GREEN 100/130. B- Some of the refiners had very good "aviation alkylate" (~ 70% of some 100LL fuel formulations) with relatively high MON values for that aviation alkylate (a less than pure form of isoctane). Those refineries could make 100LL with relatively low levels of aromatics (almost always "toluene" from the paint store). Maybe 10-20%. C- Other refineries (P66 at Borger, Tx, for example) had lower MON quality "aviation alkylate" and the had to use a LOT of toluene. I can show you detailed hydrocarbon analysis (GC-FID) test results for local (Ada, Ok. FBO) P66 Borger, Tx 100LL that has 29% toluene and another 4% of other aromatics for a total of about 33% aromatic content. 3) Fleet Experience during the transition to 100LL - - A-Starting shortly after the introduction of 100LL, with high levels of aggressive toluene, A LOT of Mooney, Piper, and other airplane owners that had aluminum integral fuel tanks (no bladders) began to leak fuel out of lots of rivet holes. That started a whole new business for G.A. with companies initially specializing in re-sealing those tanks. Later, companies developed retrofit fuel bladders for those problematic "integral fuel tanks". B- A big part of the problem was the aircraft manufacturers did an "inconsistent" (careful choice of words) job of applying the polysulfide sealant to the interior (rivets and seams) of the aluminum integral wing tanks as they were manufactured. [As we have learned during material compatibility testing, the devil is in the details when it comes to the proper application of sealants to fuel tanks. ] C) Over the decades, the level of toluene from most refiners has decreased due to better quality aviation alkylate, but some refiners - - for at least some production runs - - still (from looking at their data sheets) still have a lot of toluene. 4) G100UL Avgas - - A- Uses a very high quality aviation alkylate (2-4 MON numbers higher than the alkylate used for 100LL) and then uses xylenes rather than toluene in order to achieve the 100/150+ octane/supercharge rating for G100UL avgas. The right choice of xylene isomers will have higher octane blending value than does toluene. Using "xylenes" also has the advantage of being less chemically "aggressive" than is toluene. But the high quality alkylate and the premium xylene isomers also "cost more" than the related components in 100LL. BUT - - there ends up being no lead. B- We did extensive material compatibility testing, including a whole variety of older bladders and a whole range of tests for sealants applied to aluminum. All of that supervised (in person) by multiple FAA engineers and managers and then later approved by the FAA. 5) The 100LL we have at the airport in Ada (typically Phillips from Borger, Tx) still tends to have a lot of toluene in that fuel. A- Late October of 2023, AOPA brought their 1965 demonstration Baron to Ada. Two freshly overhauled IO-520s. One fuel bladder was 46 years old and the other ~50 years old. They were supposed to have been replaced with new, prior to the start of testing, but the bladders were on "back-order". B- G100UL avgas was exclusively kept in the LH bladder and 100LL was exclusively in the RH bladder. C-Within 30 days, we noticed fuel "spots" on the hangar floor. Investigation - - we found fuel leakage and staining on the bottom of the RH wing - - which had ONLY ever had 100LL. See photographs. 6- Oshkosh, the leakage from the LH wing tank (G100UL Avgas) was ( based on Eagle Fuel evaluation) caused by pre-existing damage to the tanks and the gaskets associated with the access panels. (In addition, there were pin-hole leaks in both fuel bladders). 7)-G100UL Avgas is NOT a threat to normal aircraft paint. A- Embry Riddle did extensive certification testing of G100UL avgas. They used G100UL in their C-172s for over a year, at Daytona Beach. They had no evidence of any fuel leaks and they had zero staining on the wings. B- As part of our due diligence, wee have deliberately spilled a LOT of G100UL Avgas onto various painted components from the many Bonanza aircraft that come through the TAT shop for turbo systems. That includes LOTs of wing tips and the lower cowling access panels, both of which are removed and replaced (with tip tanks and newly louvered lower access panels.) C- Some of that has been allowed to dry on those painted surfaces and then the process was repeated. NO SIGN OF ANY LOSS TO THE INTEGRITY OF THE ADHESION OF THE PAINT. D- We have even soaked a couple of those side panels in G100UL for a week or more. The paint was fine at the end of that. E- What does and will happen - - is if you do not properly clean up the spilled fuel, and allow it to dry, it can and will leave a light tan stain on the paint. If you do properly clean it up, it will not stain the paint - - even after repeated spills in the same location. But, to date, we have never seen any evidence of any type of "paint striping" activity to any of the dozen or more aircraft parts that were removed from our customers Bonanzas and used as "test articles." See https://g100ul.com/dl/Refueling Hygiene G100UL Avgas.pdf F- An aside - - some of the recent crystal and graphene coatings improve the resistance of aircraft paint to any damage from any variety of 100LL or G100UL - - but that is not a cure all. See the link Refueling Hygiene! 8. So "what happened" on the bottom of the Mooney wings ? A- In one case, the sump drain appears to be leaking. Likely the fittings inside the wing are also leaking. B- In the other case, there appears to be some kind of leakage from inside the wing. Not sure from the photographs. C- Almost certain that old drain valve has a "nitrile" set of O-rings. D- The paint on the bottom of the wings has likely had many months of exposure to steady drips of 100LL. In California, probably with only ~ 15% toluene in the 100LL . . . maybe. E- No information about the age of the paint on the bottom of the wings, but from its overall appearance and the multiple rivet holes that are bare and which have lost their paint - - it is likely a they are rather old paint jobs. The paint on my personal Bonanza, N11RT is about 35 years old and it is in much better condition than the appearance of the paint (away from the damaged paint). F- It would be good to know the age of the paint for each of those two aircraft. 9. What to do ? A-There is a long standing FAA / maintenance bulletin (20 + years old ???) that tells mechanics that when they find fuel leaks or deteriorated fuel lines or gaskets or O-rings, they should replace those components with parts that are made from chemically resistant materials (viton, fluorosilicones, etc.) Those types of materials are specifically stated to be for use with a wide variety of fuels, including aromatic based fluids. A lot of mechanics have ignored that recommendation over the years. Last . . . 10. I would like to have the chance to borescope an older Mooney fuel tank that has not been converted over to a bladder. A- If anyone on this forum would like to bring their plane to Ada we can do that here. You might find it interesting. If you have the STC you can probably leave with some G100UL in your tank, if you want. I hope this information helps to bring some clarity and understanding to these issues that will be the subject of conversations during the transition away from leaded avgas. Regards, George Braly gwbraly@gami.com24 points

