Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/2024 in all areas

-

5 points

-

For those of you who work on your own airplane but don't always have someone present to help you remove and reinstall the lower cowl, here is a YouTube video which shows how to do it without chipping paint or scratching the spinner. This jack makes it safe and efficient and it's easy/cheap to build.4 points

-

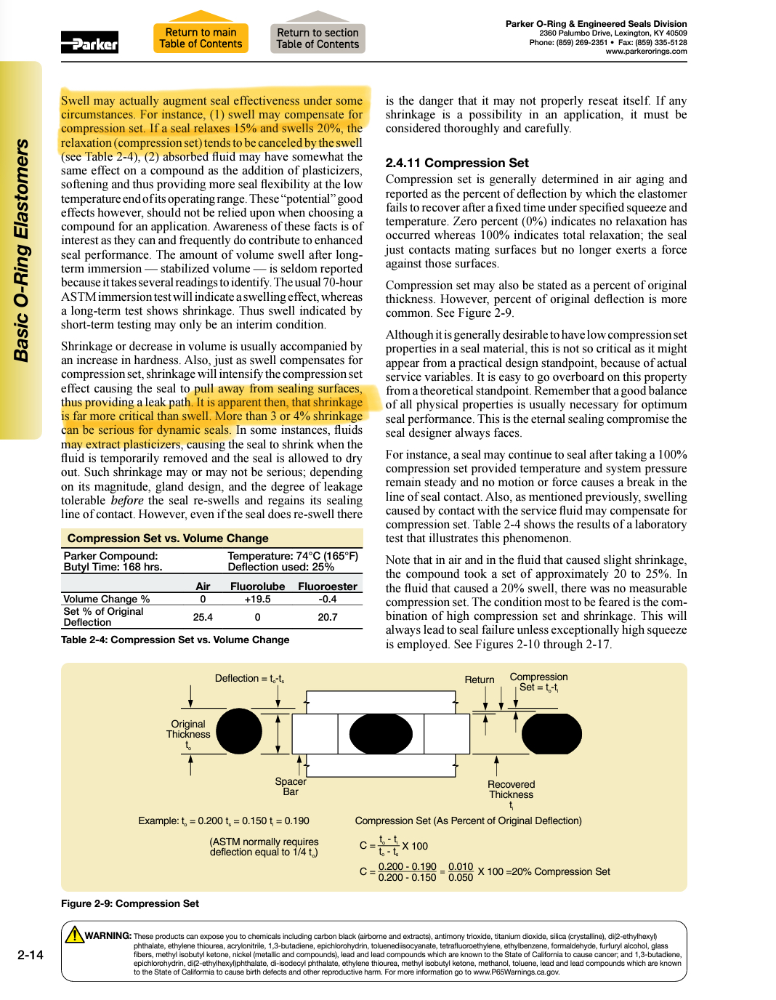

I looked at the video posted by the A&P at KRHV again. The o-rings he tested were MS28775 and MS29513 which are both nitrile which is listed in Section VII or the Parker O-ring Handbook as having only fair compatibility with 50% aromatic fuels. Also, the test may not be representative of the fuel's effect on the o-rings in service. Specifically on Page 2-7 of the Handbook, it is stated: "When deformed and exposed to a medium, rubber (Note: Parker uses the descriptor "rubber" to refer generically to any o-ring material), when confined in a gland, swells significantly less that in a free state (up to 50%) due to a number of factors including lessened surface area in contact with the medium." I just checked and SAF-AIR fuel drain valves use M83248 o-rings (Viton).4 points

-

In most of the states they've been ruled unconstitutional, and none of them have ever passed a public referendum. But red light camera companies know this, so they call it a civil penalty, and they send you some official looking fake ticket that you can usually ignore, because the whole thing is a scam. Some states, like Maryland, they can refuse to renew the Maryland drivers car registration until they pay it. So they're using the power of the state to enforce a private for profit out of state company to deprive you of property without due process. And yes, I have a problem with that, so should you.4 points

-

I served on a local county board which helped evaluate changes related to our industry and make recommendations to our country commissioners. one of the issues was staff wanted to require use of a a new type of back flow preventer called an RPZ instead of the double backflow. The latter being what has always been used, and they wanted to require a new one that they claimed was safer. During one of the meetings when I was questioning the requirement, I pointed out the problems with the new type which in some instances would require a building owner to spend upwards of a million dollars to upgrade. i had researched this issue extensively prior to the public meeting so I knew the answer to my question prior to asking. When I started pointing out all of the pitfalls of the new requirement, one of the staff suggested that if a baby died because of contaminated water, it would be on my head. Which was the perfect opening for my question which was… How many documented failures of the old back flow preventer had occurred, and as a result how many of those caused illness or death? As his face turned purple he claimed he didn’t know the answer, to which I replied well I do! The answer was zero! It had never happened. The bureaucrats had made the rule already and imposed it on more than a few residents and it had to be rescinded. The moral to the story is that while there is no argument that lead is bad for us to ingest or be exposed to, the actual danger is poses as a byproduct of fuel consumption is more difficult to quantify. It isn’t as if aviation exhaust is being pumped into schools. But the “save the children argument” is foisted and everyone’s hair is on fire. That being said, high pressure direct injection, and electronic ignition on engines would render this point moot, so if the FAA and EPA were actually interested in efficacy and an actual solution, they would get the f*$& out of the way and let some real progress In engine technology occur, rather than stifling innovation. I am of the opinion that the indirect mission of the FAA is to purge GA from existence, so endlessly harping on lead is much easier than admitting they want the whole mode of travel to go away. It’s a war of attrition with your own money being confiscated and used against you. government at its finest3 points

