Leaderboard

Popular Content

Showing content with the highest reputation on 10/29/2024 in all areas

-

Thanks Anthony! I think many here are spreading the message as well as I could. The biggest thing I learned with my incident was how much the cognitive decline was with CO poisoning. At times I didn't have any symptoms yet my mental acuity was lacking. My wife would say that's me everyday. But nowhere was the cognitive decline taught to me. The other symptoms were taught as what happens, and it's what I taught when I instructed a primary student. This lead me to believe that I would be able to catch CO poisoning while it was happening. That clearly didn't work for me. As many have stated, CO poisoning is basically hypoxia. I don't know of any studies that just examine the effect of the CO. But CO finds a way in by replacing the O2 in the hemoglobin, thus making you hypoxic. The last flight on the day of my accident, I was able to copy and read back my IFR clearance, taxi out, and take off. It only took 4-1/2min from departure until I was sound asleep. So it can get dangerous fast, this is of course without a CO detector. With a detector I probably would have fixed my leak weeks or months before. I'm not taking anymore chances with CO now. I'm currently redoing my panel and will have my Guardian panel mounted detector, an Aithre panel mounted detector, and a Sensorcon AV8 mounted on the panel. As well as the Lightspeed Delta Zulu headset for both front seats. That's obviously way overkill. But these are the companies that have helped me promote CO awareness in aviation and I believe in their products. It's nice to support them. @Rick Junkin pointed this out. Many people have reported back to me what they have found with their detectors. Many find problems that could have turned much worse well before CO would have been a problem for the pilot. Broken engine mounts, V-bands, leaking exhaust burning through a fuel line, etc... So it's great to treat the CO monitor as if it is another metric on a engine monitor. Cheers, Dan6 points

-

My senior design project as an aero engineering student was a 4-place RG plane with a rotary engine. Weight and physical packaging/drag reduction are huge plusses in our corner of the aviation world, but the BSFC is not great, unfortunately. I briefly dabbled with an RV-6 kit after college and was reading all I could on the conversions, but eventually came around to thinking a standard Lycoming is still optimal. I wish we had enough manufacturing scale to truly optimize a GA engine production facility to make better parts/engines and get the cost out. It seems every other industry has advanced by leaps and bounds in terms of machining quality, casting, etc. except our products in GA.3 points

-

I would do that anyway, even if Lycoming had them stacked up. The 500 hr Gann “Performance” engine is why I bought my airplane, I overlooked the no glass, original interior and paint missing on the leading edges for that motor3 points

-

Using the Dynon built in non-WASS GPS Don't need WASS and GPSS steering for my flying I learned a long time ago the shortest distance between two places is a straight line- "Direct To" works good for me. I've done all the ice, 200 & 1/2s and CAT IIIs I ever want to do. SE IMC holds nothing for me at this juncture in my life. The next day is always clear skies. What part of RETIRED don't you understand :-) I do a lot of flying at 1500 AGL Like Sun n Fun to Santa Fe NM 2 years ago. The next owner can install something if he wants as I left room just for that occasion.3 points

-

@rturbett Take another look at my Lower 48 map! I finally got around to checking off UT on our way down to the PPP in Ft Worth (KAFW). Great overnight in Moab, UT just because it was someplace we wanted to stay.2 points

-

Maybe obvious, but if you're a bit behind the curve, you can also flip it to Max. Seems to fill out much quicker to "jump start" things. I've overall been amazed by how well it works. I have briefly been in accumulation that might be "moderate" rates based on the above, and it seemed to keep up. A few brief encounters incl. with some lighter returns definitely got my attention (and a course change). But my experience base is limited so I defer to the others here... Just like other things, it's nice to experiment first by dipping your toe in. E.g. less ice-prone conditions and more outs. Some mentioned the tail. A FIKI bird should have panels on those leading edges. D2 points

-

2 points

-

Four years ago my panel was 75 hours @ $110/hour and I took out ALL the interior. No AP but it was pre-wired for the AP. Removing all the old wiring is very time consuming and if it's done wrong re-wiring is required - my shop knows... I thought it was very reasonable, and I doubt this pricing is available today. Dynon does simplify the wiring with the network hubs and pre-wired cables but it's still a lot of work to connect the GPS, audio panel, nav/com, etc. My view, $15,000 to install the panel shown on the Dynon website is reasonable. I think Dynon v. Garmin is like Pepsi and Coke. I like Dynon and Pepsi and I would do Dynon again, even with the wait for the AP. (I hope the upload of my panel works - I seem to mess it up most of the time)2 points

