Leaderboard

Popular Content

Showing content with the highest reputation on 09/27/2024 in all areas

-

This happened to me for my PPL check ride. It was so unnerving! At the end, the guy complained about my American accent when I spoke on the radio. He said it made me sound like I knew what I was talking about when I really had no clue. Afterwards, my actual examiner pulled me aside and told me to ignore that guy. He said, "you sound very professional on the radio, but you're just starting out. Don't ever be afraid to ask for help if you need it."5 points

-

I pretended that I was in a Cirrus or Airbus and just flew side stick. I was pretty close to home so it looks worse than it was. Like a good owner, I was more upset by the looming repair cost.5 points

-

A little update and info for everyone. We just finally completed the installation of new engine and upgrade to 310HP. The process took nearly 12 months from decision to 1st flight with about 2.5 months downtime. We took the opportunity to replace everything including prop overhaul, new hoses, new exhaust, new clamps, etc.... Total cost was just shy of 6 figures ( I already had the prop) including an annual. All work was done at Gilmer Aviation in Pell City. Results were exciting - take off roll and initial climb out are excellent and top speed was 187 True (max power). A few things if anyone else is considering this: 1. Shop around for the STC. Prices range +/- $1000. We bought ours from JD @ Southwest Texas Aviation. He was excellent to work with. 2. We had a terrible time working with TCM and Air Power through the initial order process. It took months of calls and follow-ups to get the right quote. The people at Air Power were very knowledgeable and I feel the real issues were with TCM. However, 10 calls and no return is a problem. Once we wired the money to Airpower, we didn't hear from them again for 6 months until the engine shipped. After it shipped, they were very responsive and the core return was handled well. We replaced our G series engine with a IO550-N39. It was made new, but the factory would only sell it as reman. Part of the issue was that our aircraft has air conditioning and no one could figure out what exact engine would work as the G series we needed was discontinued. I believe for non air conditioning engines, the N8 is the best option. The N series has a tapered fin design so we had to modify the baffle plates (which is in the STC). 3. Steve Leary @stevenl757 and Bob Minnis were great help. Also had a couple conversations with Don Maxwell who was very knowledgeable about this process. Thank you to everyone that helped. 4. Acorn Welding for new exhaust was a disaster. They don't return emails, phone calls go unanswered and the parts they shipped didn't fit (not even close). We have sent everything back and it seems they will make it right. We had to install the old exhaust while we wait for them to get it right. Disappointing.... 5. I highly recommend Ricky Gilmer Aviation at KPLR. His new team member (Hugh) did all of the install work and it was outstanding! Hugh went above and beyond. I really can't say enough about how good their work is. Both Ricky and Hugh came from Epps and I feel fortunate to have them on our home field. 6. Was it worth it? As we plan on keeping this plane for a while, I obviously thought it was worth it. With upgraded avionics (G3x, GTN750, GFC500, etc.,, recent paint correction and ceramic coating, new 310 engine, I think 1051K is better than new and at less than 1/3 the cost. Comparing to anything else we could buy its the best value and performance available for our mission. Not sure I would go through the expense of just doing the STC to gain the extra 30hp. But if I was rebuilding or replacing the engine and prop, then sure I think it is worth it as an add on to that process. Pictures to follow - if anyone has any questions or is considering making this change, feel free to ask me any questions.3 points

-

Defined "messed up." SureFly emulates an impulse coupling mag for starting. Spark will be hotter. Should start easier.3 points

-

Check the microswitch behind the throttle first. Sent from my motorola edge plus 2023 using Tapatalk3 points

-

Well I flew 10 days ago multiple stops no issue had my plane on battery minder for all 10 days and when i came out to start it the battery slowly turned the prop over and then stalled. I looked in the logbook for when the previous owner installed the battery and i could not believe it 1 Apr 2011! That battery owes me nothing! That is an amazing 13 year 5 month streak! I was just surprised that i got no warning at all acting more like a lithium ion battery than a lead acid and my last annual they said my battery pasted the test. I am just as shocked at the increase in new battery prices with most wanting $1000 i found chief’s had a special for $849 for RG24-16 battery which i only hope goes as long as the one that was in there now.2 points

-

I suspect Moss may have been dealing with either some incidents of remote supervision or a lot of questions about remote supervision in their district, and asked to get some official guidance. That's just my speculation.2 points