-

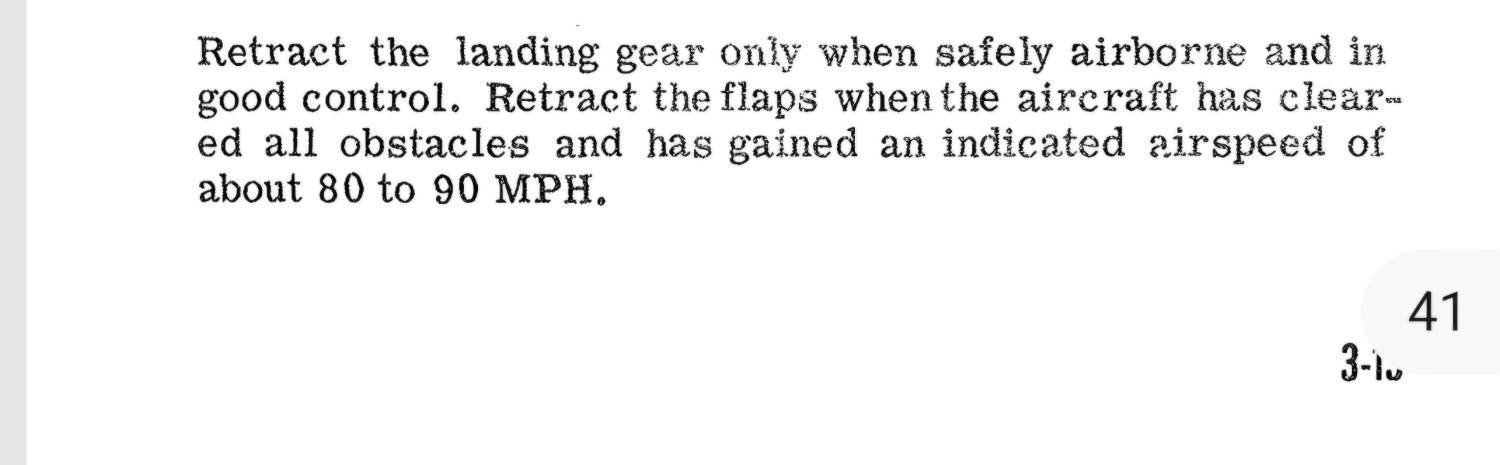

I don’t trust myself to wait till 80 kts. That would mean that I am on relatively short final. I can easily see a “gear up” in my future doing that. My gear comes down abeam the upwind numbers on a visual or FAF on an instrument approach. 100 to 120 knots depending. Maybe a little harder on the gear but not as hard as a gear up landing. I simply have a profound respect for my ability to forget a crucial step. I attempt to mitigate that with unwavering procedural compliance. This is totally personal. I understand that other folks may have completely different procedures that may be superior to mine.3 points

-

3 points

-

Oh no, now you've got me thinking about soaking old Mooney landing gear shock discs in the stuff! Maybe G100UL would be even better!3 points

-

@GeeBee The other thing to note is that if there wasn’t a mandate to move away from 100LL, and G100UL wasn’t being used in California to attempt to escalate a ban on 100LL, I personally wouldn’t be commenting on these threads at all but rather just wouldn’t purchase the STC or fuel till it was proven reliable, safe, and any untoward effects were shown. Given the political mandate and currently no other UL option, I have a vested interest in a fully vetted and safe fuel.3 points

-

Couple of caveats about this. First, while the Duke's and ITT actuators are largely the same, one difference with the later ITT actuators is that they lack a Zerk fitting to add grease in situ. Thus, you can't "give it a few pumps of grease till it comes out the screw hole, while in the plane", at least not the way those with the Duke's actuators can. You can remove two of the screws and pump grease into one hole with a cone tip until it comes out the other. But I've never had much luck with this, as access is awkward and it's difficult to get the cont tip to actually seal well enough against screw hole #1 to pump through to screw hole #2. I've gotten to the point where I simply don't try to lube the gear cavity without removing the actuator from the airplane and disassembling it. I've done this enough times now that it's not a particularly big hassle. The other caveat is that if you use this technique of pushing grease through one hole (zerk or screw) until it comes out another, you've got to be sure to take enough grease out of the last hole before you reinstall the bolt, to ensure the bolt doesn't hydro-lock against the grease in the cavity, and strip the threads of the actuator. You can guess how I know this.3 points