-

Usually someone includes a warning that 50ROP is a terrible operating point for the engine, depsite the POH's reference to operating there. Either be richer, leaner, or well down on power (I think less than 65% is OK). For my own practice, at 3500 MSL, I will be a little throttled back, ROP or LOP. It is rare that I am crusing that low, and it tends to be more fuel burn than I like. Above 5500 MSL or so, it is WOT, 2500 rpm and LOP at 13 GPH or so to get 62-64% power. This is 170 KTAS in most cases, but would be a little higher for a non-TKS wing. There are several recent threads on OVations/Eagles running LOP, including photos.2 points

-

Yes - try not to fly in ice. But the tks works - but as described. A word of operations - avoid ice if you can, but pre-run your tks before ever entering a cold cloud even if ice is not forecast because it takes like 5 min for the system to express lots of fluid from the wings so - pre-prime it - eg on the ground before you depart to punch through a layer, etc. And run it monthly at least to keep it ready and healthy.2 points

-

SB 1193 states that the ban will begin Jan first 2026 for “disadvantaged” communities and 2028 for “urban growth” communities. And these definitions can be very subjective. Once again we are forcing with mandates before the solution is completely ready for prime time. 2026 that’s less than two years from now. I have spent my entire life in California and have seen so many regulations forced upon us by the air resources board. It started many years ago with spare the air days making it illegal to have a fire in your fire place when they decided it was a bad day and not just in the summer but on winter days when the air was just fine. Recommend no BBQ no operation of gas tools and as of last year many gas powered tools are now banned. New homes for the most part must be all electric and if any of you haven’t experienced the cost of E service in CA you would be floored. Be VERY careful what you wish for because these restrictions will be coming soon to your state especially if a certain former Cali senator becomes our next president. Don’t believe a word she says. I have lived it. I can remember when the California summer blends came out for auto gas and quite a few retailers just stopped selling in the state. Can’t remember the last time I saw a Texaco or union 76 or BP chevron is checking out and moving to Texas. If the unleaded is still not ready we might not have any suppliers willing to sell in this state. Yes unleaded worked well for auto and other vehicles but not until manufacturers updated their engines. Just think of the log jam if all our cylinders have to be modified or replaced with hardened seats. Just saying be careful what you wish for.2 points

-

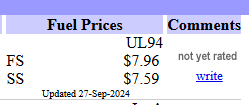

https://g100ul.com/news/g100ul-high-octane-unleaded-avgas-at-reid-hillview/ Reportedly, the cost is $6.99/gallon.1 point

-

yes, no 100LL at KRHV. Airnav shows $5.37 SS at Tracy (very rural, I believe) up to $11.37 at San Jose, just 5 miles from RHV. Average within 45 miles is $6.95 for 100LL, so I'd say $6.99 is very competitive. Time will tell if that is a promo or subsidized price just to get some traffic and try it out, or not. I'm still hopeful that eventually G100UL will be common, and the price will be lower than 100LL today due to the lack of restrictions on transport and storage without lead. We'll see.1 point

-

1 point

-

1 point

-

Yes, in this kind of arrangement, the shop is supposed wire the audio lines of your "second" radio to the COM1 inputs of the GMA 35c, and the GTN750 to the COM2 inputs (i.e. wire them "backwards" relative to normal use). The GMA 35c is then programmed to logically swap the two COM devices in software for normal operation, such that the GTN appears to be COM1. But if power to the GMA35c is subsequently lost, the internal relays that close will wind up connecting the second radio to your headset, avoiding the problem of having a working COM2 radio that you can't select because the COM1 GTN you would otherwise use to select it is offline. Note that this concept is often misunderstood or not correctly implemented by avionics shops, you can find several complaints about it on Beechtalk. Having said that, the engineer in me is pretty skeptical about this stuff. It's neat to demonstrate that when you turn off power to your audio panel, internal mechanical relays close that short radio wiring directly to your headset. But a simple loss of power is not the only manner in which an audio panel can fail, and in fact I doubt it's even the most common failure mechanism (anecdote: I've never had an audio panel lose power, but I've logged several occurrences of headset jack failure, which requires a completely separate backup strategy). Furthermore, this idea of making COM2 the "failsafe" instead of COM1 is all well and good, but it's not clear to me there's any kind of rollover mechanism that makes COM2 the failsafe only if COM1 loses power at the same time your audio panel loses power. I think it's one or the other, exclusively; and I figure if you're unlucky enough to lose power to both your audio panel and only one of your two COM radios, Murphy's law dictates that whichever COM radio died will be the one that's wired as the audio panel failsafe. Accordingly, I'm not sure why the "swap the COM inputs" trick actually buys you much. I'd advise you to not worry too much about it and just squawk 7600 and carefully get on the ground NORDO in the event of a problem. But if you've got the coin for a GMA35c, you probably have a GTX-345R remote transponder too, that you can't control if your GTN goes offline.1 point

