Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/2025 in all areas

-

7 points

-

+1 @Ragsf15e 1. Cad machine screws. If the head shows any damage, replace it. 2. Put a small smear of anti seize (use a tooth pick) on each screw before installing. It’s time consuming, but once done, you don’t have to do it every year. 3. Hand install screws. Using a ratchet screwdriver helps. Do not use a battery operated drill-driver. Even the lowest torque setting is too tight. 4. Use a new (quality) apex bit to remove the screws. Worn bits strip out Phillips head screws. You’ll spend much less time removing stuck/stripped head screws.3 points

-

I’ve had good luck using fiberglass cloth and PVC pipe cement. It melts the fiberglass cloth into the abs plastic. I do this on the backside of the trim to add strength. I then use some pvc putty to fill the larger cracks on the front side. Sand and then paint and it looks like new. Lee3 points

-

If it were my plane, I would want that extra relay and 3-way avionics master switch removed and everything returned to stock configuration. There are reasons and failure mode considerations it's done the way it is, and what you are experiencing may be one of the reasons the factory didn't include the option to turn on the avionics with the master off in the first place.3 points

-

Yes, government mandated innovation is the key to success…thank God they made horses illegal in the early 1900s or the automobile would’ve never been invented and city streets would still be full of horseshit.2 points

-

Cherokees are much worse, especially a straight-wing Arrow, that has a ton of drag when the gear is down. I flew a friend's experimental that is kind of Mooney-like but has stubbier wings and a higher wing loading. It's fairly fast but when I reduced power for descent it came down way faster than I expected, and slowed down a lot, too. The Mooney really does spoil you in some ways.2 points

-

It is a CIA plot to tell you your Watergate is bugged.2 points

-

One other thing my mechanic and I noticed was how the stainless screws were much more likely to gall and stick in the nuts (machine screws at least). I haven’t had the same issue with cad screws. After watching my mechanic drilling out a ss screw (and cringing) and then replacing the nutplate as well, I just use the cad plated ones and throw them away as soon as I see them deteriorate or strip at all.2 points

-

ABS may be best but for the folks using epoxy, I used JB Weld Plastic Bonder (purchased from Lowes). Works great; no failures. It can be used for filling and can be easily sanded and painted. I've used it to glue steel adhesive ready nut plates to the back of the interior panels and I've used it to glue thin sheet aluminum to the back for reinforcement over damaged areas. Everything seems to stay stuck.2 points

-

You should definitely remove that strange avionics master setup regardless and return to a stock configuration. The legality of that switch install aside, it opens you up to a ton of issues, not the least of which are a complete avionics failure or back feeding into the main bus. Does that not concern you?2 points

-

You sound/act like there are no and have never been any smart people anywhere working on this. Tell us why Thielert tried in 1999 and failed. Tell us why you have not mentioned DeltaHawk as a possible near term solution.2 points

-

2 points

-

If it is so easy why hasn't Rotax developed a 6 or 8 cylinder in all this time? Why is there nothing above 160 hp? Modern car engine....solid block, unleaded fuel, synthetic oil.... Oh and they don't run for hours on end at WOT....they would not last long.2 points

-

It was 55 years. Up until 1970 it was MORE POWER no matter what it takes. That was when you couldn’t see two blocks anywhere in LA. And your car was covered in soot every morning. Now you can see the mountains from the beach any time. So the environmentalists have achieved everything they ever wanted. But they have these big organizations put together with nothing left to do. So they are coming after our little airplanes so they can still be relevant.2 points

-

Excellent point but its actually really nothing to do with with older Mooney's but weight. The longbody's especially are the easiest to lock up the wheels with their heavier weight/faster landing speed and beefier double puck brakes which can flat a tire immediately. With all Mooney's it's important to not touch the brakes immediately after touchdown since speed is till high and their isn't much weight on the wheels yet making them easy to flat spot if not flat them. Its important to initially slow down with aerodynamic braking where the savvy pilot holds the nose wheel off as long as possible and only applies brakes after the aircraft has slowed down adequately that the brakes won't lock up soon as you touch them. That speed varies by aircraft weight.2 points

