Leaderboard

Popular Content

Showing content with the highest reputation on 01/04/2025 in all areas

-

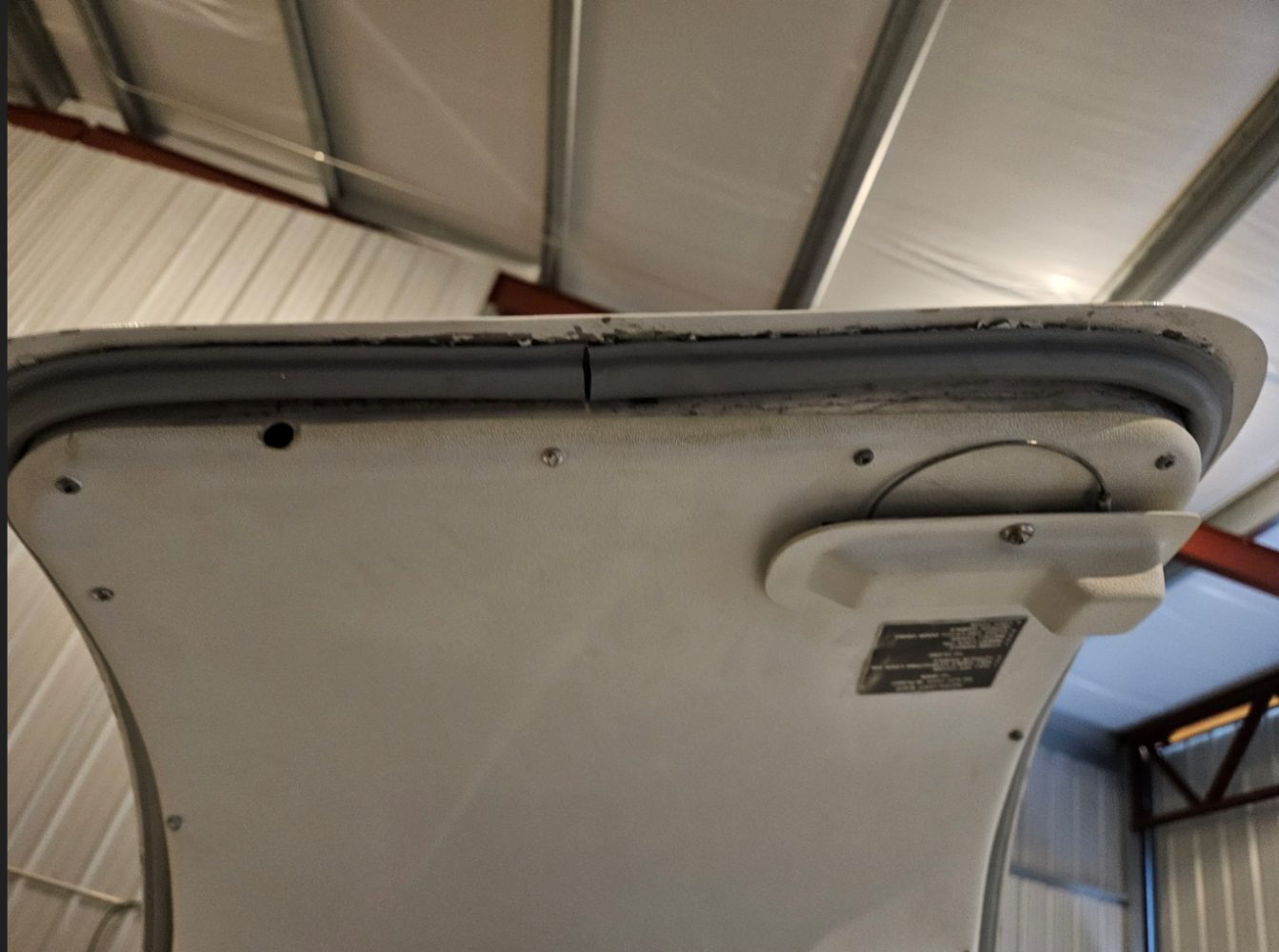

Background - it came up in another thread last year that new factory-style Mooney baggage door seals were hard to source. The Knots 2 U ones sold on Spruce and other places are made of cheap weatherstripping foam, are not factory style, and instead of attaching to the door, they go on the airframe, and therefore get scraped/damaged easily as you load and unload baggage from the plane. I'd been through several of those, with the last one not even lasting two years, when I complained here. @Gee Bee Aeroproducts stepped up, I believe bought a salvage baggage door, and manufactured a new factory-style seal out of modern high-quality silicone. I think I bought the first one. Shame on me, it took me a few months to get around to getting it on the plane, and a couple more months to post this, but it's there now. Report: The seal is great. Arrived with enough seal material to make a little more than two of them and a nice clear 2-part epoxy to glue it on. It makes a much tighter fit than the foam seal did, such that I had to lubricate the lock pins to get it to close. At first I was worried it was too tight, but after a little grease on the pins, it closes smoothly and is very snug. Before, the latch felt like it could pop open in flight if not locked. Now, I still lock it, but there's no way it's coming open unintentionally if I were to forget. I've never had a factory style seal, so I'm not sure, but suspect it's working as intended now. I also never had problems with water intrusion before, but I'm certain it seals better and tighter now. It's been on for a couple of months and has not compressed or loosened much, which is perfect. It's safe and out of the way on the door and I don't expect it to get damaged or need replacing any time soon. Thanks Guy for making a great new product for our Mooneys. A few pics below.4 points