-

So... mystery solved. I spoke to the mechanics who've worked on the plane most recently. It turns out that the oil used to recharge the Challenger air filter for the 100 hr ICA (done only a few hours ago) is red in color. The LeakTec they use is, on the other hand, the blue or green variety. I decowled the engine top & bottom today and looked carefully. The red oil is clearly distinct from the circulating engine oil, and I see the drops at the lowest point on the compressor side of both turbos. A trace along the underside of the air filter, and some lesser traces elsewhere. Nothing on the upper portions of the engine at all. My theory is that either: 1. The oil misted into the induction system and collected on the manifolds, or the compressor scroll, and dripped back down, a bit worked out along joints or the turbo housing. A trace along one of the compressor discharge hoses (routed upward) might support this. 2. It simply leaked out the air filter housing and was blown about the lower compartment, eventually collecting on the lowest points. Either way, it's very reassuring that there's no source of other red stuff (like degenerating Loctite, gasket compound, etc.). And the small amount of oil is a previously-known thing, attributed to that flange gasket or collection of dipstick drip from above. Thank you all for the inputs! I'm going to separately figure out a good cleaning solution (mineral spirits) for future use, but the current worry is addressed. D3 points

-

2 points

-

Well, damage to fuel tank sealant is a show stopper. im not putting a drop of that in my tanks until its ready.2 points

-

For me, remaining runway must include time to descend, land and stop. My home field is 5000', so by the time I'm much above treetop height, I'm not going to be able to land and stop using the overrun area. So take off, verify in control per the Owners Manual, verify positive rate on the IVSI, then Gear Up.2 points

-

2 points

-

I wound up down a bit of a rabbit hole yesterday and inadvertently discovered that o-ring swelling was researched quit a bit in the context of the Sustainable Aviation Fuel program that was investigating alternative fuels for airliners. Much of the data is not necessarily relevant to our situation, since turbine fuels and avgas are not completely comparable, but the amount of work that was done on the topic indicates that concerns about o-ring behavior in the presence of alternate formulations was a big concern. Swelling is the main effect that was studied, to assure that there was enough swelling to assure a seal, and that there was not excessive swelling to cause degradation. We have the same basic concerns, but insufficient swelling doesn't seem to be an issue based on the video, but excessive swelling does appear to be a genuine concern. The main issue is for Buna-N (nitrile) gaskets, seas, and hoses, since it is more susceptible to excessive swelling than other materials. Fluorosilicone and Fluorocarbon (e.g., viton) are less susceptible to swelling issues, but exhibit other tendencies that sometimes make nitrile preferrable. e.g., fluorosilicone tears more easily and generatlly isn't used for dynamic seal applications. Since nitrile is used in many places and may still be installed in aircraft for some applications where other materials have replaced it, it is still a concern for aircraft in the fleet. Amongst a plethora of various academic and industry analyses, there were two papers that were pretty throrough in their analysis. Although much of the discussion and results aren't necessarily relevant to avgas applications, some things in them were still useful. The two papers, for those who would otherwise complain about the lack of reference: Elastomer O-Ring Seal Swell Measurements for Sustainable Aviation Fuel Material Compatibility, a graduate honors thesis at UDayton, and very thorough and nicely done: https://ecommons.udayton.edu/cgi/viewcontent.cgi?article=1380&context=uhp_theses The capability of organic compounds to swell acrylonitrile butadiene Orings and their effects on O-ring mechanical properties, a refereed paper published through Elsevier: https://www.triceceramics.com/uploads/9/3/8/9/93899770/49_oring_article_2019.pdf Anyway, a couple tidbits out of those (and other stuff that I slogged through) were interesting. From the first paper: "Currently, there is no certified ASTM test method associated with measuring o-ring seal swell." Both papers (and other material I found) use an optical method to scan the size of an o-ring before testing and then periodically in the presence of the fuel to measure the increase in size. The o-ring is unconstrained for these measurements. This suggests that the significant increase in size shown in the video is relevant for a basic assessment of swelling. It also raises a question about how testing and verification was done for avgas applications and how much. My main takeaway from this was that there was a lot of attention paid to this sort of detail for the SAF program for airline fuels, so it's not a trivial thing. It appears that we may need a comparable level of verification for avgas applications. Maybe that's what's contributing to the delays with other applicants.2 points

-

2 points

-

The rudder looks like a later model too — I’d check the logs. Not sure about this one — lots of $ to get it going… -Don2 points

-

Depends on your definition of captive. Lead has around a 1 month half-life in blood, 2 months in soft tissue, 2-3 years in the brain, and 20-30 years in bone. Other interesting info: 1) OSHA PEL 8-hour shift atmospheric workplace limits are <50 ug/cubic meter. 2) SoCal AQMD ran a study at Whiteman airport (KWHP) with the following results (note these data are in nano-grams/m^3, 1000 less than micro-grams/m^3!):2 points

