Leaderboard

Popular Content

Showing content with the highest reputation on 01/24/2025 in all areas

-

Hi All, Yes, I’m here on Mooneyspace. Never owned one, but I have a few hours in a friend’s Mooney (which was sold and is the infamous Mooney that later flew through Area 51). Anyways, I’m happy to clarify if something was not clearly stated in the videos. As to not clutter the already long thread, please send me a direct message with your question(s) over the next few days and I’ll try to summarize applicable comments in one response. I just ask that you’ve reviewed the videos (Part 1) (Part 2) to ensure your question is not already covered there. I spent a lot of time compiling the videos and it has been quite frustrating to watch comments on many forums where it is clear people have not watched the videos. I want to reiterate that my initial primary focus was on the effects & compatibility to my personal aircraft. And based on what I learned, I performed more testing and decided to share the results. I do think it is unfair to blame paint jobs being the cause, as 100LL historically seems to do very little, if anything, to painted surfaces. I’ve verified that through the course of my testing. I really want unleaded fuels to work. I’d do the same testing for any other fuel that came to market which I had questions about. Especially so since this is the application of an STC (major alteration) and the A&P/IA has to determine if the modification is compatible with the aircraft. I thought this recent commentary by Darren Pleasance (new AOPA CEO) echoes many of my sentiments. https://www.aopa.org/news-and-media/all-news/2025/january/23/presidents-position-on-unleaded-fuel Michael6 points