-

Final test flight today- All went perfect! Dynon controls the A/P IF you want Aerocruze 100 control head can do the same. Holds altitude solid in smooth air and within 20-30 feet in all turns large and small in light turbulence A/P will follow any flight plan in the Dynon (direct to or with waypoints) Dynon will control lateral direction via the magenta line ONLY! (CDI / HSI or "direct to")) It will not control it by the heading bug! Heading (in reality GPS track and not a true heading) you will need to revert to the A/P control head (a couple button pushes) Dynon does a fine job of driving the A/P in the vertical mode. Climbs, descents, alt captures all work fine Manual trim is necessary as you change airspeed, level off etc as it would without an A/P The Trim indicator is very sensitive and you will learn to trim to extinguish the trim called for and then tap the wheel the way it wants you to trim to get the indicator to extinguish BUT it will come back on if you sustain an up or down draft that stays a while. This has been reported on many websites. You will just get used to trimming till the light goes out double check with tap on the wheel and then forget about until descent. You will try a few times to see how far out the pitch trim is by holding the wheel and disconnecting with the wheel disconnect but you will see that the trim indicator is on when very little pressure is on the wheel. ALWAYS HOLD THE WHEEL IF YOU USE THE CONTROL WHEEL DISCONNECT SWITCH just in case it is way out of trim. This goes for any airplane with an autopilot. A couple of items to bear in mind- When setting up the serial out ports from the Dynon to feed the Aerocruze will need 2 unused serial port OUTS (the Ins can be OFF) One goes to the A/C TT Serial RS 232 in pin and the other goes to pin #18 "Skview" feed. Each has a different serial "sentence" that it needs to feed the A/P Its in the install manual and the 'Interface " manual In particular the feed to pin #18 on the A/P HAS to be "Dynon ADAHRS +System" When programming the ports on the Dynon you will NOT see the sentence on the first screen list- you MUST use the right big knob to track down to the next page to find it Below is just for pin 18 setup (The other pin has a different serial sentence to input) Interface Setup Interface with the Dynon SkyView is relatively simple. It requires an additional RS-232 serial connection to the autopilot from the Dynon D1000 or D700. Each SkyView screen contains five (5) serial ports. This interface will require an unused serial port to be available on the SkyView display. Which serial port is used doesn’t matter. The settings required for the serial port are shown below. 1) Set output device to DYNON ADAHRS + SYSTEM 2) Set In /Out Baud Rate to 9600 3) Input device can be set to OFF as this is unused for this interface 4) Autopilot baud rate MUST be set to 9600 as well. NOTE: This will also affect the primary serial input of the autopilot, which is connected to the GPS. If using a portable GPS, be sure to reset the GPS output baud rate to be 9600 as well. Pay attention to the wiring diagram as far as reversing the elevator servo wires. It shows how to do it in the install manual DO IT or else you will be in reverse sensing for pitch. If you are a computer nerd this installation will be easy if you are like me it will take some effort decipher the computer geek directions. Once installed and working it seems to work as good as any small airplane A/P with its own limitations.3 points

-

Well it’s the new year and I thought I’d start the thread for this calendar year. Hope is for lots of flights throughout the year. Bonal2 points

-

Hello all, I wanted to let you know about upcoming dates for Right Seat Ready! our companion seminar and Pilot Plus One which has a left-seat pilot track as well as Right Seat Ready! Just so you know each participant will receive a double-sided laminated emergency checklist. We do have a Mooney-specific checklist for those who attend. Space is limited in class, so if you are interested get registered for send me a message. YouTube: https://youtu.be/RwledM422oY?si=I765NjGtl62wv4sA Right Seat Ready!© [RSR] Pilot companion safety seminar helps non-pilots step outside their comfort zone in the airplane, expanding their world of excitement and enjoyment of flying. RSR is a comprehensive hands-on safety course that provides personalized education on aircraft systems, dynamics of flight, emergency procedures, emotional response, and much more. Utilizing Redbird simulators, students learn to safely take control of a single engine airplane. Left seat pilots are welcome to attend Friday morning Coffee and Pastries and Right Seat Ready Nights [Social] A partnering flight school will offer various add-on packages. Our event FBO will provide complimentary concierge services. Schedule for 2025: Right Seat Ready! will be offered quarterly in locations around the country. Space is limited due to our commitment to making the course personalized and comprehensive. February 14-15: ACI Jet, San Luis Obispo CA [KSBP] REGISTRATION OPEN March 14-15: EAA Pilot Proficiency Center, Oshkosh Wisconsin** REGISTRATION OPEN May 2-3: Redbird Headquarters, Kyle,Texas REGISTRATION OPEN July 2025- EAA AirVenture, Pilot Proficiency Center, Oshkosh Wisconsin August 22-23- Avemco Headquarters, Frederick Maryland September 2025: Lakeland Florida, ACE Center ** December 2025-TBD **=Pilot Plus One offering Pricing: 2-Day Course with Redbird Simulator session: $249.00 includes course materials. Also Included: · 10% Avemco Insurance Discount · 10% Lightspeed Discount · Concierge FBO Services · Right Seat Ready! Nights Social · Door Prize: Lightspeed Zulu 3 Headset · Flight School Add-On Services Available Register: https://jolielucas.com/right-seat-ready.html2 points