-

2 points

-

My partner made it back. We flew together a couple of days later. The turbo was turboing. All is well except my bank account is sad.2 points

-

Make sure you look at the tube structure in the fuselage BEHIND the sidewalls for evidence of water leaking through the side windows and running down on the tubing and rusting the tubes. There is a SB on this and a newer sidewall insulation that should have been put in. If you can remove the interior side walls for a prebuy then you might run it near a wash rack and run water down the sides over the side windows watching inside for any leaks. There is also SB to check the bottom rear ends of the tubing frame by removing a bolt each side and checking for rust inside that tube. Corrosion on the main spar between the main wheels (and under the rear seat on metal wing Mooneys) is another big issue as are fuel tank leaks showing up in the wheel wells on the main spar (blue stains soaking through the rivet)s Be prepared for a high $$$$ first annual next year. This is a fact most of the time on this website with newly purchased Mooneys. New airplane owner gets hit with high $$$ annual first time in the shop because of "differed" maintenance by the previous owner not disclosed at the purchase. I'm not trying to scare you off but you have to be aware of the pitfalls of ANY airplane purchase. You don't know what you don't know. As my second caveat on any airplane purchase- NEVER TRUST ANYTHING SAID BY THE OWNER OR THE SALESMAN, PERIOD! Check everything out yourself with the help of a Mooney knowledgeable mechanic. EVEN down to the data plate on the engine and the serial numbers on the prop to make sure they all match the log book entries. Just things to bear in mind as you look at candidates to purchase. Cool your jets and take your time Below is a prebuy check list I made up years ago for Mooneys Check that all the model numbers and serial numbers match on everything with the log book, engine, prop, airframe, I do radios also. Actually read the data plates and compare to the logs. Check that the parts actually installed match what is contained in the TCDS and/or the logs show an STC change for the big stuff and changes for radios and electronics. Anything added like engine monitors, fuel flow gauges, etc should show an STC listing in the log books. Pull the rear seat bottom and open up the inspection holes to check for corrosion on the spar caps. Look at the spars real well in the main wheel wells for same. As noted fill up fuel tanks the night before and look for leaks the next day. If you can jack the airplane do a gear over center torque check. Make sure the A&P has the correct tools to do it. While on jacks, move the main gears in and out toward the wing tips for excessive movement. Lift the main wheels to check for play in the donuts. The donuts should expand enough after 5 mins unloaded to not have much movement. Check the mouse boots for condition in the main wheel wells. While down by the main gear look at the spar bottom between the fuselage and wheel wells. Look for smoking rivets there. The rivets that hold the spar sandwich together. That can be a big $$$$$$. I found one in AUS with almost every rivet loose on the bottom of the spar. It was grounded by the owner when Kerrville said it had to be repaired. Nose gear area - if on jacks this is easy- twist the nose wheel left and right to check for excessive play in the steering linkage. More than about 10-15 degrees either side of center before tightening up on the linkage is too much. You will see the slop way at the top of the nose gear on the rod end linkage up there. Most important on the nose gear! Look and feel for dents where the steering system touches on the tubing for dents where it touches. Turn the wheel by hand and you will see where it touches and stops. MAKE SURE THERE ARE NO DENTS THERE! The limit is 1/32" depression. Any dents and the nose gear comes out for repair $$$$ On the tail surfaces grab the tip of the stabilizer and try to move it up and down and fore and aft. If it moves or clicks you might have work to do. Limits are about 1/10th of an inch either way. Usually fixed by changing out the "close tolerance bolts' in the hinge. As noted lift up on the rudder to check for play in the jackscrew. Same limit about 1/10 of an inch. Lots of times it is wear on the 2 bolt hinge bracket at the aft end of the jackscrew and not the jackscrew it self. I found one stabilizer that moved 1/2 inch either side of center! Look over the outside surface of the entire airplane for dents, filliform corrosion, hangar rash (the elevator tips seem to be especially susceptible to this damage and NO repairs are allowed to control surfaces (no patches, partial skin replacement, etc). The FAA in one case here on MS made a big thing out of this stuff on a routine ramp check on one of our posters. Basically they said it didn't come that way from the factory so fix it. I check all the exterior control surface rod ends to see if they are loose enough to move or if dry and frozen. If dry and frozen I start looking at the logs real close to see if the lube and gear swing AD had been being done. One item missed almost always due to the effort but it can cause big headaches, is pulling the sidewalls inside and actually looking at the steel tubing frame for rust. If the windows are not sealed well, water gets in there and runs down inside on the tubes and rusts them. The insulation SB aside. There is actually a SB describing how to check for leaks by pulling the sidewalls and directing a water hose at the windows looking for leaks. Make sure everything, and I mean every switch, knob and button works as designed! Put power to it and try all radios in all modes, all lights, all warnings (landing gear warning horn, stall warning horn, etc), all exterior lights, everything that can be turned on or off or moved in and out. There was one write up on here a while back where someone bought a Mooney and the stall warning didn't work nor did the gear warning (IIRC). That makes the airplane unairworthy. If on jacks (and it should be) do a gear swing and make sure the gear works properly. I've seen them signed off 3 months ago and they hang 3" from the wells when sucked up. If its electric gear do a manual drop also to make sure it works. Had a couple on this board recently that went in for annual and the manual gear drop didn't work. So check it out. Look to see if the gear actuator has ever been removed, cleaned, checked for proper gear lash and relubed. If it hasn't you may be doing that on the next annual yourself It's that important. Disregard if its a manual gear. It goes without saying that a full log book check is required for all applicable ADs and required inspections even though the annual has just been done. The logs tell a story and knowing how to read them is a skill. Make sure you know what to look for or have someone that does. The engine stuff is the normal stuff. Compression check, oil filter inspection, looking for leaks, cracks, anything not normal. Pull the plugs and read them, they too have a story to tell. My caution to any whom I help buy an airplane? Trust no one selling an airplane period. Take nothing for granted. Don't trust anything even though it just had an annual. If you do, it will bite you in the arse. Check and verify everything before money changes hands. Once you pay for it , its yours! Good luck and show us pictures even of the prebuy! :-) :-)2 points

