Leaderboard

Popular Content

Showing content with the highest reputation on 03/06/2024 in all areas

-

I disagree. I (and I think many others) would continue to pay the relatively small amount of dues to get any additional source of information about Mooneys and Mooney people. The only reason I don't "belong" to MAPA is that when I tried to renew, they were no longer around to take my money. I think that is a good thing financially, as there has been virtually no benefit from MAPA for quite some time. As others have stated, the magazine turned almost worthless quite some time ago. When the annual MAPA get-togethers ceased, I think we were all very fortunate that the Maxwells stepped forward with MooneyMax. Also thank goodness for the Mooney Summit, Mooneyspace and the Mooney Flyer.5 points

-

I brought the instrument to my I&E shop at work and we solved the issue. It is the gauge. It's reading exactly half of what it should. I could take it out myself and addjust it as it's no different than any other gauge built in that time period. BUT the FAA doesn't like that stuff. So It's going to Air Dallas Instruments for a rebuild. They found the paperwork on these gauges. I also have a few backup options I found if need be. Just goes to show, not all IA's or instrument shops are equal.3 points

-

Flew to Duxford museum in UK, Which fast aircraft don’t have trim tab and whole tail rotates? Blackbird and Mooney they had an interesting pink Spitfire, she is gorgeous or he is handsome (I checked under the pants, I know what I saw and I won’t disclose any gender) While pink painting is “à la mode” these days, these Spitfires were actually pink in 1940, they flew at dawns and dusks, like pink USS Winslow, Pink Panther and Pink Sherman (not obvious from Black/White WW2 pictures) https://www.wearethemighty.com/mighty-history/why-this-world-war-ii-british-fighter-was-painted-pink/3 points

-

This is a key point. These boxes have incredible functionality. While I think it’s important to understand what they are capable of, it’s far more important to develop personal SOPs that work for us. The weird part to me is that in recurrent training, I see far more pilot errors in what I consider to be common tasks than those which involve getting into the more esoteric weeds. With the possible exception of using TOGA on an early missed (I have to look at the downside a bit more), my SOPs for the missed are pretty much identical to yours.2 points

-

I want to thank Marc for starting this thread. Here are my takeaways. Preface: I've been flying with the GFC 500/GTN combination since 2019. I've flown it a lot both doing approaches in Actual IMC and practice approaches in VMC. I had not done missed approaches before the MAP, so this was a beneficial thread from that point if view. The only issue I've had was with the autoswitch when running ILS approaches. 1. Based on the "box" for accurate autoswitch, since I have no intention of taking the time to figure out whether I'm in the box or not, I will not be using autoswitch. (I haven't been using it anyway after my issue with it. At least now I know the reason for it). The monitoring whether it's going to switch or not and the actions to take if it doesn't switch takes more time than just doing the switching manually. I've had the same issue as Adam when doing the Stockton ILS. At least now I know the reason. 2. When going missed after the MAP when the splash screen appears, I will continue to do it as I have in the past before going through all the machinations we have been discussing here, ie, aviate, navigate, communicate. That means TOGA, Power, Cleanup, HDG or NAV, Talk. 4. If I ever want to go missed before the MAP, it will be ALT, NAV, Preselect a new Altitude, Power, VS (or IAS), Roll up the Rate for either. At the splash screen tap it and I'm off on the missed approach. In this situation I wouldn't use TOGA. Thanks for calling my attention to going missed before the MAP.2 points

-

2 points

-

I don’t agree, I think it has been a dying commodity for the past 5 years. 10 years ago, here at MooneySpace, people talked about their MAPA memberships in the same breath as their AOPA and EAA memberships. That hasn’t been the case in the past 5 years. MAPA has been replaced, like so many other outlets, by free stuff on the internet. Questions about your Mooney? Go to MooneySpace for free. Want a Mooney magazine? Get the Mooney Flyer for free. Trey and Lela ran a good organization, but I think they saw the handwriting on the wall and sold before it was too late.2 points

