Leaderboard

Popular Content

Showing content with the highest reputation on 02/22/2022 in all areas

-

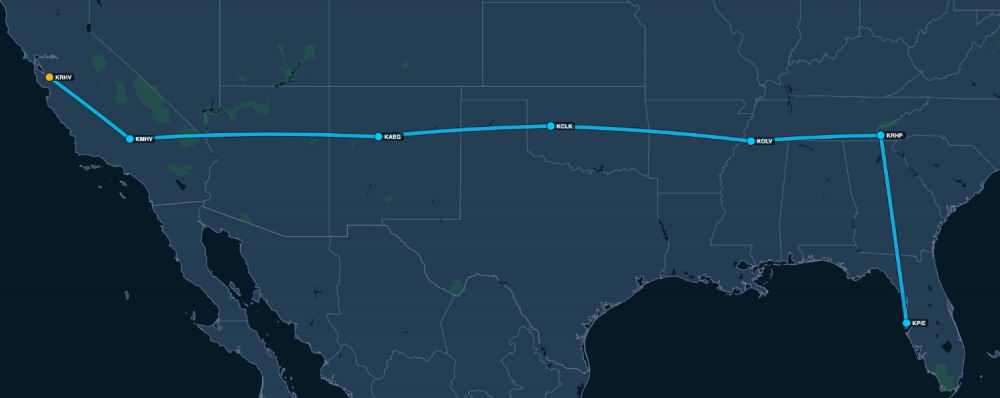

First Airplane First Mooney ( 1982 M20J ) First big trip across the USA Special shoutouts: @jgarrison you are the man.. thank you for helping me thru everything. @Lrn2Fly for teaching me the all the "mooney things" on the long ride home, you sir are a fantastic instructor. Especially reading back 30.07 altimeter setting with a "British Spy" accent, I will do that for the rest of my life Met some great people along the way, notably Nik at Nik's aircraft on the field at KRHV ( aka Flying S Aviation ) and ran into @larryb on the taxiway, nice to have met you ! Stopped at Mojave KMHV for fuel, and was in the traffic pattern with Proteus. https://en.wikipedia.org/wiki/Scaled_Composites_Proteus That was pretty cool. All the amazing views out west Parked next to a T6 Texan at KAEG Met some fine folks in Clinton Oklahoma KCLK Great BBQ near KOLV Met some of the salty aviators that hang out at KRHP ( my summer airport ) and all the friends I have not yet made at KSPG ( my winter airport ) Happy to be part of this community !13 points

-

While Frank's intentions may be good I would be way more upset with the person selling him these items who had already found out from Avidyne that they were on the list. I would spend my time working to get my money back rather than wasting time trying to destroy Avidyne. The title of this post is completely inappropriate. There is no secret. Their response to his inquiry let him know that they needed his serial number. As soon as he gave it to them they told him it was on the list. Checking with them before the purchase would have eliminated all of this. He may not like the policy but it's not their fault he bought the units. Aviation Consumer back in 2016 quoted Avidyne’s Tom Harper on this policy - there is no secret. They aren’t trying to hide anything. Avidyne has also clearly spelled out what type of accident they are talking about (49 CFR 830.2 https://www.law.cornell.edu/cfr/text/49/830.2) Frank said earlier on Beechtalk that if you had a flat tire and then cut yourself getting out of the airplane your avionics are now worthless. Total exaggeration - absolutely not true. First google response when I did a search : http://www.aeapilotsguide.net/pdf/09-10 ... ionics.pdf Frank buys and sells salvage airplanes and has done so for decades. Whose fault would it be if after selling a rebuilt airplane where the buyer insists on not doing a pre-buy and then afterwards the buyer finds some un-airworthy items? It would be the buyer's fault unless there was deception involved, then Frank may bear some of the blame, but It certainly wouldn't be Cessna's or Piper's or Mooney's fault. In this case Avidyne didn't sell him anything bad, in fact they didn’t sell him anything - the Seller did. Making it Avidyne's fault removes all responsibility from Frank and the deceptive Seller. Avidyne didn't get a dime on this sale nor did they get the equipment. But they get hassled for a policy that they've had for years and feel is in their best interests. It's also in writing in their original warranty which is between them and the original purchaser. If he thinks it's worth his while go after the seller or never do business with him again, focus his energies on that. Had this been avionics just removed for an upgrade it would not have been an issue. Had he checked with them ahead of time to see what their policy was it wouldn't have been an issue. Playing the blame game doesn't get you anything except a whiny reputation. We’ll see who takes the high road here. Does Avidyne go on all of the online forums and tell everyone not to buy Franks previously wrecked airplanes or does Frank go on all of the forums bad-mouthing Avidyne for a policy they’ve had in place for years?9 points

