Leaderboard

Popular Content

Showing content with the highest reputation on 05/11/2022 in all areas

-

I was allowed to use my drone at the local airport. So I am sharing the end product here... Hope you enjoy it. Oscar5 points

-

I showed my son this story. He wasn’t impressed. He said “what’s the big deal, I thought you said those were like a big 172. I landed one of those when I was 8.” I pointed out to him that I was there when he “landed the 172” and it was more of a controlled crash. Unfazed, he replied “I doubt this one was a greaser either.” I’m really going to enjoy parenting a teenager.4 points

-

WAT is making some REAL and good progress on the development of this light. If you want to be informed of future information, please PM or email me at gallagheraviationllc@gmail.com3 points

-

Made it to Gaston's!! Monday and Tuesday I stretched my Mooney's wings. It's been a while since the pandemic to really take some long trips. Also over due since the panel upgrade to really press me working in the system dealing with reroutes, etc. (Though out of the NYC area I just filed Direct and got "As Filed" ) 95% of the the trip was VMC, but there were some Broken and Scattered layers around due to all the humidity from the rain they had. So it made me not blow off filing so I could climb and descend through the layers without wasting time looking for holes. Only one Approach at Bastrop, LA (KBQP) due to the low morning layer that hadn't really burned off. As for Gaston's... Neat little place. I got they're later than I had hoped so didn't really get to spend a lot of time there. But it certainly is a fly-in destination! I opted to go to Baxter Co (KBPK) since I hadn't seen the runway for myself and they come to pick you up (staff had told me this is the easier of the two local Apts. Turns out it was a good thing I didn't try to go into Gaston's (3M0) which I found out from one of the grounds keepers who was giving me the ride. Airport is open, but the ground is saturated from all the rain they've been getting. No problem for the taildraggers and probably most Pipers & Cessnas. But he said they were sinking down in on landing and that might have been enough to put my lower gear doors into the grass. Also has to REALLY impact the ground roll on TO! All in all a good 2 days. I knocked off AR, GA, KY, LA, MS, WV from my states to fly to. Seven more to go....3 points

-

You cannot set the dual magneto engine to 20°. Whoever told you that is giving you bad information to cover up some other problem. Look at the type certificate data sheet, it’s only optional for non-D suffix engines. Whoever told you that is giving you Incorrect information to cover up some other problem, Because if it doesn’t run right at 25° it’s not right. I have a small feeling that your problem may not have been fixed.3 points

-

I had a young eagle like that once. He asked if he could fly and I let him. He was about seven years old and held altitude +\-50 feet and heading +/-5* for about ten minutes and through two 90* turns. When back on the ground I told him how impressed I was and he just shrugged and said he plays a lot of flying video games. Is it possible the passenger was a flight sim junkie?2 points

-

My fear that using it as rudder trim would overwork the servo since that's not its purpose. If I had a YD w/o rudder trim I'd be keeping the ball centered in climb with my right foot to avoid replacing servos any more often than necessary.2 points

-

Nope, the road was well compacted and a mix of gravel/crushed pavement. That's always a risk with grass strips/unimproved runways, they're hard on everything. I try to avoid them if possible but every now and then doesn't bother me. I'm not a bush pilot but I'm also not afraid to get a little dirty sometimes. Passing a neat airport town like this was certainly not something I was going to do. I bought this plane to have adventures with, after all!2 points