-

Well, I fixed it. The problem was me. And a few unexpected limitations of the electric trim and the autopilot. The power to the electric pitch trim servo is routed through the Garmin G500. (Not a GFC 500, just a G500) The G500 must be powered on for about 22 to 28 seconds before it closes the relay for the electric trim. Additionally, the autopilot itself must be powered on for about 3 to 8 seconds before the electric trim will work or you can successfully initiate an autopilot test. I didn't expect this. The problem started when I picked the plane up from annual. The plane is still fairly new to me, even though I've got 90+ hours in it, so when picking it up from annual, I thoroughly reviewed my checklists before doing anything. And after getting the engine started, before doing anything else, I reviewed the checklist. Then I immediately turned the avionics power on, the electric trim, and hit the autopilot test button. The autopilot test failed. So leaving the engine running, I turned electric trim off, avionics off, and master power off, then turned them all back on. And the electric trim didn't work, and the autopilot self-test failed. So I flew home, and spent a dozen hours testing what was going wrong. But since I was always just testing the electric trim and autopilot, I would turn the master power on, turn the avionics on, turn the electric trim on, and then hit the AP test button. A lot of times, because I didn't need the G500, I'd pull the breaker for that before testing. Which, unknown to me, would ensure that the pitch trim servo would never get power. After talking to Steve at Autopilots Central, he told me what voltages I should expect to see on each of the wires going in and out of the yoke, and where that power was coming from. It all 'clicked' for me when I was testing the voltage on the 4 wires to the AP disconnect switch with the power on. All four should have about 14V. One going into to the AP disconnect has power from the autopilot circuit breaker. The other power in comes from the electric trim switch. (And unknown to me, through the G500!!!). The power out from the first input goes to the sonalert and the flight computer, the power out from the second goes to the electric pitch trim servo. I didn't know which wire was which switch or if the wire was input or output. Just that pins 3 and 6 went across one switch, and 4 and 8 went across the other. Since the sonalert was working when the AP would fail its self test, that meant I should expect to see +14V on the first one, both input and output. When I measured it, I did find +14V. That was pins 3 and 6. On the second one, I found no voltage on either of them. So while I'm sitting there staring at the multimeter, I hear a tiny 'click' and the voltage goes to 14V. I reach up and try the electric trim and I hear the servo spin. I press the autopilot test button and it completes successfully. So I turn the avionics and master power off, and immediately turn them back on. No voltage. So as I'm staring at the multimeter again, I hear a tiny 'click' and voltage goes to 14V again. So after about another 30 minutes of turning stuff off and then back on again, and pulling breakers, I finally come to the conclusion that after the electric trim switch, power goes to a latching relay on the G500 and from there to the AP disconnect. Until the G500 has been powered on for about 30 seconds, that switch will never get power. Once it has gotten power, I can pull the G500's circuit breaker and it will maintain power though. So ends the saga of the electric trim that wouldn't. Just need to get the servo re-installed and I'm back to 100% functionality!2 points

-

2 points

-

I never received any other contact. The aircraft has a fresh engine, and several upgrades/updates. It was VERY original when I got it, including the original gear pucks, and did not have the "8 second ride" AD completed. Gave the instructor and I a good scare one time during a landing. We got good and sideways before I straightened it out. The engine went bad over west Texas, when one of the engine studs failed due to bad metallurgy, causing a domino effect. The number 3 cylinder had 3 out of 8 studs holding it when we got to a runway. This event prompted the engine to be 0 timed. Been an outstanding aircraft beyond that. As I said, I'm open to offers. To the OP, I'm sorry to hear about your GP. He was a cool individual and I enjoyed chatting with him during the transaction. He showed me the actual flight envelope of this plane during the sale. Solid pilot. May he rest in peace...2 points

-

V 2, minus the Milwaukee battery adapter that won't be here until Sat. /// Side rant, Amazon Prime sure has gotten slow lately, it's ridiculous. /// Assuming this works the way I expect, I'll pull the motor and tire off, strip the rest of the paint and powder coat it so it'll be pretty. Sent from my Pixel 6a using Tapatalk1 point

-

1 point

-

1 point

-

Wrap the cylinder in a rag, put your air gun on the fitting and pull the trigger. The puck will come right out. The rag is to keep you from getting sprayed with 5606 and to catch the piston.1 point

-

You can reinstall the caliper on the hydraulic line and step on the brake pedal. It will push the puck out. Its going to make a mess. Once the puck pops our removed the hydraulic line and cap immediately. You don't want air in the system. When you put it back together add some hyd fluid to the caliper and slide the puck in hold the fitting at the top. Push the puck in and keep tapping the housing. The idea is to make sure there is NO air in the puck. You will need the puck to still have about an 1/8 of an inch to go till flush. Reattach the brake line loosely and press the puck in till flush while wiggling the caliper to brake loose any air bubbles and tighten the fitting. If done properly you should not need to bleed the brakes.1 point

-

I use Auto Switch, but my SOP is to always verify that I have the appropriate nav source as soon as I am established on the final approach course. That’s good to do whether you use Auto Switch or not.1 point

-

Awesome I will await your hopeful success. I am doing annual next week, so if we can tighten the nuts down to add tension I may not need it, but I would still rather get it replaced now than at failure. But we can install it a later date.1 point

-

This is really critical learning from this thread. I guess I always just thought autoswitch was still flakey and while I have it enabled, I always plan to manually switch on IMC approaches and use the autoswitch as a pleasant surprise when it works. Now that I understand it better, I think I will likely disable it and stick with manual switching so I am never surprised by what the automation is doing.1 point