-

Well you just can’t make this up, but here goes. I thought the problem was fixed. Not so much. See if you can follow the bouncing ball. Approximately three years ago I had a mag failure leaving Monterey. Had the mag pulled and flew it home. Fun part was a ride home in a G3. Had mag overhauled and flew back with a A&P to reinstall. He had a hell of a time getting it to run correctly. Can’t recall why. Finally got it sorted and flew home. Fast forward to a few weeks ago when I started having rough engine on left mag. We found shielding on right side was grounding to main wire on P-lead. Couldn’t figure why that would make left mag run rough. Fixed leads and all normal for one flight. Next flight, left mag check not running rough but 150 RPM drop. Back to the drawing board. We decided to pull the mag and found the following. Mag cap was not indexed correctly and mag installed upside down. So all these years checking right was left and left was right. Capacitor on right side was toast and right points a little toasty. Purchased a overhaul exchange from Kelly Aerospace with two new capacitors and all is back to normal.5 points

-

Decided to go ahead and post the photos on the panel upgrade for my 98 Ovation, N2155K. We opted to go full Garmin stack. G500Txi + EIS GI275 GFC500 with YD option GTN 750xi GMA350c Audio Panel - I prefer a physical Audio Panel GNC 255a Nav/Com Guardian Avionics Aero 553 Multi-Function CO Monitor in panel FlightStream 510 I already had the GNX 375, so we kept that as the Transponder and GPS #2 We've got most of the squawks addressed, still a couple of minor items to clean up, but couldn't be happier with the new equipment. Such a big change!4 points

-

Yes and no. We’re pretty damn stingy with TV / screen time around our house. However, when we hop in the airplane for a flight to grandmas, we hand the 6 year olds their Kindles with movies, cartoons, etc. Peace and quiet ensues for the next 4 hours. As a bonus, my wife and kids want to go on trips all the time - wife because she gets to read her big books and kids because they get to watch movies. I just feel a little wrong/dirty that my kids want to go flying more (much more) for old spider man cartoons and Disney flicks than they do for the wonders of flight. I hope I’m not raising more people who never look up at the sound of airplanes going over…3 points

-

This is a teaser for registration for this year's Mooney Summit, which will be opening in the next few days. This year’s Summit is September 18-19 2022 at Peter O Knight Airport (KTPF) and the Tampa Theatre. Some exciting changes this year: 1. New venue! Enjoy Tampa and the historic Tampa Theatre this year. 2. Online Silent Auction! The Silent Auction will be open to all, not just those in attendance. Watch here on MooneySpace for details on what's up for auction and how to bid. 3. Online raffle - no more tickets to keep track of! Raffle will still be for registered attendees only. Things that haven't changed: 1. World class subject matter expert presentations 2. Roundtable discussions of all your favorite topics in the hangar on Airport Day 3. Social events on both days with all of the friends we haven't seen for a couple of years. I'm tying up the last few loose ends for the online registration page and will have it live very soon. Stay tuned! Cheers, Rick3 points