-

I want to tell a quick story to illustrate my above point. I'll give the short version. I was in a G5 at a small airport. Me and the other pilot both walked the aircraft and pulled chocks. We later decided to squirt on a little bit of fuel. The fuel truck came and did their thing. Whey they left, I went and checked the fuel door and looked at the tires from the front of the aircraft, no chocks in sight. We did the flight and everything was normal. But I got a call from the mechanic that night and he asked if we had hit anything. I said no. He explained that the sidewall of a tire was all scuffed up and a brake line was a little bent. We figured that we must have picked up a piece of rubber on the runway when we landed. Well, we found out from a pilot who contacted us about a month later that what had actually happened was that while fueling us at the departure airport, the line guys had put a small stubby set of chocks on the main tire. When they tried to pull them after fueling, the rear would not pull free. So rather than bringing it to our attention, they took the front chock and stuck it back behind the tire and assumed we would just pull away from the rear chock that was jammed under the tire. These chocks were not visible from the front of the aircraft as they were behind the large main tire. Well, the cock stuck to the tire, and came up off the ground and got jammed in between the tire and strut. We got very very lucky that when we retracted the gear, the chocks fell free. The pilot who alerted us to what had happened had seen this happen and had inquired to the FBO about what had happened... that is how we found out. Now, I was certainly mad at the FBO.... but ultimately it was my fault. So now, before I close the door, I do a walk of the entire aircraft to check once more for anything that may have happened since the full preflight. It is a pain in the ass, but it is my responsibility.2 points

-

That is exactly what it does. I can climb out with my feet off the rudders and the ball is centered. When altitude is captured and the plane accelerates, the ball is still centered. I fly a M20F with 2xG5s and GFC500.2 points

-

@M20Doc, thank you for sharing. It sounds like you’re doing the appropriate thing by bringing it to the shops attention and hopefully they will respond appropriately. In my line of work I also often find things that others could have done better and it has lead to some interesting conversations.2 points

-

Engines will come and go and get overhauled during the life of the airplane, but a tired Mooney airframe can’t be “zero-timed”. All that just to say that a well-maintained low time airframe is worth a premium. Getting those two cylinders taken care of should make this a good airplane for you. (Although one thing I would be very concerned about on a 2005 or 2006 Bravo is has it had the WAAS upgrade yet? An often-used argument is that “I don’t need WAAS - everywhere I fly has an ILS”. The next person you try to sell it to may not feel that way. Anything resembling an airplane is selling right now. When, not if, the market slows down, a non-WAAS G1000 airplane will be much harder to sell. If it doesn’t have WAAS what is your plan to add it? Garmin doesn’t make GIA-63W units anymore, although they service and exchange them. If Don Maxwell or Brian Kendrick has a pair of used GIA-63Ws it will cost somewhere between $30,000 and $35,000 to do the upgrade.)2 points

-

1 point

-

Always wanted to visit here ever since I saw Just Plane Silly's video on it. Finally got the chance on my way down to Vance AFB where I am awaiting UPT. Mooney is currently in annual and I cannot wait to go make some more adventures like this one. If anyone has some other cool spot I could check out around Enid, OK let me know! Excuse the trash thumbnail, I'm an aspiring douchy millennial YouTuber.1 point

-

Engine monitors and data collection seems to be the new wave of the future. This is a new thread so how about some ideas on how to create sub categories to collect the date. Maybe create a list of problems/issues: Sticking valves burned/failing valves clogged injectors clogged air filters. failing/bad plugs. failing/bad plug wires. bad probes. high/low egt's high/low cht's induction manifold leaks timing out of spec Fuel pressure issues. fuel pressure issues. Maybe post grafts showing before and after images. I know MB is a source of data but you have to pay for some of it. Why not establish our own library/collection of data/information? Thanks,1 point

-

Like kpaul... mine was also installed by Garmin....and tested and certified by Garmin. As per Garmin representatives, YD after takeoff during climb was normal OP. Each to their own, but mine works flawlessly.1 point