-

That SB isnt the most clearly written. Yes, the COMPLIANCE NOTIFICATION section doesn’t reference the -5 suffix on the prop cable part number but the INSTRUCTION II section regarding propellor cable replacement references the entire part number with the -5 suffix. Between that and the info from LASAR, I am fairly confident that this part works in my plane. I’ll let you know how it goes when it arrives hopefully this week or early next.1 point

-

The reason I wouldn't use TOGA before the MAP is the lack of lateral control (this is momentary after the MAP). The upside is guaranteed pitch up., but that is easily handled in a couple of seconds with ALT (stop the descent), NAV (to maintain lateral control), Altitude Preselect (set the missed approach altitude), and VS or IAS (to get the plane climbing). I'm open to input if you can show me why TOGA is a better alternative in this situation.1 point

-

In case you want to refurbish what you have, there is still a repair shop that takes them, and it's mentioned here, but just to update that information. It is www.walthamclocks.com. They open at 10. When you call 334-774-3584, use extension 100 and even though it says voicemail, I have gotten a live person each time. Not cheap. My rebuild is $350. I last had a rebuild 20+ years ago for $150 so that's about right. They're not to be confused with the clock builder Waltham Clocks, which was in Waltham MA and went out years ago. The repair shop is in Alabama and still in business at this writing, March 2024. Mine is a swiss one, probably Breitling, though there are ones made by Wakmann and some labelled Pioneer. Don't know if they repair all types but worth a try.1 point

-

1 point

-

If I am reading that correctly it is P/N 660189. I found this from McFarlane, however the -005 isn't referenced, but it is listed for propeller. https://www.mcfarlaneaviation.com/products/product/MC660189-005/ I might call McFarlane back with this and confirm it will work.1 point

-

Check out SB-174, it covers your SN. You should be able to cross refrence the part #s in 174 with current McFarlane part #s and avoid the 8 week down time. This worked for me, PM me if you need more details. SBM20-174.pdf1 point

-

Havent looked at my governor but I am running a McCauley 3-blade scimitar prop.1 point

-

I would look very closely at the possibility of a bad temperature probe before looking for anything else.1 point

-

You need a better relationship with your IA. The IA trusts me to do work every now and then I help him on other planes. I trust him with the log books, cause it makes his job easier. He does not charge me enough for the inspection and I write the check for a bit more.1 point

-

Mooney's are small and hard to land. Heard that around the "mooneyverse".1 point

-

I’m almost to that point. I’ve got a lead on two clusters right now. Will know more in a day or two. I’ll visit my mechanic on Friday to see what his schedule is like. Sent from my iPhone using Tapatalk1 point

-

I’d encourage digging deeply in the couch cushions and going forward with the EDM900 if you possibly can. Did mine a couple years ago and it’s an amazing change. I would you my old cluster but I gave it to the son of my Mooney’s original owner as a bookend. That’s about all it was good for. Oil pressure was the only component that really worked anymore. Anyone who said they would even crack the case on my old cluster made no promises that they could fix anything, much less warranty it.1 point

-

Found it. Looks super helpful. https://www.mcfarlaneaviation.com/products/product/TOOL132/1 point

-

Luckily for me, no J bar. I’m going to take another good look under there this week and see what I can do. I have some thin/short open ended wrenches that I use for the tough spots, hopefully the back nut isn’t too big.1 point

-

1 point

-

Well, I just dropped 25amu on the panel. My CFO says I'm broke now!! lol I did have the avionics shop cut a spot for an EDM-900 and put a face plate over it. I plan on doing the EDM-900 later this year. At this point, I honestly wish that I'd went ahead and had them install the EDM.1 point

-

For at least a couple of years now, the MAPA Safety Foundation has had nothing to do with the MAPA people that produced the magazine, etc. Thirty years ago I couldn’t wait to get my magazine in the mail every month since I knew almost nothing about Mooneys and was anxious to learn anything I could. Eventually though it was just the same things rehashed. MAPA (the magazine, not the Safety Foundation) hasn’t really been relevant in at least the past ten years.1 point

-

You don’t need FAA approval, any AP should be able to do it with nothing but a signature, same year: The only trick is the nav lights are tied to gear down light, so you’ll need to disconnect that connection.1 point