-

Perhaps my wording was not optimal. As @dzeleski mentioned, the condition of the equipment will always be suspect after a crash, and for something where reliability is crucial a crash creates a significant increase of risk due to potential damage creating latent faults. Even in racing, at least under the rules I raced in, the majority of your safety equipment is one-time use. Seat, harness, helmet, are all done after a crash. Throw them away. It doesn't matter what they look like or feel like, the composite materials in a helmet or seat may have internal cracks that are not visible and so can no longer be relied on. A harness gets only a single crash stretch cycle before it needs to be replaced. It is common practice for safety crews to chop up the harness belts after a crash to make sure that they don't get re-used. I would hope that an avionics box or gyro instrument would be held to a higher standard than that. Electronics are subject to failures due to cracks in solder joints, circuit boards, connectors, etc. It is not rare for manuals for such equipment to have drop limits, that if a unit gets dropped it has to be returned. Same idea. I would be surprised if Avidyne is the only manufacturer that keeps track. I would not assume that Garmin et al do not do this.2 points

-

I agree with this as well, but he makes a lot of significant changes with the prop and throttle so it’s a little tough to tell exactly what is causing what. He’s also got the control quadrant which can make those changes “abrupt” if not done carefully.2 points

-

You have a leak and that’s the place to start. Also, the flow divider issue may have been related to something failing up stream like internal hose deterioration. If this were my plane I would replace every fuel hose and send BOTH the fuel servo and the flow divider in for service. As stated remove the finger screen from the fuel servo and inspect before sending it. Check the electric fuel pump for leaks. Mine was a Dukes 1499 series and just rebuilt and in process of installation and inspection and it has the finger screen just downstream of the pump outlet. Remove and clean it and install new O-rings. Remove and check/clean the injectors and verify the fuel lines from the divider to the injectors are clean. While you are at it, go ahead and replace all of the rubber fuel line clamps. Don’t forget to flush the new fuel hoses before installation.2 points

-

I’m a 32 year owner of an F model which has the same engine as yours. As Rags mentioned, I wouldn’t mess with the mixture in the pattern unless you’re in the higher elevations. What caught my attention was that you said your fuel pressure was 36 PSI.That is way too high. Something isn’t right. My F will have an inflight pressure in the 24” to 25” range. With boost pump on, I see a solid 27”. I think the red line is 30”. As others have mentioned, it might be good to have another set of eyes have a look. Sent from my iPhone using Tapatalk Pro2 points

-

2 points

-

Yeah if it’s already running poorly, adjusting mixture isn’t terrible, but must folks are going to follow the standard technique of everything full forward, switch tanks, etc. Honestly, if you’re in the pattern, just getting it back on the ground soonest is your best bet. If I may (as a CFI, but only a shade tree mechanic…) - when doing patterns, there’s not much point in adjusting mixture or prop if you’re near sea level DA. Full rich, full prop, don’t touch them. If you’re at high DA and need to adjust mixture for full power, then do that prior or during takeoff (target egt method is one way). The engine is rated for 2700 rpm and full throttle and it’s the fastest way to get altitude. Then you’ll pull throttle back on DW but leave all else alone until further reduction to start descent. When you’re using like 5 power settings through the pattern, things get complicated and there’s not really a good reason for it. It will be important to identify exactly where the fuel is coming out because there are like 4 places down there that are designed to let fuel out. Try flooding the engine… there’s a drain directly below the servo tgat will pour fuel. Boost pump broken? There’s a drain for them. Find the one if it’s coming out there and follow it back to the source. Take pictures, post that info. Just my 2 cents.2 points

-

Who does the maintenance? Maybe it's time for a new shop??? We just had this discussion today at lunch, though it was really from the other direction. A friend bought a plane 20+ years ago, but when he was first looking at it the shop that did the pre-purchase, that was also the shop that had been maintaining it for year, found a HUGE list of issues. Friend sent the list to my mechanic (Air Mods @ N87) had a great laugh. But he couldn't get up to see the plane right away. So the friend found another mechanic who was able to look at the plane - and also had a great laugh with the list. This was a well known "New England" shop, but obviously there were issues with their work. And they were willing to tell whomever what they thought they should hear vs. what the straight story is. So, just saying... Maybe your guy isn't really finding these issues until YOU find them. Might be worth someone else looking at plane to give you an honest evaluation.2 points