-

Happy new year to all Mooniacs ! First flight in Mooney (second flight of 2025): quick trip to Amiens (LFAY), cold weather here in Normandy but nothing compared to “freezing bones” in Chicago The first flight of 2025 was Wing-Shift ULM (sort unregulated LSA), takeoff on skis at 9500ft elevation on top of Alps, a very short flight though: at -15C, this is the best fun one can have with LOT of their cloths on, it did not last more than 15min my wife complained about flying in freezing cold on “something that looks like motorcycle”, I reassured her that it makes us younger: the cold help to preserve meat for long conservation, this analogy did not go very well2 points

-

2 points

-

Hmm, our country has a history of passing laws to PROTECT minority populations; I guess minorities of minorities get laws passed against them! And, you're okay with that, apparently. I am not. Whatever is 'coming' should be based on RATIONAL, not EMOTIONAL, reasons. In another post I shared the results of a government study (southern California Air Quality Management District) that showed the airborne lead levels around Whiteman Airport (KWHP) to be no greater than in the Los Angeles basin as a whole. Further, the levels were way below the Federal limit! Yet, many here on an aviation forum, of all places, seem perfectly okay with rolling over to, at the very least, paint staining, swollen O-rings, and a higher price to 'solve' what, in reality, is a political issue, NOT a health one! Frankly, unbelievable. The Consent Decree is not only unclear on what constitutes "commercially available" fuel but is based, originally, on the fact that Proposition 65 warnings were not adequately provided to residents surrounding airports (as well as proper airport signage). This is the basis for the 'lead free' requirement. Thing is, Prop 65 covers all kinds of chemicals that pose a potential "risk to society", not just lead. It turns out things like benzene and toluene are also covered by Prop 65. So, once the NIMBYS and real estate developers "get the lead out" of our fuel, what do you think is going to happen next? This is entirely POLITICAL. At what point are YOU going to fight for your freedom to fly? So, yes, I blame Kalifornia. They have long been the leader in restricting freedoms.2 points

-

This is the old Bob Hoover “fly the thing as far into the crash as possible” situation. Keeping the plane above stall speed was the best plan to protect the occupants, even if it meant a 65-knot wings-level impact with the roof of the warehouse.2 points

