Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/2025 in all areas

-

WOW !! Thanks for the recap. Considering that our engines are antique technology these prices are just insane. So my engine has 500 HSMO and $60K added into the panel in the past 5 years and an airworthy air-frame wrapped around it... why are planes like mine selling for a $100K at best?? I think we are all nuts. Nothing like enjoying a hobby that costs about $10K a year even if you only fly one hour, and can get you killed if you don't do everything just right. Just sayin... I think we are all nuts.4 points

-

I was shopping for a place to overhaul my IO360 with angle valve. So I figure I share my notes here. Lycoming factory overhual - $58k + core Lycoming factory rebuild exchange - $64k + core Lycoming factory new - $105k (not sure if core is required) Lycoming factory rebuild exchange IO-390 - $88k Well known shops such as Firewall Foreward, CCS, etc - $53k Less known local shops - $32k to $40k. Lead time on non-factory overhual run any where from 3 to 5 months. Lycoming apparently is not interested in overhual business... Wait for it.. drum roll, 27 to 30 months months lead time!!! They also ask for 20% deposit while they holding on to that money for almost 3 years. Safe flying guys!2 points

-

APS and Deakin, Atkinson, and Braly did not invent LOP. They just "re-discovered" it from the days of piston airliners and military. They looked and found the manuals on operating those big radials across the oceans and their "invention" was showing that the same principles applied to our little engines.2 points

-

All you need is a nutcase who insists on succeeding despite the unfavorable odds. There are not many of them around. Occasionally one appears, and the result is an Austro or ..... G100UL.2 points

-

if i'm remembering correctly, it may even be simpler then that, just don't go full throttle at sea level at 110 degs and you should be ok2 points

-

For what it’s worth, the Smithsonian channel has a series called extreme airport Africa and in its newest episode they feature an M20R flying a mission to help with preserving rhinos. The episode is titled Flying Grandmas (not referring to the Mooney) anyway I just thought someone might be interested.2 points

-

Great chance to own a Texas Hill Country Hangar-minium on an 3.6 acre Airpark lot. If your passion is aviation, dark skies, enjoying nature, wildflowers or just privacy - this one could be a full time residence, a weekend getaway or an amazing migration destination for aviating snowbirds. A lighted 3800 foot runway, 80 feet wide, is the centerpiece of this exclusive Hill Country Gated Community, located between Fredericksburg, Kerrville and Harper. Your 69 x 50 hangar has 950 square feet of air-conditioned and heated living area within the huge 3450 s.f. hangar, located at the SW corner of Aviation Loop. The hangar door is 40'4" wide by 12'6" high to accommodate your airplane on to the epoxy floor. You have direct taxiway access from your property. One dedicated bedroom and two other multi-purpose rooms that are currently set up with beds work well when the family gets together on weekends. This could also be used as your residence while building a larger home on the 3.6 acres and then later used as a guest cottage once your home is completed. There are no lots for sale in this community - grab this one while it's available! It offers endless possibilities, limited only by your imagination. Sensible deed restrictions and cooperative owners in this community protect your investment but give you flexibility. The yearly mandatory HOA is $1150 for neighborhood amenities including runway maintenance. This was used for a vacation residence for the past 20 years by aviation enthusiasts. They were the originals owners. The kitchen was in the process of a mini-remodel before he could finish it. All $10,000 in new stainless appliances are included and installed. The new owners can decide on finishing touches. $450,000 more pictures:https://www.homes.com/property/1335-aviation-loop-fredericksburg-tx/1x2h4v8ccmtct/1 point

-

I'm using Forensics Detectors Low-Level CO Monitor in my Cessna. At $199, it's portable, alerts at 10 ppm, and no panel mods needed. Best value for cockpit safety. https://www.forensicsdetectors.com/products/low-level-co-detector1 point

-

I agree that we’re at a point where we should be looking at how to do some kind of amoc request or ask for an extension to the inspections. You’d think this might be in AOPA’s wheelhouse, but I emailed them and haven’t heard anything. Im not sure who’s the right industry point of contact to pursue this, but I doubt it’s individual owners. Well, unless nobody else is doing it. An amoc to install an appropriate sized, high quality auto clamp with recurring inspection until parts are available would be ideal. So who should we discuss this with? I suspect the faa would want engineering data, parts reasearch, checklists, etc…1 point