-

Very true, as the guy that's not only paying the bills but doing all the work, after repairing most of connecting rods in my gear doors, all with enlarged openings (mine has 3 gear doors per side). I have since reduced my gear down speed to 110-120 kts from 140. Occasionally If I am getting slam dunked I may exceed 120, but my norm is 110-120. That's going to be challenge for a new Mooney pilot but it doesn't take that long to be able to get it slowed down without the gear and then the gear will thank you for it.2 points

-

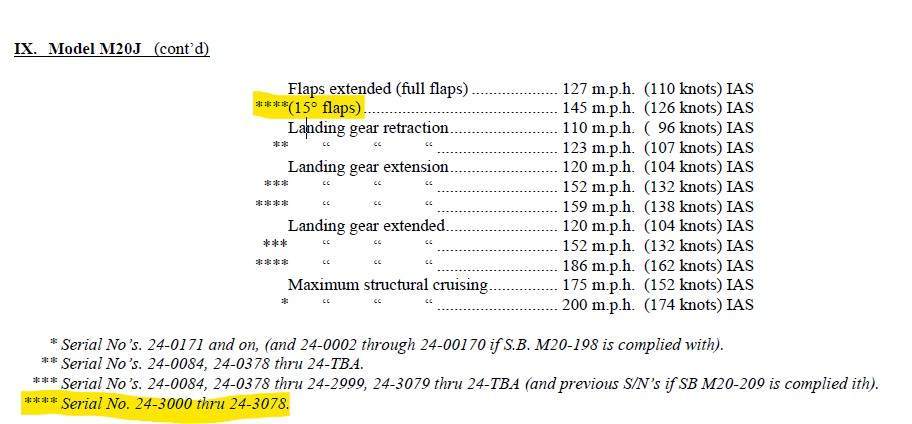

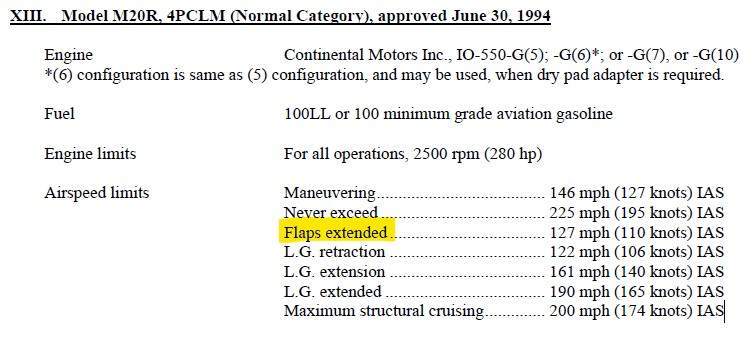

This is most misinterpreted limitation in the POH. In order to have a higher limit for partial flaps, don't you think they would specify a an amount of flaps and a higher airspeed? See the J models - the only Mooney's that have an approved higher partial flaps air speed limitation and its only for a small range of serial numbers, which are not even the last ones produced. After 34-3078, with the introduction of the 28V J's they went right back to single flap speed limitation. You won't find any such higher partial flaps speed in any other Mooney including the R, they all look like your R:2 points

-

The gear up and down switches are DPDT switches. One pole controls the relays that control the motor and one pole controls the indicators. The adjustment of the switches is critical especially on the Dukes actuator because, if not adjusted correctly, it is possible for the actuator to overrun and bend the tubes.2 points

-

@MikeOH there's definitely the economics at play that you're postulating. For awhile, it seemed that shops, in general, were throwing out very high repair estimates. If they got the deal, great for them. If not, they had plenty of work anyway. Some of the 6-figure gear ups really got my attention. I don't think the repair market is as hot now, but it's still strong.2 points

-

In the military we called it maintenance induced maintenance. We broke more things while inspecting them than we discovered already broke.2 points

-

Circuit breakers definitely wear out, especially if they are manually pulled from time to time. Agree that it's not particularly likely to be the problem, but it's definitely in the the set of things to check and/or consider replacing.1 point

-

Maybe another thought is replacing the field cb? It’s unlikely the cause but it’s cheap, easy, and you’ll make sure all the connections there are good. do you by chance have an engine monitor? You might set it to 1 second recording and look to see if it catches any electrical excursions at the time the cb pops?1 point

