Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/2024 in all areas

-

Folks, I recently won a field approval to install a B & C standby alternator for my 1981 M20K (231) late last year. I just completed the installation and, though I have only flown once with it, it works as advertised. The 20 amp alternator mounts to the empty vacuum pad on the back of my TSIO-360-LB1B. I am very happy about this because of all things on my airplane, the gear driven alternator - with its finicky coupling - is the weak link. I started this process right here where someone pointed me to an existing field approval for a slightly different airplane - one with the -MB engine. I got a copy of that 337 and called the installer at LASAR and he gave me a rundown on the install and the process to obtain the field approval. I then emailed a copy to my mechanic and enlisted his help - he was willing. I then emailed my FSDO’s Principal Avionics Inspector who seemed immediately positive about the prospect of a field approval. The inspector had me edit the 337 form here and there, and had me draft an AFM Supplement. I think the FSDO was so easy to work with primarily because the B & C system is such a well-known quantity. TJ at B & C was an excellent resource and helped me immensely with technical questions along the way. B & C has its own technical publication section available on its website that was very helpful as well, with line-drawings and installation instructions for the PA-32 and the Bonanza. If anyone wants help, I have compiled quite a trove of documents I used to prove that the install would 1) work on my airframe, 2) work on my electrical system. Ethan6 points

-

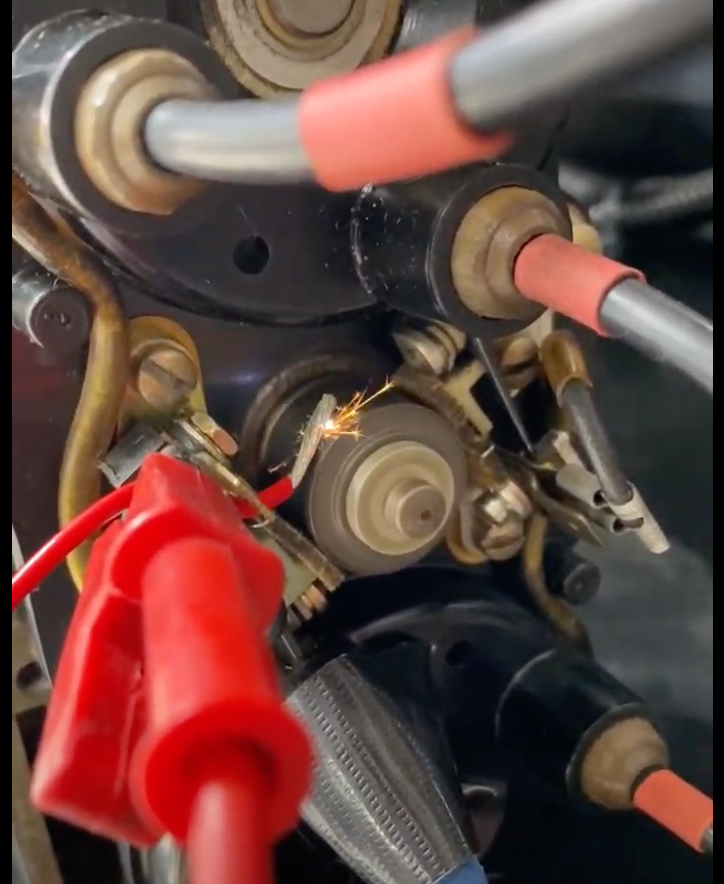

As you may recall, last year on May 9, 2022, I experienced a complete flame out and off-field landing just short of Double Eagle (KAEG) in Albuquerque. The root cause of the D-3000 dual mag failure has haunted me - until now. The mag failed at 209 hours after the overhauled exchange. Mags checked good upon departure but both point gaps closed to zero during cruise 1.5 hours after takeoff. The FAA sent an IA the next morning to remove the mag. The inspector found that both point gaps were at zero. Also, inside the cap was a condenser wire with melted insulation where it had been rubbing on the cam. The common thinking seemed to be that the burned and shorted condenser wire would have simply grounded out one mag leaving the other unaffected. The glaring evidence that everyone seemed to ignore was the burned and shorted wire was causing a much bigger problem. With the help of my local IA and his mag tester stand, we mounted up a dual mag and shorted out a wire from one point connection to the rotating cam. Sparks flew and temperatures rose quickly on the cam. So, what happened in my mag turned out to be an installation error with a condenser wire touching the cam that took 200 hours to finally wear through the insulation. The cam heated up softening both point rubbing blocks nearly simultaneously to the point of closure. It does baffle me that the mag is designed that it is even possible for this wire to be routed to cause such a problem. At least there's some satisfaction in knowing that the mag itself is rather robust as long as precautions are taken not to misroute the condenser wires in the path of moving parts.5 points

