Leaderboard

Popular Content

Showing content with the highest reputation on 05/10/2023 in all areas

-

Just a quick report that I got my Acclaim Ultra back from annual yesterday from the Factory Service Center. My observations: The work was outstanding and reasonably priced. They kept me informed along the way. They found things that other shops had missed. They test flew the aircraft when they finished. I flew a 1400 mile trip yesterday with no squawks. Kerrville is a nice town. Mooney is very much in business.10 points

-

Let's see, who are we going to listen to? Someone who has used the Factory Service Center and picked up his airplane this week? Or someone that likes to make a negative jab at Mooney? They have a lean crew doing an excellent job. Leave a message and they will get back to you. Send an e-mail and they will return it. This comes from my own recent experience with them over the last year and a half. The people there are doing an excellent job of keeping the fleet flying by making parts. Also the Factory Service Center is doing a great job of servicing airplanes. If you don't want to use the Factory Service Center, don't. But if you haven't been there personally like @Brandt has, why make those negative comments? How is that constructive?4 points

-

I want to thank James @OSUAV8TER for seeing this project through. The original halogen design was defective at best and it’s great that WAT, with James’ effort, developed this huge improvement for our benefit. Now to replace the wingtip lenses, melted by a previous owner, at $362 apiece (sigh…).3 points

-

2 points

-

Thanks again MSers! Kurt ended up being able to help out. Sent from my iPhone using Tapatalk2 points

-

If you're climbing out from a high DA airport that could kill you. There's no best way to do that.2 points

-

Fellow M20E owner here - agree with the step to add the Garmin G5s. Well worth it for IFR flying and they work seamlessly with my 430W. I have an STEC 30 AP, I wouldn't necessarily recommend getting it a as a new AP because STEC has said once they're out of parts for repairs, it's done, but it fits my needs very well for having an AP in the cruise stage of flight. I did a panel refurb with a JPI 930, CIES senders, and a flat one-piece panel with all new switches, CBs and wiring, and all new engine controls. From the picture, it looks like your engine controls (Throttle/Prop/Mixture) might be original, would highly recommend considering replacing those with brand-new McFarlane ones as part of the panel work, 50yrs is a long time for those critical flight controls.2 points

-

2 points

-

I use mine. I set it before start, during runup, and before shutdown. Mine holds fine, but for runup, I guard the pedals. After shutdown, I may release it, but with me in the seat in case it rolls.2 points

-

The OP symptoms sound exactly like the trouble I had after acquiring my '78J. After having the master cylinders rebuilt system flushed, etc., it turned out the left master cylinder on the pilots side would physically conflict with another component when fully depressed, and become hung-up, unable to release. This was not a hydraulic issue, but a physical conflict between components which would prevent the cylinder from retracting. When you apply the parking brake, you have a tendency to push harder on the brakes then just about any other time, and this led to the issue only showing up when using the parking brake. You might want to have the owner check this.2 points

-

The questions you are asking are more about basic use of navigation systems and autopilots than anything specific to the GFC 500. If I were you, I would buy a couple of hours of dual with an instructor and it should all become clear.2 points

-

2 points

-

2 points

-

In the USAF every tool box has foam inserts with cutouts for each tool. Last step before releasing the aircraft is to open EVERY drawer and visually confirm that every cutout has a tool. If one is missing, it MUST be found.2 points

-

First rule of automation. "It is dumb and it is dutiful". It will do what you asked it to do, relentlessly. Second rule of automation "If it is not doing what you want, disconnect and hand fly". So always monitor performance and be ready to fly at any second. Third rule of automation "Know the modes cold". Know where the mode is annunciated and always verify what you pushed is what you got, You have to study the manual to know what the modes do. Keep an extra copy by the toilet.2 points