-

1987 Mooney M20J - N5801N This Mooney has been upgraded extensively. Virtually everything besides the airframe has been replaced/upgraded. It features a 100% glass cockpit (vacuum free) with active TCAD traffic, on board XM weather and STEC-55X autopilot. Lycoming factory remanufactured IO-360-A3B6, with Left Mag and Right Electroair electronic ignition. Powerflow Exhaust Hartzell “Top Prop” 2 blade propeller Fuel tanks resealed circa 2010 New Landing gear rubber discs and gear-over-spring 2023 LASAR upgraded nose wheel truss LED landing light LED tail beacon Artex 406MHz ELT McFarlane throttle/mixture/prop controls Aspen Evolution 2500 ‘3 panel’ system (new 9/2025 with 2y factory warranty) STEC 55X autopilot with auto trim and electric yoke trim, integrates vertical speed and altitude preselect with Aspen system Avidyne TAS-600 TCAS Traffic Awareness System JPI EDM 930 Engine Computer RC Allen RCA2600 LCD Digital Backup AI Garmin GNS430 WAAS GPS #1 Garmin GNS430 WAAS GPS #2 Garmin GTX330 mode S transponder with Extended Squitter Garmin GMA347 Audio panel, 4 place intercom and music input Aspen XM weather module Aspen Synthetic Vision Software Aspen AOA software Aspen Connected Panel CO Guardian electronic CO detector Skyradar ADS-B receiver Bose hot plugs, 4 places Hail damage in 2023 Remote damage history from early 90s, NTSB can be found online Paint & Interior in fair condition TTAF:6450, TSMOH: 2208, Prop: 2208 No Squawks, everything works. 10.4GPH 155KTAS ROP 9500ft Only selling to upgrade to Acclaim. $109,0001 point

-

I use that when I need to fill in an area. Afterwards, any small imperfections can be filled with Bondo glazing and spot putty. My glareshield was in pretty sad shape and I fixed it up with and then sprayed it with SEM texture and black color coat.1 point

-

My first flight in a Cessna was after I think about 400 hours in our Mooney. We rented on in Maui and took a CFI along. I told him I'd never sat in a Cessna but to just give me speeds and power settings. Two hours later I was coming in to land and when I was where I pull power on the Mooney I pulled the power. He immediately reached over and shoved it back in as I said "sorry, I'm used to my Mooney."1 point

-

1 point

-

Actually they do pre-punch parts. Maintenance wouldn’t be possible on some things without doing so such as for example the seat rails are pre-punched. You could never drill out all the holes under the floor panel, as it is you can’t get a bucking bar on some of the rivets. But you are very right about your factory and LASAR comments. The factory is pretty much over and LASAR is so cash poor that buying the raw materials for parts is a struggle. Sent from my iPhone using Tapatalk1 point

-

I'm no expert but if I remember correctly from my time with an Ocean Engineering group, stainless steel and aluminum were not great together. I think you are correct in your assessment (yet we use them anyway). Hopefully there's a materials expert on M/S that can offer an expert opinion. I think Cadmium has fallen out of favor due to its toxicity and carcinogenic characteristics. Cadmium corrosion (a white powdered dust) was a bad thing to inhale.1 point

-

There are some of us who were around when this SB came out and remember the background of what actually happened. Even though it was only a couple of springs that went bad due to a bad heat treat in a batch of springs, the risk factor of the gear up landing if one was to break again (think lawyers) was high enough to make the 1000 hrs change out a reality. This would also preclude changing the SB to longer time limit today with today's litigious society. If it was an inherent problem with the design and wear factors of the spring itself we would have seen springs failing many times in the years before this SB came out. What changed? What have we done now when the springs were not available for years? We flew and didn't have spring failures. Many Mooneys would have had gear up landings because many Mooneys had more then 1000 hrs on the spring they came with before the SB. Fleet average might realistically be 1 or 2 gear operations per hour given 4000 hr airframes only 8000 operations over 40 or more years. Is there a limit to how long a god spring will last? We don't have those numbers so it seems reasonable to change the spring at some time down the road. I'm sure Al Mooney never figured his designs would be flying 60+ years after they left the factory. SB's are, after all, "optional" for Pt 91 airplanes (Australia aside :-) Your choice. Can anyone report on any Mooney gear failure due to a back up spring failure recently? Please provide the details so I can research the issue. Due to the very detailed SB requirements this is a prime place for "maintenance induced failures" if not done exactually like the SB proscribes. Being as esoteric as this particular maintenance action is it is not one to be attempted by just any A&P. Do I dare say "Johnson Bar" anyone :-)1 point