-

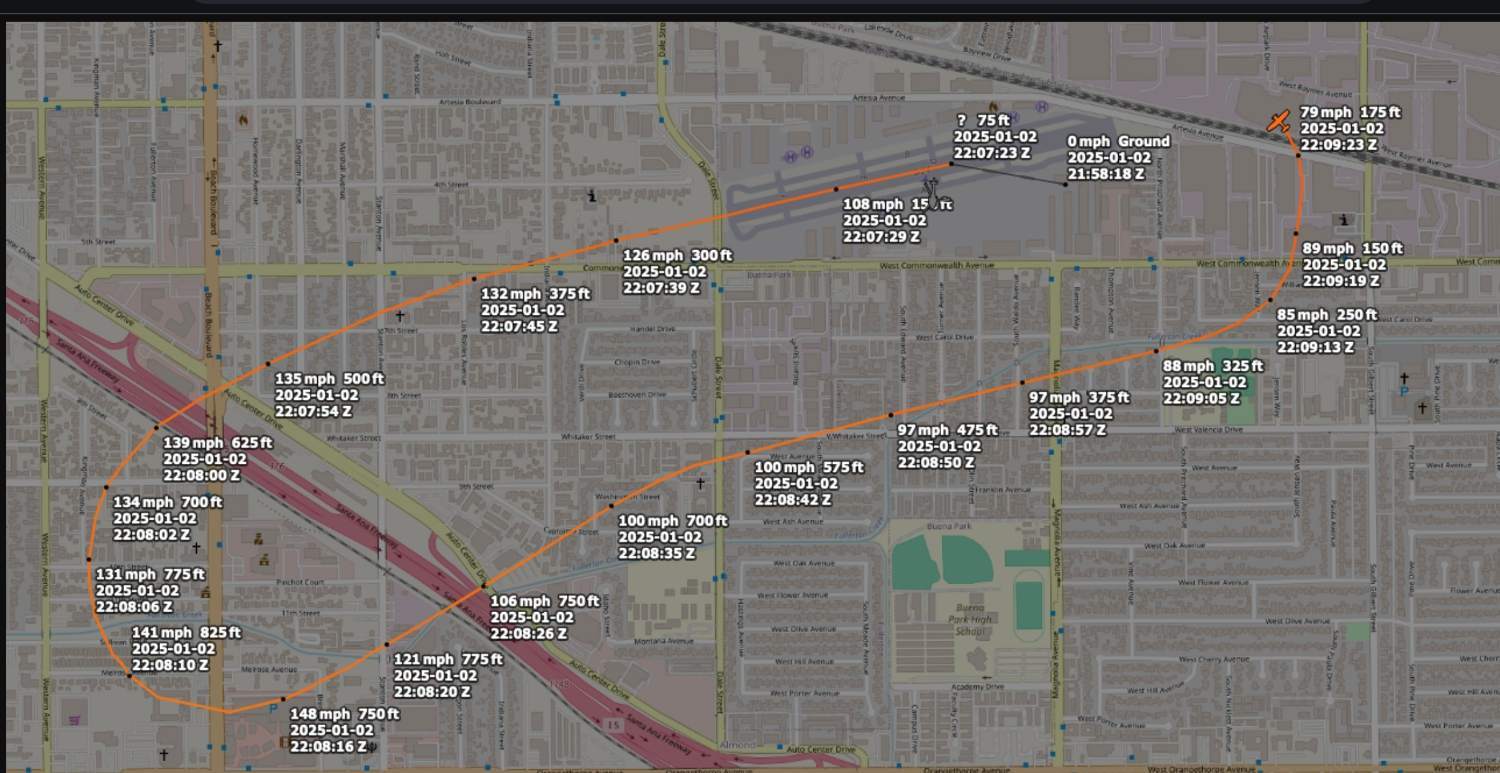

It is hard to conceive that the pilot did not deviate and land on 6 as @Skates97 suggests. Even the controller offered it to him, clear to land on 6, winds calm. My guess is that he was stressed under very high workload and opted to land with a conventional (comfortable) left-base pattern on 24 instead of an unconventional teardrop onto 6. This probably reduced workload, which might have been a safe decision, until it wasn't. At 22:08:35, he was at 700 MSL / roughly 600 AGL with 100 mph airspeed. Stall is only 63 mph on an RV10 (not adjusting for weight). Maybe he thought he was too high and too fast to land on 06 which is only 3100 feet? Looks totally doable, even if you had to slip it in at the end. Tragic. So sorry for the family and the community at Fullerton. Time to go practice some unconventional approaches and short field landings.2 points

-

If your muffler is THAT close to the cowl, you've got much bigger issues than just the little tab sticking out. The engine mounts are probably toast, allowing the engine to "sag" down and interfere with the cowl. Once you bend that part up, it won't be long until the whole muffler is rubbing. Post a sie view of the front of you plane, and measure the gap between the spinner and the cowl top and bottom. If the sag is noticeable, have new mounts put in.2 points

-

2 points

-

2 points

-

2 points

-

I'm not a CFI while you teach and share fantastic resources online. My reasoning for delaying GPS being able to visualize flying to an airport without having a device show you where you are. It really makes you think about how to navigate between places, through an approach, visualize the holds, etc. Having that foundation to rely upon has helped me stay ahead of the boxes, I'm comfortable flying older airplanes, and can still go if I have a GPS failure. I 100% agree that with new avionics, you'll have to relearn how to use the devices and that programing the devices is harder than tuning a VOR or setting up for an ILS. In many ways, the complexities of these devices make having an autopilot all the more important.2 points

-

If you remove the good support rod from the other side and take it to the welder with the broken one, they can get the angle(s) from the good one. They can also check the good one for serviceability at the same time.2 points

-

As previously mentioned Corrosion is probably the ultimate deal breaker as it can easily total a plane if it’s in a critical area. I would say the biggest thing you want to look for is a plane that flies a lot and is getting maintained. It should be kept clean with an absolute minimum of squawks. What ever you find initially will only scratch the surface of what’s actually there. The top end of the market will generally provide the lowest total cost of ownership. There are a lot of flying projects out there. Unless you like spending lots of money and not flying I would avoid those.2 points

-

I have a little bit... I won my first blind sealed bid for a salvage J that was not repairable from a landing accident. I traveled to the storage location to evaluate it myself, and discovered the crank was severely bent on an otherwise seemingly nice 220 SMOH engine, so that devalued the salvage a good bit. I discovered some extras that were not listed in the ad copy like removable rear bucket seats and the turbo normalizer kit, that had extra value for me. I made a spreadsheet of what I didn't need and thought I could sell, and assigned value to the components/upgrades I wanted to keep to improve my plane, or stock my spares stash. I tallied all that up and bid appropriately and won! I paid to have it delivered to me, and after a few years of disassembly and selling things on the side, I actually made all my money back and a bit more, plus had upgrades and spares for my J. (My labor was $0/hour though!) I don't believe sales prices are ever disclosed... insurance companies obviously want to keep that secret as well as the salvage businesses that compete against each otehr. Over the next couple of years, I bid on 2-3 more and even traveled to look at one, but did not get them. I bid lower since they would have been nice to have but not as great of deal as my first one, but others got them of course. You're generally bidding against salvage operators that need to make money on them, so if you're doing one for your own use you can likely outbid them. I think most of the salvage folks will value what is easily sellable within some short period of time and bid based on that, and everything else is gravy but those parts must be inventoried, listed, and stored and that has expense. Some like Wentworth have taken to stripping an otherwise fixable airframe of avionics and maybe even an engine, and then listing the empty airframe on ebay... I hate that practice. If you're wanting a fixer-upper to fly again, you'll have to consider getting it transported to you in such a way that it doesn't cause additional damage, or fixing enough on-site to get a ferry permit. Both of those options are more effort/expense vs. bring a hulk of an airframe somewhere that won't fly again. If you're trying to turn a salvage fixer-upper into a flipper for profit, I suspect in most cases you'll need to get it for nearly free to make that pencil-out. If you want to do it as a way to use sweat-equity to get into your own plane and enjoy it for years, then it might be worthwhile if you have the skills and the time.2 points