-

Hi All, Coming to market is an outstanding, fast 1964 E model. This aircraft has been owned by a two pilot family since 1976 (One a WWII fighter pilot and the other a long-time Fed Ex captain) and has been very well cared for. It is in excellent shape mechanically and has a basic IFR-capable panel. In 2020, the owner Harry Moyer set the Guinness World Record for oldest active pilot in this airplane, shortly after which Harry's son Ted became the primary caretaker of the airplane. Ted has unfortunately passed, so the aircraft is now for sale. 88R has many speed mods, and actually served as a test aircraft for many of LASAR's mods as a result of Paul Loewen and Harry's longtime friendship. It's certainly faster than the '66 E that I've personally come to know. The airplane has complete logs and is currently undergoing an annual inspection in San Luis Obispo, CA. Now would be a great time to perform a pre-purchase inspection. So far I have only advertised on Mooneyspace. After the annual is complete, I will be posting the ad on the other major sites. Complete specifications are listed below, and additional photos of the aircraft and logs are coming. I've tried to include as much information as possible, but if there are any additional questions please reach out to my father, Mike, who is handling the sale on behalf of Harry Moyer. His contact information is at the bottom of the list. 1964 Mooney M20E ‘Super 21’ Registration: N6688R Serial # 431 Price: $76,000 - All funds to be handled via escrow Airframe: 5753 TT Engine: 1571 SMOH by Western Skyways September 2000 – 1041 STOH Ly-Con overhauled cylinders installed 3045.1, 2008 - Lycoming IO-360 A1A Propeller: 1571 SPOH, 1024 SNEW Hub – Hartzell HC-C2YK-1B F7666A2 (B Hub installed 2008 / No recurring AD) Max Gross Takeoff Weight: 2575 pounds Empty Weight: 1621.34 pounds Useful Load: 953.66 pounds Total/Usable Fuel Capacity: 52/50 gallons Empty CG: 44.87 inches General: Mostly original, FAST classic Mooney with manual landing gear Next annual inspection due: May, 2023 World record holder - Flown by Harry Moyer, oldest active pilot (No longer flying) SB 208B complied with 05/2023 (And in prior years) Flight controls rigged by LASAR November 2017 Airframe treated with ACF anti-corrosion formula April 2019 Fuel tanks stripped and resealed July 2007 by Willmar Air Service (Now ‘Weep No More’) Aircraft landed gear up in 1970 - Well repaired and documented Avionics: Electronics International UBG-16 engine monitor with oil temp, bus voltage, amps EI FP-5L Fuel Flow Instrument L3 Lynx NGT-9000 ADS-B In/out transponder Dual Narco MK12D Nav/Comms King KN 64 DME Narco CP 136 TSO Audio Panel Brittain Autopilot Installed, INOP Additional Equipment: MANY Speed mods - Aircraft occasionally acted as a test bed for Paul Loewen during his time at LASAR Flap Gap Seals Aileron Lower Gap Seals Brake Caliper Rotation Dorsal Fin Vertical Seal Tail Root Horizontal Fairing Wing Root Leading Edge Fairing One Piece Windshield (NOT the 201 windshield - retains avionics access) Single-piece, smooth belly Cowl Enclosure Fairing Rudder/elevator Hinge Covers LASAR Steering Horn installed December 2017 GAMIjectors Zeftronics Voltage Regulator Overhauled exhaust January 2020 406 MHZ ELT Sky-tec Starter Exterior: Painted by Art Craft Paint in Santa Maria, CA February 2017 Interior: Basic gray cloth in good shape Aircraft located in San Luis Obispo, CA (KSBP) Contact: Mike Kunde Hangar 46 Aviation Hangar46Mojo (at) gmail (dot) com (805) 215-8914 (Call and leave a message, please)1 point

-

1 point

-

1 point

-

What do you guys think would happen if someone ordered one of these from Mooney?1 point

-

1 point

-

You could add gear cables to your list of stuff to make on PMA, along with the intake boots!1 point

-

1 point

-

1 point

-

For runup, I just hold the brakes. Same as when I was a student in the old 172.1 point

-

No that’s the one. I did think it was a female pilot but I could be wrong. Fighter pilot stories only require 10% truth anyway, so this one is solid gold even if i said a “female pilot did an inverted break and a -4g base turn”.1 point