-

4 points

-

It is very unlikely the LED devices are failing. It is almost certainly the mounting and control circuitry assembly is failing. Like most PCB assemblies, Heat and vibration are the problem. And don’t forget water, which can get in and corrode the circuitry. The LED light assemblies are much more complex than an incandescent bulb. And therefore have more failure modes.3 points

-

I fly my J all over the country, but I cross the rockies infrequently. If I were to do it often I would definitely go for the turbo. I absolutely love my J and its efficiency, utility, and low maintenance/operating costs but the performance at altitude is great up to about 13.5K but after that it is slow going and your climb rate is insufficient IMHO for anything but good weather in the mid teens as you won't outclimb a downdraft. In the big picture, the reliability and maintenance costs for the turbo are not significantly more (some here will argue it isn't any more), so if you are really interested in flying often in the midteens, go for the turbo.3 points

-

3 points

-

I've flown around the mountainous west a lot in two M20Js I have owned. I've been to Leadville and got my T-shirt. The J does fine in the mountains VFR and there are lots of routes that aren't all that high. But, I'm usually operating well below gross weight. If I were going to regularly load it up, I would consider a turbo. The MEAs are high and IFR routes are not always practical, so I mainly fly VFR in the mountains with flight following. The turbo is faster because you can fly it higher and get higher TAS. Eastbound, you also get a boost from the prevailing westerly winds aloft. Going west, the same winds can work against you. But this really is only significant on long flights. There are times when a turbo would have gotten me above clouds that blocked lower routes and it will get you above the low level turbulence common in the summer. But, the turbo doesn't help much with the two biggest problems that have affected some of my trips: icing and large areas of summer thunderstorms in the Midwest. In the mountainous west, the winter freezing levels are low and the icing layer is often thick enough that you have to climb through a lot of icy clouds to get high enough to be out of it. So, if my primary reason for getting a turbo was to improve dispatch reliability, I would also want deicing.2 points

-

I have a Mooney 231 (K) model with the LB1B engine, the Merlyn upper deck pressure controller (waste gate controller) but no intercooler. I live in Portland, Oregon and have flown it about 1300 hours over 9 years. It's the only airplane I have owned and I fly it in high country frequently. I really like the options the turbo gives me. It allows me to fly with my family at the high MEAs out here. It takes some of the stress out of high density altitude departures. It allows me to top weather when I would otherwise have to plow through it and pick up whatever it decides to throw at me (ice, turbulence, hail). I've had a good experience with the engine and have not had any major problems with it. The last engine we had made it to 2400 hours (1000 hour top). It was running strong when we decided to buy a reman and I regret the decision because it was running smooth as silk and felt great. The engine I now have is a factory reman with about 600 hours on it. I had to refurb a cylinder the last annual because it only made 15/80. That wasn't the biggest deal in the world and wasn't all that costly. You could probably make a 201 work for you but I suspect you won't regret the 231 or 252. You might want to look hard at 231s because they are cheaper and have better useful loads than 252s. Mine is 1000 pounds. Also, most 231s have the newer LB1B engines (instead of the GB engines) many of the 252 upgrades including the Merlyn waste gate controller and intercoolers.2 points

-

I don’t have any K time so can’t comment there, but I have flown my J around the Rockies a bit, landed at Leadville, and operated at a few other high altitude airports… it does fine, really. Obviously I wouldn’t do it midday in the summer at max gross, but the runway and climb performance was plenty adequate for my wife and I and a bunch of bags and maybe 40 gallons onboard for the really high airports like LXV. That’s a lot of flying miles in a Mooney. I operated from COS and GJT with full tanks without any issues either. To me the real question comes down to whether or how often you plan to fly on oxygen. I personally don’t want to (flying with our dog) and so I flight plan to avoid the need for it. You can get really anywhere at 12k without going too far out of your way… but if you wanted to go *over* the rocks, obviously you need the turbo. If I lived out there I would probably have a turbo, but I don’t think I would really *need* the turbo except occasionally.2 points

-

Yeah - Ultimately the DZ has seemed like a solution want of a problem (for me), but there are at least a couple of use cases where I keep thinking it would be valuable. I’m happy with my portable, and really haven’t had any problems with it. But e.g. when I’m flying in someone else’s a/c, I normally just grab my headset and a certificates lanyard, and it’s not unusual then to be flying around with no CO detection. Having it integrated in the headset means you always have it with you.2 points