-

2 points

-

2 points

-

1 point

-

So what do you do when your policies leave your municipality broke beyond belief? Well you could become fiscally responsible, or you could just do this https://www.reuters.com/sustainability/new-york-fine-fossil-fuel-companies-75-billion-under-new-climate-law-2024-12-26/1 point

-

@N201MKTurbo I think I would have been inclined to take them up on the offer and asked for them to include full tanks of fuel when I picked up. I wouldn't have liked it but sounded like a bad situation for you all around. I would have hoped and expected that they got everything right the second time around. Hopefully your experience was a horrible one off! Sorry, that stinks.1 point

-

Here ya go- Check that all the model numbers and serial numbers match on everything with the log book, engine, prop, airframe, I do radios also. Actually read the data plates and compare to the logs. Check that the parts actually installed match what is contained in the TCDS and/or the logs show an STC change for the big stuff and changes for radios and electronics. Anything added like engine monitors, fuel flow gauges, etc should show an STC listing in the log books. Pull the rear seat bottom and open up the inspection holes to check for corrosion on the spar caps. Look at the spars real well in the main wheel wells for same. As noted fill up fuel tanks the night before and look for leaks the next day. If you can jack the airplane do a gear over center torque check. Make sure the A&P has the correct tools to do it. While on jacks, move the main gears in and out toward the wing tips for excessive movement. Lift the main wheels to check for play in the donuts. The donuts should expand enough after 5 mins unloaded to not have much movement. Check the mouse boots for condition in the main wheel wells. While down by the main gear look at the spar bottom between the fuselage and wheel wells. Look for smoking rivets there. The rivets that hold the spar sandwich together. That can be a big $$$$$$. I found one in AU with almost every rivet loose on the bottom of the spar. It was grounded by the owner when Kerrville said it had to be repaired. Nose gear area - if on jacks this is easy- twist the nose wheel left and right to check for excessive play in the steering linkage. More than about 10-15 degrees either side of center before tightening up on the linkage is too much. You will see the slop way at the top of the nose gear on the rod end linkage up there. Most important on the nose gear! Look and feel for dents where the steering system touches on the tubing for dents where it touches. Turn the wheel by hand and you will see where it touches and stops. MAKE SURE THERE ARE NO DENTS THERE! The limit is 1/32" depression. Any dents and the nose gear comes out for repair $$$$ On the tail surfaces grab the tip of the stabilizer and try to move it up and down and fore and aft. If it moves or clicks you might have work to do. Limits are about 1/10th of an inch either way. Usually fixed by changing out the "close tolerance bolts' in the hinge. As noted lift up on the rudder to check for play in the jackscrew. Same limit about 1/10 of an inch. Lots of times it is wear on the 2 bolt hinge bracket at the aft end of the jackscrew and not the jackscrew it self. I found one stabilizer that moved 1/2 inch either side of center! Look over the outside surface of the entire airplane for dents, filliform corrosion, hangar rash (the elevator tips seem to be especially susceptible to this damage and NO repairs are allowed to control surfaces (no patches, partial skin replacement, etc). The FAA in one case here on MS made a big thing out of this stuff on a routine ramp check on one of our posters. Basically they said it didn't come that way from the factory so fix it. I check all the exterior control surface rod ends to see if they are loose enough to move or if dry and frozen. If dry and frozen I start looking at the logs real close to see if the lube and gear swing AD had been being done. One item missed almost always due to the effort but it can cause big headaches, is pulling the sidewalls inside and actually looking at the steel tubing frame for rust. If the windows are not sealed well, water gets in there and runs down inside on the tubes and rusts them. The insulation SB aside. There is actually a SB describing how to check for leaks by pulling the sidewalls and directing a water hose at the windows looking for leaks. Make sure everything, and I mean every switch, knob and button works as designed! Put power to it and try all radios in all modes, all lights, all warnings (landing gear warning horn, stall warning horn, etc), all exterior lights, everything that can be turned on or off or moved in and out. There was one write up on here a while back where someone bought a Mooney and the stall warning didn't work nor did the gear warning (IIRC). That makes the airplane unairworthy. If on jacks (and it should be) do a gear swing and make sure the gear works properly. I've seen them signed off 3 months ago and they hang 3" from the wells when sucked up. If its electric gear do a manual drop also to make sure it works. Had a couple on this board recently that went in for annual and the manual gear drop didn't work. So check it out. Look to see if the gear actuator has ever been removed, cleaned, checked for proper gear lash and relubed. If it hasn't you may be doing that on the next annual yourself It's that important. Disregard if its a manual gear. It goes without saying that a full log book check is required for all applicable ADs and required inspections even though the annual has just been done. The logs tell a story and knowing how to read them is a skill. Make sure you know what to look for or have someone that does. The engine stuff is the normal stuff. Compression check, oil filter inspection, looking for leaks, cracks, anything not normal. Pull the plugs and read them, they too have a story to tell. My caution to any whom I help buy an airplane? Trust no one selling an airplane period. Take nothing for granted. Don't trust anything even though it just had an annual. If you do, it will bite you in the arse. Check and verify everything before money changes hands. Once you pay for it , its yours! Good luck and show us pictures even of the prebuy! :-) :-)1 point