-

I was asked earlier if there was something I could share here of interest from the AMPA discussion. With permission a statement from one of our most respected members: "Folks who are planning to branch out into aircraft design and manufacturing should bear in mind that this item under discussion (despite its name) is NOT a spring. Its function has nothing to do with its "springiness". It is a uni-directional torque translator. It allows torque to pass in one direction from the motor and manual actuator to the extension mechanism but just free-wheels in the other direction. Its function depends on the slight reduction in diameter when it is "tightening" and expansion when it is turning in the other direction. The key is the phrase "no back" in the name." Peter2 points

-

Dan, Dan, Dan... you need to get out more often! When Mike would come to our fly-ins, I noticed that he was always wearing the same cargo pants. In fact, upon further research it appears that he wore these same cargo pants EVERYWHERE he flew (ex. the Caribbean trip, the Artic Circle trip). Just curious if Mrs. 201er finally got him to wash them. Here is a photo from back in 2016.2 points

-

1 point

-

1 point

-

I should check before each flight, but I do it if I see that they look flat… I usually use an analog gage. Oscar Sent from my iPhone using Tapatalk Pro1 point

-

Mine was marketed as a 2005 built in late 2004, I got ticked off when I bought it they represented it as a 2005, for what it’s worth I had Mooney enter in the log it was a 2005 for what it’s worth. I think 318 was the test bed for the g1000, has the GFC 700 and other stuff, was then refurbished and renewed at the factory and sold as a 2004/20071 point

-

Wow it never had speed brakes when i owned it, so the relay might not be where it would be if the factory had installed them. You might have to follow the wiring. The fact that it doesn’t have a one piece belly is probably proof positive that it’s never been landed gear up. Almost any pre-one piece belly Mooney 231 that lands gear up, gets a one piece belly as s result of the repair.1 point

-

Might be easier to ferry it. My M20E used to live in Japan for a large part of its life. It flew across the Pacific twice. 110 gallon ferry tank in place of the rear seats.1 point

-

It's easier to remove the tailcone. Taking off the wing involves fuel lines, aileron linkages, flap linkages and the gear linkages, plus wiring for lights and of course the pitot tube. An experienced crew can remove the tailbone in about a day, drilling out rivets just behind the baggage door.1 point

-

Typically, installing an isolator (required for magneto ignition) of the wrong value would result in one of two conditions. First, too small of an isolator value would result in jumpy and high readings as the R-1 would be picking up the noise near the bottom of the p-leads pulsed signal. The isolator would not be attenuating the signal enough to where the R-1 is only capturing the peak, registering one pulse. Conversely, if too large of an isolator is installed, the RPM indication will typically be low or even 0 at lower power settings, slowly becoming erratic and more accurate at higher power settings. Is this a new installation? Safe to assume the aircraft is equipped with two magnetos? If you have a serial number of the R-1, I'd like to review its original configuration to make sure it was set up correctly for the aircraft it is installed in. If it is not a new installation and has been functioning well previously, has any work been done on the aircraft recently?1 point

-

1 point

-

I have a quadrant system as well. Can’t tell if the fluctuating MP is due to the engine issue or him yanking the quadrant back and forth. In order to get that much fluctuation on a quadrant, you need to move those controls pretty aggressively. Sent from my iPad using Tapatalk Pro1 point

-

All throttle changes I am doing are reactionary to the RPM decay and the MP increasing. Base and final you can see the EGTs just drop away every time MP increases.1 point

-

@Marauder caught something I didn’t see and it caused a couple of neurons to fire. I remember a while back someone reported higher fuel pressure after replacing the electric boost pump. I have no idea what the results of high fuel pressure would be.1 point

-

Bonanzas do have the inner gear door that opens at the beginning of the gear retraction. Supposedly, clear the obstacle before retracting the gear as that door opening increases drag. Don't remember seeing that in the POH nor was ever apparent to me flying a Bo. The high gear speeds did make for a very effective speed brake however.1 point