-

Maybe I don't make book numbers, but I'm sure faster than brand neighbor's brand X, and that's all that matters1 point

-

Well I was at a 500 hr oh anyway, so that made it feel like a good time. It does start a little easier but I never really had a problem with that. One really nice thing that I didn’t anticipate is that the timing never slips. It always has about a 30 to 50 RPM drop on a mag check. It’s been that way for ~5 years with zero change. No mx is nice!1 point

-

I try to be below 120 (typically 110-115) before dropping the gear and start with partial flaps at 100 which gets me quickly to 90 for full flaps. I try to be kind to my plane and this just feels right.1 point

-

@Hector I’m sure your Mooney is fine. I’m a good bit east of Cole here in north georgia and the storm passed just east of me. No wind damage personally, but lots and lots of trees down in the area. Lost power around 5am and it is looking like it could be a couple of days before they get that sorted out. I’ve got plenty of fuel for the generator so everything is good on my end. (And I sure am glad my mooney is still in a hangar out west.)1 point

-

Yes, I borrowed a battery from my neighbor with an E. All I’m able to do is scuff the nose wheel tire with the friction drive. Even with hangar threshold ramps, it struggles. i just ordered a 40 EZ gas tug1 point

-

This owner is ok. A section of my fence blew out (vinyl fences are a bad idea in FL... it blew out with Irma and Ian) but otherwise I don't think we have any outside damage. I will go to the airport tomorrow but I'm not concerned about the airplane given it is hangered. Punta Gorda, where I keep the airplane had a lot of flooding, but my understanding is that the airport does not flood. Hopefully others made out ok. I would imagine Mooney X is cancelled. Tampa has lots of flooding.1 point

-

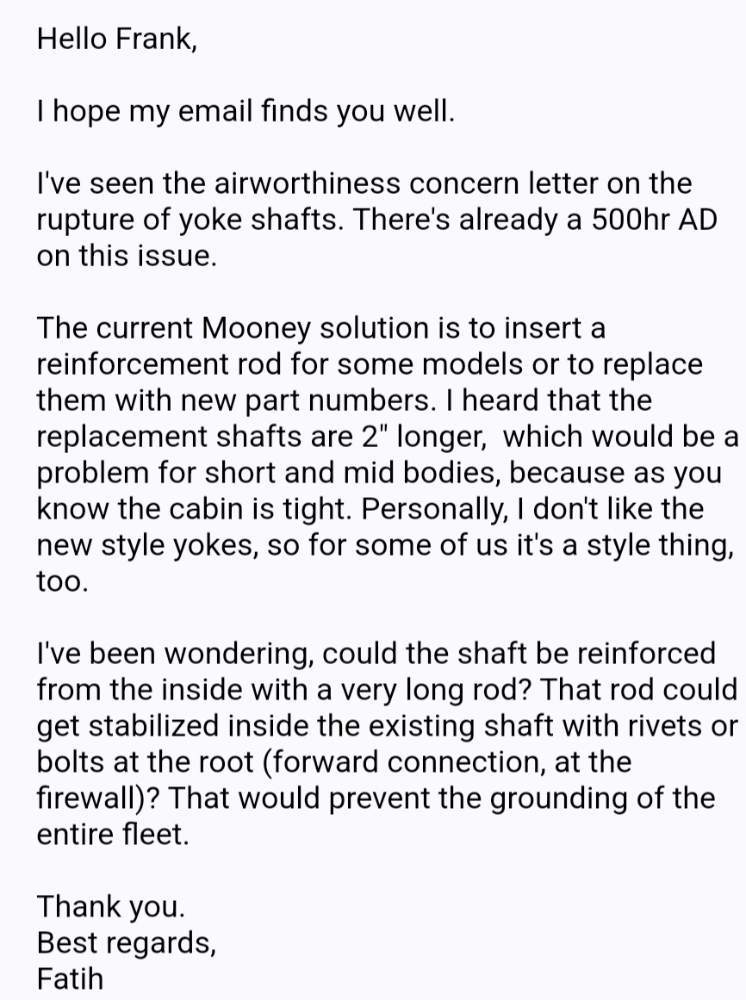

If I'm not wrong, the new style yoke shafts are 2" longer, further pushing the already bigger yoke into your stomach. I don't understand why one cannot strengthen the old yoke shafts by sticking a longer rod inside of them and then rosette welding them, instead of using a 2" insert held by AN bolt. I'm fit, no tummy, yet the cabin is crammed. Especially for the front pax when rear seats are occupied. Edit. Wrote to Mooney.1 point