-

Try LP Aero or Great Lakes Plastics - both make lenses for various OEM's and STC holders. Send yours there so they can compare? Or use it as an excuse to get Aveo wingtips like I did. Also, 3M sell some 2 part plastic glues that are awesome. I have seen C172 wingtips 'welded' back together. Especially good if you grind a gap and bridge it, just like you would do with a metal weld. I suspect you could do a half decent repair, its not like you have to spot traffic? Aerodon1 point

-

Never thought about it much, but it would seem you could make a curved steel plate, conforming to the wing, lined with carpet, and big enough to cover at least two ribs. Hole in the middle to install the jack points which would hold the protective plate in place. Maybe a better idea would be to just make a small cup facing down and screw the jack points through the cup. This way the cup would surround the top of the jack so it couldn't slide off the point.1 point

-

True, it took 3 weeks from finding the spalling to IRAN. The engine is going on the plane now. Everything was checked but only what needed was replaced. Cylinders were my idea as I was putting in new cam, DLC lifters, lifter plungers, pushrods as needed, new rod bolts, nuts, gaskets, intake tube hoses, bearings. ~800 hours ago, it was pulled for a gear up - case, crank were certified and line bored. New prop, OH governor, Cam and lifters certified too but that didn’t stop the spalling. The owner @ that timed decided to not overhaul or replace the cylinders - that was the only thing keeping it from being a full overhaul then. Lots done since then. I Didn’t want to wait 5 to 6 months. I know what is in the engine now, and it was running great before the spalling. Seems the right option… Edit: oh, and it has ~2200 hrs since factory rebuild/major, ~4100 hrs since ‘new’ -Don1 point

-

I cannot find it now, but years ago there was a video going around of a Mooney in a shop putting the jacks through the wings. Sometimes it rolls off scales or the gear is retracted when the jacks are under the wings but not set at the hard point, or faulty jacks are used or whatever. I think people have researched many different ways to do it over the years. In A&P school we had an instructor who had spent a career at the airlines, and emphasized that whatever airplane it is, airliner, twin, single, etc., if it isn't being held up by the jacks, the jacks should not be under the wings. Apparently it's a fairly regular occurence to put jacks through the wings of airliners, too. A hangar neighor was weighing his Comanche and had the jacks under the wings while it was on the scales. A dust devil came by and moved the airplane just enough to roll it off the scales and put the jacks into the bottoms of the wings.1 point

-

UL94. I am in. Ditch the lead. Same infrastructure. No STC. Lower fuel costs. DO THIS!1 point

-

1 point

-

Because if you want nice stuff in NoVA, you go across a bridge to DC or MD and buy it there. Better selection and cheaper. MoCo in MD has county liquor stores, that have some nice offerings at a good price. But there are also independent liquor stores.1 point

-

https://schemedesigners.com/paint-shop-referral-list/ @wombat I'd use this as a starting point, reach out to a few and ask for recent referrals. Then you can discuss value, what went well, what not so well, and how accurate the time estimate was. All prices have continued to climb for a strip and paint, and some of the amazing values of 15 years ago are now right in line with other shops. If you search MooneySpace about the most mentioned shop is Hawk. It's always funny that with respect to paint shops it seems you'll often hear the "stock market" disclaimer...past performance is no guarantee of future results. But I think that it's at least a solid place to start looking.1 point

-

OK, I have to ask, how does that happen. I read preliminary and final FAA accident reports so I don’t make the same mistakes others may have. Even Mooney space is all about learning. I regularly help my mechanic do my annuals, and we place my aircraft on jacks that I made. We each work a main wing jack simultaneously calling out each pump so we stay in unison. After about four pumps on the wings, we move to the nose and lift it up (via cherry picker) to maintain a level condition. The main wing jacks are raised until a safety pin can be installed. Once the pin is installed the hydraulic jack is slow released to put load onto the pins and not the hydraulics. I have reviewed our procedure many times thru my head to try and think if we’re missing anything that might make it safer. If you know please share how the aircraft fell off the jacks.1 point

-

You are all making this WAY WAY WAY too complicated. Slowly advance the throttle over 2-5 seconds and when you get to full throttle, glance down at the engine instruments and see if there is anything different from normal. And have done some transition training so you know that 'normal' is actually about correct. If yes, keep going. If not, abort.1 point