-

Got my practical test done today. It's been about 3 months of rescheduling for weather, conflicts, and rental plane maintenance but we finally got it done! Passed the exam a few weeks ago on my first try, and passed practical flight portion today first try. I got home and my mind and body have completely given up on me. I am couched.24 points

-

Last week we were at 4500' off the California coast by Santa Cruz. We were just starting Commercial training. Before doing any of the new Commercial maneuvers, I start by doing slow flight, then Power off and Power on Stalls. The airplane, a 231, has been upgraded to 2 G5s, and the GFC 500 autopilot. As such, when operating outside of the ESP (Electronic Stability Protection) envelope the ESP needs to be disabled in the G5. Additionally, the AP circuit breaker needs to be pulled because, if the airplane is operated outside the envelope with the AP off for more than 10 seconds, the AP will automatically turn on and engage the servos in LVL mode. I hadn't pulled the circuit breaker, but we had slowed to just above the stall and, unbeknownst to me, my student had used the electric trim to trim up fully. Pulling the CB disabled the electric trim. First, we found that the stall warning switch was inoperative, but continued the exercise anyway. Power was added to maintain altitude on the backside of the power curve and the nose was lowered to increase speed and lower the AOA. To relieve yoke pressure trim needed to be adjusted down. With the electric trim off the student tried to trim down with the trim wheel. It wouldn't budge. The student said that he couldn't control the pitch with the yoke, the force was too strong. At that point I added my control input to the yoke. The force was so strong that with both of us locking our arms straight out we couldn't overcome the pitch up force. I tried to unlock the trim wheel with both hands--unsuccessfully. In all of my flying I have never had a flight where the outcome was in doubt. But for a few seconds that's exactly what I thought. Knowing that the 231 is somewhat nose heavy and on final at 75 knots with low power setting on a 3° slope the plane was controllable, I pulled the power. That did relieve some of the control pressure. I tried to unlock the trim again with the trim wheel. No dice. It was totally locked up. We were on flight following with NORCAL, and I was about to declare an emergency, when I decided to turn the AP on and see if the power of the trim servo would unlock the trim. I pushed in the CB and waited while the system went through its PFT. It took a few seconds, but ultimately finished successfully. I had the student try the electric trim---and it worked. The trim became unlocked. We had dodged a bullet. I said, "Let's head back to San Jose. We're done for the day". I got no argument. Epilogue: I told the student that until we found out the reason for our issue, we wouldn't be flying the plane. The maintenance shop was able to recreate the problem. I called Paul Kortopates and related the issue. He told me that a Service Instruction had been issued on December 14, 2016, SIM20-88A Stabilizer trim stop screw Modification. I've attached it here. It applys to the M20J, M20K, M20L, and M20M. It was to be done within 100 hours. On this airplane it apparently had not been done, so the force of the electric trim on trimming up for slow flight had pushed the trim wheel past the stop and locked it up. I'm posting this because for those owning aircraft to which it applies, you should confirm that it has been complied with. Otherwise, you might be put into an unrecoverable situation the likes of which we were lucky enough to have overcome. SIM20-88A Stabilizer trim stop screw Modification.pdf23 points

-

Yeah. That was me. Dead sticked it from FL210 through the clouds, icing, in the mountains, and broke out at 1500 agl. All I had was this road so I put her in nicely. There happened to be a bit of water from the left tank (just switched tanks). The water went into the fuel flow divider and froze. -36 C OAT. When the water froze, it expanded and shut the flow of fuel to all cylinders. No possibility for restart. I let the plane sit for three hours as I dealt with the local sheriff department (who were excellent btw). Fired her up. Run up was perfect so I flew it outta there. lol. Another day in the office. I’m now working g with the FAA, continental, and another shop to remedy this issue.23 points