-

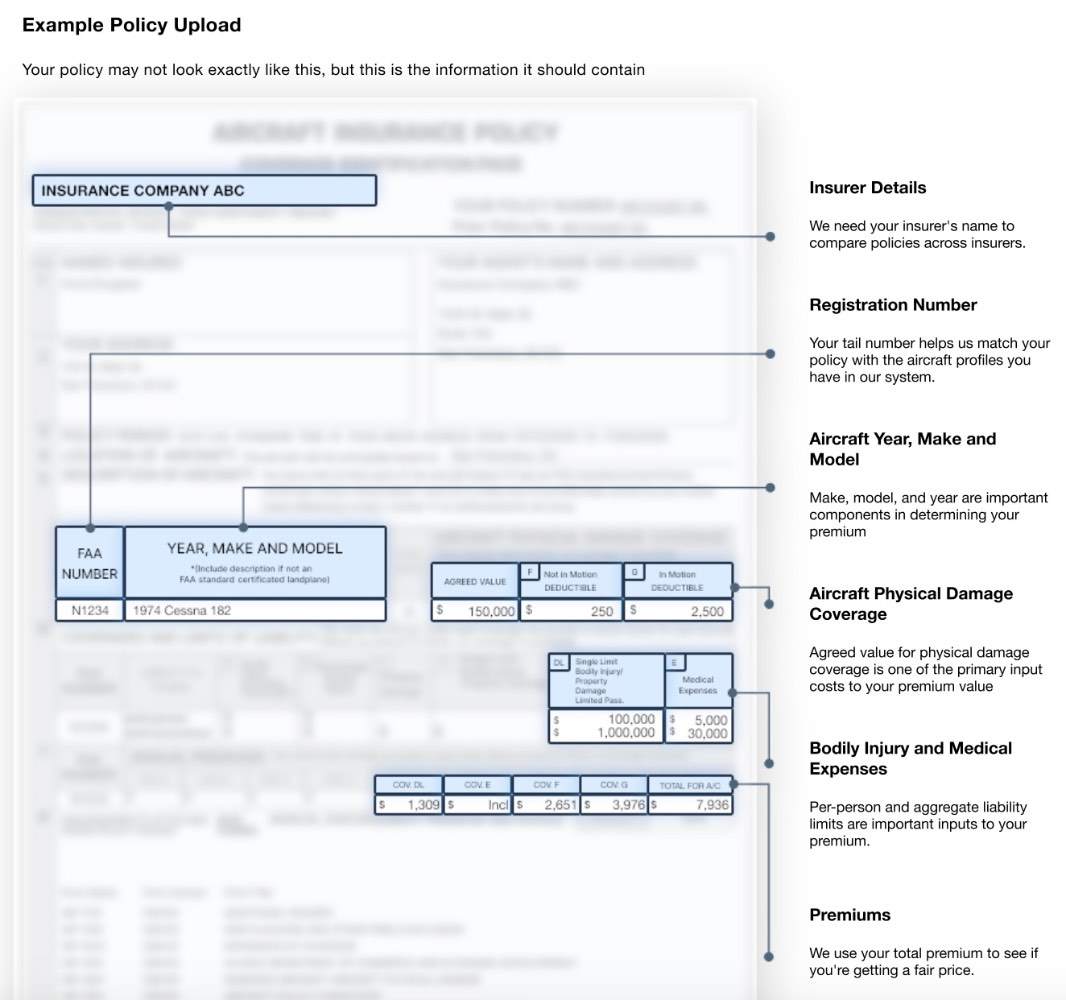

While price is one of the most important data points, what this tool doesn't do is evaluate coverage quality. While most auto insurers have fairly common policy coverages, aviation coverages can be substantially different from insurer to insurer. Some important items: Is Non-owned hull & liability covered? To what limit? $100K? The value of the insured aircraft? A percentage of the aircraft's value? How many seats maximum? What about emergency landing expenses where there's no damage to the aircraft? $10K? $25K? Up to the value of the airplane? Hail damage limits for cosmetic hail damage? 10% of the agreed value minus a deductible? Or is all hail damage covered? What about getting that written off the policy if you primarily hangar your plane? Crew bodily injury exclusions? Someone gets a low price on insuring their Mooney Acclaim, but did their agent tell them that their insurer excludes crew bodily injury? So if they're receiving training and the CFI is injured in an accident, they policyholder will be defending themselves if the CFI brings a demand/suit. Does the tool just use the baseline of $1MM Each Occurrence for Bodily Injury and Property Damage limited to $100K each passenger bodily injury? We really like to see $200K each passenger (this usually only costs $70-$300 more per year).4 points

-

To my cynical eye it appears to be a data-gathering exercise in preparation for a new business for them.4 points

-

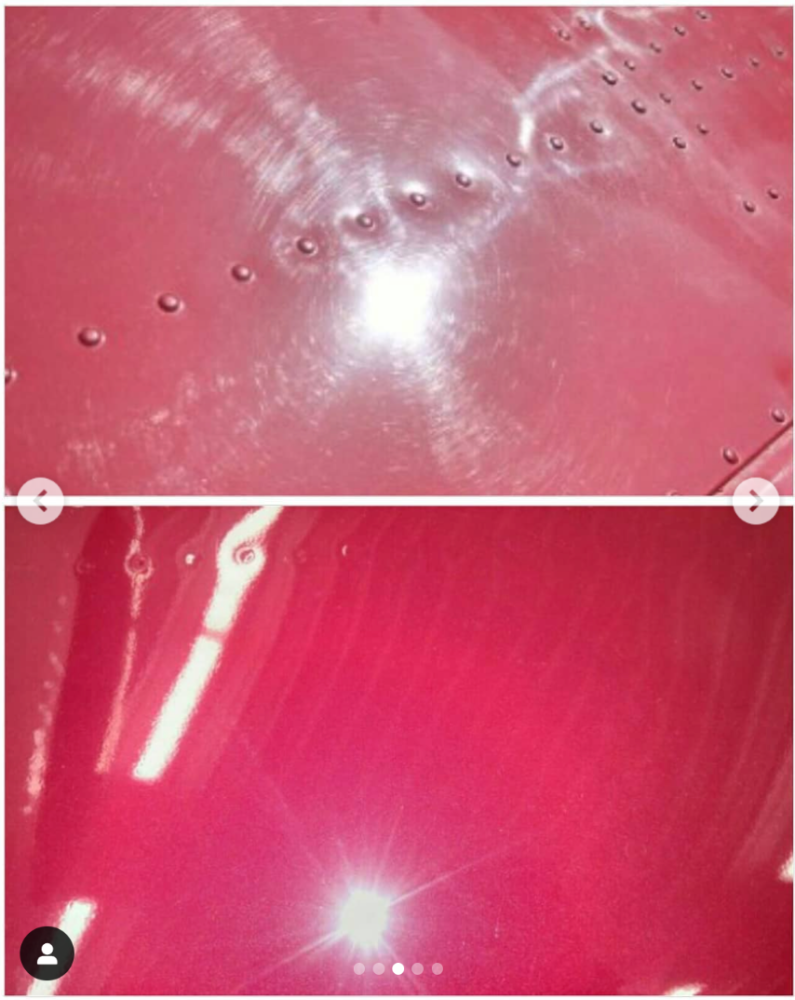

@AndreiC most of the money you spent towards the labor of the actual paint correction. The coating most likely took about a 1/5th of the time and the cost of the coating itself couldn't of been any greater than $200. You're still in a good spot really. Since the paint correction has been completed, and you have protection applied, your paint will continue to look good. You could apply another ceramic coating on top of the poly earlier than a year to ensure continued protection without having to get a full paint correction as well. Coming from a guy who has done a paint correction or two ...4 points

-

that would be the brake fluid reservoir with a long line going to the brake pedals.3 points