-

I live on an airpark and to date have not heard a peep from the local population re "lead poisoning" . There are 2 schools in close proximity to the departure end of the prevailing runway. Perhaps like almost all issues in this glorious country, ones acceptance of a green agenda overshadows logic. However, I flew into and out of Santa Monica for about 10 years and look what happened there.1 point

-

1 point

-

OK then. Mine seals very well installed backwards, and looks like it was meant to go that way to fit into the shape of the fuselage frame. But you should probably install it like the factory did. Thanks for the photos Guy.1 point

-

I started out for just a question for those who patched or resealed, but wound up adding a line for those who hadn't. So fixed it. thanks!1 point

-

Well said!! I read an article yesterday reporting that the state government of Vermont is trying to sue the oil companies for contributing to negative climate changes that have impacted Vermont. They are looking for such evidence going all the way back to 1995. Apparently the recent storms which ravaged Vermont are attributable to the nefarious activities of the oil companies dating back to the 90’s. This is exactly what we can expect when lunacy in government goes unchecked. Those who prefer to bow when they could fight, will soon find a time when they can neither bow low enough or fight hard enough to stem the tyranny which has ravished so many of our state governments.1 point

-

You should rephrase options for question 1 to for those of us that have original sealant. I have 35 year old sealant that is not leaking. Only repair was of an inspection plate several years ago.1 point

-

Most airliners/jets/turboprops have wet wings, and wing maintenance is a constant issue for all types. There are successful and busy companies that make a good living doing nothing but mobile tank repairs on airplanes. All types of wet wings can and do develop leaks. Even bladders can and do leak and age out. GA airplanes seem to have it better than most, it seems. "Tank diver" is an actual job description for maintenance of big airplanes. I didn't know how to answer the poll since I'm not sure what constitutes a leak vs a seep or something simple like a leaky screw that is repairable. I have had a regular leak near the top of one of my tanks, but it's not an issue if I leave it only about three gallons from full so I've never bothered to fix it...yet.1 point

-

It may just be contacting during startup/shutdown, when the engine shakes more than usual, or if it idles rough. It's definitely worth fixing the little protrusion, but it is a good idea to check the motor mounts, too. Does the spinner line up well with the cowl or is the spinner a little lower than the cowl lip?1 point

-

That does seem very close. As Nick said, check the rubber mounts for sagging. Would also double check the motor mount. They do crack on occasion and the cracks can be hard to see. Also check that your exhaust risers are not broken. This should be more obvious.1 point

-

I don't understand why everyone keeps blaming california, it's been 50 years, they marked a line in the sand. unfortunately, we are a minority of minorities, more cars passed your airport yesterday then all ga planes still flying. i'm just trying to say it's coming and isn't going to wait for our antiques to keep up1 point

-

1 point

-

The manufacture date is molded into the edge of the discs. Be careful if they're upside down--I thought mine said "06-96", but they were upside down; when removed for replacement several years after buying my 1970 Ranger and turning right side up, they actually said "09-69". New shock discs land so much smoother than 40+ year old ones! There's much less worry about the flaps, Rangers have 125 mph electric flaps and 120 mph electric gear. Plan on simple 500 fpm descent (I prefer power on, periodically reducing throttle and richening the mixture to reset cruise values all the way to pattern altitude), then give yourself 3-4 miles to slow to Flap speed and drop Takeoff Flaps by pattern entry. Once you can do that regularly, you can reduce the distance from the field, but after 17 years I still aim for about 2 miles or a little more. Good luck, search well and enjoy your new ride! Mine has been great fun, and we're still enjoying it!!1 point

-

Why would you want a metal 3 blade prop on a J? They're heavier, slower, vibrate more, cost more, and have no extra ground clearance. Sent from my motorola edge plus 2023 using Tapatalk1 point