-

Some of you might remember me. Back in 2019 Signature over torqued the front gear of my brand new Acclaim Ultra and refused to pay. 5 years later, I face them in court tomorrow. They are risibly stating using a huge boom was not an issue and that it’s my fault. I haven’t cowered. I covet your prayers. These guys are nasty. On better news, I now fly a Honda Jet. This is more accountability than anything else. Cheers, tail winds, and Gods overarching presence to you and yours.23 points

-

Hello to all my friends at MooneySpace! I haven’t been here for a while since I sold my Acclaim in 2018. I sold my RV a couple years later and haven’t flown since. I just wanted to give you all a shout out from Mexico. My wife and I are retired and we moved here about two years ago. We split our time between Puerto Vallarta and San Miguel de Allende. I really miss flying Mooneys. Did so for 25 great years, as the proud owner of an Encore and then an Acclaim. I hope all of you who are still flying are keeping the flame alive and enjoying these incredible aircraft. I’d be curious to know if any of you have ever flown your Mooney to Puerto Vallarta? I flew my Acclaim to Cabo several times, but never to anywhere on the mainland. I get a tiny taste of aviation every day because the skydiving concession in Puerto Vallarta is right next door to my condo. They land about 40 single and tandem jumpers on the beach in front of me every day. Pretty neat. Fly safe, my friends, and enjoy your Mooneys! Saludos, Joe Zuffoletto, aka José de México :)23 points

-

My grandson soloed a few weeks ago in our Citabria making him a fourth generation pilot. I told him he had to learn in the Citabria, but he will have access to the Mooney for his instrument rating when the time comes. He got his drivers license two days after turning 16 and soled the next week. He also has discovered girls. He will find all three pursuits expensive! lee23 points

-

23 points

-

Just a quick report that I got my Acclaim Ultra back from annual yesterday from the Factory Service Center. My observations: The work was outstanding and reasonably priced. They kept me informed along the way. They found things that other shops had missed. They test flew the aircraft when they finished. I flew a 1400 mile trip yesterday with no squawks. Kerrville is a nice town. Mooney is very much in business.23 points

-

I have not been doing much flight instruction work over the past few years, but I have noticed a couple common occurrences recently, both on flights and on various social media posts (Facebook, in particular). It seems a pilot will complain about the airplane not settling down, yet their approach speed is correct (such as 70 KIAS for an M20J). Here are the things that come to mind when I hear this: Observation 1 - Idle RPM set too high. I was flying with a client and he couldn't get the plane to settle. I said "let me demonstrate one". So I take it around the pattern and have the same problem he had. We taxied off the runway...I think his idle RPM was 800-900. It's quite possible you may know exactly what to do and, all things considered, be using correct pilot technique. But in reality, a high idle RPM could be forcing bad results, or worse, forcing you to use to bad pilot technique to get a desired result. Observation 2 - Not closing the throttle all the way. This one is often recognizable to me by sound. A pilot sets up a very good final approach attitude, airspeed, glidepath, etc. Everything is great...until the end But in the flare, the pilot hasn't completely closed the throttle control. The pilot may not be able to experience a full flare unless he spends an exceptional amount of time floating down the runway trying to bleed off airspeed. "Ballooning" is often the end result leading to either a go around or wasted runway as corrections are made. Note on your next flight - Check your engine idle RPM after the engine is fully warmed up. You may find your idle speed is too high and spoiling your otherwise great flying technique. - Make it a point to feel the throttle control reach its "closed" limit before you touch down. Happy Saturday! Insurance is fine and all, but it's nice to talk about flying.22 points

-

I have flown quite a few Angel Flights in the last couple of years. I do it for the same reasons I fly - I really enjoy it - and Angel Flight is a way to help others. But someone told mom and today I feel like the kid caught with his hand in the cookie jar, vaguely embarrassed. A few weeks ago I was informed that I need to make my way to Angel Flight Central’s gala on Nov. 18 in Kansas City, there to receive AFC’s 2022 Pilot of the Year Award. Then today I was surprised to receive a call from the CEO of the National Aeronautics Association. At a ceremony that will likely be held at Oshkosh next year, I am to receive the NAAs Distinguished Volunteer Pilot Award. It’s a good thing I was not flying when I got either piece of news, I probably would have put it in the ground. My aircraft, as many of you know, is nothing special. A 231 with an engine now well over TBO, oil leakage from the rocker covers has reached the incurable stage, we are waiting for a new Conti to show up. It is Mooney’s most manual version of a turbocharged piston. And yet I have safely carried well over a hundred patients and their companions, all shapes, types, and sizes, even found a way to cram a collapsible wheelchair, the patient, and patient’s mom into the plane (definitely within W&B), and on occasion, cargo to the weight limit of the aircraft. We need more folks. If I can do it in my lowly 231, you can do it!22 points