-

Lost a beautiful AC560 that was getting King Air brake conversion. The mechanic did a high speed taxi just fast enough to stretch the gear bungees with the handle up. As a sign to how well they were built the purchaser brought a hammer and banged out the prop blades and flew out. Probably not my style but impressive.1 point

-

OK, I think I will bite the bullet and go with the WX500. I like having all the tools that I can to deal with potential hazards.1 point

-

1 point

-

That is so funny...I call it "making memories." Reminds me when I brought my son an unannounced dirt bike home when he was around the same age.1 point

-

1 point

-

I’ve not seen it either, and on my cars etc have adopted an OCI of 10,000 miles and maybe once a year, same with the bike and lawnmower, running Shell Rotella 5W-40 Diesel oil. Wife Inherited a 1923 Ford Model-T that had very dirty oil in it that has been there I’m pretty sure since before WWII. It was always stored covered and I had its head off etc to replace valves and saw no evidence of etching on the cam etc that you might expect to see if there was even a slightly corrosive environment over so many years. The 5 ton truck I drove as an Enlisted soldier for four years never had its oil changed in those four years, because ad the operator I woukd have been the one to change it. I believe for those that do Oil Analysis the the TBN and TAN will tell the tale. Many years ago, at least 40 because that’s when I joined, the US Army adopted the strategy of only changing oil on vehicles when SOAP analysis indicated it and dropped the calendar interval, and at least when I Retired in 03 were still doing it that way, I have no idea when they started, but the policy was in place when I joined in 82 so before then. Doing so has saved the taxpayer no telling how much money and supposedly the environment, I say supposedly because 100% of Army oil is recycled However the airplane just costs so much and the possible repercussions so severe that I’m reticent to completely drop the calendar interval and adopt an hour interval, but am seriously considering going to 25 hours OCI as it just looks too black if I let it go further. I don’t do analysis, if I did then I’d be more comfortable. I am not against oil analysis, just think it’s being mis-used and not marketed for what it is, it’s absolute perfect to analyze your oil, tell you exactly what condition the oil is in, how dirty, if there is fuel dilution etc., but many are using it an an engine analysis, and I don’t think that’s what it’s best use is.1 point

-

I have done 1500’. I would not recommend it to anyone who needs to ask if it’s a good idea. It’s minimal margin affair that requires as much judgment as precision. Indeed judgement is the most important aspect for short field landings. Going around is easy and far superior to going off the end of a paved runway. Night ops change everything.1 point

-

1 point

-

We started to do Perfo which is manufactured in GB, but due to complications with importation, we went with Runmat...made in the US. We've been using the PERFO test section for almost two years and the runmat for about 6 months. So far, no issues. We'll know more in 25 years. Braking action was an unknown, but no one has reported any issues. So far no issues.1 point