-

It was an RV-10, father and daughter on board, some reports say14yo and otherw 16yo, probably 16 as she was a junior in HS. From the ADSB track and tower recording this is a sad one that shouldn't have happened. Plane took off on 24, made crosswind and as he was turning left downwind something went wrong and he called tower with emergency coming back to the airport. Tower advised that there was a plane just rotated but to continue to 06. Tower then told the Cessna departing to begin a right turn for an emergency aircraft coming back. Tower went back to the RV and told him #1 cleared to land 6, winds calm, traffic no factor. Then told him 6 or 24 cleared to land. Pilot (stressed/overloaded?) responded 26, then 24, he would land 24. Tower again told him 6 or 24, his choice cleared to land on either. At the time he declared he was between 650-675' AGL, just turned left downwind. All he needed to do was turn about 15-20 degrees left and would be pointed right at the numbers for 6, instead he flew a downwind with a tight base but looks like stalled and then went through the roof of the warehouse. The warehouse that he hit is on the north side of Artesia which is the road that a Mooney a few weeks back made an emergency landing on, hit a fire hydrant before hitting a tree. That accident was maybe a few hundred feet up hte road from this one. Even with the bad decision to go for 24 instead of 6, I don't understand why the pilot didn't just try to put it down on Artesia.1 point

-

Also a CFII, but don't do a ton of instructing as work gets in the way. I do a lot of flight reviews & IPCs, however. I agree with @Ryan ORL 100%. To @jamesyql, if your STEC has alt hold, that's a solid system. For me personally, I'd take a good navigator and a good autopilot first before worrying about an EFIS (or anything else for that matter). @Paul Thomas not throwing shade at all, but delaying training on the navigator is not a good strategy. It's an essential component of efficiently managing the aircraft and should be started as a wholistic part of training no matter the stage. In IPCs I tend to discover that most pilots know the basics, but really struggle managing holds, vectors to final, and simply using it effectively in busy airspace the way approach and departure controllers expect. Knowing how to work the advanced functions of your navigator when in actual IMC and getting tossed around will literally save your life. It's funny that @Ryan ORL mentioned the GNS480 - it's the navigator I have in my Mooney. Frankly I love it and it's FAR superior to the 430/530 that Garmin replaced it with. Would I love a new GTN? 100%, but they really offer nothing for me besides quick entry of lengthy flight plans. I do like the VNAV feature, but it's really of no value when operating in the system as you get stepped down when ATC wants, not what the Garmin thinks. It's very cool for VFR flight, however. For me personally, I fly better on gauges vs tapes. I don't have evidence to back this up, but I believe we detect subtle change better on needles vice tapes. Again, I'd trade my gauges for a G3X tomorrow - but $ lol. I do have a digital AI and that is my poor mans EFIS that works just fine. I GENERALLY have a personal minimum that I wont enter IMC intentionally without an autopilot. Without autopilot, you're one minor hiccup from an emergency. This sort of supports my first statement, to focus on spending money on what really matters - the navigator and autopilot (and know how to use them REALLY well). I broke my own rule a while back to ferry a plane for a buddy with an inop autopilot. Four solid hours in a bumpy layer - wife threw up twice...not fun. I was SPENT by the time I landed. I was busy the whole time just flying the aircraft. I had zero time to really manage the airplane. Never again. I know there are old timers that bah humbug autopilots, but not this guy.1 point

-

I'm well aware, but you missed the point that your demonstration with the cowl flaps is not free of conflict of interest and was not independent. This is an example of why some people find you deflective. This is discouraging, as there are two Mooneys and a third aircraft that have been reported here. If there is also a twin Cessna then that's four. If you're not aware of the scope of the problem, that is a concern in itself, as I suspect that's not a even a comprehensive list. I'm not trying to be negative, but again this seems like deflection. If a food additive is killing a very small percentage of the consumers, moving focus to the vast number of survivors is not helpful. Blaming the victims for 'you already had leaky tanks', is also not particularly helpful, especially when the fuel has been advertised "that operates no differently than the 100LL that you are accustomed to". There are significant concerns that go to the safety of operation of aircraft using G100UL, especially in the long term in the context of latent failures and increased maintenance. Continuing to deflect the concerns as "inappropriate" or otherwise not significant is concerning in itself and is further eroding confidence for some of us.1 point

-

One way I see it could happen is we get 94UL, that I know could go into widespread distribution almost overnight, you just keep making the same Avgas you have for decades, just don’t put lead in it, shipping, distribution etc all remain the same. Those that don’t have high compression engines just burn it, those with high compression / turbo’s run ADI. That way you get honest Avgas that meets specs, the aircraft should require no mods to prevent vapor lock, it has the same storage life of 100LL, shouldn’t be any more expensive than 100LL, plus it will go into the same trucks and tanks etc that 100LL did as it’s just 100LL, without the lead I think? And we know it won’t cause any issues, except maybe valve recession, but I think any unleaded fuel may cause that, unless we leave a little lead in or add an additive, they exist. An issue with car gas as I see it is getting it, it’s one thing to be able to burn it and another to get it.1 point

-

I absolutely got your point; it's the same as mine: it's going to take YEARS for the effects unleaded avgas to play out, G100UL or anything else. Precisely why I 'have a beef' with Kalifornia governmental overreach! And those in other states should be concerned, as well. For, if Kalifornia prevails in its ban, other states will soon follow.1 point