-

I decided to fly my 1994 M20J MSE to Sun 'n Fun this year despite the terrible winter. It's got to get better, right? Got from the Seattle area to Twin Falls for fuel on Monday the 27th and then stopped by snow showers. Made it to Shreveport LA the next day via Santa Fe for fuel (the Santa Fe terminal is still under construction and will be until Sept.). Wednesday morning the airplane started very rough with #1 cylinder not firing. Clogged injector or stuck valve? 350 hours on a factory rebuilt engine, so I guessed injector. Went to local auto parts store and got a wrench and some carb cleaner and cleaned injector. No change. No local mechanic available; apparently he only works when he needs beer money. Shreveport is only about 70 miles or so east of Longview TX so I called Don Maxwell who immediately swung into action and sent Mike to rescue me. He staked the exhaust valve in #1 which got it running and I flew it to Longview where Don and Paul and Mike performed the rope trick (they like to call it Rope-a-Dope) and reamed the valve guide. Don graciously loaned me his truck which I repaid by filling the tank. Great guys, the Maxwells. I didn't see Jan, but she is reportedly busy planning MooneyMAX. I gave up on Sun 'n Fun due to the weather forecasts and frankly I was a bit beat. Flew to Payson AZ and visited a friend that moved there form southern CA and built a great home. Then to get back home. With the weather so bad in the pacific NW and the freezing level down near the surface, the only reasonable route for a non-turbo, non-FIKI airplane was low up the coast so I stopped in San Jose CA to let the weather clear a day and then flew home. There were a few low clouds and heavy rain showers along the coast, but nothing like what I flew in in Ketchikan when I flew Beavers up there. The only glitch was that the FBO at San Jose broke a stop off the nose gear towing it. But, Mooney has the part in stock and I'm letting the insurance take care of it. About 30 hours flying to not get where I intended, but as I told my wife, if I really needed to get there I would have purchased an airline ticket. The journey is the adventure. Skip21 points

-

21 points

-

Suggest making your enroute stops at larger airports with luxurious FBOs and expensive fuel. I know this is contrary to official Mooney CB doctrine, but bear with me for a minute... Early in my family flying endeavors, I dutifully planned XC trips with small airport/cheap fuel stops enroute as a GA loyalist. Doing so effectively ended my wife's interest in GA flying for about a decade. There were a couple of incidents of sitting around at run-down facilities waiting on weather with no Uber/Lyft/cab service that didn't sit well. The last straw for her was my cheerfully diverting for an unplanned potty break stop, but choosing a tiny little airport that turned out to have not even so much as an accessible porta-potty, requiring her to drop trou in the open air. That was 20 years ago, but it's still the first story she tells every time traveling by GA comes up in our friend group. I want to emphasize that my wife and kids aren't high maintenance types, and in theory they're all about adventurous travel. But everyone has their limits, and statistically, GA flying is at the edge of what's fun for most people who aren't actually flying the airplane. She still flies with me on occasion, but we're not really a GA travel family, and I trace it all back to my choice of stopover points when I was young and enthusiastic about GA flying. These days, if I'm traveling with anyone other than another pilot, I'll happily buy eight dollar avgas and pay ramp fees in exchange for comfortable lounges, free cookies, on-the-field maintenance, nearby nice hotels, readily available Uber service, and so forth. The monetary cost is incredibly cheap relative to the emotional expense of a bad travel experience.20 points

-

Thanks to all who lend their wealth of knowledge and experience to beginners and novices like me. I will always love my Mooney and Mooney community. Best of all things in the new year to you all! ps. Let us commemorate with retiring the dumpster fire that the garmin pilot thread has become!20 points

-

This sure is a cynical group. Personally, I would rather have expensive-but-available Mooney parts than cheap-but-unavailable parts. I only rarely need actual Mooney parts but when I do need them, it's usually something standing between me and actually using my airplane.20 points

-

I just got off the phone with Mr. Pollack (Mooney CEO) there IS an agreement that will allow for the manufacture of the 40:1 Gear Sets that we have been hoping/waiting for. The Authorized POC will be contacting me within the next couple of weeks and I will get the cost and timeline information and share with the group as well as the order process. This is GREAT news and wouldn't have been possible without Mr. Pollack's willingness to put in the (unpaid) effort to make this possible. I appreciate everyone patience and encouragement during the process that got us to this point. More to follow once I get more information. V/r Matt20 points

-

Hi, Friends! After a year of panel, interior, powertrain, and other updates, I have finally picked my 67 (68) M20F up from the final major planned maintenance - paint. Mural artist Matt Kress, in conjunction with Ace Aircraft Refinishing in Bartow KBOW, extended his artwork to an airplane for the first time. After a brief planning discussion, all artistic control was given to Matt... and one rule - I was NOT allowed to receive any visual updates (my idea). The 'unveiling' was this weekend and I could not be happier! Allow me to introduce "Anomaly."20 points

-

An OP takes a moment to share a fairly excruciating if not traumatic experience with us here at the board that involves death, family and children. Then by whatever methods, the thread is allowed to devolve into a pissing contest. As a community, i find that in terribly poor taste. A thread of this kind should genuinely be about providing an ear for the OP, supporting the OP, lending a helpful hand, and hopefully not pulling out the rulers for appropriate measure. There are hundreds of other threads for that. IANAL, and what’s typed is strictly my own opinion.20 points