-

I am; the windlace is done and will be picked up from the upholstery shop today. I should be back in town tomorrow and my goal is to have the overheads back in. This weekend. Lots of small screws.1 point

-

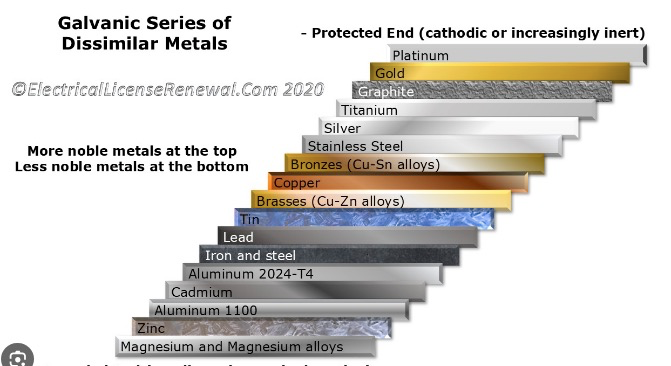

Just bringing this thread back from the dead: Since I’ve been based at a coastal Florida airport (beautiful spot, but hot and humid) with my Mooney since 2020, I made a habit of replacing corroded or worn fasteners with stainless steel ones. The line for hangars are decade long and I'm on the outside tiedown. But the more I’ve read on this, the more I realize that cadmium-plated screws are actually less noble than stainless and closer to aluminum on the galvanic scale. Counterintuitive as it seems, that means cad-plated screws can promote less corrosion than stainless when installed in aluminum. Sure enough, I started noticing filiform corrosion forming around my fuel tank access panel after swapping the original screws for stainless steel ones. Does anyone have an experience with this?1 point

-

Yes, with one caveat- the KX-155 is well known for its reliability. Only time will tell if the Trig (or any of the very new radios, even Garmin) will match it going forward. My gut tells me the new designs will be as good or better than the older generation. The GNS-430 is now over 25 years old and still going strong.1 point

-

Just like there are good and bad shops, there are good and bad customers. A good customer is engaged in the maintenance on their machine, without "standing over the shoulder" of the guy while he's working. He pays his invoices on time, and provides as much useful feedback to the shop as he can when an issue arises. I know there are lots of pilots (looking at you, Cirrus owners) who just toss the keys and say "fix it" but I try to work with my shop, as much as I can. Sure, there have been some invoices where I've questioned a couple of things, but it's either been cleared up by my shop, or they've given me a satisfactory explanation as to why something took a bit longer. That's the best approach moving forward I think. Just ask for 15 minutes of their time to sit down and go over your invoice, have them break it down line by line.1 point

-

Just extremely disappointed with bullshit. You Americans have no idea how much worse it is here in Europe for light GA. I’m seriously questioning whether or not my plane will be able to fly after the AVGAS extension until 2032 passes. I lost all motivation to put any upgrades into my plane or do any facelifting and it desperately needs both. And it’s all because of this bullshit. I mean look at what SpaceX accomplished in just 4 years at Starbase, and we can’t get a reliable high powered engine running on less than some prehistoric fuel?? While there are Billions of cars on the road? Laughable. Well it would be if it wasn’t so sad.1 point

-

If I'm reading this right, you say you can run the flaps with the flap CB pulled???!?!?? Something is seriously wrong if that is the case. I can't quite form a mental schematic of how your NON-STANDARD avionics switch could play into this, but it sounds like you are backfeeding both the master relay and the flaps! Uh, maybe TWO exceptions! And, both are pretty BIG FLAWS, IMHO! Despite your 'preference' for leaving the avionics switch in place, you might consider at least temporarily disconnecting it and seeing if these two 'flaws' go away.1 point

-

But they could run at 2700 rpm damn near forever 8), 3500 rpm, 4000 rpm??? there's really no reason you need to run at wot unless you want like 400hp or soemthing1 point