-

And, during that time, you could still buy 'conventional' oils; they were NOT banned!1 point

-

When I went to A&P school my instructor told the class over and over, this course is not to teach you how to weld. It is to teach the difference between a good weld and a bad one. On a certified aircraft you need a real welder.1 point

-

Whille wee may be free to not use G100LL for now, that "freedom" will be short lived and, unless there will be another alternative on the market soon, this fuel may be the only fuel available. Absent some seismic shift in the political landscape, 100LL will be banned sooner than later. My home state of CA probably being the frontrunner, as with many other misguided and wasteful mandates.1 point

-

Buffing is not rocket science. Polishing is rocket science. Words have some very specific meanings here (IMC and IFR are kinda of the same but different). I am going to regret this but here we go. 1.) Single stage paint is a layer of paint and a protective coating. Clear coat is a transparent layer put over a base color. Paint looks bad primarily due to scratches or oxidation. To fix bad looking paint you need to remove oxidation and scratches, there is no other solution other than remove clear coat or paint. You do this by cutting, sanding, polishing, etc. You are taking an abrasive and removing material to get a flat defect free surface. Determine how think the paint/coating is if insufficient you need to strip/paint. You can find a decent paint/depth gauge on Amazon for $300 If you have a lot of depth do whatever If you don't care do whatever I used Comet powder to start buffing out the boot/trunk of my 71 MGB. It was red and not original. Whoever shot it (single stage) sprayed well and deep. I could have put an angle grinder to it and had paint left. ++++++++++++++++++++++++++++++++++++++++++++ Everything above this line is dangerous. You can seriously mess up your paint with heat, abrasives, etc. If your true goal is museum quality finish you want somebody who absolutely knows their stuff. I can jet a carb but if I want to race Reno I am hiring a pro to jet my carb. For an airplane I would never recommend a paint correction (cut/polish/sand/etc.). You don't get up that close, a plane with decent paint and some wax looks good at 200 yards. If I am flying closer than 200yds to your plane we are very "good" friends... Once you have good paint the key is to protect it. I like Jescar Powerlock. Put that on. Wash it often with a neutral PH (won't strip wax) cleaner as often as you can. After first wash following Jescar put some wax on (you don't need everywhere mainly leading edges). I like Collinite 845. ++++++++++++++++++++++++++++++++++++++++++++++ The above paragraph is where everyone goes wrong. I can make a piece of paint look perfect but that is for TODAY. You cannot keep going back to sand, cut, polish, etc. You run out of paint. The key is to wash frequently with good clean mitts/rags and a grit guard. Reapply wax/etc. It is about maintenance more than anything. Polishing should and be a ONE time thing. I do a pretty good job keeping the 71 MG looking good. My Mooney it looks great from 200 yards. READ THIS - IF you spent $15K+ on paint recently please PLEASE PLEASE do not be stupid. You had enough money to spend $15K to paint a toy so you are not poor. Paint correction is really hard, I do not recommend it (polish/sand/cut) for a plane any more than ceramic coating (different topic) but if you feel the need for it, best to hire a professional. Washing (very clean mit/rags use grit guard in bucket) and waxing/buffing do that all day long. Abrasives though is in fact rocket science.1 point

-

The oil will coagulate at those temps and not flow. Ask me how I know.1 point

-

Have not heard line up and hold. Typically I’ve heard “Hold Short Runway…” Could see why confusing. I think it would warrant a call to the tower in question to discuss phraseology with supervisor. Taxi into position and hold = line up and wait.1 point

-

Here in Switzerland, all Swiss aircraft have HB-something. All Mooneys have HB-Dsomething (I am HB-DFA). There is one Mooney based at a different airport that I have to admit, I would never buy/fly.... HB-DIE1 point

-

Not an N number but a ship number. I was preparing to go to DFW in a 757. The ship number was 666. It was painted big as life on the nose gear doors. A lady stopped me in the gate house and asked, "Is that our airplane?" I said, "Yes M'am, a Boeing 757." She said, "Oh no Captain, I can't get on that airplane.". I said, "Mark of the devil?" She said, "Oh Lord, yes!" I decided there was no use convincing her there was a ship 665 and a ship 667 I just said, "M'am, let's get you on another flight" and escorted her to the agent. She booked her on the next flight out. As Paul Harvey says, "Now for the rest of the story". We taxi'd out and on the way the air-ground sensing went awry and it was screaming all kinds of warning and cautions at us. We returned to the gate. They decided to get us another airplane due to arrive in about an hour. I was walking through the food court when I saw the lady. She said, "Back from Dallas so soon?" I said, "No we had a mechanical and had to return to the gate.". She said, "The Lord was watching out for you." I smiled and said "We pilots need him more than most folks!".1 point

-

It is most likely a sticky microswitch. There is a up limit switch and a down limit switch on the worm gear at the flap motor. If this is the problem it is an easy fix, just remove the belly pan (or rear most panel for older models) and clean the switches. These microswitches are really light duty and it only takes a little grease or gunk to cause them to stick. Good luck, Lee1 point