-

That's a bit of an oversimplification, I think. Some swelling is expected, and beneficial, but excessive swelling (as seen in the vid) is detrimental, as described in the linked document. For an o-ring used as a static gasket, 20-30% swell is acceptable, but for a seal (dynamic), only 10% or so is allowed. Swelling also weakens the material and makes it more susceptible to tearing (for a seal) or extruding out of the groove for a gasket. The issue as noted in the vid is that the swelling was significantly past acceptable limits, especially for a dynamic seal. Mooney fuel systems have dynamic o-ring seals in the fuel selectors, gascolators, carburetors, fuel servos, etc. An excessively swollen o-ring in any of those may restrict or seize the motion of the sealed shaft, or may tear when the sealed surface moves, resulting in leaks. None of that is good, and excusing excessive swelling as just "it'll seal better" is ignorant at best and disingenuous at worst imho.2 points

-

The problem is not finding people who have been exposed to lead. But to find those with NO exposure to show that the lead is the cause. Just because everyone who is exposed to lead has X issue, doesn't mean the lead caused it. You need to show that those not exposed don't have X issue.2 points

-

My guess is that there are a few in the FAA that are saying Uh-Oh, can this get me in trouble?2 points

-

All too common. It seems many new Mooney owners get their initial instruction from their Cessna or Piper instructor with very little Mooney experience and are taught to use much too fast of a final approach speed. We see it at PPP’s too. The same poor instruction leaves the new owner deficient in learning to properly trim the aircraft leaving them unable to slow the aircraft. I expect the complaint about RPM was a red herring. Not going to be able to get the rpm much lower going over 100 kts with the airspeed turning the prop till the plane slows down. Add in leaky brakes, worn pads and a tail wind and it just underlines the need to go around when not properly established and stabilized on final. Sent from my iPhone using Tapatalk2 points