-

Looks like the FAA office that issued the AD has to approve an AMOC. I've looked over the clamp and turbo recently and can't immediately think of how it would be done reasonably. Eliminating the V-band clamp from the design would require major changes to the turbo and tailpipe not consistent with certified airplanes. Maybe we need to be asking the FAA to extend the deadline for compliance until the manufacturers of the new riveted clamps can catch up. Or to put pressure on the manufacturers to make them. V-band clamps are a standard part in the automotive world and high quality ones are available for less than $50. This should be a solvable problem and an opportunity for someone with a manufacturing facility to make a good amount of money. https://www.faa.gov/aircraft/air_cert/continued_operation/ad/alt_moc#:~:text=An AMOC provides an acceptable,an acceptable level of safety.1 point

-

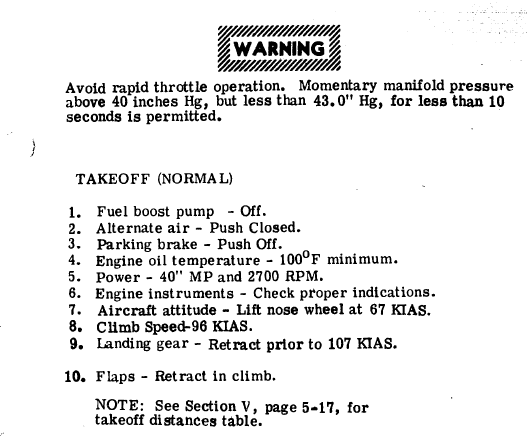

Item 6 - Engine Instruments - Check proper indications. Verify expected MP, RPM, and fuel flow once you've set full throttle. If your MP is a little high, reduce throttle until it's not. If any of them are unexpectedly low, abort takeoff and figure out why on the ground. Note - it's not uncommon for RPM to be about 50 below maximum until your airspeed comes up and reduces the load on the prop. Mine goes from 2650 while starting the roll to 2700 around 40-50 KIAS. With a turbo, you have the benefit of the fact that it should always make full power at any airport, so this is even simpler than a naturally aspirated plane and is the same every time.1 point

-

It used to be a fairly common STC for many Pre-J models. A previous owner put them on my C.1 point

-

Hey Guys and Gals, Just got this in for the latest update. Hello Scooter Good news - We have one more meeting to look over the drawings that, the Bendix King and Duncan Engineering, created. These revised additional drawings will be completed this month, then FAA approval after that... We still believe it will be the Q2 of 2025 (is our latest estimate). Scooter1 point

-

1 point

-

The list on the WingX website is from 2019, so I guess it doesn’t get newer than that. WingX is compatible with Stratux devices, which really is the cheapest possible solution. You can make one yourself or get one on eBay for very little money.1 point

-

1. Diagram is missing the rat on a unicycle (Rube Goldberg joke) 2. How do you access the engine breather line? Thank you for sharing.1 point

-

1 point

-

Looking good! I sincerely hope you have a better time once they pull the panel off and start working on the wire bundles. That's when the mysteries begin to pop up :-)1 point

-

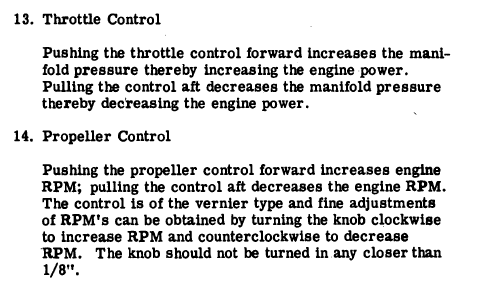

It's hard to feel because turning the vernier lets you really crank and put some pressure on the cable against its stop in the engine compartment, which you don't want to do, if you keep turning it in past full throttle. You are not supposed to use the verniers to advance the controls too close to the dash. My POH has warnings not to turn the prop or mixture closer than 1/8" using the vernier, though oddly enough, not the throttle, I just noticed: You can feel it hit the stop if you slowly advance the vernier in, like during cruise, but I find it hard to do while spinning it in relatively quickly and also rolling down the runway for takeoff. I find it easier to feel when you have reached full throttle if you just push the button and slowly, steadily, but firmly advance the control in. Your experience may vary, this is just what I do. My TSIO-360-MB engine has an automatic wastegate that under normal circumstances prevents overboosting, so full throttle is proper for takeoff. Under certain temperatures and density altitudes, it may overboost by 1-1.5 inches, which is allowable for a short time, and if it does, I just dial out a little throttle with the vernier. I was under the impression the Bravos also have an automatic wastegate and do not overboost normally, but I have never flown a Bravo. My takeoff practice is consistent with my POH, shown below. I do use 36" instead of 40" because my engine was changed to a MB series as part of the 262 conversion.1 point