-

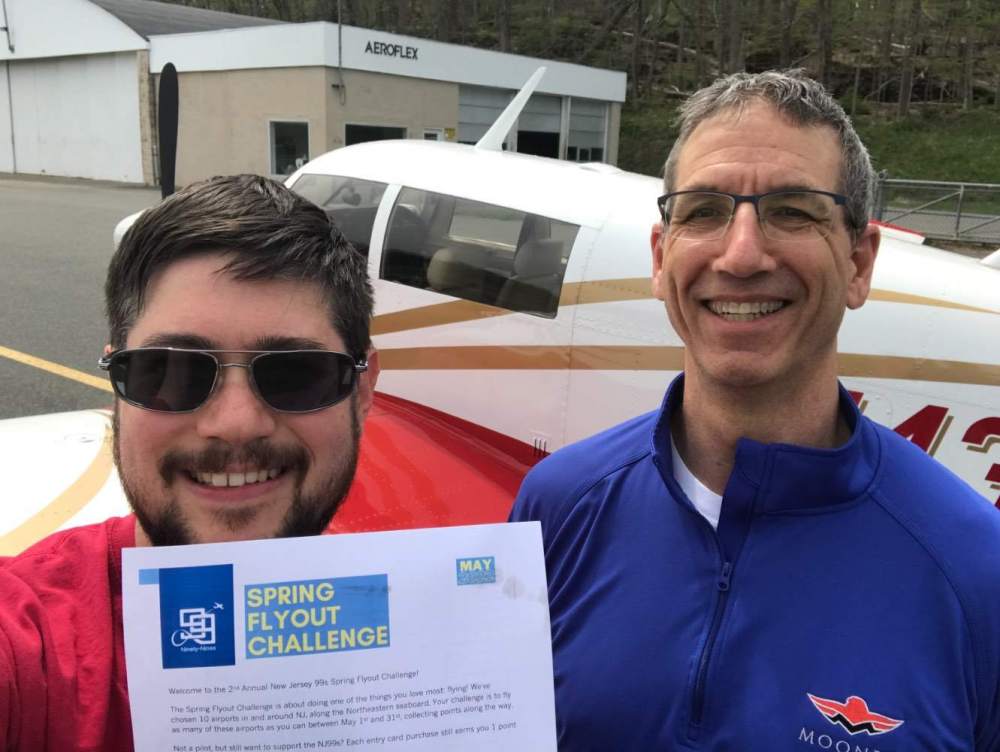

Had a really close call with a Turkey Vulture on final to Andover Aeroflex with 2000ft runway. Had to make an urgent evasive turn. Surprised I was able to still make that landing. Then had a near miss with a Red Tailed Hawk on departure. And then a close encounter with a Bald Eagle on base. Of course @carusoam was slow with the phone to get any pictures so blame him. But we did get lunch and each got 2 points in the NJ99s Spring Challenge.1 point

-

A simulator, many many of the younger generation fly those things for hours and hours. They really do understand the instrumentation and what control does what, plus this may not have been his first ride in a Caravan. My son learned to fly RC on a simulator and it’s pretty similar really, plus I don’t think I saw flaps down on the Caravan which I wouldn’t expect to see if someone really didn’t know, and due to trim change I wouldn’t tell them to do myself, but someone with just a little knowledge and or training would have dropped flaps. ‘So I think it’s plausible1 point

-

it is a COM antenna. “The DM C63 series antennas are VHF communication antennas designed for high mechanical strength with machine tapered aluminum alloy radiating elements. These vertically polarized antennas cover the frequency range of 118-137 or 138-174 MHz for both transmitting and receiving applications. The DM C63-1/A and DM C63-4/A are designed for mounting on top of the fuselage. The DM C63-2 and DM C63-3/A are low profile "bentback" radiating element designs for mounting on the bottom of the fuselage. They are well suited for helicopter installations.” https://www.dallasavionics.com/cgi-bin/products.cgi?master=avionics&category=antennas&man=edo&url=dmc63-3a.html1 point

-

1 point

-

In my area, a desktop Redbird cost $50 hr and the full motion Redbird cost $60 hr. Not only is it much cheaper, it has added benefits in that it’s much easier to practice emergencies, simulate less than VFR weather and pause to review or discuss something with an instructor if needed. The cons though is you don’t get the needed practice talking on the radio nor with your specific avionics if your an owner. Sent from my iPhone using Tapatalk1 point