-

Many commercial aviation insurance clients (flight schools, maintenance shops) have been seeing rate decreases. We'll see what happens with personal aircraft.3 points

-

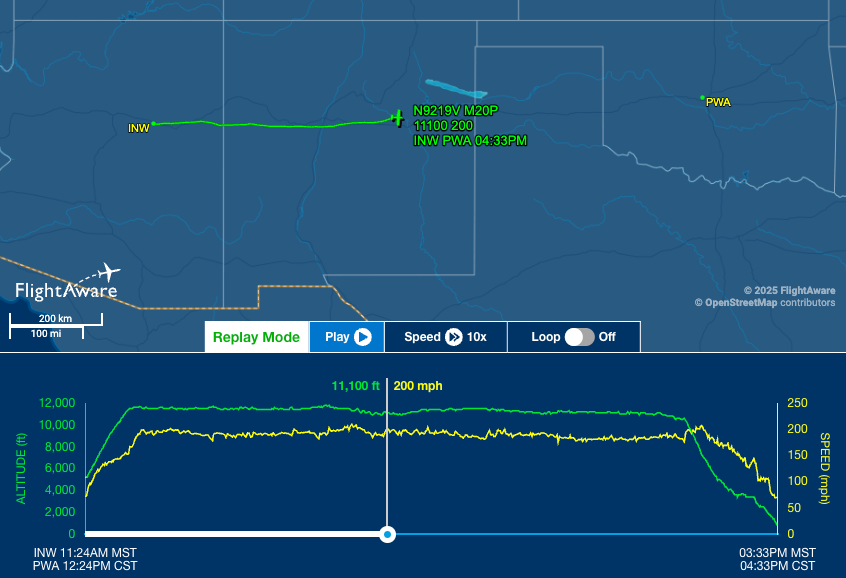

After owning my Mooney for about five years, my flights have more or less limited to California. This is the first time I took my Mooney across the country, or at least half way. 1100 nautical miles from California Central Valley to Oklahoma City with only one stops. 65.5 gallon total. Converted to statute miles, that's 19.3 mpg. Incredible flying machine. Of course 20+ tail wind helped a lot. At times, I was cruising at 180+ knots ground speed!!2 points

-

Nobody can guarantee the safety of your data -- any data they have is, by definition, not safe.2 points

-

Well, I talked to PermaGard and got some slightly better news. They said that their product is relatively easy to apply after the initial preparation and application (so just to maintain it), and for a small plane like mine/ours they would be able to sell it to me directly. They said that just watching a 1-2 hour video that is available on YouTube would be enough to understand how to apply their product, and that one could get a Mooney-like plane in a day of work, taking it relatively easily. So I can, with relatively minimal cost, do the yearly maintenance of the coating, and with that things should last a while. My concern was that I did not want to be stuck with having to pay a specialized contractor to do it every year for a large (~2 AMU) expense. @Marc_B: my plane needed paint correction anyway, the paint was old, badly oxidized and just plain dirty (with dirt embedded in the paint). So that is how I explain the high cost of what I got -- they needed to go over the paint at least twice with their buffing/polishing before applying the PermaGard product. Apparently GulfStream uses the PermaGard product for their planes. Maybe it's not so bad...2 points

-

I flew again to the pacific coast of el salvador. On my way there I overflew a volcano. What did i find in the crater? A lake!! Sent from my iPhone using Tapatalk Pro1 point

-

Anyone ever forget the tow bar? I wonder if the Mooney style non-locking tow bar might fall out on its own, perhaps in a turn? Probably not after retracting the gear and breaking everything though1 point

-

I'm trying to help Tal out with a replacement Tacho for his M20J. It appears that the gauge is the same part number 880039-517 (2" electric), but my plane (M20K) has a sensor on the magneto and his has a tacho-generator where the cable drive is found on the engine. The Tacho part number matches my parts manual for my serial number. But I cannot find a part number for the sensor? Anyone know these B&D Tacho's well enough to know whether they are compatible with tacho generators and magneto sensors? Anyone know where to find the sensors in the parts manual or elsewhere? Aerodon1 point

-

FYI - Bob Fields Inflatable Door Seals is offering a $75 discount on all Mooney door seals to Mooneyspace users at www.aerocessories.aero. Be sure to use discount code MS2025 to claim the discount.1 point