-

Sometimes it’s tough to stay within the restrictions without overthinking them. Especially when the manufacturer doesn’t define “continuous” for us. Clearly it’s ok to takeoff and initial climb full throttle and 2700rpm. Even if you weren’t staying in the pattern, you’d leave that power setting up through 1000’ or more to give yourself options in case there’s an issue. In the case of a pattern, do the same thing, full power, full throttle to 1000’, level off, accelerate to desired speed (~110mph?) and then retard throttle to ~20” (or enough to hold DW speed. I think that will keep you within your constraints and is reasonably non-continuous. The 5 minutes restriction is not applicable in the pattern - your whole video was only 3 minutes and clearly not all at full power the whole pattern. I’m not telling you to disregard limits, but think through what you’re doing and why and make sure it’s needed. I think less power changes (throttle, mixture, prop) will help you know when something is actually going sideways. Personally, I would track down the fuel leak, fix anything found, and run the engine again before sending off the servo, but again, I’m not a mechanic.1 point

-

I once had the B nut on the fuel pump end of the fuel line from the pump to the servo back off and it dripped fuel. I would check all the connections and especially locate the source of the leak before pulling the servo. I can’t think of how a servo could leak as you describe. There’s no fuel reservoir in a servo like a carburetor. Servos can get crudded up with varnish and corrosion if they sit a lot. Most common failure is probably the diaphragms. You might also call Al Jesmer at Precision Airmotive and discuss it with him. Skip1 point

-

1 point

-

1 point

-

I’m not a mechanic, but it appears to be a fuel starvation issue such as the fuel pump going TU or even a bad fuel line connection causing it to suck air. At full power it might still be drawing in enough fuel, but at low power settings, air may be getting into the fuel flow. Another item to check is to make sure both tanks’ fuel vents are clear. A partially obstructed fuel tank vent might result in the similar fuel starvation issue.1 point

-

Chris I changed the one on the copilot side a few years, what a bear to do, it was binding up. My pilot side is the opposite there is play up and down significantly more the before. Therefore being the opposite set of circumstances led me to inquire about it1 point

-

1 point

-

Make sure your shop reads and heeds the Continental service bulletin on installation of the drive coupler cotter key. A failure to do it right can result in engine failure. As to the coupler, personally, I install a new one every 500 hours and I only buy new, not rebuilt. It is internal to your engine and too critical of a component to not get right. https://www.aircraftspruce.com/catalog/pdf/avl-9610-sb.pdf1 point

-

I sense some stress in the above posts… 1) It appears the writer is trying to do the right thing… 2) Has never done this before… 3) lost sight of what he was trying to accomplish… 4) wrote some disrespectful things about other MSers… This is where somebody writes a reminder… MS is on the internet… it is not the internet… It isn’t a place to be unkind to other people in the community… Even momentary unkindness… written on the internet… seems to stick around for quite some time… People come to MS, because they want to be here… Expect to not be understood, all of the time, by everyone… Stay focused… Take the time… bring everyone up to speed with what you are trying to do… how you are going about it… Recognize all of the people that have left you quality guidance…. They have pointed out bumps in the road you haven’t gotten to yet… Imagine what it is like being amongst many people that have decades of aviation experience… you have the audience you want… you started the conversation… Then you forgot why you started the thread… Where are you going to go when you really need some Mooney related help? It is easy to have people hit the ignore button on you… being the most ignored MSer isn’t the goal is it? There are right ways and wrong ways to achieve an objective… work on doing it the right way… real MSers have tried to point out the right way for you… Keep in mind… using a tiny screen as an interface for MS… leaves out a lot of information… you have to look people up to know something about who they are… Go MS! Best regards, -a-1 point

-

First off kiddies- Mooney didn't make the springs in-house. They were farmed out to a spring maker. The batch that was bad had cracking right in the bend of the tang from heat treating Springs can be tested for strength and rebound but they tend to fail suddenly for a variety of reasons. Mooney HAS the part drawing describing exactly how to produce the part. They have a drawing for EVERY part in any Mooney on exactly how to make it. But its called "PROPRIETARY INFORMATION" held by the certificate owner. There are dozens of file cabinets in Engineering that hold these drawings I saw them many years ago. The drawing will detail exactly what material to use, what the dimensions are, what kind of heat treat etc. Doing an OPP is not just reverse engineering the part. One actually needs paper work to support how the part is supposed to be made to make it match the "APPROVED" part. As an owner you can't just magically say "presto -chango" this is an approved part because I made it. You can't just say "I think this is how they made it" You need some kind of legal reference on how it was made OR a complete DER sign off.1 point