-

I think for Mooneys those are almost always Johnson bars that popped out of a worn downlock block.1 point

-

I fly with a 5gallon container of TKS fluid int he cargo area which doubles as ballast.1 point

-

I used to hand fly to cruise and down regularly. I would turn everything off on the Airbus if I was hand flying. Too easy to get out of synch with the auto thrust if you don't. PNF's don't like it because it increases their workload, but it is good exercise for them.1 point

-

That could be good news provided the airplane you need to fuel is permitted to do so. Engine and airframe manufacturers have stated warranty will be voided and of course the STC issues will have to be resolved. I guess it’s better than no fuel available but as I have stated before, our government is forcing a solution before it’s ready for general consumption. Personally I don’t think our current fuel is a problem but that’s just my opinion. When it becomes readily available and I think my o360 is an engine that can run it then that will be that. But there is going to be a period of uncertainty about how it affects our engines long term that we still don’t know.1 point

-

? I would say the opposite most aviation piston engines are direct drive which means they have to be low RPM, reduction gearboxes bring in a whole extra layer of complexity and weight but are necessary to run higher engine RPM. I don’t know why belts haven’t been done and before anyone says that’s nuts, there are quite a few helicopters that are belt driven, and have been for decades, but I prefer direct drive. I believe a clean sheet aviation engine would have to have a least water cooled heads, that would allow car gas. Kawasaki was I think the first pent roof combustion chamber bike and they couldn’t pull off the four valve head without water cooling, so I believe that means it’s not doable, probably. I don't understand the drive for a Jet-A diesel as opposed to a spark ignition motor running car gas? Military maybe? I know they went to one fuel long ago and Companies have striven to produce products that can burn Jet-A, both Lycoming and Mercury Marine have produced spark ignition engines that can burn Jet-A for them as opposed to building Diesels, so maybe there is Government money available for Diesels?1 point

-

Actually the OSHA PEL (Permissible Exposure Limit) is 50 PPM for an 8-hour Time Weighted Average exposure. So this is the max you should be exposed to for a normal 8-hour shift. If you are exposed for only 4-hours per day, the allowable would be 100 PPM for that 4-hours with Zero exposure the other 4-hours. If you worked a double shift (16-hours) the allowable level about be 25 PPM. OSHA Maritime standards require that workers be removed from the work area at over 100 PPM, except for ro-ro (driving cars on an off ships) allow 200 PPM. The 35 PPM is a NIOSH Recommended Exposure Limit, and it is not legally binding. The ACGIH TLV is 25 PPM. This is a consensus standard. The other two are Government agency standards.1 point

-

1 point

-

Mine will build pressure, it’s easy to check just turn the Master on after engine has been off for 10 min or so, if it’s building pressure it will pin the pressure on the gauge What I do is after shutdown is I push mixture in with the Master still on, pressure quickly goes to zero, pull mixture fully out again and turn Master off. I also always leave keys on instrument panel except when I’m away, then they go in my pocket. Two weeks ago, the day after I did his condition inspection on his Pitts, a neighbor got hit in the back of his neck by the prop, he apparently moved it and one or both mags were hot. It would have killed him the Dr said if his neck hadn’t been fused with steel rods in it, but he was hospitalized for several days, hot mags with any fuel in the cylinder are dangerous, and when I push the mixture in to bleed off the pressure some fuel is going into one or more cylinders probably not much, but maybe enough if the mags are hot to kill you.1 point

-

When I did my Dynon flush I was able to negotiate it at 90 hrs. They told me they wouldn't go that low again. They did the removal of ALL the old equipment and the complete install - HDX 10", comm., xponder, ADSB, Audio panel, STBY Horz, EMS system and retain Comm #2, everything! Just the initial programming will take a few hours.1 point