-

It’s been years since I had my CC with the Verado, back then they only had inline 4’s which I had and an inline 6. The 6 was smooth as glass as an inline 6 is better balanced than a V8, it reminded me of the old Tower of Power way back when. The Verado was a much better engine than a Yamaha in my opinion. My boat couldn’t handle the weight of the inline 6, I was slightly underpowered with only 175 HP because it was outfitted as a dive boat so we always carried at least 6 dive tanks, usually 10. I’ve been happy with my 4 cyl IO-360, it’s smoother than I expected, four cylinder swinging a two blade prop I expected more vibration than I’m getting, and it’s frugal which I like. From memory I think between 10 and 12 thousand running WOT at 2200 50 ROP I burned 12 GPH with the 235 IO-540. It just wouldn’t run LOP very well, actually it would run like -25 LOP but if I ran the exact same speed ROP it just wasn’t much fuel savings. I’ve not bothered trying that test with the Mooney, I’m convinced the engine I have is the poster child for LOP, where the 540 just wasn’t. I was stationed in Germany for a tour, hence the name.2 points

-

Aeroled Polaris is a less expensive alternative to Chroma nav lights. Installed about 200 hours ago and leave them on continuously. No problems.2 points

-

Generally, lower power is easier on the engine. The airlines used to cruise the big radials at around 55%. But, as others have pointed out, there is a point where the temperatures are too low. Low oil temperature will allow moisture to collect and cause corrosion, and Ed Kollin (Camguard creator) argues that low CHTs cause poor lead scavenging and increased deposits in the top end leading to valve sticking. The oil cooling and CHT cooling is designed by Mooney to handle high cruise powers because most people buy airplanes to go fast. Bottom line is that running at 65% is probably the best for economy and longevity.2 points

-

I had a burnt out nav bulb so I figured what the heck? I replaced both with some Whelen Chroma LED lamps. It seemed a no brainer. I don't like the OR6502 series for one reason. This line in the ICA: If any one LED fails, the unit must be repaired or replaced. Replace the entire unit for one dead LED? Really? How about a few extra so you can have one or two out? With the Chroma, I can simply replace the bulb unit. Knowing that I had to either put in a relay or leave in one incandescent bulb in the circuit to prevent daytime dimming of the annunciator panel, I left the right aft white nav light incandescent for the time being. The install went good, it all worked. Then I was preparing to leave KMTN the other night and none of my LED nav lights worked. No green, no red, no white on the left aft..Only the incandescent worked. I fortunately kept my incandescent bulbs, so I changed them on the ramp. Took about 45 minutes but I got them all done and everything was ops normal. I flew home to Georgia that night. Today I tried the LED's again. Tried them one at a time. I tried an improved ground. No help, so I am back to incandescent. Don't know if I will try the OR6502 because of the ICA limitation.1 point

-

1 point

-

I, too, would bet on mounting of the LEDs as the problem. Solder attach of large surface mount components (high-output LEDs, in this case) for long term reliability is difficult to do properly. Environmental and operational thermal cycling of the solder joints combined with the TCE mismatch between the LED and the substrate (circuit board) commonly results in solder joint fatigue failures over relatively short times if not well engineered.1 point

-

Yes they also call it Aviation Form-a-gasket. https://www.aircraftspruce.com/catalog/pnpages/09-28500.php1 point

-

1 point

-

Call J&J Airparts in TX, they can often hone Nickel and if so re-ring it. They’re not real fast though. Sent from my iPhone using Tapatalk1 point

-

Article I wrote on page 23 - https://themooneyflyer.com/issues/2023-AugTMF.pdf I am biased, but I am a HUGE fan of the 252 with the Encore upgrade. 1100 pound useful load. 175 KTAS on 10.1 GPH. Turbo for high density altitude operations.1 point

-

I think that many times the idea of do you or don't you need a turbo misses the additionally capability of what a turbo affords you. For me, the turbo Mooney is a huge value add for capability, safety, and options. Even when you're not trying to climb over mountains, there are many times it's a huge plus to be able to climb over weather. Less drag and often better tail winds at altitude. The upper teens and low flight levels are often much less congested traveling across the country (jets much higher, all the NA folk much lower). Glide ring is much larger (the higher you get) which affords more opportunity with any in flight issues (other than fire). Being able to generate full power even at high density altitude airports is a HUGE safety margin for departure, climb out and obstacle clearance. ODPs in mountainous areas often have climb gradients that many lesser NA aircraft (read not Mooneys) may not be up to. But in the end it all depends on the flights you'd actually make. For me the M20K is my sweet spot...and is probably why 6 (4 K's and 2 Bravos) of the other Rocky Mountain Mooney pilots I fly with have turbo Mooneys. We all love them and actually use the added capability routinely.1 point