-

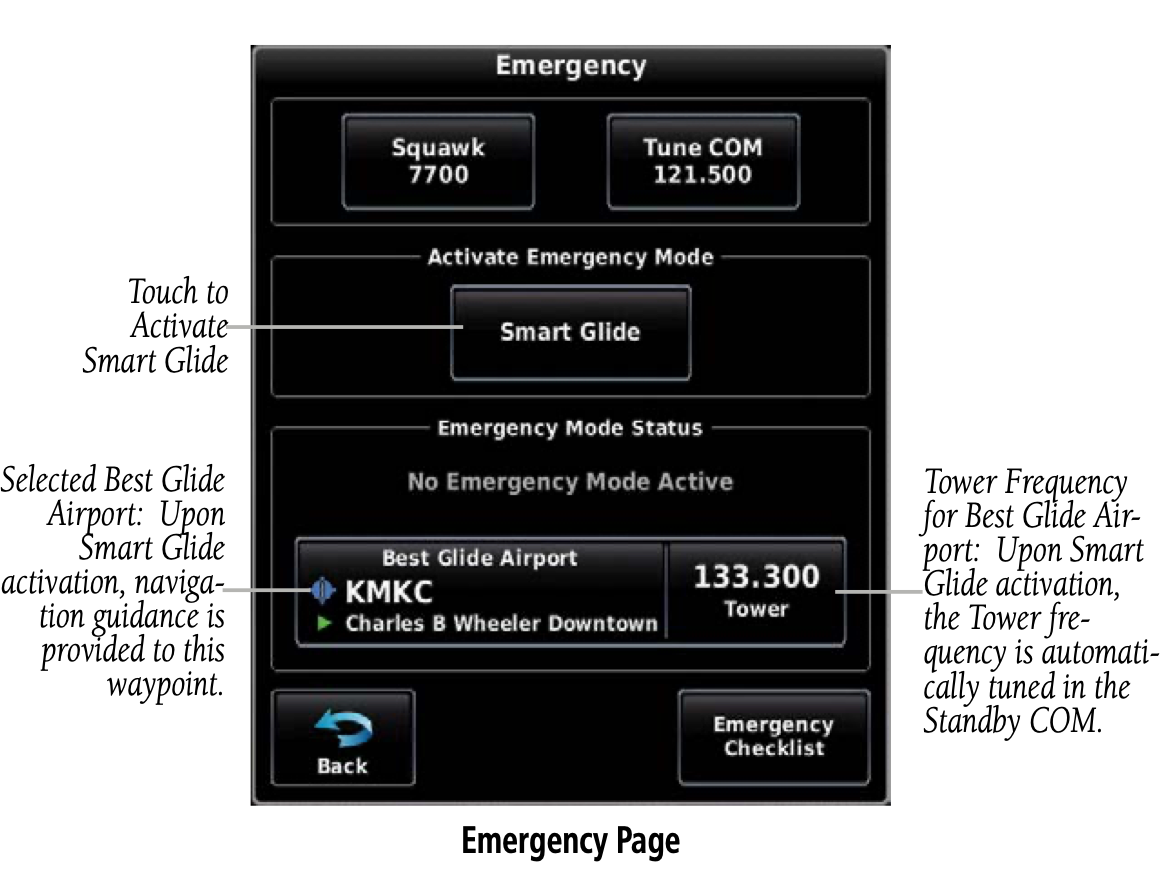

From the GTN xi manual: Smart Glide Function Functionality changes based on whether or not a suitable destination airport is within the estimated glide range. Suitable airport within glide range: • Configures Map to show pertinent glide information, including Smart Glide Range Ring and arrival AGL • Replaces existing flight plan with a direct glide route to a suitable destination airport • Provides a list of alternate airports that are within the estimated glide range • Indicates the best glide speed for the aircraft at gross weight • Triggers autopilot flight director modes to target configured best glide speed and follow the GPS Smart Glide direct-to route1 • Alerts pilot if glide destination falls outside the Smart Glide Range Ring • Allows direct tuning of emergency transponder code 77002 • Tunes standby COM to destination CTAF or tower frequency • CDI scale is set to 0.30 nm No suitable airport within glide range: • Configures Map to show pertinent glide information, including Smart Glide Range Ring • Indicates the best glide speed for the aircraft at gross weight • Triggers autopilot flight director modes to target configured best glide speed and level the wings1 • Allows direct tuning of emergency transponder code 77002 • Tunes standby COM to emergency frequency 121.5 • Provides altitude voice callouts for 2,000, 1,000, and 500 ft AGL 1 Requires a GFC 500/600 autopilot. 2 Requires a compatible transponder that can be controlled from GTN Xi.1 point

-

1 point

-

That doesn’t sound fun. RPM is pretty important. Hopefully mine is easier.1 point

-

Looks kinda like PSP (pierced steel plating) that has been used all over the place since WWII. The airport where I was a lineboy as a teenager had psp covering the ramp, and this was in southern Germany and it never, ever got muddy. It did have a good gravel layer underneath it, but the general idea is sound. It got a little slippery sometimes, but exposed steel is like that, and it looks like what you have may be a bit better. Should be interesting but it looks like it could be a good thing.1 point

-

Most airlines have strict criteria for stabilised approach by 1,000 feet, no matter the weather conditions. Flight Ops will know by recorded means if too high, low, fast, slow, landed too long, short, or even too much brake application. The Captain will probably get a please explain call. Easiest solution is to go around.1 point