-

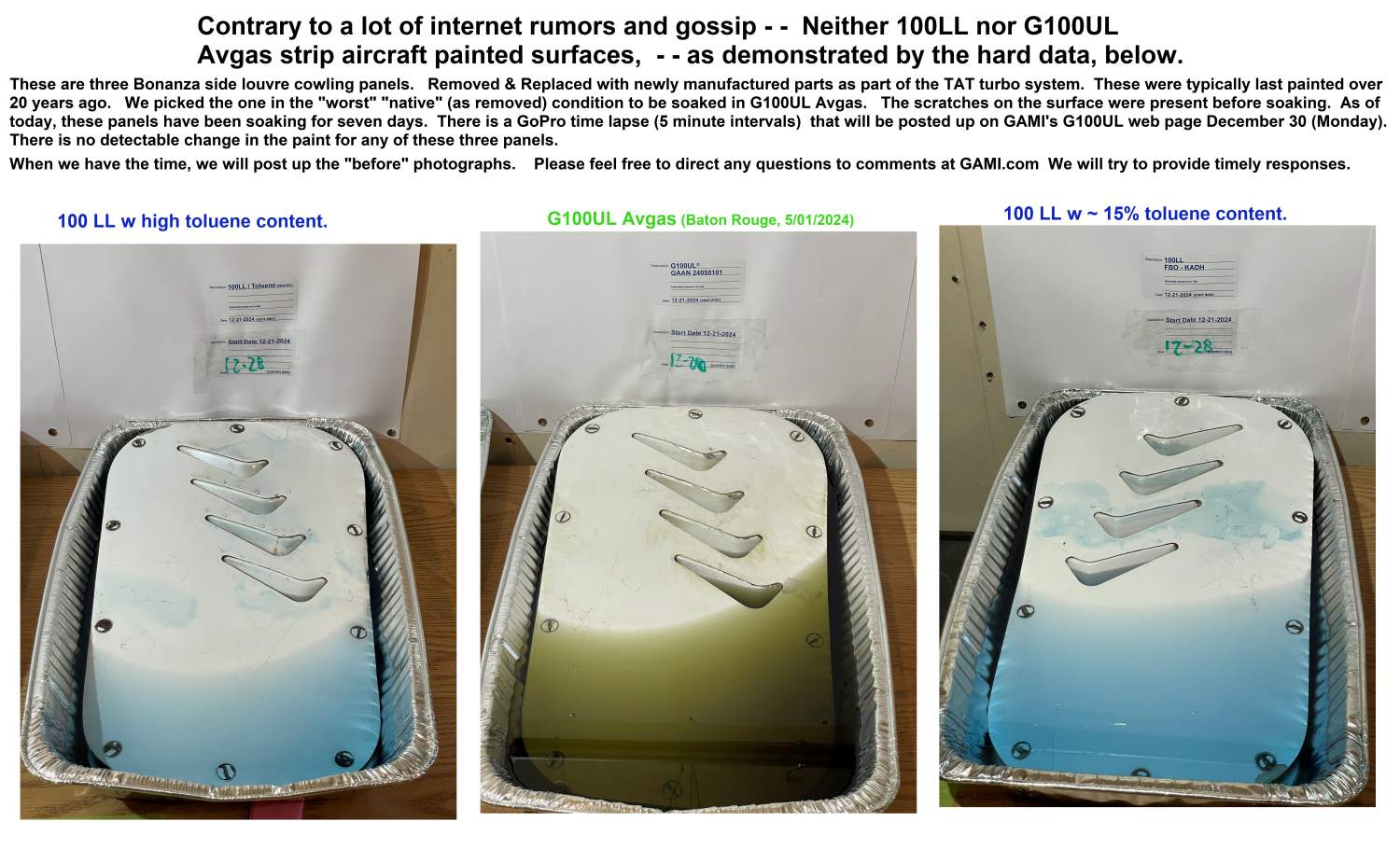

Please see the data in the image, posted with this message. These are old parts removed from the Bonanzas which we remove and replace with newly manufactured parts when we install turbo systems. The paint is ~ 20 years or more old on each of these panels. There are scratches and bare spots where paint had previously "flaked off" on each of them - - prior to beginning the soaking. In particular, the flat head panel fasteners all exhibited some age from repeated removals and replacements over the years. One cannot detected any difference from the "before" and "after" photographs. We will try to post up those "before" photos as well as a time lapse photographic history of the previous seven days of soaking - - hopefully on Monday. This small data set represents about the fourth or fifth time, over the past 14 years, that we have conducted similar testing. All with the same good results. If you doubt the validity or integrity of this data - - you are invited to visit our facility in Ada, and see this testing, first hand. George Braly1 point

-

So you're telling me that people have actually gotten an invoice for "Airspace Usage" from Vector??? Or more likely, they received an incorrect LANDING Fee. Which is my point of discussing what is "legitimate" and what is BS. If one of these people actually has an Airspace Fee invoice, please show it. And I'm not disputing there may be issues with Vector's auto billing, at least I'm assuming it is automatic. On a cold day I could see ADS-B showing I landed (or even went subterranean) on a low approach. So the system didn't see it as an overflight, but a landing. For that you'd simply need to respond that you did not land, it was a low approach and until further evidence of a landing from Vector, your email/letter is proof of no required payment. Then put it on them to prove you landed. And if they try to send you to collection, you have proof you did respond. I would not just toss it in the invoice in the trash.1 point

-

Have not followed the entire thread, but just an observation from a Johnson bar guy. I would suspect that there is less wear putting the gear down since gravity and gear door aero forces tend to make it want to come down. Putting the gear up on the other hand……I can see significant benefit in putting the gear up early. I know many CFIs preach the idea of gear up only when no runway remaining. When they fly with me, I welcome them to try…. The point being….I can imagine some huge loads on the gear train when putting the gear up at higher speeds on electric gear Mooneys, especially those with the lower doors…. I wonder if folks with lower doors experience faster wear than no doors? I also agree that routinely waiting for short final might be a problem waiting to happen…1 point

-

I did this with my A&P last year. If I recall properly, there is a spring inside and when you loosen that single bolt in the center on the top the entire canister separates from the top cap. That bolt goes all the way to the bottom of the canister can screws in at the bottom. It wasn’t hard, but getting a socket/wrench on there was a bit of a pain. Was worth changing, mine was a bit browned. No record of any previous owner changing it. Just be careful of the spring to make sure it goes back together the same way with new o-rings. My filter came from cav with new o-rings.1 point