-

I’ve got another update. My mechanic sent me this picture earlier today, showing the two gasket are mounted together without the spacer PN LW12347, which is exactly what Mooney SB 120 was talking about, and that previous thread mentioned. This is outrageously incompetent from the mechanic that installed this engine. It could’ve very well caused a crash, and it had happened before (N11385). I’m going to report this occurrence to transport canada, and meanwhile I’ve order the spacer and hopefully it will arrive soon.1 point

-

There was a guy I met in the early 2000’s in Chicagoland who had a rocket with boots. I have no idea how he did that, and having flown booted twins for a bit, I’d never choose boots over TKS. CAV is the only source for TKS. -dan1 point

-

The M700 is just a PA46. Pressurized since the first Malibu rolled off the line in 19841 point

-

I have a Dukes in the RV8 and, while it didn’t have a lot of time on it, (100 hrs) it was about 12 years old. It’s located inside the cockpit and started leaking, easy to detect. It turns out you have to have the Dukes pump rebuilt every 10 years. Sent it to Aeromotors and they turned it around in a day. I didn’t ask them to rush it or anything, I called to see how long it would take and the gave me the tracking number. Awesome company!1 point

-

Thanks everyone, very helpful advice. I am based in CT, but plan to primarily use the plane for trips to Newfoundland and even Labrador year-round---which was the driving factor for wanting FIKI. Absolutely beautiful up there even with the bone chilling cold. Additionally being able to cruise in the FL's meant I can cross the Cabot Straight between Nova Scotia and Newfoundland with a dry footprint.1 point

-

That sounds far more terrifying and way cooler than my lil story. Hahaha1 point

-

1 point

-

I’ve replaced 3 of my 4 servos under warranty. 0 cost to me with each replacement.1 point

-

I remember before RVSM flying a 5 leg day in a 737 with no A/P and no A/T. These guys are girly-men.1 point

-

@Pinecone I'm guessing that $3,000 isn't the 'right price' Oh, and might I suggest a safety deposit box vs. 'on the shelf' as a secure storage location1 point

-

Wankel’s are cool, I wish they were further developed. They have similarities to turbines, sort of a middle ground between reciprocating engines and turbines. Mazda was the first Japanese manufacturer to win the 24 hours at Lemans in 1991 with a four rotor 2.6L (158 cu in) Wankel capable of 900 HP but detuned to 700 for the race for fuel consumption and reliability, it is a 24 hour race after all, still 700 HP on 158 Cu in ain’t bad, not even turbocharged. Of course you can turbocharge a Wankel, the last RX7 was and I think in factory trim made over 250 HP from a 1.3 L engine, the 787’s engine was essentially two RX7 engines bolted together, hence 2.6 L. To me it’s among the sweetest sounding engines ever built. Wankel's were banned in 1992 by the FIA. Mazda Wankel conversions were popular at one time in the EAA world, but as with all auto conversions there were issues usually reliability. Wankel’s died years ago as in I think 1973, due mostly to fuel consumption. Lots of power from a small lightweight engine but it drank gas, also due to very high exhaust temps it was tough to meet emissions. GM had built a very good two rotor Wankel with astonishing reliability and an expected life in excess of 500,000 miles and those of us that were driving in the 70’s can attest that regular engines were horrible then, if you got 100,000 miles you were in the minority. Unfortunately it just couldn’t get good milage so it was scrapped and instead the Vega got that wonderful aluminum block in line 4 cyl. It was also I believe slated for the Monza https://en.wikipedia.org/wiki/General_Motors_Rotary_Combustion_Engine1 point

-

Yea, we are also going to the show today. When we left FL we heard the controller informing others of the practice in Pensacola. When we got to Houston Angel 7 was on approach.1 point

-

There's a lot of things that play into this, but, just my opinion, these are a couple of pieces to the puzzle: -A tremendous amount of skilled labor and management from the baby boomer generation has retired in the last 5-15 years. It's been very difficult to replace those skills, that work ethic and that knowledge base. -In the 1980's and 1990's Jack Welch CEO of GE was heralded as a genius and Just-In-Time Inventory management was his brainchild. He promoted keeping almost no inventory and using logistics to get what you need just when you need it so you don't have to store it or pay inventory tax on it or tie up capital, etc. For a short time he looked like the genius many people thought he was, but long term it broke down an entire infrastructure of businesses stocking items, even though it turned FedEx and UPS into shipping giants. Back in the 1970's-1990's for sure, maybe even early 2000's, if you wanted an aircraft engine a Distributor would have one in stock and it could be shipped out right away. In the unlikely event that they didn't have it, the factory might have it in their warehouse, if not there was enough manufacturing capacity to order it and get it to you in a month. The great recession of 2008 lowered demand so it wasn't all that noticeable until a huge demand upswing started around 2018-19, then another wrench got thrown in, Covid. Now people have time on their hands and they don't want to travel on the airlines and flight training skyrockets. Covid gets blamed, but really just revealed how broken everything was. Now the distributors of many products, not just aviation-related products, stock almost nothing, choosing just to dropship it from the manufacturer, and with a huge unexpected demand in the past few years it's revealed a massive shortage of stock, even the ability to produce end products in an timely fashion. This didn't happen overnight. It's taken a few decades for things to crumble to where we are now. It's starting to get better but it will probably take another decade at least to strike a balance.1 point