-

I don't know what to tell you Walt. Sorry you are having those bad experiences. Not all shops are out to rip you off. I have worked in aircraft maintenance for over 35 years mostly on the airline side as a Chief Inspector/Director of Quality Assurance. Now I run a part 145 repair station maintaining a fleet of flight school aircraft as well as doing outside customer work. I try to run our shop the same way we ran the airline maintenance department. We have a great budget and no reason ever to cut corners for any reason. The outside work is really just filler and to keep things interesting for my maintenance personnel but we approach maintenance on those aircraft the same way. We don't need the outside customer work to keep the lights on or make payroll so I try to be very reasonable (actually more reasonable than I should) on everything. We don't up charge parts or charge extra fees for anything. What has really been an eye opener for me are the aircraft owners. Someone has an expensive nice aircraft, pays thousands of dollars in hangar rent and insurance every year (I know this because I have my own aircraft), wants their aircraft fixed NOW, and then gripes about every little thing on their invoice. Meanwhile they are buying things like a $3200 EIS system on a carbureted O-360 so they can save gas because they went to Oshkosh and the salesman told them they would save 10%. And don't tell a customer a flight control bracket that you found cracked and broken during an annual inspection costs $400 (Used. Again my cost, no up charge). You would think the whole world was going to explode... Even after you show it to them I get asked, "Well isn't there a cheaper alternative"? One would think they would be pleased it was found before it let go in flight. You bought a 50 year old aircraft for goodness sakes for over $100k and you pay over $7 for gas for it! You want to it ready to fly every minute of every day. Did you really think it was going to be inexpensive to maintain it? Do you really want the maintenance on your single engine aircraft to be "cheap".20 points

-

Hello all, After a rough couple months of spam-bot invasions I have decided to make some critical changes to the way new users to the community are validated and how Supporter level memberships work. Here are the key changes: When a new account is created here it will be placed in a group called Unverified Members. This group can browse the site but cannot create any new content. To upgrade this account to a Verified Member you have two options: a) pay a $2 fee for instant validation which is good for the life of the account or b) contact me @mooniac58 with a picture/scan of your valid ID to prove you are who you say you are. The old manual $10 minimum donation for upgrade to Supporter level has been replaced with a $25/year automatic subscription system that will renew every year on its own unless you cancel it. No more waiting for me manually upgrade your account, etc. Those that purchase the $2 instant validation will get a $2 credit towards their first year of Supporter level access...so $23 for the first year and $25 thereafter. Generic Donations: Separate from the membership plans, users can still donate arbitrary amounts to support the site using the new donations page. Those that donated prior to today with the old system will continue to have Supporter access until 12 months from your last donation as long as that was $10 or more. These are the current membership levels for members: Unverified Members - New accounts, can browse site, cannot create content or message others. Verified Members - Either paid the $2 fee or proved in another way that they are a real person. Can post new content but not in classified forums. Limited to 200MB total storage for attachments, photos and other files. Supporter Members - Signed up for $25/year subscription. Do not see advertisements on site. Able to post non-commercial topics on the classified forums. Storage limit of 1GB. Sponsor Members - These accounts have paid a fee to have a limited number of commercial posts on the forums (usually 1 per month limit). Some final notes: While I am confident new spam-bots are not being registered on the site, I am quite sure that they have dormant accounts that were created in the past that still exist undetected. For this reason we have and will see brief uprisings where they rise up and make a bunch of spam posts. We will ban each of these as they occur and wipe the content. I don't expect much of this and the past few days have been clear skies here. If you created an account prior to August 5, 2025 and did the normal email based activation then you are in the Verified Member group. No one was downgraded during this process and you don't need to do anything to validate your account. Please do not do the $2 validation process (I am still working on hiding this option for everyone except unvalidated accounts in the site). I will be making small changes here and there to try and make it more clear how new users validate their accounts. For now I hope newly registered members find their way to this topic to get the instructions. Eventually I hope to figure out how to customize the site more to guide new members through the process better. And lastly a big thanks to everyone who has supported this community over the past 17 years! Craig19 points

-

19 points

-

Hi Goalstop - my name is Kyle, a fellow M20E owner and Garmin employee. Can you possibly pass along the details directly to me please? Kyle.Ludwick@Garmin.com. We would like to help with this issue! Apologies in advance for the trouble you've gone through. Kyle19 points