-

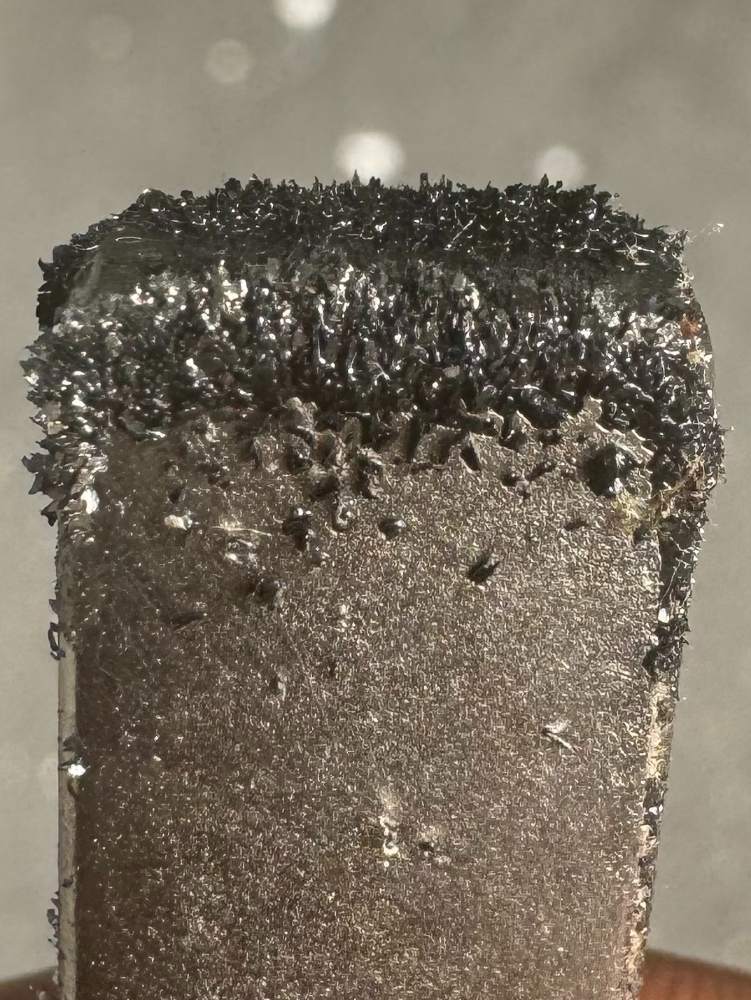

CAM LOBE CORROSION? A DULL TALE OF 1200 HRS SAFE LYCOMING OPERATION Surface corrosion noted on a cam lobe after pulling a jug isn’t great, but in isolation it is a terrible reason to split a Lycoming case – it may need overhaul soon, or maybe not... My illustrative anecdote: >10 years ago, a newb pilot/owner buys an M20C with a 600hr SMOH O-360 that had spent some time sitting and needs a little cylinder work at the outset. After pulling a couple jugs, the well-known Mooney A&P/IA who did the prebuy finds surface corrosion on multiple internal components and even some pitting on cam lobes but normal lobe height and lifter faces. The A&P sends pics of the extensive pitting and says newb owner you must overhaul. The collective “wisdom” of the internet also says that the newb pilot/owner/doctor must overhaul and asserts that he is just another vertical-tailed doctor killer-buying sucka. His demise in a smoking crater seems likely to all because he is arrogant enough not to accept A&P or internet guidance without asking questions. The sucka pilot then takes deep dive into authoritative literature by Mike Busch and others, learning that (1) there is zero danger in running it until cam/lifter truly spalls and (2) it’s easy to monitor the situation through the filter so that once it happens, further damage to the engine can be prevented. Armed with real knowledge, the arrogant newb pilot/owner pushes back hard against the A&P/IA, getting him to sign it off under some duress. Though this newb’s demise seems imminent to all, he flies regularly, uses Camguard, and keeps engine dry in winter by heating it uniformly and continuously. He also cuts and scrutinizes his filter nervously at every oil change, finding nothing for many hundreds of hours. He gets a good engine monitor, learns how to use a borescope, and learns spark plug maintenance, allowing him to monitor the top end as well. He does oil changes and oil analysis religiously but ultimately quits oil analysis after learning enough about it to conclude that it’s utterly useless for real world maintenance decisions on this engine. Finally, after flying for another 1200 hours over 10 years and accumulating ample instrument time, he notices a subtle but consistent decrement in TAS on recent flights. At the next oil change, he finds ample ferrous shavings in the filter (pic). He had become lazy recently and was only cutting every other filter, and so he pulls the previous filter off the shelf and also finds similar metal, realizing that he flew about 80-90 hours with cam lobe(s) and lifter face(s) coming apart. He flys it one last time to a major engine shop 3hrs away for overhaul, marveling at the aircraft’s fast and smooth performance during this serene flight and wondering if he is making the right decision. At overhaul, the suspected cam/lifter spalling is confirmed, and metal shavings are flushed from the oil cooler and governor. The prop is IRAN’d/resealed, and the hub is found to be in fine condition, as is the crankshaft. He’s finally back in the air and still (mostly) enjoying the continuous learning involved in the Mooney ownership journey….1 point