-

10 minutes faster, 10 more gallons of fuel... I am was impressed that we both left our airports so close to on time that we intercepted and ATC made me climb to 9000 for sequencing to Salem.1 point

-

I’m with you. As I have a tailbeacon, the lights are on all of the time, and I guess it’s three years later they still work. However I think that new aircraft should be all LED, and good quality LED’s will last a very long time, but to spend the $$ that they cost to replace the old incandescent? You just don’t get anything for the money from what I can see. Low quality LED’s are noisy, so noisy that they can interfere with Comm / Nav equipment. I put inexpensive LED lights in my hangar, they are so noisy that they break squelch on my radios. So if you buy LED’s from Ebay, Amazon or whatever they could cause a problem. The USCG check procedure only checked Comm freqs of course not AIS etc.1 point

-

1 point

-

The dimming circuit depends on the filament of an incandescent bulb having a very low resistance when the bulb is not powered. The landing gear annunciator light is grounded through a 470 ohm resistor and also through a diode to the nav light circuit. When the nav lights are powered, the diode is reverse biased and the 470 ohm resistor limits the current and dims the annunciator bulb. When the nav lights are off, the filament(s) provide(s) a low resistance path to ground through the diode shunting the 470 ohm resistor and allowing more current through the annunciator light bulb causing to burn brighter. The annunciator bulb draws much less current than the nav light bulbs so that even though current is flowing through the nav lights, they don't illuminate. It is a circuit design that is just maybe a little too clever .1 point

-

I’ve had aeroLEDs on mine for at least 9 years too (previous owner). One leaked and filled with water (still working). One (white tail light) went out. Both were replaced free even though I had no warranty info, proof of purchase, etc. In the last 8 years, I leave them on and no issues.1 point

-

I designed my Dynon panel so the next owner only has to install a G 175 to be fully IFR capable although it would be single source WAAS GPS only navigation (perfectly legal for all IFR navigation) no VOR-ILS-ADF etc. I figure if someone ACTUALLY did enough IMC flying that really needed all sources of navigation they need a different airplane than a 60 year old Mooney.1 point

-

Probably rodents since there's a dead one in one of the pictures. Their urine is very corrosive and in the pictures you see the patches that were affected.1 point

-

Great job! @jlunseth might be interested - if memory serves correctly he was thinking about this awhile back. It might be worth a trip to Oregon to get it done.1 point

-

I like those two items separate. The portable CO detector, which seems like it has a much more robust detector, can be replaced when needed. I wouldn't want to send my headset off for service when the CO unit times out.1 point

-

Whelen's bottom line The challenge comes in when the power supply box for the strobes fails. Since the nav and strobe lights are together on the wing tip, if the strobe box goes out people find it's better to bite the bullet and switch to the LED strobe/nav. Mooney made a smart manufacturing move to simplify when on later models (maybe only Acclaim) they mounted the strobe power unit on the backside of the baggage compartment in the avionics bay, rather than mounting a unit in each wing. It makes wiring and syncing a breeze when you eliminate the power supply and switch to LED units.1 point

-

I haven’t gotten on the LED nav light bandwagon. I still have incandescent bulbs. In 40 years of airplane ownership, I think I have replaced 3 nav light bulbs. I fail to see what problem LED nav lights are solving.1 point

-

I'm willing to bet the aluminum curve varies more than the amount you want to trim off in thickness These are all hand built, no to identical airplanes Pop a window out an lay a thin strip of aluminum (on the inside) matching the curve and see how much it all varies from top to bottom. None of this stuff is close tolerance manufacturing Just look at how the rivets are set. Highs and lows in the surface.1 point

-

To continue 8 GPH at 23 squared gives me 135 kts which is 16.9 MPG 6 GPH at 21 squared gives me 120 kts, which is 20 MPG, but 120 is usually too slow for me, and 3MPG just isn’t a big enough number to matter to me. Maybe if I had to push range though. Climb higher and run 155 kts at 10.5 GPH gives you 14.8 MPG, but I’ve found that I burn more climbing than I realize so unless it’s a several hour flight I don’t. Just for grins a Legend Cub’s book cruise speed at 75% power is 82 kts, an O-200 will burn about 6 GPH which gives the Cub 13.6 MPG, the Mooney J model gets better fuel milage than a Legend Cub at any cruise speed. My C-140 flies at 91 kts burning 5 GPH which gives it 18 MPG. I’ve not checked any lower speeds and the fuel burn is a SWAG as it doesn’t have fuel flow, but I’m sure it could match the Mooney at 20 MPG.1 point