-

Didn't mean to denigrate Richmond. It's the state Capital and has California-spec highway overpasses that are much more needed in northern Virginia (near DC), but they put them in Richmond because, ummm, it's the state Capital (LOL!!!). There are spectacular neighborhoods in Richmond, some even cut into hillsides with great views. Many of the houses are really cool turn-of-the-century (which century?) stuff that you just can't find anywhere else. Prices really aren't that high, but property taxes may be steeper. Coming from Sacramento environs, you're gonna think everything is cheap here! Virginia open secret - the liquor is still sold in state VA ABC stores (this was one of the moonshine capitals of the world). Selection is pretty good, but if you want something rare (say Pappy Van Winkle), you will only find it in Richmond, not up here in NoVa where the Yankees live ("rich men north of Richmond"). Hit me up if you do decide to come out here for a tour.1 point

-

Flame front movement is slower LOP than it is ROP, some of the old big radials had a timing switch that would increase timing when you ran the engine LOP when you used the switch, yes even way back then LOP was known and very widely used. So increasing timing when LOP is in effect not increasing timing, but correcting for the slower flame front and putting it back to where it should be. One reason for lower CHT’s when LOP is from essentially reduced timing. This from this link https://enginehistory.org/Operations/R-4360Ops/r-4360ops1.shtml 5. Manual leaning and the use of spark advance enhanced the range capabilities of the aircraft because of improved specific fuel consumption. By carefully maintaining recommended cylinder head and carburetor air temperatures with stable turbo supercharger operations, charge density could be held at an efficient value. Since flame speed is typically reduced at leaner fuel air ratios below approximately 0.077, advancing the magneto/engine timing from 20° to 30° spark advance maintained peak cylinder pressure at the most effective 15° after top dead center position. This combination, manual leaning and spark advance also lowered exhaust gas temperatures, which favored longer valve exhaust, system and turbo supercharger life. Last but not least cowl flap openings could be reduced because the engine ran cooler. The issue with bumping timing isn’t that it causes any issue at LOP, it’s that it runs hotter, engine life is therefore shortened etc when run at high power ROP, like in T/O and climb etc. So you are improving LOP performance slightly, at the expense of engine longevity if Lycoming is to be believed. This is in the SI linked to above. Ideally we need manually adjustable timing like was done in some of the old radials, but while the fuel burn difference was significant when you had over 16,000 cu in of engines I’m not sure it’s that big when you have only 360. But yes as just a general statement advancing timing increase efficiency and power output, way back I think in 1930’s Buick was the first to fit Vacuum advance because at low power an engine could tolerate it and it significantly improved fuel efficiency and of course being vacuum operated it automatically pulled timing at higher MP’s to prevent overheating and detonation. Modern cars of course use knock sensors and run much closer to detonation and of course more efficiently too, but they on average rarely produce full power and when they do it’s for very limited duration1 point

-

I would say the gear swing is part of changing a tire. So is removal and replace of the brake caliper to get the wheel off. Took me about 4 hours yesterday to do all three tires. Tires have doubled in price from 10 years ago.1 point

-

Surprisingly, I got quick replies from a TCM customer rep and from RAM aircraft. Neither is good news, however I'll post what they said here below. Eaton Manufacturing seems to be the holdup. I doubt contacting them will help since they are working for TCM and everyone else. Someone (AOPA?) should be working with the FAA to come up with an extension to the inspection protocol for the AD. TCM: Drew, There is no confirmed date yet when they will be available. Of course, this a high priority for Continental. The best advice we can offer at this point is to get then on order. Thanks Michael Yousik Sales & Support Specialist North America US Southeast, US West, Canada West RAM Aircraft: We can have these added but my be awhile we are short staffed in engineering and we have having long lead times on these clamps and are not due any until September of this year. Thank you Jim Robinson Senior Manager Special Projects1 point

-

The term common sense applies here...................don't fly in the approach path of other aircraft! Procedural change details to follow soon. Seems simple to me.1 point

-

I am based in KFCI, about 15 miles southwest of Richmond, 5500 ft, ILS, about 1h drive from Williamsburg, wait for T-hangar is about 1 year, Petersburg KPTB is a little closer to Williamsburg, then there is Hampton Roads executive, Franklin, lots of choices. My house and also my office are about 15 min from airport, feels about right. I have lived here for 30 years, reasonably familiar with the area, PM me if you want to talk1 point

-

100% agree. 6 SM visibility is not even close to IMC! I'm completely heads-down by 400 feet when I would be making my first turn. Sorry, no way I'm buying this was a disorientation accident. Yeah, my opinion.1 point