-

This happened quite a while ago but it's only now that I'm willing to bring it up. I was flying my 77 J enroute from CYTZ to my home airport CYXL on Jan.31 2025. It was a 650nm flight over mostly remote part of Northern Ontario. Roughly three and half hour into the flight, about one hour from reaching my destination, in the vicinity of Nipigon Ontario, at a cruising altitude of 5500ft, the engine started to sputter. I immediately turned boost pump on and then my engine quit completely. I acted upon the situation as everyone would, I was lucky that there is a highway right below me, and I quickly turned my plane gliding alone the highway looking for a suitable landing spot. Then I tried to trouble shoot the problem, and declared mayday on both Center frequency (but I'm on the edge of their reception) and 126.7. Oil, fuel pressure were in the green. I had plenty of fuel. Propeller was windmilling, there is no oil spraying everywhere or any catastrophic failure. I even had fuel flow, though only 3-6 gph. But I had no power. Engine monitor show all four cylinder cold on EGT. I tried both mag, didn't switch tank because I already ran one dry, and determined I cannot bring the engine back. The subsequent landing on the highway is uneventful. Clipped two small roadsign during the landing roll, but I'm fine and the plane is now being repair in Toronto, after a temporary repair was carried out in the field and got a ferry permit from TC. The landing happened just before sunset, temperature at landing was -20c. If it would've happened ten minutes prior or later, I would've end up landing on a frozen lake. That was the only highway along my route for almost 300 miles. I think I got lucky here. After landing, I checked the oil, sitting exactly at 6 qts. I spun the prop and noticed smooth movement with no issue, and normal compression in all four cylinder. I then checked my fuel tank and I could see plenty of gas. The only thing abnormal, that I noticed, was when I turn on the boost pump there is a strong smell of fuel. During departure out of CYTZ, when I turn on the fuel point in the takeoff check, I also smelled a whif of gas but I did not thought to much about it. Shortly after, police, fire and ambulance arrived, though I do not require fire and ambulance (luckily I don't need to pay for ambulance). A snow plow came, plowed out a side road and move my plane there, where it sat for two month getting the wing patched up and a ferry permit issued from TC. A local float plane company sent a few mechanics and inspected the engine. They found the fuel line out of the engine driven pump to be loose at the connector, causing a very significant fuel leak. The reason why it is loose, according to the mechanics, is likely because the fuel line with fire sleeve over it was rubbing against the firewall, loosening it over time. Both mags are firing properly and sparks are produced on all 8 plugs. I'm not sure how much I believe this theory. Since during the flight, I ran the right tank dry, and my fuel accumulator read exactly 32 gallon used. The fuel flow transducer is located after the leak, so if there is any leak, I'd ran out of fuel before my fuel accumulator reaches 32. The mechanic in Toronto that usually worked on my plane said it might be due to some kind of icing issue inside the injector servo or controller or something like that, and the float plane mechanic did agree that it's also a possibility. He says I should not loose power completely if I still have fuel flow and green fuel pressure. To add, I did sump my tank in Toronto and noticed no water in fuel, and fuel cap o ring is fairly new. It was noted the boost pump was functioning properly providing proper pressure with no leaks. They removed the fire sleeve on that fuel line, reconnected the hose properly and ran the engine up, and it ran fine. So we eventually flew it out to toronto for permanant repair on the wing with a fueling stop in Thunder bay. Now the plane is sitting in my mechanic hangar in Toronto, I've asked my mechanic to thoroughly inspect the engine again, which I asked him to do last time when I was dealing with the prop governer fuel leak isssue. I'm really not sure how do I trust this plane again. For the past year that I've owned this airplane, I was always on the way of fixing something. The engine was looked into at least twice under my request to make sure the pervious owner's mechanic who installed the engine did not make any more mistake that's not yet discovered. Just sharing my experience here. I guess from now on I will use 1% alcohol added into the fuel to prevent icing. I'd love to hear everyone's thought's on this.18 points

-

Yeah Ethan, great question. Emergency situation not much time. I wanted to go to enterprise. It was on the rum line and had a good tail wind. Pretty sure I could have dead sticked that runway no worries. Seattle Center advised not going to those airports as they were IMC and higher terrain. La grande was 90 degrees off my right wing and right into a headwind. It was a tough call, but I figured I could drop in the valley and find something suitable. So I turned for La grande. I’m my own worst critic. The one thing I didn’t do is declare an emergency. I told Seattle center that I had “loss of engine power and could not maintain FL210”. The controller and I ended up arguing a bit over a few details on the way down and it just made things mores stressful. And at 8000 feet he said the frightful words “radar contact lost”. I said out loud, “Brad, do some of that pilot shit!” Lol. I followed a canyon on the terrain page of the MFD and prayed to God that I’d break out. And He graciously gave me 1500 ft. And a dirt road with power lines and an eagles nest. Good enough for me.18 points

-

18 points

-

18 points

-

I want to thank everyone for the advice given to me that helped to make this happen! I bought a Mooney! My instructor and I were flying the flight school's Warrior and flew to a nearby airport. As we were taxiing back to head back to the runway I hit the brakes and pointed out the window "wow, look at the paint on that Mooney!" My instructor was pretty tired of hearing about Mooney this, Mooney that, so she said "you're such a dingus" and we kept rolling. Later that day I pulled up Controller to drool over Mooneys, and that exact one showed up for sale. I couldn't believe it. It was way over my budget too! A few Google searches later and I happened upon Mooneyspace and a guy had a sort of "near miss" with buying it. I reached out to him and he sent me the Prebuy information that he did, as well as the local Mooney Expert's information. Really nice of him to do that for me. I met with the owners and they were just the kindest people ever. Couldn't ask for a more lovely couple. The plane is a 1968 M20F, it isn't perfect but it is WAY nicer than what I thought I would end up getting. Some faded paint and minor issues, but nothing major. It's under an hour drive from me, and the A&P that did all of the speed mods, and maintained it for a good 20 years has a shop just 25 minutes from my house. Everything has lined up so well. I'm still in shock, and so excited. Today I have the keys! The owners kept every receipt and picture, so I have some nice pictures of it as they put some speed mods on it. I don't think I'm going to get any sleep tonight...18 points

-

I know some people here have much better machines, but my trip yesterday was an eye-opener to the capabilities of my E model. Took off from KRKS (Western WY) at 10am, and five and a half hours later landed at 91C in Eastern WI, crossing five states (WY, NE, SD, IA, WI). 993 miles non-stop at an average speed of 190 mph, burned 46 gallons of fuel at 13,500 feet. Of course tailwind helped (around 25kts), but I still feel amazing about it. I used oxygen all the way, and felt none of the fatigue I used to feel after flights above 10k. Here's a picture of one of the more spectacular buildups I had to dodge along the way.18 points