-

Truer words were never written! I grew up in the 'burbs of LA during the peak years of smog; it was BAD!! I'm talking 1 mile visibility due ENTIRELY to the smog, not weather (well, ok, an inversion was responsible for the really bad days!). Your eyes literally watered from what was likely sulfuric acid from the sulfur dioxides dissolving in the moisture in your eyes! It actually hurt to breathe in deeply; no joke! If you haven't experienced it, it's hard to understand how bad it really was. The problem was solved by the advent of EFI/O2 sensor feedback and catalytic converters. The latter is the real reason lead had to be eliminated; lead ruined the catalytic converters. Back then the lead emissions were the least of the concerns for smog. I.e., lead elimination was just a beneficial artifact of solving the smog problem. As you say, the big government organizations MUST survive...particularly, the SCAQMD (South Coast Air Quality Management District), a Taj Mahal government organization and edifice if there ever was one! However, they did manage to perform a study (which I cited somewhere in the 50+ page G100UL thread) of airborne lead levels around Whiteman Airport (KWHP) and found them to be no higher than anywhere else in the Los Angeles basin. Furthermore, the measured levels were many times LESS than Federal EPA levels! So, yes, they are coming after our little airplanes that emit minuscule levels of lead under the guise of "NO amount of lead is safe" and the standard fear-mongering of "save the environment" and "it's for the children." This is a politically created 'problem' that is forcing an expensive and sub-optimal 'solution' upon us. Yeah, IMHO1 point

-

1 point

-

It's recommended to balance a prop (and the engine too, by default) at the commonly used cruise RPM. Only because that is where the engine spends most of its time. Whether that is 2400 or 2500 rpm, makes little difference.1 point

-

I like the Trig radio. I have one in my Citabria along with a Garmin GTN 650. The Trig audio is better than the Garmin radio. The trig is remote mounted and tied into the PS engineering intercom/com. Lee1 point

-

1 point

-

@Freddb34, this is very correct. The best way to stop is to cross the numbers at the right speed. I don't use my brakes until slowing to 50 mph.1 point

-

let's be honest, these problems would've been sorted long ago if the money was in it. heck there was too little money to change fuels for 50 years only happening now due to threats from congress. current environment, someone pay enough i bet we coudl get rid of those threats atleast for another 10 to 15 years1 point

-

There has been so much trouble with the "new tech" Lycoming iE2 TEO-540 that Tecnam switched to "old tech" Continental GTSIO-520 engines. Reportedly Cape Air retrofitted engines. Continental GTSIO-520-S ready for P2012 installation | Magazine | Business Air News Tecnam offers Continental engine option for P2012 Traveller and Sentinel series1 point

-

Sounds like if your 3-way avionics master switch were to fail or have an internal short, it could be back-feeding power into your master relay or your panel, depending on how they wired it. You know something is back feeding power, and it would have to be either the fused line you sent a picture of, or your non-stock avionics master relay.1 point

-

1 point

-

FYI, here is the Chinese company that makes TEL. https://www.tetraethylleadcn.com/tetraethyl-lead/tetraethyl-lead-ethyl-liquid.html1 point

-

True, the Arrow has a glide range with gear and flaps out about the same as a brick!1 point

