-

Posts

118 -

Joined

-

Last visited

About Scottknoll

- Birthday 07/10/1984

Profile Information

-

Location

KPTW

-

Model

M20R

Recent Profile Visitors

2,992 profile views

Scottknoll's Achievements

-

Directly from the FAA: https://drs.faa.gov/browse/excelExternalWindow/6EA0F05ECCA8304486258305006833CF.0001 The TCDS is for ALL M20 aircraft (Type Certificate 2A3), so you’ll have to scroll down to the J model. FAA moved all their stuff to DRS: https://drs.faa.gov/browse Airworthiness Directives, etc.

-

Scottknoll started following Aircraft insurance cost for 2025 , Starter Swap W&B Question , Logbook Page Removed and not Disclosed - Criminal Misrepresentation? and 7 others

-

I thought the question was about the starter? That document is the FAA TCDS (Type certificate data sheet). It lists the original prestoline/prestolite starter as Flight Station (F.S.) -23.0

-

I agree, a new CFI was needed. Very glad you found one quickly. The PIC is responsible to determine airworthiness (conforms to type certificate and is in safe condition for flight). It might be his “opinion” that the aircraft is unairworthy, but your old CFI definitely cannot “Ground” an aircraft. Anyone who can legally be PIC can determine the aircraft to be airworthy. Remove and replace faulty CFI, problem solved. I’m guessing your old CFI and thinks an A&P must perform ALL maintenance. 43.3 (g) You must own or operate the aircraft to perform preventive maintenance (can’t do it to your buddies plane) 43.7(f) you must hold at least a private pilot certificate to return the aircraft to service following said preventative maintenance. That said, fuel cap o-rings are about the simplest thing you can do and you crossed one problem of the list.

-

Yes, I’d love to see this. I had an actual aircraft appraiser create a report for an avionics upgrade. That was 3 years ago and it came in at 408k. Info used for 2022 appraisal: 1998 M20R 29-0135 AFTT 2600 Engine 300 Factory Reman Prop 70 Since New 310HP TKS FIKI G500Txi (10”PFD & 7”MFD) GTN750Xi GTN650Xi GI275 EIS GI275 SBY ADI GFC500 w/YD PMA 450b GTX345 All LED exterior lights except beacon LED glare shield lights w/new dimmers Artex 406ELT Oxygen System USB(3)/Lemo plugs(4) Recent Weep-no-more reseal Painted 2012

-

Thanks for putting the effort into this. Wasn’t expecting much from the AI after seeing the disappointing 2025 Mooney M20 video The analysis was actually pretty good. Would be interesting to know total fleet (ovation) hours for accident rate, but I’m not sure there’s an easy way to do it accurately.

-

Mine does have the fuselage static drain. 1998 29-0135 You should be able to open the battery access panel and see the static lines from the left and right side of the fuselage to see where they go and if they connect to a drain.

-

Still available, owner is open to accepting offers ($110,000 OBO)

-

Just to pass along some information. The entire door apparently needs removed from the airplane to properly install this Mooney door seal kit. Not sure if it is due to the type of glue required (low viscosity?), but my A&P and I determined it was not worth the effort. Seal seemed quality and I’m sure would work very well if properly installed. I have a set (Cabin & Baggage) for sale if anyone wants to make an offer.

-

Hangar neighbor is considering selling his 1977 J model. Hangared at PTW, most of the recent annuals have been done at Air-Mods MSC in NJ. Past 7 years it’s been flown for work travel, mostly day trips ~100-150 hours annually. Listing here for him before it goes to the major websites. AFTT= 5620 Eng SMOH = 1346 Prop SMOH= 1772 AD list attached, full logs available. KMA 20 Audio Panel (2) KX155 NavCom Garmin GTX345 ADS-B in and out WX-900 Stormscope Autopilot Century IIB single axis (Heading Bug) 6 disc CD changer! 2024 AD List - N201RW.pdf

-

I used the black max for about 4 years. I sent it back for service 3-4 times. Only way I knew it wasn’t working was occasionally a humidity sensor. I ended up buying a drybot about 9 months ago. The tube to insert dry air works a lot better. It is a 5/8 OD silicone tube, it slides right into the oil filler port below the tap off for the breather line. I can hear the oil gurgle and know it is pushing air past the oil into the crankcase. That was never the case with the Blackmax. The drybot monitors its function and output. It is desiccant based and dries it as necessary. It’s not cheap but seems much more robust than the black max. If making your own or using the Blackmax I’d recommend using 5/8 OD tubing for connecting to the engine. It makes a nice airtight fit down inside the filler port, past the breather tube. No worries of foam falling off. There’s also an orange dust cap that fits on top of the oil filler port, the tube passes through this dust cap. Their website has pictures. Only downside is I think it pushes oil up out of the oil pan and into the case itself. So when taking the drybot out, roughly a quart shows up about 15-20 min later. Oil reading seems about a quart low until this happens. The IO550 also hides a quart through the rest of the engine if it’s been flown recently. So it can show up to two quarts low until it all drains back into the pan. I have a spare Blackmax if anyone wants to make an offer…