-

When I saw this I wondered if any of my regular passengers could do the same. I think my son could, but I doubt anyone else I regularly fly with could. He’s just very observant and curious when we fly together so he knows what all the instruments are and how to read them. I often turn the controls over to him when I need to divert my attention and he can maintain heading, altitude, and turns and altitude changes are appear mastered. I also let him change frequencies when he was younger, but he got bored with that and won’t do it now unless I really need the help. Obviously the passenger in question is very familiar with the plane. He refers to the pilot as “my pilot” so perhaps he even owns the plane. I think this guy is most likely similar to my son. Flies often, knows the plane and most procedures, but is not a pilot and has never had a true lesson by an actual flight instructor. Maybe one day we’ll know, maybe not.1 point

-

I have known certified pilots that can't hold a heading and altitude. I have had passengers with no flying experience and 10 seconds of instruction that have been able to hold heading and altitude like an airline pilot. There are three that I can think of in the last 40 years.1 point

-

I wonder if the GFC500 engine out glide feature could be coaxed to be useful in a situation like this? Can that feature only be activated if the engine is out or can it become helpful for your pinch hitter not-pilot co-pilot? I know it wants to pitch your plane to best glide which won't work with cruise power, but I wonder what it would do with just enough power ?1 point

-

I am sorry...here it goes again... Trend Analysis Report N9341V.pdf Report Card N9341V (1).pdf1 point

-

skeptical of what? Very impressive for sure. Plus winds were reported at 50@10 Gusting to 16 with runway 10 in use. That cross wind exceeds the limits of many pilots I know!1 point

-

Byron is correct. I have attached the original Lycoming Service Instruction. The timing needs to be nearer TDC for starting and the impulse coupling has a "lag angle" to provide this. Mags used for 20 degree timing have a 15 degree lag angle. But the dual mags were only made with a 20 degree lag angle. This is why 20 degree timing is not approved for dual mag engines. If the engine runs better with a dual mag set to 20 degrees, it is possible that there is some issue with the mag. Maybe the internal timing (E-gap) is off. Also, if an eligible engine has the timing changed from 25 degrees to 20 degrees, it requires a logbook entry and re-stamping the data plate so future maintainers will know the correct timing. SI 1325 Timing Change for IO-360 Series Engines.pdf Skip1 point

-

You know, sometimes it is just best to walk away. Send the pictures to the shop, see what they say. If they compensate you fine, if not head on down the road, knowing you will never use them again and you can relate your experience to others. At least when the shop closes their doors they'll know why. Going to war is expensive, takes a lot of your time and has really no effect on where you end up. If you take satisfaction in making the offender miserable, I guess war is your zeitgeist. Otherwise, walk away.1 point

-

!UPDATE! So I've been debating starting a new Thread for this but I could just Update everyone on this one. First of all the plane is back in Texas. This is not without a few hiccups of course. First Shout out I'd like to give to Professional Aircraft Accessories in Cincinnati. They turned around my Mags in 3 days and I believe someone there decided not to take time off to help get it done. Outstanding service considering there is a forever wait to get Mags overhauled. Second shout out is to Joe Spielman that drove out there and helped me get everything done. He's a traveling A&I out there and just an awesome guy. Shout out to the guys at K62 for helping me out. Dan Bell the airport manager got me space in a hangar to work on the plane. Jim Moore who let me use all his tools so I could help out the A&I. Several people offered help also, so I could get back to Texas. The issue we ran into was the timing. We kept setting the timing to 25 btc and it would run like crap. This was what was stamped on the engine. We looked it up online after we checked all the wires and stuff and verified they were all good. Turns out you can set it to 20. We did that and it ran like a dream. Next Day I flew her back to Texas for an uneventful flight. The trip was a bit pricey overall but I have my Mags rebuilt now and I met a lot of cool people. It's pretty cool being part of such awesome community.1 point

-

My 70F is a bit low at 16.5 gph for takeoff. I run 65% LOP in cruise and see about 9 gph.1 point