-

Exactly. 15 years ago Lycoming introduced the iE2 engine. Also if you think it is so easy look at the Orenda V-8 liquid cooled engine development. It started as the Thunder Engine in the 1980's and then the Orenda in the 1990's. Then Texas Recip in the 2000's and TRACE in the 2010's. No applications. Lots of money wasted in 40 years. iE2 Engine | Lycoming Aircraft | Lycoming Engines Turbo charged 540 with electronic engine controls. First experimental with the Lancair. Then certified on the Tecnam Traveller P2012. You won't find many still on the Lancair or anyone that likes it. And Beechtalk reports that Cape Air put their entire fleet of Tecnam P2012 up for sale in May - reportedly the engine was an issue - heavy and expensive. The iE2 has been a commercial failure. There are no other installations in 15 years. From 2010: Ready for takeoff: Lycoming’s iE2 — General Aviation News Lycoming IE2: Incremental Technology - Aviation Consumer By automotive standards, the IE2 is about on par sensor wise. But it doesn't need the oxygen sensor circuit nor the transmission controls found on modern cars to improve fuel economy. The basic inputs are venturi pressure and temperature for mass airflow calculation, MAP, induction temperature, CHT, TIT and RPM. For crankshaft and top dead center reference, the IE2 has two magnetic position sensors, one on the crank and one on the cam. They sense crank position by magnetically detecting a missing tooth in the gear train, but unlike Hall-effect sensors, they aren't powered, thus eliminating at least one failure point. Speaking of power, its delivered to the engine via a dedicated dual-channel power box that can run the engine either from the aircraft bus or from the default position-a dedicated permanent magnet alternator installed on the accessory case. The engine is designed to run independently of aircraft electrics, although it doesn't have to. It has provisions for an additional alternators on the accessory case or via front-belt drive. Starting with the air, gone is the traditional Bendix RSA throttle body and injector system. In its place is a throttle body that still has hard linkage to the power lever, but one that's equipped to measure mass airflow and temperature, with redundant temperature sensing capability, since air density and flow is such an important player in power setting. The engine control unit is housed in a single box the size of a thick netbook and is dual channel-either channel can run the engine. The ECUs use sensed throttle position as a target reference for the pilots power command, then the mass airflow data is used to fuel the engine accordingly by referring to a customizable look-up table and fine tuning that according to a feedback loop with programmed limits and protections. The IE2 uses electronic pulse injectors whose reliability in automobile use has been raised to nearly failure-proof levels. These run from a common rail at a pressure of 3 bars or about 43 PSI. This fueling option adds a measure of reliability because the engine is set up to run each cylinder as an individual power unit-if one fails, either due to fuel or ignition, the other five will continue running as smoothly as the software can make them. The system is configured with return lines which circulate fuel as a hedge against vapor lock. Ignition still terminates in two plugs per cylinder, but rather than mags or remote spark generation, each plug has its own direct-fire coil similar to the high-reliability type found on modern motorcycles. In automotive and motorcycle apps, direct-fire coils usually attach to the plug, but on the IE2, there’s no room for that. All of the coils-12 total-live in an array mounted on top of the engine where the fuel injection spider would otherwise be found. As you'd expect, the ECU channels cross control, so if one fails, the other can still fire at least one plug in each cylinder.1 point

-

Working the gear in the air vs ground is not the same — the forces are different for sure… Just a heads up… -Don1 point

-

If you like the shop and the quality of work, I would just accept it and not quibble over it. Mooney owners have a bad reputation for being cheap bastards and given the decreasing number of good repair shops and mechanics, I would want to develop a good relationship with a shop you trust. A lot of things on a Mooney are difficult to access and take extra time and unless you are standing there with a stop watch you really have no reasonable basis to question their numbers except a bunch of opinions from the internet. It looks like they noticed air leakage from the #1 exhaust valve during the compression test and lapped the valve. If it were mine, I'd run it for a few hours and recheck the compression to see that it came up, but that's just because I'm an engineer and like to verify results. I'm sure it's airworthy as is or they would not have signed it off.1 point

-

Service Bulletins are not mandatory for private use under Part 91. The no-back springs are very expensive to replace and do not have a significant history of failure over the history of their use in Mooneys, so most people don't bother with changing them. If your A&P insists on performing every Service Bulletin as though it's mandatory your ownership experience is going to be very expensive.1 point

-

If it weren’t for these spammers I would never have learned how to change my flight on Ethiopian Airways.1 point

-

1 point

-

Galvanic corrosion occurs when an less noble metal (anode) is in contact with a more noble metal (cathode) in the presence of an electrolyte (e.g., water with salt or other impurities). The corrosion removes material from the anode. So, in the case of stainless steel in contact with aluminum, the aluminum is the anode and would corrode. So, why is it that you can get away with stainless screws on an aluminum airplane without damage? There are two reasons: 1) If the airplane is mostly hangared and not subject to warm, moist, salty air then there is no electrolyte which is a necessary ingredient for corrosion. 2) There is an area rule: If the area of the anode (aluminum skin) is much greater than the area of the cathode (screw heads) then the corrosion proceeds at such a slow rate as to be essentially unmeasurable. Skip1 point

-

1 point