-

The last sentence above is correct! But the first paragraph above, it's quite obvious that you fly into very different airports than I do. I'm used to seeing runway edge lights, VASI / PAPI when on approach, and the REILs. "Approach lights" are quite rare where I fly. My last approach in actual was 900 overcast, visibility > 6 miles with winds 8-10 knots from the south, so the temporary tower had traffic using 18; very unusually, that airport does have an ILS to runway 36 only. Due to much lower ceilings and visibility at surrounding fields, many of us diverted there (my destination was 400 overcast, 2 miles in mist). So no "bright approach lights" to look for.1 point

-

I'm installing a GI275 EIS with GEA24 on a Piper Saratoga SP (PA-32R-301T), also with a D3000 dual mag, and having the SAME issue. The RPM works OK until I reach about 2350rpm, at which the tach goes erratic and jumps +/- 100rpm. The problem persists regardless of which mag I select on the ignition switch, but goes away when I retard the power below 2350rpm. So far, I have checked (1) proper pinouts and installation of proper in-line resistors per Garmin's manual, (2) proper supply of power and clean ground at the GEA24, (3) proper shielding and ground return of the p-leads, and (4) proper contact of the P-lead compression fitting to the mag itself. I have even refabricated the entire P-lead and RPM pickup cables from scratch. So far, none of these have solved the issue. Garmin support suggested doing a factory reset of the EIS (which I did) but that did not yield results either. Just adding one more case study to the list. I'll bring updates once we solve this issue.1 point

-

Call him back. I just talked to Skylar and he found it -- apparently it was misplaced in his inventory.1 point

-

David's tools are great and he can get them to you quickly. Much easier than building yourself and not too expensive.1 point

-

If a company provides a free service, you are the product. Usually.1 point

-

I've always been skeptical when they insist on knowing the company I'm using. If they are truly performing a market pricing survey, while they may need policy coverage details, the name of the insurer is irrelevant.1 point

-

Why in the sam hill would people voluntarily live somewhere like that???1 point

-

Since you're learning about your Mooney, I thought I'd throw this in there: Resist the urge to remove your hydraulic reservoir to clean it up or paint it to improve the appearance. One of the most frequent posts on Mooneyspace is when newer owners do any kind of brake work and get air in the lines and fight trying to remedy the soft brakes. I t doesn't mean that your brakes shouldn't be bled by someone that really knows Mooney brakes to get rid of the dark gelled nasty brake fluid that's likely in the system But let someone that has years of experience deal with that.1 point

-

The harder that one part is screaming, the more difficult it is to override and do something else!1 point

-

Brain is pretty remarkable, but can lead you astray. Funny how one part of your brain is screaming "level your wings" but another part can override that instinct and do something more rational.1 point

-

I participated in the insurance data submission program with Foreflight when they were building this capability. They asked for a copy of my policy, so they have all of the qualifiers along with my premium. Since they have my policy information I didn't have to input any additional data to see that my premium is in the "good deal" range (Thanks @Parker_Woodruff!) @redbaron1982 did you need to fill out a survey of some kind to get the assessment of your premium? If so, can you share what details they asked for? I think that would give us some insight on the level of detail the Foreflight algorithm uses for the premium comparisons and perhaps answer some of Parker' questions. EDIT: I did a little investigating on the Foreflight tool and found this when I started through the process of uploading policy information. As expected, it appears they are only comparing the very basic data at this point.1 point

-

Meguiars uses the phrase "body shop safe" to identify products that don't have silicone or any other ingredients that could interfere with paint. This document answers the question "Is it body shop safe"? Meguiars Body Shop Safe.pdf1 point

-

I had a shop find several airworthiness issues with repair estimates that I disagreed with. In some cases it was their assessment that the condition was an issue at all (1) and in others it was their estimated cost to fix it. (2) I paid them for their time so far including the inspection and took my plane back. I then got a ferry permit and had a mobile A&P certify that it was safe for the flight to my preferred A&P. I then flew it there and he completed work as necessary to resolve each discrepancy. 1: An example is that the plane had been flipped in a windstorm in the early 60's and the left wing skin had been damaged. The wing was repaired and the logbook entry and 337 said something along the lines of "Left wing repaired in accordance with Cessna maintenance manual and acceptable practices according to part 43". The annual inspection note said something like "Left wing repair documentation is insufficient." and they recommended pulling the skin off the wing so they could see exactly what was done and document that. They estimated $10k for this. My A&P's note in the logbook was "Found logbook entry documenting left wing repair in logbook and 337 dated (whatever the date was)" #2: They found that the jackscrews for the elevator trim were bent and offered to buy me a new pair from Cessna at a total cost of $47k. The plane was only worth about $35k to begin with. I found new replacements from McFarlane for $1,500 for the pair.1 point