-

1 point

-

I suggest doing the work on your own annual at least once. 1. it will save you a lot of money. 2. it will help you appreciate the cost you pay for an annual because it sucks lol. 3. you will learn a ton about your airplane and it will really help ease your mind when it comes to what has been checked. I do absolutely every piece my AI will let me do along with hitting everything with tri-flow. I follow the manual and go through every item and he'll go through all the items after me that I'm not allowed to do and verify it all. it's a tedious process but also kind of fun to do. He didn't test fly mine but he did do a startup and warmup. I don't think there is a need to actually fly. Just run it on the ground a good 30 minutes and put it under a load with the prop several times to test it. After that, if there were any issues they should have been caught.1 point

-

Know where the modes are annunciated. Because you pushed the button does not mean you got what you pushed. I always double point with my finger at the FMA.1 point

-

I find that in the heat of the moment you can miss switching modes. For instance, you are using GPS and GPSS and you’re cleared to a fix, then at the last minute they start to give you vectors. So you change to heading mode for a few minutes then clear you again to the fix again but forget to switch back to GPSS.1 point

-

1 point

-

Gary Main sent me these two articles on turbo inspection some time ago. Bearing Housing to Turbine Housing Clearance-Maint Tip #11.pdf Low Boost #2-Maint Tip #4.pdf1 point

-

Its a Monroy tank thing. The gauges don't know about the Monroy tanks, and they way they work is, the first few gallons are out of the Monroy extension, then the fuel comes from both the Monroy and the factory tanks. So, what you need to do is calibrate the wing gauges (and panel fuel gauges) so you know what you have at various points. On my 252, when the fuel gauges (panel) read 27 gallons, I have about 34 gallons on that side.1 point

-

1 point

-

It would depend entirely on your previous experience, abilities and comfort level in the Mooney.1 point

-

It's about 3.5 inches, the wife would guess seven but that's because I lie to her all the time. It's about 3.5 inches over 14 inches.1 point

-

I'm not worried. I've heard this explained directly by the FAA reps at the IA seminars. Plus, the regs on this topic aren't that hard to read and seem to be consistently understood by most people. For those like you that may not understand them or have additional questions, there's a handy AC on the topic: https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_43-9C_CHG_2.pdf It has this nice tidbit, in plain English: "Section 91.417(b) requires records of maintenance, alterations, and required or approved inspections to be retained until the work is repeated, superseded by other work, or for one year." No, I like the history and don't see any benefit to me to not to keep the old records. It is good to actually understand the regs, though, and if I saw a benefit to not retaining the old records, or lost them, I know there's no regulatory barrier to not having them. Likewise I've helped other people with airplanes with spotty records or missing logs, and know that it's not a Big Deal. Mike Busch, like him or not, has also opined on the topic. In the past he's pointed out that one benefit of not allowing a mechanic physical access to your logs and getting records from maintainers in the form of self-stick pages, is that you aren't required to attach it to the logbook if it is something you'd rather not keep. It has to be kept with the maintenance records for the required year, and then you can throw it away if you like. So Mr. Busch has the same understanding of the regulations and suggests one way to use them to an owner's benefit that is completely within the regulatory guidelines. Because, according the regs, most Part 91 fixed-wing private aircraft aren't required to track age or service time on all parts and maintenance is generally "on condition". Relevant ADs are written with this in mind and you don't need to read very many ADs to know that there are quite a number of ways that this is easily handled. Many GA aircraft owners do the same and see some benefit to doing so, sometimes just for posterity or history. It is not, however, a regulatory requirement. Lots of airplanes have missing logs or get sold with zero logs, e.g., at estate sales, gov't auctions after seizures, repossessions, etc., etc., and still wind up flying legally and safely and get by just fine. The market is full of them. I've not been able to see much price difference in the general market except for the case of entirely missing records, where some effort will be needed to reconstruct the required documentation, particularly the AD list and TTAF, for which there is FAA guidance on how to reconstruct without records. You don't even need the time on the propeller or engine. This has been done countless times over the years by enterprising individuals and is nothing particularly new or rare.1 point