-

For starters take a sponge and squeeze tks fluid into the dead spots, run a couple of gal of fluid on high flow on a cold day, eventually the low pressure light will go off, thereafter run 5-10 min every month on high until you see even flow along the panels1 point

-

Just like a Garmin G3X or TXi or GI-275 needs a waas navigator for IFR enroute and approaches, the Dynon needs one too.1 point

-

the cam in these engines is optimized for 2450 RPM. At slower speeds, you get more reversion, and more deposits in the intake and on the valve stems.1 point

-

FWIW, I've had a Zulu 3 for a long time that I've absolutely loved. So I bought a Delta Zulu and figured I'd move the Zulu 3 to be a passenger spare or something. FWIW, imho the Delta Zulu is much less of a headseat than a Zulu 3, and it sounds like this sale is an attempt to get rid of some Delta Zulu inventory. If you are in the market for a new Lightspeed headset, I'd recommend the Zulu 3 over the Delta Zulu. The Delta Zulu was not very well thought out, which is a shame because the Zulu 3 is great, especially in comparison. Anyway, just my 0.02. I suspect they're trying to get rid of some of the Delta Zulus this way.1 point

-

1 point

-

The purchase price is a small part of the overall cost, so don't get too hung up on that. Look through the log books. Look for anything that looks odd. You may want to use the assistance of an experienced Mooney mechanic to help. I used @jetdriven here on MS. He helped me learn through the process. We spent a lot of time on the phone and the small amount billed was well worth it. Corrosion is a big thing, so have a good shop do a good pre buy inspection. And tell them explicitly to check for corrosion. Where are you? And where is the plane? We can recommend some good shops around the country to do this. And mentioned, hours on a regular basis is a good thing. Many people prefer to buy with a high time engine (priced appropriately) so they can control the overhaul shop or do a Factory Reman or even New. Some sellers do a quicky overhaul and a not-so-great shop (if the plane you are looking at has a very recent overall, ASK US about the shop) just so they can sell with "fresh overhaul." One plane I looked at, had such a great overhaul, it was overhauled again a year later and 5 years later had a top overhaul, and 2 years after that, replaced a cylinder and another one the next year. I agree that getting close to the instruments in the plane is cheaper (and faster) that doing them later. At a minimum you want a WAAS capable GPS. Steam gauge versus glass panel can be a huge debate, but you can fly either and do your instrument rating with either. You can spend more than a cheaper plane in avionics (see my thread in the Avionics section). Also, plan on some flying with a good Mooney experienced instructor. They are not hard to fly, but they do have some quirks and you need to fly precisely, especially for landing.1 point

-

1 point

-

I would run it at 19/19 and lean it as lean as you can get it without it running rough. If you are concerned about dehydrating your oil, change it more often or fly at high power every now and then. I would say any time spent flying is better for the engine than time spent sitting on the ground. No matter what power setting.1 point

-

I met with a Dynon engineer yesterday. Dynon owns an early M20J and has been flying it as an autopilot test bed for a couple of years. The engineer wanted to verify some part numbers and measurements for the elevator and trim systems on a late model M20J and that's why he contacted me. I was glad to help. He told me that they hope to certify the M20J and M20K together. I don't know how far along they are on the K and the certification date is anyone's guess, but they are seriously working on it and they are making progress. He said the next in line was probably the Cherokees. He didn't mention other Mooney models. That's all I know.1 point

-

What are you going to use it for? If doing landing gear check I think the dial type is the best.1 point

-

$52 ea. We used these or something very similar in A&P school. It's just a plate. Nothing special about it. https://ryanaircrafttools.com/products/1598 Or $39/ea: https://flyboyaccessories.com/products/cylinder-torque-plate-for-lycoming-engines1 point

-

1 point

-

I'd really like to thank Robert for letting me check out his gorgeous Acclaim at St George! Had a chance to sit in it and see how well it fit and while the cockpit is certainly snug, not uncomfortable at all and the amount of usable space in the cabin is quite surprising. Also, the wife loved it! So now I've decided that a M20M Bravo will be my plane! Let the looking begin (or continue..)....1 point

-

Tesla driver friends tell me that now with their DMV annual renewal fees, our glorious state has imposed an additional $500 fee. Did I ever mention I LOVE my climate here!!!1 point

-

Gas tax funding is going down, electric cars don't pay taxes on the gas they don't use. Also, Kalifornia is busy giving money hand over fist to illegal aliens, and ignoring the citizens from whom the money is taken . . . .1 point

-

I see nothing wrong with this man's post and I don't blame him for posting here.1 point