-

That's nuts, you won't be able to land once ATC is privatised (I know how medium/big airports works in countries with "private ATC"). In Europe, the only places with thriving GA and public ATC are France & Germany, the airport are still accessible to light GA (most of the rest has gone into the turf) For 38m$ from Avgas seems on the low side? from some "100LL transition" discussions, I understand 800mUSG is sold annually in US (100mUSG is sold in Europe where Avgas tax vanishes instead of going back to GA ), that's 5cent on gallon in taxes, it seems low? I would have expected 160m$ with 20cent on gallon and maybe 80m$ once the whales had their share Infrastructure is not supposed to make money, it's a money hole when you look at direct costs and revenues, the only benefit you get from it are the indirect economics around: tourism, pilot training, airtaxis, accessibility, flying schools, helimeds, jobs, council airports...most GA Part91 operators, don't require traditional airport services that cost dozens of millions per year, you only need a gate to get in/out from ramp, the "the user pays for what he uses" is a good logic instead of "the user pay to acess": for private comany owning airport GA is viewed as nuisance without much profits: not much money anyway compared to Public Transport1 point

-

I already reached out and he responded that he was out of the country for business over the holidays and wanted to have some owners on both side of the fence tour the facility. I am planning on taking him up on the offer if we can work out the details But I feel the benefit of discussing things on the forum is that we all can learn and discuss.1 point

-

Maybe just take the oil lines off and see if that tells you anything, after A&P looked at it probably clean everything and spray suspect area with developer and see if that shows any cracks1 point

-

1 point

-

@GeeBee not arguing, I'm asking... It's one thing to have swelling that is part of the spec. It's another thing to have swelling where it's either not part of the spec or more swelling than spec. But we see of a lot of generalizations that "it's known" or "don't worry about it" as well as "holy crap unleaded affects this WAY different than 100LL." What we don't see a lot of are specific tests with specific airframes showing this is either within spec or outside of spec. So what we're left with is conjecture on either side and irrefutable for both sides. We need to see testing data from GAMI for more than just less detonation compared to UL94 on the test stand. As another aside, over on BT there was a previous military publication suggesting harmful effects from cycling high and low aromatics...we've yet to see if there are detrimental effects from patchy coverage of an unleaded fuel that's routinely cycled between 100LL and high aromatic UL fuel. I'm not aware of any such testing being done either...has this been tested by GAMI?1 point

-

Exactly why I created this poll. My gut told me the market is REALLY small. I don't have a clue how many gear sets get inspected and fail inspection every year. Whether that's because they aren't getting inspected, or that they all pass...don't have a clue on that, either. I'd think the same, or even less, would be true for the no-back spring issue but the fact LASAR is offering them...???1 point

-

I sit on the Board of my local airport. Our airport is the busiest non-towered airport in Missouri. The airport is owned by the city and staffed with city employees. We currently have 132 aircraft permanently based at our airport and a couple of active flight schools. The airport barely breaks even. Our voters passed a bond earlier this year for community infrastructure improvements and there were plenty of locals complaining loudly about the money for the airport improvements. If it weren't for fuel sales, the airport would be in the red every year. That would not be popular with the taxpayers. Bigger airports may have more ways to generate revenue, but the battle for tax dollars still continues and oftentimes its difficult to find allies on the City Council or at Planning & Zoning. I can see why airports may consider this an option for capturing some revenue and I suspect it will become more common rather than less common. However, I am not a fan, and most of the money for airports comes from the federal government. I think the stoplight cameras are a good comparison to this issue with Vector. Fortunately, Missouri has outlawed stoplight cameras in our state. Maybe we can get the state to outlaw Vector.1 point

-

The main issue I have with this, is that there have been instances of damage to aircraft and potential damage to elastomers used in the aircraft. You'd think for an STC that the manufacturer would be responsible for proving that if modifications were or were not needed and be able to show open and clear data as such regarding what was tested and what wasn't. GAMI (or any potential fuel manufacturer) is the one that should be responsible for convincing me as the owner and operator that their product is safe. Continental and Lycoming have a list of authorized fuels by engine model (doesn't include high octane UL). I'm not sure which o-rings, hoses, and seals could potentially be at risk. It's not OUR job to be test pilots with our aircraft, paint, tank seals, and potentially our own lives and the public, solely because we care to remove lead from the environment. FACT: GA pollution is not only just lead. Just saying that "we know about that and we're okay with it" or "don't worry about your paint because that's cosmetic and doesn't matter to us" or "you have wet wings and they leak from time to time so it's not our fault if that's accelerated"...doesn't address the concern. FROM GAMI's G100UL ICA: "When replacing seals or O-rings in the fuel systems of aircraft or engines operating on G100UL Avgas replace Buna N or nitrile fuel system components with components made of silicone or fluoropolymer elastomers (such as Viton) where practical. When replacing flexible fuel hose assemblies utilize tetrafluoroethylene (Teflon) lined hose assemblies per TSO C53a or TSO C140 where practical." If my Airframe and my Engine is on your STC AML...you should be able to tell me exactly which parts that I need to replace to run your fuel safely. It is your job to prove safety, not mine. You are the STC holder that has shown your data to the FAA, and you haven't shown this to me. So if your product is ultimately unsafe or leads to unairworthy condition, the liability is yours. I cringe when I hear "we have to stop loving the problem" because the follow up is we need to start loving a new problem.1 point