-

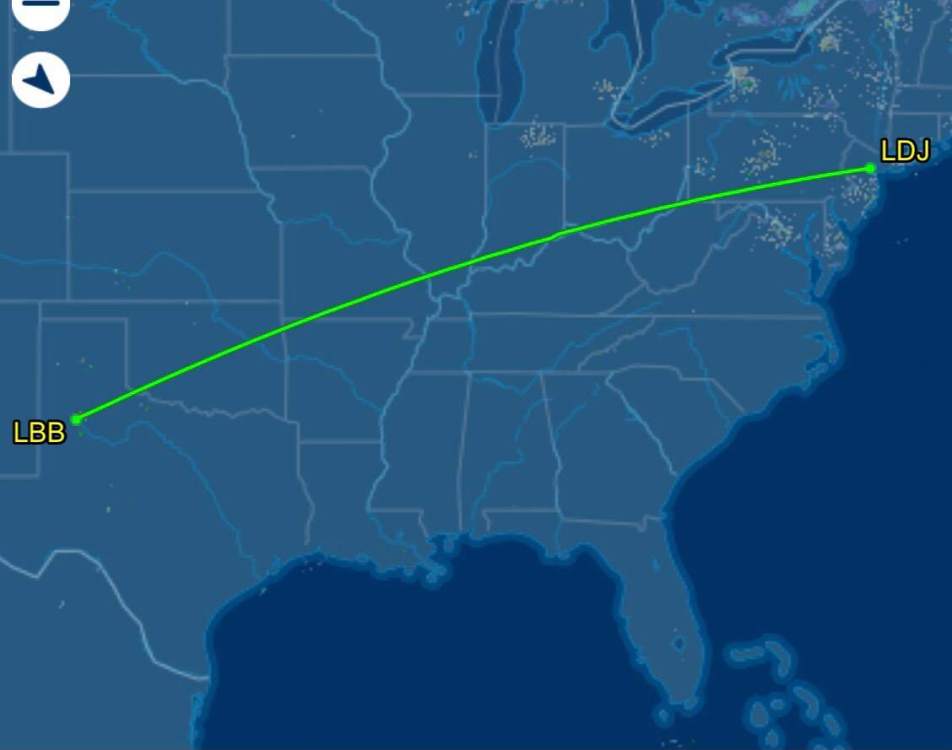

This was my second longest flight by distance 1380nm (longest was Denver to Linden 1400nm) but a pretty short one by time. Only 7:30 in flight time. Had a bunch of 8+ hour flights before but not quite as far. Very nice tailwind this time. Was planning for 150KTAS at 9000 with a 30 knot tailwind. Ended up getting a few knots extra out of the airplane and a few out of the tailwind making it closer to 190 knots ground speed for much of the way. All while at or slightly lean of peak at 8.0gph. WOT produced 21” and RPM 2560. OAT went from 15C down to 2C as the flight progressed. Fuel used for the flight was only 62 gallons. Landed with 38 remaining. Weather was absolute clear and smooth all the way. Rare to have such a large swatch of the country without weather. I didn’t pick the weather. It just happened to work out so favorably for my return. Had a top notch in flight meal service. And no limits on the beverage cart!1 point

-

Good Lord! If I even dared suggest that to my wife...I'd be flying home DIVORCED!!1 point

-

I'm kind of a newish member here at MooneySpace. I'm really off put and dismayed to read the personal attacks going on here. These all seem childish, unnecessary, and ultimately pointless....unless the point is to make other members "afraid" to post lest they be attacked in the same way. This thread is both important and interesting. In Australia, on the AMPA forum, a similar discussion started almost exactly at the same time. I'm happy to report that it is quite civilized and has a lot of good information. Unfortunately I cannot provide a link as it is a "AMPA members only" forum. Peter1 point