-

the advanced timing doesn't kick in till at altitude with reduced manifold pressures, won't impact starting at all.1 point

-

90F out, will be hotter than Atlanta all weekend here. Thankfully the humidity has dropped from 90+%. Wind wise I would say average for a windy day. Skywest liked it so much they did it twice for the experience. https://flightaware.com/live/flight/SKW5053/history/20240926/1945Z/KDEN/KJMS1 point

-

Interesting discussion. I've had a beautiful mag compass in my office for a few years now, gift of my grandfather-in-law who was a WWII aircraft mechanic who later worked at Boeing and UW (a fine man). It's a horizontal-mount whiskey compass that seems very well-built and brisk to turn, better than most I've seen. I'd wondered about putting it in place of my plastic center-post-mounted compass in the Acclaim. A combination of backup and nostalgia (which isn't what it used to be ;). Any thoughts on process and documentation? I think the compass is "required".1 point

-

Agree there too, that is where the captive market comes in. Some may consciously take advantage of it, but I believe the majority may just not be as well organized, but they don’t have to compete as much as other businesses and that affects the ethos in general. I mean your plane is in a thousand pieces on the floor and they say “it’ll take twice as long as we said, maybe”, what are your options? Everyone else there is in the same boat.1 point

-

1 point

-

Ah so ka. That picture is worth a couple thousand words. It would be tedious trying to fish many wires around those rivets with such little space above it. Do you think pushing a piece of thin piano wire through from the other end, then taping the wires to it and pulling them down would be any easier? It would need to be thin enough to flex out around the linkage.1 point

-

The picture in the airworthiness sheet shows the yoke being cracked. Either can happen I suppose Sent from my iPhone using Tapatalk1 point

-

1 point

-

The diameter of the shaft itself isn’t the problem, it’s how it’s attached to the bracket for the linkages. The old one was welded into a cradle leaving a hollow shaft with lots of space between the end of the shaft and the vertical bracket to feed the wires. With the new one, the shaft is inserted into a sleeve not only leaving very little room at the end to get wires in there, but then you have to squeeze around the two crossing rivets.1 point

-

As an aside, I got an annual done several years ago at one of the shops you use for annuals. Good shop. Expensive. They found an issue with one of my trim rods requiring replacement (thank goodness Mooney was quick-ish). They replaced the rod and finished my annual. When i picked it up, I did a very thorough inspection and noticed that the paint below the tail pivot seemed different but I really wasn’t sure. Trim was set to the middle (to) position. I was disturbed by the fact that the tail and the trim indicator might be different and they told me, yeah it might be out of whack after we had the trim all apart. Let us know how it feels and we can adjust the indicator. Well, I thought it through and took off with the trim centered. Airplane was trimmed very nose up so it was exciting but i was mostly ready for it. After landing I looked and the paint was lined up as I thought it had use to look but my trim was way off center. I had them set that to TO trim. So maybe it’s not an exact science…1 point

-

1 point

-

The parts are available. Just see that you have back-up spare parts on the shelf. John Breda1 point

-

Unless the shop has a trim board for checking the elevator and stab angles and willing to jack the airplane to level fore and aft it won't get done during any annual. Airplane has to be leveled Stabilizer set to a specific Leading Edge down setting using the trim board AND then the elevator up angle is checked and set by adjusting the spring bungees on the inboard ends of the elevators (adjusting the fwd ends of the bungee control rod and NOT trying to adjust by the spring retainer nuts at the aft edge of the bungee unit!!) This is all spelled out in the Mooney TCDS (Type Certificate Data Sheet) a portion of which I have clipped below. You will notice that the elevator up angles and the P/N of the bungees are different via serial number. You being a 1970 model I believe you will fall in the after 680001 number field. Be sure to look at the cautionary note on the extension springs at the bottom if you decide to have someone adjust these settings. You will also notice that the later Fs have a higher elevator bungee angle than the earlier ones. Something to think about if you have pitch trim issues. Control Surface Movements Stabilizer (L.E.)................Up.......½° to 1'.............Down ........5¼° to 5¾° Elevator Trim Assist Unit (for Aircraft with Serial Nos. to 680001): With stabilizer set at 3½' negative setting to the thrust line, adjust trim assist unit 740128 for elevator up angle of 5' =/-1'at the zero spring travel position. VII. Model M20F (cont’d) Elevator Trim Assist Unit (for Aircraft with Serial Nos. 680001 and up): With stabilizer set at 3' negative setting to the thrust line, adjust trim assist bungees 740188 for elevator position of 19' +/-1' at the zero spring travel position of the bungees. (This rigging to be obtained before installation of the 740171 extension springs). Leveling means Edge of skin splice over aft fuselage radio access panel. Spirit level is used to level.1 point