-

I will throw in my 2 cents worth - Before spending any money on any airplane, choose a plane that has been flown regularly and cared for. You will save a lot of headaches, dollars and downtime by choosing wisely. What looks like an attractive price could be a money pit. Planes that have been sitting and flown very little are typically not as well maintained as planes that fly regularly. I average 100 hrs/yr on Myrtle, for example. I would be very leery of a plane that had only been flown 10 - 20 hrs/yr for the last few years. Ideally, choose a plane that has a panel you can live with. Upgrades will likely be costly and likely keep your aircraft down for a significant amount of time. A full panel will likely take 5-6 months of downtime. Budget for an expensive 1st year of getting maintenance "caught up". Choose a plane you can afford to FLY not just a plane you can afford to buy. My total annual expenses including fixed and variable costs average ~$25,000 / year. That includes hangar, insurance, gas, maintenance, etc. Which works out to about $250 per operational hour. This is a little different guidance perhaps than you were looking for, but hopefully you will find it helpful.1 point

-

I had a set of new gears scanned, measured and have the CAD files as well as the Rockwell Hardness testing of the gears1 point

-

Who knows? I had assumed not because surely that was tested, but I thought the same for O-rings too. Anything in my opinion that swells fuel resistant O-rings literally almost overnight is questionable to be put kindly. I don’t what the diaphragms are made of I had assumed Nitrile as it’s sort of been the go to for a long time, but assumptions are just guesses under another name.1 point

-

I've been at this flying game for 60 years and I have a firm saying- NEVER BUY THE FIRST AIRPLANE YOU LOOK AT- PERIOD! You need to look real good at many Mooneys before you can calibrate just how good one is over another Many new pilots before you have gone down that path to their detriment. Many right here on MooneySpace You don't know what you don't know yet. SECONDLY- I'm also an A&P and grew up in the time of wood and fabric airplanes- Wood airplanes are another arena all together. Not 1 in 1,000 A&P mechanics today even knows what to look for on a wood wing. Does he or you know what dry rot looks like? Or delamination of a wood wing Mooney In today's market conditions, a "really good price' brings skepticism to many of us A "free" annual by the guy that has been doing all the maintenance on the airplane for years is also subject to skepticism. As with all airplane purchases- Caveat Emptor You need to find someone very familiar with Mooneys to check things out with you Do not go into it alone.1 point

-

I think we have come to an impasse and will just agree to disagree. No malice and no heartburn. I do have a question: Do you and @GeeBee have any imagination that G100UL might possibly be a greater health hazard than 100LL?1 point

-

This is where we disagree. I am not a lawyer, and you are evidently not one, either. I am, however, someone who is a litigant in two similar cases which were argued and won in the Illinois Supreme Court and the Federal District Court for the Southern District of Illinois. We are on the cusp of a 7th Circuit win on the State’s appeal next year, too. And the arguments are similar to what I present here…. Regulatory overreach which, according to the law, not public opinion, is impermissible. -dan1 point

-

The reason I had a question was one of the fields I didn't understand, as I didn't think it was necessary... Related to who did the inspection, DER and some other alphabet group I didn't recognize, and none was an option, so I picked NONE. It went through, didn't cost me any money as all of the AD's that were mandatory and didn't allow special flights were complied with. Was briefly concerned as the mechanic said the FAA guy wanted to come inspect the plane, which I thought was a waste of taxpayer money, thought in my own mind anyway. All done airplane back and waiting for annual.1 point

-

The server doesn’t let me hit both the “laugh” and the “like” button at the same time, but I want you to know, you deserve both!1 point

-

Airports are infrastructure. If we are all paying for things we use, and only that, why I look forward to the generous net inflow to me of funds from all the crap I subsidize but don't currently use as an upper middle class American taxpayer (without a lot of shelter schemes). Vector are a bunch of parasites. **** them and the horse they rode in on. It's a clever-seeming internet scheme, and those little hyenas are probably making a few bucks, instead of doing something useful like launching rockets, building houses, defending the country, or curing cancer. All these people think they're smart, maybe even think it's Schumpeteresque creative destruction. Occasionally some of these profiteers (and they go back to some of the LBO days) get shamed publicly. There are other outcomes as have been in the news recently. Fight these asshats. Throw caltrops in their path. Bankrupt this crappy little company. If they're listening, I say "Get a job". Ask me how I feel.1 point

-

Speaking on behalf of every American GA pilot , we are not accustomed to it in the US and are enthusiastic about not becoming accustomed to it.1 point

-

1 point

-

1 point