-

1997 M20R 1mm/200k pp liability 350 hull Pilot 1 ~ 8000TT 300 M20R ATP Pilot 2 ~ 3500TT 800 M20J, 15 M20R, Comm/IFR $4433

-

Ice detect light, shines down the leading edge of the wing. Required for FIKI installations I believe.

-

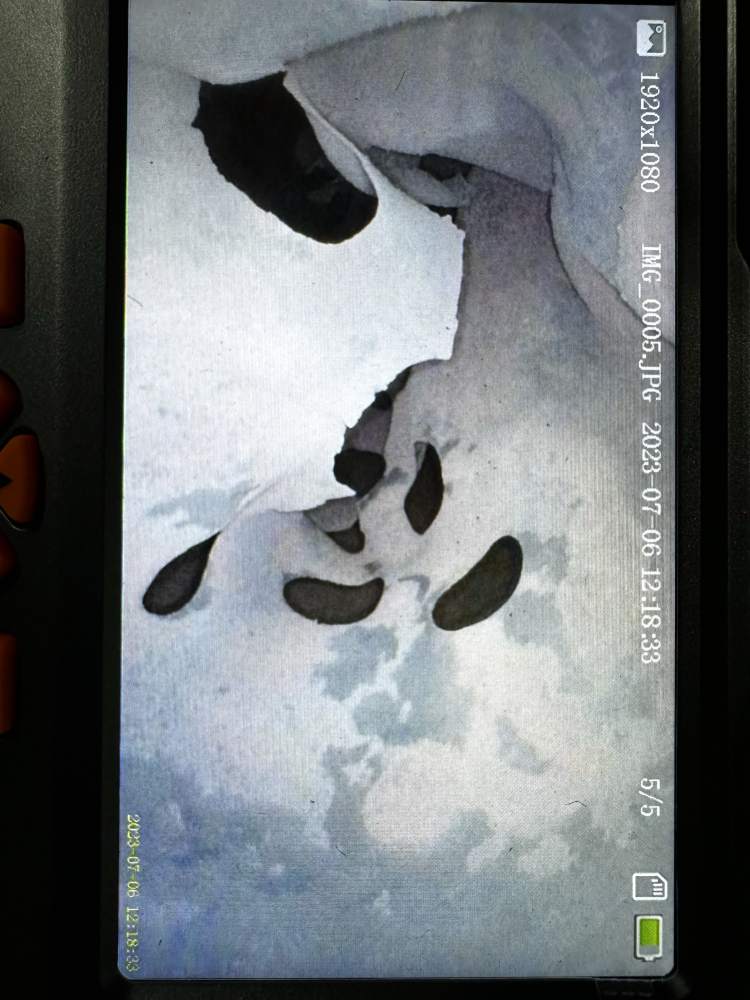

Another pic after we removed the muffler.

-

The Ovation has a cross flow muffler. Cylinders 1/3/5 enter the right side, go straight through the muffler via a tube with holes. That 1/3/5 exhaust then goes out the left side. Opposite for 2/4/6, left to right and out the right side. Perhaps that makes it easier for broken pieces to exit the exhaust.

-

This is inside the muffler of our Ovation. As I understand some Mooneys don’t have mufflers. I was bored during my first true owner assisted annual this June so I stuck a borescope up the exhaust. IA had already taken the heat shroud off the muffler and there were no cracks. I don’t think it would have been caught, feel lucky we found it. We used aerospace welding (now a Hartzell company I think) and it was about 3amu and 5 weeks. Aerospace Welding Minneapolis, Inc. 3344 Highway 149 Eagan, MN. 55121 800-597-4315 Here is a picture from my borescope. They are supposed to be tubes straight through the muffler that have holes in them to dissipate the flame (hence the term flame tube). As they get old and deteriorate they start to warp and block the flow. These were this bad and we still had strong takeoff performance, glad we found it when we did. No record of replacement in ~ 2500 hours. Also, an additional thought to consider is that we had no rattle. Even after removing the exhaust and muffler there were no loose pieces, just deformed metal inside the muffler potentially blocking flow.