-

Actually, if Mooney only wanted to be a parts supplier and nothing more with no dream of ever building a plane again, then the best thing would be to file bankruptcy. There would be a "sale of assets" of the engineering drawings, IP, certificates which would go to a new Parts Building Only company. The New Parts Company would right size to less overhead, smaller facility, All the liabilities related to building planes would stay behind in the bankrupt legal entity. All the overhead costs for legal and insurance related to full aircraft manufacturing would be gone. The 3rd party supplier agreements would be gone but the 3rd party suppliers would still need to abide by the Intellectual Property rights that the New Parts Company would own. But everyone overlooks the fact that the Chinese Meijing Group still owns 20% of Mooney Corp. We can say that Meijing was dumb for dumping $100+ millions into Mooney but I doubt that they are stupid. Most likely the money that Meijing put into Mooney is in the form of loans that are secured by the assets of the company including the IP, engineering drawings, certificates, etc. That means that Jonny cannot sell or give away or release any engineering data like on the simple 20 and 40 gears. There is no indication that Jonny and Wyoming LLC US Financial came with bags of money to buy out Meijing or make them whole. Look at what the VanGrunsven family did in the Vans Aircraft bankruptcy. Founder VanGrunsven had been selling his ownership in the company off to the employees (who had no real significant money to put into the company - which sounds like US Financial at Mooney to me). However, VanGrunsven had secured all the assets of Vans with loans to the company in his family name. When Vans filed bankruptcy, VanGrunsven was on both sides of the settlement. It was 'win-win" for VanGrunsven regardless of whether it was a Chapter 7 liquidation or Chapter 11 reorganization. He had every outcome covered. If it went Chapter 7, he could jerk all the designs, engineering, certificates back he was secured. (also all the machine tools). In Chapter 11 (which is the way it went), he is the biggest creditor and wound up with 100% of the stock. VanGrunsven was the "puppet master" in the entire settlement. The employee stockholders got hosed.1 point

-

Based on the listed discrete inputs it isn't clear that it can help much with annunciations unless you have the EIS, which will handle volts, amps, and low fuel. Nothing for gear and others you might have. After installing the EIS, for my M20J, I only had the gear left (no vacuum, ram air, etc. annunciations) so I used an Eaton style annunciator for the gear and was able to remove the annunciator panel. YMMV depending on what annunciatios are in your annunciator panel.1 point

-

One issue is that any crack is potentially hidden under the plastic (powdercoat?) finish which is flaking on mine (looks like a crack, but evidently metal underneath is good). I talked to my A&P about this and specifically asked if we could adapt with this nice, machined billet ACS yoke (https://www.aircraftspruce.com/catalog/appages/acscontrolwhl3b.php?clickkey=7575) That got a hearty NO response. So it's ok to spend $750 for a 50 year old used part made of cast metal that is known to crack, but we can't substitute a modern part like the ACS which is both stronger and cheaper.1 point

-

Like @EricJ said, the “first” part IS the Moss interpretation. The “second” part is simply the supporting rationale for why an in-person A&P is needed, and NOT a remote supervisor. Mike Busch’s reaction is an emotional knee-jerk to the “second” part that simply isn’t there. Again, it’s just the rationale for the in-person supervisor. I appreciate Mike Busch because he does a great job of providing good, common sense advice and information to owners and A&Ps. But he isn’t always correct.1 point

-

I wound up with another F (that Jimmy found me). Met ALL of my needs and all but one of my wants (have to manage my vertical myself on approaches). My list was NDH, low time motor, WAAS navigator, autopilot w/ alt hold, and not ugly. Needed nothing, and could not be happier. Aircraft was owned by LASAR in the 80's & 90's, so it has a LOT of mods. Not to mention, she's a looker.1 point