-

I just signed up with SavvyAnalysisPro to help distill some knowledge from the 1s & 0s in my monitor. I'm also working with Paul @kortopates. (Thanks for the help!) Figured this would be a great way to see what information can be pulled from the monitor and see how to leverage it for baseline or troubleshooting. I was kinda surprised at what all you can pull from the engine monitor and how Savvy was looking at it: max MAP, max RPM, max FF, EGTs, CHTs, TITs; but also some things I wasn't thinking about like voltage, oil pressures, etc. How do you know if you're getting full power...well it's probably in there. How do you know if your ignition system is humming...in there too. I'm interested to see examples of what to look for and tell-tale signs that you need to look further or address something. Also would be hugely educational to see the troubleshooting process looking at plugs vs wires vs mags...alternator vs voltage regulator vs battery... curious how you dissect some of these things electronically... Marc.1 point

-

depends on what power setting, rpm, manifold pressure, and choice of mixture setting. Early pohs have full rich to 75% power, leaning after that. With engine monitoring many of us fly differently now. There are still variations by poh but we’ve got to start at the same altitude, mp, rpm and mixture. Then yes, they should be the same.1 point

-

Do you have an engine monitor and are leaning it to a set ROP or LOP point? If you’re just leaning to rough and richening slightly, it might be hard to tell. I’d definitely say 14.5 in a climb is normal if not low (depends on altitude, should be 18ish at SL takeoff). 11.5 in cruise also seems legit at 75% and ROP. If you set 65% and just LOP (say 10 degrees on the richest), you should see ~9gph.1 point

-

First, what does your POH show? The Lycoming operators manual for your engine shows fuel consumption at 75% should be about 12 gph for best power mixture and 10.5 gph for peak EGT. But that’s in a test cell and the installed numbers may be slightly different due to the induction and exhaust system losses. Your numbers seem pretty reasonable. Skip1 point

-

1 point

-

Spell check… More manly to Not cool the turbo? +1 Bob Kromer’s writing skills…. I own a Mooney because I read what Bob wrote about the M20C… he covered the topic nicely… all technical, no fluff…. Stuff that can be relied upon… Pp thoughts only, -a-1 point

-

So I would like to update this for anyone that finds themselves in a similar situation, 66 model Mooneys had a separate "remote" gyro installed on the pilots side underneath the panel which can also be accessed through the outside of the plane from a panel located between the main top engine cover and the windscreen. In 1967 Mooney installed the gyro into the turn coordinator. If you have the trim knob on the yolk, you have a remote gyro. Porter Strait Instrument has a past employee of Britain that built these levelers working there with great knowledge and will still rebuild some of these units. The simple way of testing the system is to apply suction via mouth to each of the red and green lines, you will see the yolk move to one side with red and back the other way with green. I found that red was just fine, green couldn't hold vacuum. Both red and green have a T in the line and that is located in the baggage area behind the interior paneling. (the panel farthest from you looking into the baggage area). This T has line going into the tail servos (which can be access through the tail inspection panel on the pilots side) and the other is routed directly to the ailerons. After disconnecting the T you can vacuum check both the tail and ailerons vacuum for leaks. I very quickly found a leak on the green side of the line in the tail servos rubber boot hidden on the back side. I've been told people have had success using bike tube repairs. I'm going to have the boot replaced (hopefully). Hope this helps anyone out there with similar issues. After many many hours of research, calling around and talking with some guys I feel like I know this system almost like the back of my hand now. To anyone searching around and looking at the maintenance manual(highly recommend on in the download section), be very specific with what year of the diagram you are looking at because they are all lumped together. Also replacing the o-rings inside the push button cutoff valve in the yoke will make a great difference and that simply just pops right out by hand. For my original post the black cracked line goes into a vacuum filter located behind the pilot side paneling.1 point

-

Your eyeball is, in most respects, way more sophisticated but, in this case, the relatively simpler iPhone might save your life. Neat observation!1 point