-

I'm jealous! Whenever a bunch of Brazilians get together, one is bound to find FUN! I grew up in Ecuador, next door... AMO Brasil! As far as a place to stay, check this place out: https://fly-inn.com/listing/private-room-with-bathroom-3-miles-from-sunnfun/ We are at Sun N Fun every year, too. We exhibit there. Come by our booth and say hello! Look for FLY-INN in hangar A, right down the center aisle. You can't miss us because we are the most packed booth there! Go to fly-inn.com to check out our logo, and then swing by! – Carollyne1 point

-

I manufacture these tools. A set sells for $325 plus shipping. I have plenty of stock. David1 point

-

1 point

-

Pretty simple. Because the aircraft's pollutants and its noise (and sometimes the aircraft) do not stay above 300 ft. Some concentration of lead emissions, a known multisystem human toxin, make their way to the area in and around the airport. Now the court has to get into the facts. This particular aircraft in the cited flight was flying Base to Final and got pretty low - well below pattern altitude of 1,000 ft.1 point

-

1 point

-

Perhaps, but would you miss them if you never found them? Its much more of a social event and expo than shopping. If you like big crowds, fairs, fair food and air shows it can be a blast. I kinda felt I saw I ever wanted to see going once. If it was closer to me I would likely go to see the air shows, those are fun to watch, walking through looking at the aircraft, and there is no shortage of those at sun n fun.1 point

-

When you give a d bag a badge, they think they are King Kong. That guy needs his ass kicked.1 point

-

It was in writing. I don’t think it was a money issue as much as they were not available at the time. This was the year 2021 where you couldn’t get anything. That’s not an excuse, as I pointed out ever so professionally. I told them it was not their right to substitute, it was mine; and the burden of availability should have been my issue which I promise I would’ve resolved. Anyway, what do you do? 2 overhauls in one year, very little flying happening, I have it back, how do you rectify that? I just figure if I have an issue and the shop is still owned by the same, I will be making a visit with a reminder. All I can do. In the meantime, I run a black max engine dehumidifier.1 point

-

I had a client took his plane to a shop at another airport in the DC area, and they handed him a discrepancy list of like $25,000 worth of stuff, but looking at the list it looked to be about 4000 bucks of stuff. When he showed him, the documentation that a few of the write ups were trivial and actually allowed by the manufacturer, or how you could treat the corrosion on the rear wing attached fitting without pulling the wing off, the shop rolled his plane outside told him to go F himself and then faxed the discrepancy list to the Washington FSDO and told him the plane had to leave on a trailer. I fixed the three discrepancies that were legitimate on the ramp and then we ferried it over to my shop and fixed the rest. The FSDO guy said he’s not giving a ferry permit, even though I had inspected the aircraft, so we got the DER that he hired to engineer the wing skin crack repairs to state that it was safe for not more than 100 hours of flight time. Then he called the FSDO and got into a fight with the inspector because he still refused to give a ferry permit saying it was unairworthy, even though the DER says you don’t get to tell me that it’s not airworthy because I’m actually a designated engineering representative of the FAA and I’m telling you that it is. But it was really crazy how that went.1 point

-

At least every decade. Sadly that’s not always the case. It seems like every Mooney I lube for the first time, I find a rod end or bearing that hasn’t been lubed since it left the factory.1 point

-

If it’s the ships gauge, the outboard sender is probably inop Phil. Suggest checking ground first. If it’s the wing sight gauge, scrounge a replacement. Dr Kim is correct, they are available with inaccurate scale markings1 point

-

My instructor told me about him ferrying a Citabria out west. He landed in day time, got some fuel and food, and wanted to do one more leg. So he took off after dark. And had to fight himself the whole flight to not roll inverted. He had done a lot of flying over the past few years in the East. Lots of lights on the ground, not so many stars due to air pollution (years ago) and light pollution. Out West, lots of stars, not many lights on the ground. So his mind kept telling him he was upside down.1 point

-

This is the short version of what Cliffy wrote. Your mechanic does not know what they are doing and is scamming you. There are some washers that have ridges on them if you have the original washers. They go against the hemi ball. The washer with ridges are actually little bushings that go into the ball. It looks like one on the lower left may be installed on the outside of the door tang. Even so to get the doors to work best, the right number of washers need to be installed between the joint and the two door tangs. Your picture shows two washers on the outside of the tang and that is wrong. that looks like a nose door. The drawing posted above is for the main gear. Find the parts manual and look up the drawing.1 point