-

Let’s separate problems. This has nothing to do with overhauling a cylinder or oily plugs which is where we started. I go in and out of KTOR for antelope hunting and if I am light I don’t even bother with the turbo. I don’t see mixture as a problem either. I honestly don’t know what the perceived issue is here.1 point

-

In my experience, it runs fine on 5 qts. If it gets down to 4, I start to see the oil temperature increase and the pressure decrease some. It will lubricate down to 2 qts (Lycoming's minimum spec.) but that's not really enough oil for cooling at cruise power.1 point

-

1 point

-

Not if you pass out... When's the last time you've had your CO detector calibrated? I wouldn't get overly confident about the reading and chart to decide how much time I have. Get on the ground ASAP. But it's true, the airplane isn't on fire and the engine isn't quit so get down safely without wasting time.1 point

-

Was looking around at the physiology and treatment. Found an interesting bit on UpToDate (treatment ref. for docs): "High-flow oxygen — In a patient with suspected or confirmed CO poisoning, we recommend initial treatment with high-flow (100 percent) normobaric oxygen via nonrebreathing face mask, regardless of pulse oximetry or arterial PO2. Elimination of CO starts once the patient is removed from the exposure and is almost exclusively via the pulmonary circulation through competitive binding of hemoglobin by oxygen. The half-life of COHb in a patient breathing room air is approximately 250 to 320 minutes; this decreases to 75 to 90 minutes with high-flow oxygen (>15 L/minute) provided via a nonrebreathing mask [61]. Normobaric high-flow oxygen therapy is relatively safe and available, and it hastens the elimination of COHb even though evidence does not exist that, compared with breathing room air, supplemental oxygen actually limits or prevents delayed neuropsychiatric syndrome (DNS). In a trial of CO-poisoned patients, six-week cognitive sequelae were lower in patients who were treated with normobaric oxygen compared with patients not receiving supplemental oxygen (41 [60/146] versus 53 [9/17] percent), but this finding did not achieve statistical significance [62]." Looking at those half-lifes, you would not expect to be OK on a return trip soon after fixing the problem. I had forgot the part about competitive binding with O2. Those facts would imply it has to do with the partial pressure of O2, which would argue for max O2 supplementation in flight and probably a descent. Interesting that they will also "dive" sicker patients using a hyperbaric chamber. I don't have much personal experience in this problem so just passing on for interest. BTW your standard pulse oximeter will not work normally (it sees the carboxyhemoglobin similarly and will think that "color" of blood is carrying oxygen). So don't put on a pulse ox in the presence of an alarm and think "oh I'm ok now". OTOH if the pulse ox is low, you might have a second problem (too high, O2 system not working, etc). as well.1 point

-

1 point

-

If not already, lean of peak might help a little as you get it on the ground. Rich mixture makes more CO. Either way it’s bad.1 point

-

Remove the back shell from one end of the black CPC connector so that you can access the pins with a DVM with the connector connected. With the master switch on, there should be about 10 VDC between pins 1 and 2. This voltage comes from the gauge. If it's not there, investigate the gauge and wiring. There should be near zero volts between pins 3 and 4 with no fuel pressure. This is the transducer output. Turn on the boost pump to create fuel pressure and the voltage between pins 3 and 4 should increase. If this doesn't happen, it's the transducer.1 point

-

Get a Sensorcon. Then you'll know! https://sensorcon-sensing-products-by-molex.myshopify.com/collections/carbon-monoxide-meters?srsltid=AfmBOoqMEIgnwco1gX22n91VWCOVxxoZqHyHJECrdDLT2i1aklkGFuuQ I have the less expensive model, works great. The Mooney is good, truck heater is good, no leaks around the oven or gas log fireplace.1 point

-

1 point

-

1 point

-

1 point