-

I purchased my '67F N9611M a few years ago and have flown the pants off of it, going from my home base of Mexico City to Airventure (2x), Victoria BC (6x), the Caribbean, lots of places all around the western US and all the way up to Yellowknife NWT via Saskatchewan. I've flown N9611M over 650 hours and that means I've spent a bit more than that inside of her. As cozy as she is, she was in need of a little help. While the seats, carpet, and lower upholstered panels were re-done by the previous owner, they left the plastics as-is, cracked in some places, ruptured screw holes in many places, and a general yellowing effect which didn't look great with the brighter upholstery. Below is a photo of the original interior: As you can see, the previous owner decided to leave the original upholstery on the arm-rests and the "vintage" plastic panels look a little dated. Frankly, had the panels been structurally sound I probably wouldn't have touched them but hours of long x-country flying had taken their toll on the arm rest seams and from time to time my elbows would get pinched from the open seams. I also had a theory, still to be tested, that the panels in their condition were letting a bit more noise into the cockpit than originally intended. With all this in mind, a couple of months ago I began the process of disassembling the interior of the aircraft in order to move all of the pieces to my workshop and begin the restoration process. This was the second time I had removed some of the interior, the first being during my pre-buy, but this interior removal was certainly more thorough and involved more electrical connections and visits to Mooneyspace to figure out how to get those darn circular vents off. The de-install went well and I found an airframe still with zero corrosion and only mildly decaying foam fiberglass insulation and foam, generally in pretty good shape for an old bird! Once at my workshop, I surveyed the damage and found that there were three intact panels in total, all window frames, and the rest had some form of cracks, punctures, or other deformations with the worst offenders being the footwell side plastics, the ceiling panel, the door, and the pilots side lower panel. In my research, I had found that there were two main schools of thought when repairing and re-beautifying the panels. One, was to follow the Aero-Comfort system of reinforcing the panels and then covering with a fabric or leather. I had spoken to Hector a couple of times and was impressed with their product and found him to be knowledgeable and helpful, however I really enjoy my 1000lb+ useful load and wanted to add as little weight to the aircraft as possible. While super-lightweight coverings do exist, and would have solved another problem with the window joins (which I'll get to later), the weight consideration, getting FAA approved products into Mexico, and cost all played a factor in deciding to restore the panels via option two. Option two, which I went with, was to fix the panels from behind, and then paint. The trick would be to figure out how to fix them so that they wouldn't break again, at least not for a long time, and then how to paint them in both a color and sheen which fit with the existing upholstery scheme. First thing to figure out was what material we were working with. According to the manufacturer, Spartech, it's ABS plastic. Yes, there are some special mixes and flame retardant elements in there but it's ABS. The next thing to figure out was the best way to repair ABS plastic. After exhausting the interior plastics threads here on Mooneyspace which all offered different options for plastics reinforcement including glue, fiberglass, and tape(!) solutions, I turned elsewhere for inspiration and found it in a lovely video from an Australian gentleman. It seems that the best way to reinforce ABS plastic is with ABS plastic! Being in Mexico City, it can be difficult to acquire the right, certified materials for any job and while they do exist, proper caution is wise. Case in point, after visiting a construction market to purchase ABS welding rods, I tested the rods and found that they were smoking considerably on a piece of test material. When I returned to the market to ask the vendor about the product he'd sold me, he confessed it wasn't pure ABS and instead had a PVC mix at somewhere around 15% which was causing the smoking and would have resulted in an inferior repair. I had read somewhere that Lego blocks are manufactured out of 100% pure ABS plastic, and so went off on a hunt to dig up some white Legos. Luckily, Mexico City has a lot of Lego and just around the corner from my house was a Lego seller with several 40 gallon drums filled with used Legos, sorted by color. Scoop! After bringing back the legos and verifying with a test piece, I started to weld the panels back together. Some photos below showing the extent of the welding pre-sanding. Below you'll see a before and after sanding of a hole repair. And a couple of shots of the footwell panels which were quite damaged from years and years of use. Special note: these panels were especially de-formed and I was able to straighten them using a heat-gun on the low setting before then welding them. I'm not sure how to post my own videos here but I have some nice ones of shaking the panels and flexing them to try to break them again and they're flexible and strong as can be expected. The only time I managed to re-break one was when I flexed it on a non-sanded weld. Maybe it was the thicker plastic section hitting the thinner section at an angle? With all of the panels welded and sanded, it was now time for paint. I chose an oyster white to soften the appearance of the interior and went to work. In the first picture, you can see the difference in color between the yellowed original panel, the original color seen where the strap covers had blocked UV exposure, and one coat of the new color. And below is all of the panels laid out for painting, with the floor panels in the bottom left playing around with colors. After rattle-can coats of paint on each panel, they were ready for install, and yesterday I went out to the plane to begin assembly. I'm re-doing the headliner but have been itching to fly so thought I'd put together the plane to see how things look before final assembly. And once again, the before picture for reference. Installed, the panels look very good. There are a couple of paint imperfections, mostly in deep corners, and I think a better paint product (or maybe more skill on the part of me, the painter) would have solved this issue. That's where I've gotten for now, next up is: headliner and ceiling panel install de-install of the panels to upholster the arm rests with the same material as the seats install of freshly painted passenger headphone jack covers (more on that next time) sourcing and install of those thin window joining strips I'm looking for help with adhesives recommendations for both foam to aluminum and foam to vinyl, as well as if anyone knows where to find those little strips which go between the windows?18 points