-

Hello everybody, now after nearly one month some updates to the alternators mystery: Main alternator field voltage check on F1 positive but without current flow. Coals? The main alternator was VERY difficult to remove. Two bolts above no problem, one left down a catastrophe. The Continental guys must have dwarf hands... After removal and sending to a special repair shop they detected both coals were down to the metal and scratched the alternators axis. So the alternator has to be replaced. The alternator had about 1200 hours without service. Continental recommends service every 500 h. It's worth doing so! See first 3 pics below! The 20A standby alternator from B&C was very easy to remove. Just 4 screws. Shear Coupling was broken. A $42 item, that can decide over your life! This part should be replaced after a certain amount of time. Mine was still original and broke after 18 years! See pic 4. B&C is very cooperative! Top specialists and very quick delivery! Super perfect! Thank you TJ! My shop will going to install the alternators in the upcoming days. In future I will have a closer look at my subsystems and will prompt more actively my maintenance shop for such details. These can decide about your life. Fly save and have fun Peter1 point

-

You can oh 4 cylinders and not even be close to oh the engine. God forbid you need a new cam, crank or case… the cylinders aren’t a large percentage of what you pay for in an oh. $20k seems possible for an oh but likely low.1 point

-

1 point

-

I'm not sure there is a wrong oil as long as you use one for your temperature range and meets engine specifications for oil. While certainly there are differences in oils, and changing oil frequently is never going to hurt your engine, I'm not sure all the bruhaha about what oil is "best" amounts to much. Today's oils are all superlative compared to what was being used when our engines were originally certified. When I bought my Mooney years ago, the previous owner was using Havoline 10W-30. Yes, car oil. I bought it with about 1700 hours on it and switched to Aeroshell W100. The engine was running fine at 2400+ hours when I exchanged it for a factory reman. Everyone has their favorite oil story, but generally when an engine fails, it is not an issue related to oil type, or brand. Buy what you like, run it for 2000 hours and let us know how you like that oil. If it is a bad oil, we'd all like to know!1 point

-

I appreciate your response. That’s pretty much how I felt. Yes, to many of us the airplanes are not just toys. Realizing I’d have seven hours of driving ahead of me because someone decided letting us know that we wouldn’t be able to get our planes out was “not my job” did not make me very happy. Then one of the first patients I saw at work was my age and had a terminal diagnosis so I stopped feeling sorry for myself and moved on. It is really disappointing though to see this downward spiral toward higher prices and less service. The airport recently announced they were ending the 2 year leases and instead doing month-to-month leases where they would be able to adjust the prices more often. My accounting company wants to charge 33% more this year (even though last year so many people were out sick that the service was horrible). Seems like the “new normal” is paying more for less and being expected to like it.1 point

-

1 point

-

I started with a SkyOx that came with my J. I then bought the Mountain High system. Save your money and just start with the MH system. If you buy something else today you'll just get the MH system later anyway and spend more money total. My experience is that a 24 cu-ft tank will last two people 24 hours at 15,000 feet. My SkyOx lasted about 4 hours. It's not that the O2 fills are that expensive (although they are) it's the hassle. The extra endurance of the MH system is worth every penny. Now in my K I have a built-in 115 cu-ft tank and a full tank lasts literally a year, and 99% of my flights use O2. There are other benefits as well. MH beeps at you if you stop breathing through it or a hose comes disconnected. With a SkyOx system you'll never know there is a problem unless you are constantly testing your O2 sat.1 point

-

Pilots in US just can’t understand that airplane supply in North America is much bigger then anywhere in the world and is hard to get a good airplane (let alone Mooney) in different parts of the world years ago i helped a friend in South Africa import first PA28 for his flying school. Container shipping was much cheaper then ferrying over Atlantic but you would need to find experienced outfit to dissemble and secure the plane in container. At that time USD was very weak to world currencies so that played to our advantage but had to pay 40’ container ourselves. Future planes we packed and shipped by SA transplant in Vacaville who could pack there in one container so it cut the cost. Unfortunately, he died in crash few years ago. of course you would need an experienced crew at your end to assemble the plane as well as someone in US to organize all this. I helped with shipping 4 planes and finding a good shop to disassemble the plane and place in the container is most important task good luck.1 point

.thumb.jpg.44bc5ad17b44ec09b48bdca2a82f7a76.jpg)