-

I promised to not post about politics anymore. This is not politics, it is government. I have a friend who works for Harris Corp. they were contracted to build the system to take the 2020 census. OMG They built a system that met all the original requirements using COTS cellphones. They bought all the phones, wrote all the software and were about to be done way ahead of schedule and under budget. Somebody from the government decided that cell phones were not secure enough and said that they could not use the internet. They made them destroy all the phones they bought. They wouldn’t let them sell them because they had government software on them. Harris said they could wipe them all. The gov said no, they had to be destroyed. So all the software they wrote was worthless. They had to design custom handheld devices that had to be brought back to the office and the data had to be downloaded to a private network. Im not telling all the details, it is too much to write. In the end they built three different versions of the handheld devices, wrote four complete software packages. In the end it cost 10 times the original contract and was almost not ready for the census. The devices were barely usable. He said the problem was every week somebody would have a different idea of how it had to be done. There was no single person in charge of the government project and nobody really knew who was running things.1 point

-

My thoughts exactly. This is nothing but bureaucratic nonsense to make the systems they spent billions on last year sound like the problem. The amount of money this agency wastes on its pet projects and legacy costs is staggering. 13 billion dollars… They really need a systemic overhaul from top to bottom. Our government doesn’t seem to be accountable anymore. For anything. If it doesn’t work throw more money at it! Sidebar, when I was in college I interned for my uncle who was an electrical engineer. He was the primary engineer for the local airport which does barely have commercial service, but it’s a small class C airport. He did the runway and taxiway lighting for the airport for 35 years. Every year or two it was “upgraded” in some way. Really? Or were they just making sure they spent the money they were given? https://www.transportation.gov/sites/dot.gov/files/2024-03/FAA_FY_2025_Budget_Request_508-v5.pdf Waste fraud and abuse is at least 40% of this bloated beast!1 point

-

1 point

-

Oops, forgot I never closed this thread out. Jimmy came through and found me the perfect airplane. I could not be happier.1 point

-

Not once in the almost 14 years I’ve used one. My strategies. Mount in a way that allows airflow around it. Keep the screen brightness low while still readable (bright screen = heat) Turn screen off when not actively used. Have it already charged so you don’t have to charge while using. Don’t leave it in the airplane when you land for lunch (and in a shaded spot during preflight).1 point

-

If I have my iPad Pro 11" sitting in the sun, it will overheat. If I put it in the shade it's okay.1 point

-

1 point

-

Oh and I was once informed by a (female) coworker that it needs to be named Trudy because it is "just the right amount of slutty." I'm not too sentimental about these sorts of things, but even I have to admit that the name has stuck. She's always gotten me back down when we go up, Trudy!1 point

-

My practice, with electric gear: Gear comes down when the glideslope is one dot high, set descent power, then half (takeoff) flaps. I leave the flaps there and do not go full flaps unless I have broken out and a landing is assured. The plane lands just fine with half flaps or even no flaps. This is to avoid the high workload that comes with a full-flap go-around. If you have to go around from 75 KIAS with gear and full flaps, and you're trimmed properly for that (near full nose-up), the pitch-up action is very strong, so you have to do partial power, put in some nose-down trim, raise the flaps to half, let the plane stabilize a bit, raise the gear, more power, more nose down trim, raise the flaps. It's a lot to do while bumping around in the clouds in IMC near the ground, trying to fly a missed approach and not run into a tree you can't see. Leaving the flaps at half removes pretty much all the workload. You won't be trimmed as much nose-up. You just go full power, establish positive rate of climb, gear up, flaps up. I don't usually do touch-and-goes in the Mooney but my practice is the same for those. They're easy with half flaps, lots of work with full. It's good to practice full-flap go arounds because you may need to do one someday. Obstacle on the runway, someone pulls out in front of you, etc. But I don't want to do it in IMC. And if you're flying an instrument approach, there is pretty much always plenty of runway so landing with half flaps is fine. I also only use half flaps if the wind is gusting more than 5 knots or so. Really reduces the plane's tendency to balloon up off the runway in a gust. I have about 2 hours in a manual gear Mooney but don't think I'd do anything different.1 point

-

I have manual gear. My father in law (also a pilot) teases me that all the knob turning and lever pumping makes it look like I’m running a steam engine during approach and take off.1 point

-

1 point