-

I will say that it took me years to sort things out and get it comfortable. Beyond the suggestion I made above above, plugging leaks is key. I do close up one of my aft vents so I don’t pump all the heat out. More importantly, one of the biggest leaks was the wiring pass through from the cabin to the aft cabin. Avionics guys love this pass through, but are terrible at plugging it up after working there. It is actually easy to access through the aft hatch. This applies equally to Acclaims. My last leak is coming out of the side walls. The wing to fuselage junction is hard to seal, so the side panels are a source of leaking air, especially at the spar junction.1 point

-

Enjoy the adventure. I have great memories of planning (and often modifying) and completing long cross country trips to new places. Like so many things, others will have done more, and some others done less, so just value what it meant for you.1 point

-

Second Brian Kendrick, known him for almost 30 years, he ran the factory service center for a while and also was a company test pilot, he can test fly Mooneys to trouble shoot what few shops can do, did prepurchase on my airplane and 3 annuals thereafter, he test flew the airplane, figured stall warning was not coming on because mounted too low from factory, had to redrill TKS panel for new rivnuts to move stall warning up, he will find stuff that other people don't, airplane had 190h on factory reman, still spent at least $50k on repairs not counting upgrades in the first two years, biggest line item tanks, think 11k at the time, Brian replaced stuff in a preventive manner like flap limit switches because he knew they were going to fail rather sooner than later, re-glued TKS stall triggers because he knew they were about to come off soon, doing an annual with him and dropping the bird off for let's say at least 4 weeks will make most of your trouble go away, whatever he does not have time to fix he will explain to you so you can get it done locally1 point

-

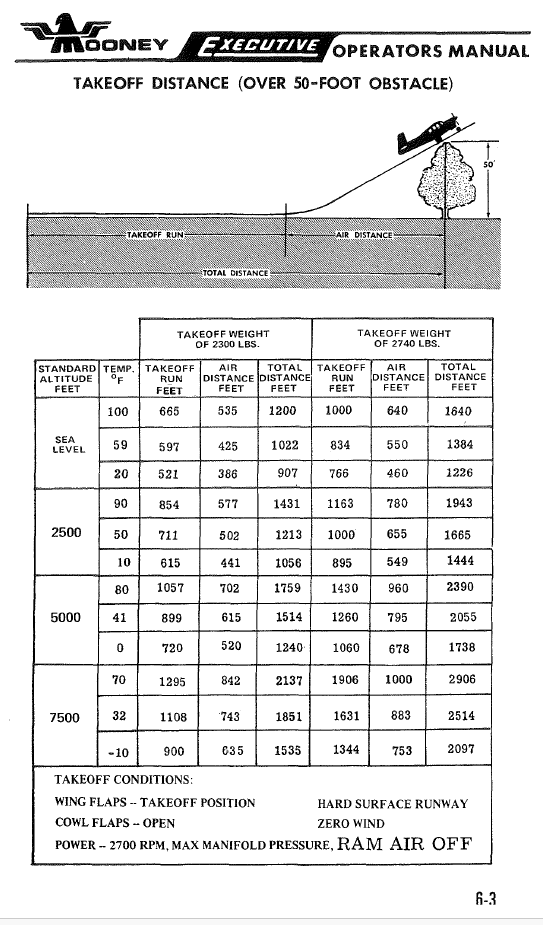

The Koch chart is fine, but the "nerd math" you're asking about is right there in the performance data from the POH I posted. You just have to interpolate. Compute takeoff weight with your particular load (including fuel) and interpolate between the 2300 and 2740 data points, then note the temperature at the selected pressure altitude and interpolate between the temperature points. Or vice-versa, you can start on either axis. At the risk of sounding like a jerk, this is basic private pilot stuff. Regarding mixture setting vs. performance, yes you need to lean appropriately for the DA, and target EGT is a fine way to do so. But note that the curve of power developed vs. mixture setting is pretty flat across its peak. Per the graph below, in the max power rage, differences of 200 degrees EGT only change the power developed by a few percent. So you're not going to see any meaningful difference in takeoff distance and climb rate by getting the mixture setting "perfect" vs. "good enough". This seems to be widely misunderstood, and I fly with lots of pilots who I think spend way too much time fiddling with the mixture during runup at higher DAs in normally aspirated airplanes. Set the mixture "pretty rich" just prior to runup; lean it promptly past peak RPM to roughness; then move it back to about peak plus roughly 1/2" of travel, and you're done. Takes about 5 seconds. If 2% power is the difference between clearing and hitting terrain, that's a judgement problem in deciding to take off in the first place, not a problem with leaning technique.1 point