-

Test pilot. And he has flown Mooneys with instrumented turbochargers. And his data suggests idling on the ground to "cool the turbo" may not be good. And by not "cooling off the turbo", it may last longer. That last sentence may be my own deduction.1 point

-

I checked out their hangar in Prineville today as I was down there for work. Looks like they are very early in the actual moving process. There are some moving boxes and an Ovation in the hangar but it’s an otherwise empty and nondescript hangar with no signs of life yet.1 point

-

1 point

-

1 point

-

I have a moderately modded g model with everything essentially other than the J windshield. It does 145 knots which is respectable considering the low fuel burn. Useful load is about 865 lbs and increasing as I do upgrades. I think by the time I’m done I’ll get it into the upper 800s. I wouldn’t count a g model out as they are good planes and perform well considering the power plant. It’s faster than any Piper Arrow even if it has the 200hp engine. If you get one with the Johnson bar and in good condition they represent the least expensive to own and operate complex airplane that’s still fast enough to get places and has good backseat legroom. They are in my opinion the most utilitarian model of Mooney ever produced and I am not biased at all…1 point

-

1 point

-

1 point

-

Your panel in your 76 looks a lot like mine when I installed my Aspen 2000. Initially I kept all of the analog stuff. After 20+ years of flying IFR with analog gauges, my mind wasn’t ready for tapes. I eventually forced myself to learn (especially the ASI) by covering them with a sticky note. Now after 9 years of flying with them, it’s second nature. And I got to clean up the panel and removed the old stuff. As for remorse. When I was looking at what was available back in 2012, the Garmin G500 was just introduced and Aspen had their stuff. The G500 initially didn’t have a backup battery and when it was available it was $5k. Aspen’s battery backup and reversion mode sold me. If I had bought the G500, I’d be sitting here today wanting a G500 Txi or a G3X. Aspen’s upgrade path to the Max was a helluva lot cheaper than upgrading the Garmin stuff would have been. As for the VSI, I never look at the tape and always use the digital number. I guess flying the same plane for 31 years, you get used to what power settings you need to get you what you want. I look at the number just to confirm the performance. One thing I put into context is that the avionics available to us today are light years ahead of what we had for years. It’s all good. And I have flown enough stuff over the years to say our panels are a huge step up from what a good portion of the freight dogs and charters are flying behind. 2022 2013 Sent from my iPhone using Tapatalk Pro1 point

-

Lots to unpack here. Deakin's graph has a lot of relevant information if you’re interested in how all of these different systems affect one another and how they change during each phase of flight. Deakin is not just making stuff up; by way of his association with APS, George Braly and Walt Atkinson (RIP), He has/had access to one of the most sophisticated Aeroengine test stands in the country. Every single one of them agrees that Idle cool-down is useless and adds heat to the Turbo in most cases. Bob Kromer (Mooney test pilot) wrote the attached email which was posted to Beechtalk many years ago. The email clearly shows he agrees with their stance based on his real world experience with the test data from M20Ks flight tested with thermocouple equipped turbochargers. Also, I think that comparing an Aeroengine that has been loafing in descent to a Farm implement or Semi that has been in heavy use is a poor operational comparison. I have no dog in the fight as all of my turbos are on ground vehicles. I will say that neither John Deakin nor Bob Kromer are the type of man to just make random recommendations without supporting data, especially when they contradict the POH. Turbo.pdf1 point

-

Way to go Dylan! Somewhere around here is an Eagle parked on RT 66…. Great use of checklists, soft field, and cross wind, activity! Best regards, -a-1 point

-

Nah Gus, it’s not me. Although seeing the selling prices over the past year has me thinking about it. No, the guy I’m thinking about is one of those lucky early 70 year olds who got hit with a sizable double digit insurance increase this year. How could I give up views like this? Sent from my iPhone using Tapatalk Pro1 point

-

Years ago when I was returning an engine core, I could not remove the quick drain. It had "become one" with the engine. Ever since that experience, I apply anti-seize to the threads when installing a quick drain.1 point