-

Here's an idea; limit your legs to 2½ hours. Never had a bathroom issue with that. New airports, new experiences. Quick stops, get out and stretch your legs. You're refreshed for the next leg.18 points

-

We just completed "Phase 2" of a 3-Phase modernization of our 1965 M20E. The first phase was redoing the panel last year which included a JPI 930 install, CIES senders, all new circuit breakers, new Garmin GMA 345, new Garmin GTX 225, IRANing the 430W, new engine controls, all new switches, a new, powdercoated and laser-cut 1-piece panel, new headset plugs, new antennas and digital coax, and a few other odds and ends. Phase 2 is the interior, and we chose to go with AeroComfort due to their stellar Mooney reputation and first-hand experience with one of their planes and oh man am I glad we did. As most here know, Hector is absolutely fantastic to work with, and the whole project was on-time and on-budget. We did a full interior with them and dropped the plane off at SAT to let them do the install. Along the way, we installed Alpha Aviation inertia reel seatbelts, replaced all the insulation & soundproofing with new, and had a custom leather wrap done on the yokes Hector recreated from a picture. I'll let the pictures do the talking... PICTURES BEFORE / AFTER COMPARISON18 points

-

My wife and I had a great time at Air Venture. After having the plane painted I decided to have it judged this time around and we came away with the Lindy Award for Outstanding Mooney in the Contemporary (1956-1970) Category! More pics over on the (newly redesigned )blog. https://intothesky.com/2023/07/30/oshkosh-2023-in-the-books-with-an-award/18 points

-

Just wanted to throw up some pictures of my 65’ E interior job. I’ve been working on this on the side while I was doing my panel upgrade in 22’. I ordered SCS carpet in brown and Airtex upholstery in biscuit (ordered at Oshkosh, delivered in Dec). Seatbelts were down by Aviation Safety Products in GA who did an awesome job and about one week turnaround. My wife did the vinyl work using our Sailrite sewing machine including the boot around the controls (post 65’s got that plastic cover), wind lacing around all openings, and the armrests. My aircraft did not have the headrest built into the seat structure, so I fabricated them out of a square tube, 1/2” diameter aluminum tubing , then riveted it all together. All of this was way more work than anticipated, but that’s airplane sh#t for ya…..18 points

-

I'd suggest not lifting a finger to help these plaintiffs lawyers at least until there is an NTSB report firmly implicating a spark plug failure. Those vultures latch on to anything that might have happened that could be traced to a manufacturer of in order to leverage a windfall settlement, and they succeed far too often based on the most tenuous evidence. They do little to serve justice but are a major contributor to our operating costs.18 points

-

The park was gorgeous. I put on a 360 mount to do some recording, and it turned out great. We only flew in it for an hour. We went up Ruths Glacier, flew around a little in that area, and then spiraled up to pass Denali, then down another glacier (not pictured). Most of the other passes were fogged in, so we kept it pretty conservative. The other pilots flying were super chill and gave us tips. I kind of wish I had recorded that. Overall, I wish we did it longer, and I wish we could do it again. The weather is shot for the next few days, and then we need to head back to MN. I forgot the cowl flaps on some of this. I climbed from 6,500 to 16,500 and forgot to close them when we reached the top. Oh well.17 points

-

In my information consumption of the Richard Mcspadden fatal accident, I came across this excerpt. I heard it, in his own words, in the last two minutes of the most recent AOPA Hangar Talk Podcast, dedicated to his memory. It was striking enough that I felt it useful to transcribe his words into text here. Please excuse the grammatical exceptions, used to enunciate his words. Well said indeed. "Gratitude, consumes me when I fly my Super Cub. This bright yellow magic carpet that takes me to wondrous places- physically and mentally. Morning flights are especially magical. The air is smooth. The Super Cub rigged so well, that it's akin to having an autopilot. I can take my hand off the stick to sip some home roasted coffee. Or adjust the satellite music flowing through my headset. I feel some warmth from the paltry cabin heat which knocks the chill off my legs in sporadic waves. I'm viewing an imax movie out my front windscreen but I'm not just watching the action- I'm in it. Immersed in this spectacular panorama. The smells and sounds are real, and I'm so grateful to capture it. well aware that it's transient; both in a moment, and in a lifetime. Flying has brought so much to my life. In many ways, has been my life. The feeling of gratitude to the many people who boosted me here comes back frequently. In ways, it seems unfair that I was exposed to aviation and given opportunities few have. And I feel a growing urge to give back. Cast a wider net. And expose more people to this splendid experience that can change the trajectory of a life. Flying inspires, and fosters connection- in a community. And we could use more of that now." -Col. Richard "Spad" McSpadden17 points

.thumb.jpeg.7ba106fbf2b10cba03047ba965aecd84.jpeg)