-

Lazy Eights are another maneuver that's weakly specified in the ACS, mostly to accommodate airplanes of varying performance. Because there is no requirement to enter the maneuver at any particular speed, or gain any particular altitude at the highest point, or use any particular bank angle at the apex (ACS just says "approximately" 30 degrees), you can meet the standard with very little pitch and/or bank. A poster on another board once called this variant of the maneuver "Comatose Eights". The argument is that the comatose variant is easiest to fly. But it takes forever, isn't much fun, and I frankly find it hard to teach them that way because the pilot usually cannot get the airplane to continuously change pitch and roll when the total pitch and roll delta is small. What I'd call an "aerobatic" lazy 8 is max speed on entry, whatever pitch gets you near stall speed at the apex, and the max bank angle you're willing to tolerate (in the extreme, it's a 90-degree wingover). That would legally require parachutes, require an actual aerobatic airplane in practice, and probably earn a bust from the examiner even if you were legal due to being grossly in excess of "approximately" 30 degrees at the apex. I think they're easiest to teach in a typical piston single with about 40 degrees of bank at the apex, and that seems to satisfy the examiners around here. Note that if you're doing it right (and being evaluated correctly), nobody is looking at the attitude indicator during the maneuver - you judge "approximately 30 degrees" at the apex by looking outside. The bottom line is that despite the intent of the ACS to take subjective judgement out of the examiner's hands, there is always going to be some degree of interpretation, and this interpretation is most prevalent in the commercial performance maneuvers. Fortunately, most examiners seem to be reasonable about this, and only bust people on things that are clearly stated in the ACS as standards. For the lazy 8s, that's having an exit energy at the 180 point which is within 100' and 10 knots of the entry energy; and - the thing my students tend to have trouble with - continuously changing bank and pitch throughout the maneuver. I spend most of my coaching time pointing out that the pilot has become "stuck" on a fixed pitch and/or bank angle at some point in the maneuver.1 point

-

If those Mooneys are hooked up does that mean that there might be a mite in about 9 monthes :-)1 point

-

You might want to choose a different term than "hookup" Urban Dictionary: hookup1 point

-

That's the problem with automation. It's very confusing if something doesn't work. And most of this stuff works 98% of the time and when it doesn't I usually don't know why. Sometimes I can figure it out later; often not. And, it is a big distraction to try to figure it out during the flight. I think it is a good idea, if choosing to use it, to set a limit by which point if it hasn't done it's thing then you do it manually.1 point

-

1 point

-

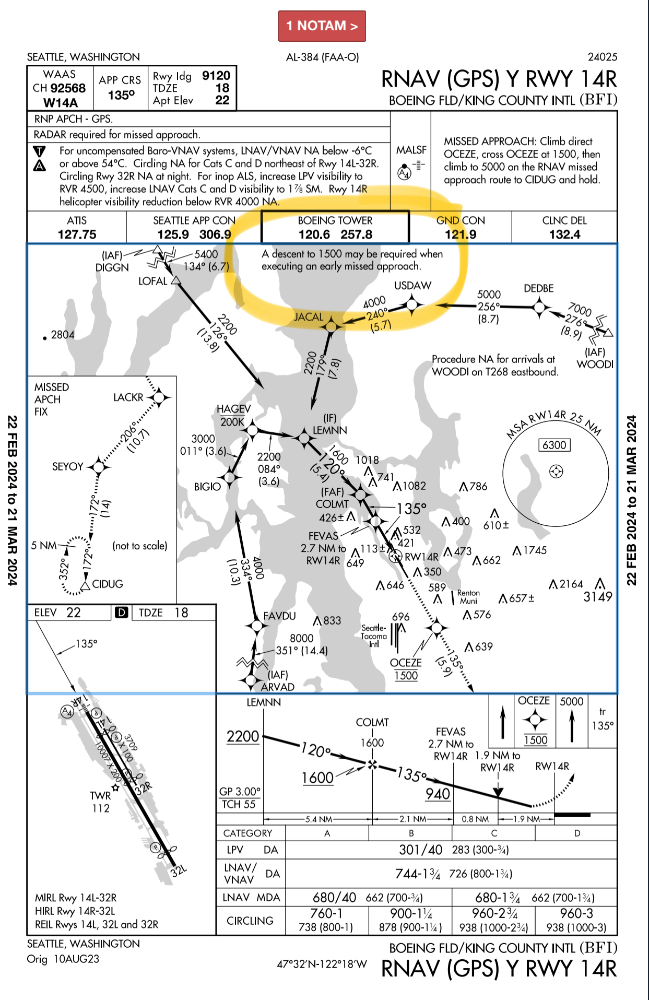

Sometimes you might want to activate the GTN missed approach, but not the autopilot Go Around (TOGA). If you miss early on this approach you may need to descend rather than climb. The KBFI published missed approach procedure underlies the KSEA final approach course, hence the altitude restriction. It’s important to plan this sort of thing during preflight planning and to review it during the approach briefing.1 point

-

1 point

-

1 point

-

Better to make them. Use 0.040" thick aluminum. Use Machinist's Blue Dye and a sharp scriber. Trace out the parts. Cut, file or grind very slightly larger thn needed to permit hand filling with a file. Take your time, save alot of money and end up with a better product that fits your application. John Breda1 point