-

You will not find anyone more honest or knowledgeable. he is an all around solid guy and doesn’t mind if you get your hands dirty with him.1 point

-

Well, I can get close to the nerd math for you! On the back of my old checklist in the airplane theres a Koch chart. You can use that to scale your takeoff data from sea level to whatever altitude/temp combo you want. This explains it with an example. I used it to give me an idea of how much DA effect to expect and I found it reasonable but maybe slightly overestimating the effect. https://learntoflywithkris.com/koch_chart.html1 point

-

Not sure what version of the M20F POH you're looking at, but the 1975 edition has takeoff and landing data up to 7500' at 70 degrees F, which is about 10,000' DA. Takeoff distance chart is pasted below, landing distance is shorter than takeoff distance for all cases. Real world performance of any stock, airworthy M20F is not meaningfully different from these numbers.1 point

-

If it helps any, I am using both ForeFlight and Pilot. In terms of a switch, most really depends how easily you take to technology differences. Overall, both apps will give you what you need and you’ll probably find 90% of the useful features are the same. The main difference is flow - how to get to what you want. In a nutshell, ForeFlight started as a flight planner with in-flight functionality. Pilot basically emulates Garmin’s GTN-family oanel mounts, including its menu system and flight plan entry (which can be a plus if you ate flying a Garmin panel). That difference in emphasis means some tasks will be easier in one the other. the only way to know if the switch is worth the savings is to grab the trial and use it.1 point

-

I bought an inflatable door seal (basic economy version) awhile back (https://aerocessories.aero) and I'm finally getting around to installing it under the supervision of my IA on an 1993 M20M Wednesday involved removing the door seal that Mooney installed 29 years ago. Sounds simple enough, right? 90 percent of the seal itself came off easily. The adhesive was another story. I bought 3M Citrus Adhesive remover around the time I bought the seal in anticipation of the project. One thing I can say for sure, is that plastic scrapers don't work. I would still be scraping. Scotchbrite abrasive pads worked a little bit better as the adhesive softened. (Waaaaaaay too much adhesive was used originally). Finally I used a steam machine (www.ev-international.com) with a brass brush on the end and that finished up the removal nicely, so that the area looks new from the factory now. Next I laid out everything in the kit along with the instructions and realized that the instructions were written for every possible application (Beech, Piper, Bellanca, Mooney, etc) and that there were very few Mooney specific instructions. (I was having flashbacks to the day I received the package and was intimidated by the instructions, or lack thereof, so set it aside.) How hard can a door seal be? I called the company in San Antonio that now owns the STC, Aerocessories, and Tom the owner answered. The reason I called was to see if there were any pictures of Mooney installations. Yes there are, Tom says, but once he finds out that I'm an hour away, and since he's the new owner of the STC he would like to see how an installation on a Mooney goes. He offers to come out the next morning and help . . . never turn down free help . . . Tom helping * One very important detail that sadly I think I would have missed in the instructions is that the seal is only glued on the one side of the "L" shaped seal, the smooth side that hugs where the plastic trim meets up, not the other rough side. This makes sense since that side of the seal allows space for inflating/deflating. We made a lot of progress with the install and it went well. But one thing that we discovered was that the plastic door panels, which have been covered in ultraleather need to be trimmed to allow more clearance for the door seal. So Hector at AeroComfort is going to peel the upholstery back, trim down the upper and lower door panel edges and and then re-glue the ultraleather. My plastic panels need to be trimmed Picture that Tom showed me of another Mooney whose plastic panels had been trimmed (mine does not have an ashtray) Picture that Tom provided of another Mooney with the same Economy Manual version that I bought. The seal is now finished and hopefully next week I get the panels trimmed and put back together. I am excited about the inflatable seal which will help with noise. I sat in the Mooney this afternoon with music playing in the hangar and it was pretty impressive how much inflating the seal cut down the noise. Tom has the product on his Piper Commanche that was installed back in the 80's and still going strong. I am amazed at the customer service and the level of interest in working on getting a set of instructions for the Mooney community. That's a company worth supporting. More to come once I finish up . . . Now I'm working on getting my Medeco locks (aircraftsecurity.com) installed while the door is apart . . .1 point

-

A low dielectric strength...? Kind of like low electrical resistance... Something that doesn’t block electrons flowing through it... If given the opportunity, you can probably look this fact up for each material considered.... High dielectric strength materials are used in capacitors to separate the large surface areas of very thin metal foils... Marking it clearly with 100LL only is probably a good idea as well... See if that stands out... Because the label on the wing will get hidden by the mat... Best regards, -a-1 point