-

As I gain experience, my tolerance for taking off with low ceilings continues to decline. I remain IFR proficient but I very much try to take off and land in VMC conditions.1 point

-

I don't use the vernier throttle to dial in on the takeoff roll - I push the button and slowly but firmly advance to full throttle. The vernier is too slow and it's hard to feel when you're at full throttle. Confirm turbo operation by verifying manifold pressure - you can also hear and feel it kick in passing 28-30" MP. Verify power set - MP, RPM, and fuel flow as expected (36" MP, 2700 RPM, 22-23GPH for me, your numbers will vary). After that, eyes on the airspeed indicator and out the window. You'll be flying too soon to look at much else. Scan for warning lights and to confirm power set as time allows. Be ready if anything is off to pull the throttle and stop on the runway or land straight ahead.1 point

-

I have not inventoried the many things in the engine compartment that are not a part of or directly attached to the engine, but there are probably several other than the air/oil separator on which I learned my lesson. The brake reservoir and related stuff is probably happier if the fluid is not completely congealed, etc. I liked the earlier post about warming the entire plane in a hangar which would warm everything but it raises another issue. A few years ago we had a really excellent pilot/instructor who put on Saturday morning seminars at Modern Avionics at KFCM. He did one on cold temp ops. One of the things that stuck with me was the choice between heat soaking and cold soaking an aircraft before a cold weather flight. So, basically, icing occurs when the temps are between +5 and -15 degrees. Warmer and no ice is likely, colder and any moisture has generally already found a way to freeze in the atmosphere. So if, for example, one wanted to take off and fly through a thin layer of clouds with possible icing, which we get around here quite a bit during the winter, and the ground temps are at around freezing, warm soaking the plane in a hangar the night before would help. The airfoils would be warm at takeoff and would discourage the formation of ice. But if taking off in super cold temps and, say, climbing into the flight levels, cold soaking is preferable because having warm surfaces would melt the ice crystals onto the wings where they refreeze into icing, whereas cold surfaces would not have the same effect. I don’t have a choice to warm soak so have not practiced this alot, and the pilot/instructor was flying turbine aircraft at the time so the issue is somewhat different than what we piston pilots experience, but I thought it was worth mentioning. Oh, and don’t forget to bring a windshield scraper/brush and a rag. I have had frost form on the wings in International Falls at -10dF in about an hour. Even better would be a garden sprayer with TKS.1 point

-

I live in Minnesota so experience pretty much the same temps as you, although I am in the Twin Cities area so a little warmer but I get up to International Falls in the winter once in awhile. I have a 231, which is turbocharged, and the consequence of that is that I need to be very mindful that the Oil Temp does not fall below 100 dF, which it can do in cold conditions. The turbo bearing needs oil and the space for oil passage is very thin, so the oil must be thin enough to lube the turbo. I always preheat if the temp is below 40 dF. I call my FBO the night before and have them plug the plane in (engine heater). I can start it down to about 20 dF without preheat, but am told that creates unwelcome wear. Below 20 it is pretty hard to get the engine to start and there is a risk of wearing down the battery. I never open the cowl flaps for any purpose in cold temps. Sometimes the East Coast people will jump in and say, oh heavens, what about hot spots! Cold for them is anything below 40. I will take all the hot spots I can get, whether during starting, runup, taxi, or in the air. The problem we both have is that we are around sea level in elevation and the air in winter, especially below about 5,000, is very dense and very cold, making it superior for cooling, which is not ideal for an air cooled engine. I have my A&P install an oil cooler block when it starts to get cold. They have made me a couple, they are just thick foam bound with duct tape that is stuffed into the cooler. Definitely helps with the OT, although it is still possible to get an OT that is too cold. If necessary I will run ROP and as close to the red box as I dare. I attended the GAMI live seminar several years ago. The whole point of LOP operation is to flatten out the power curve during the combustion cycle to avoid a high peak ICT, which is what happens when operating in the red box and what causes high CHT's. They warned that CHT alone is not a good measure of peak pressure in very cold temps, in other words, you can still get the high peak ICTs you don't want even if the CHTs look ok. My normal ROP operation is 125 ROP, I will go as low as 100 in cold temps. I ran my last engine out to several hundred hours past TBO so apparently did not hurt it much if at all with this method. One thing not mentioned is that during cold temp ops it is very important to warm not just the engine itself, but the entire engine compartment. I learned this the hard was practicing fast approaches and landings for an anticipated trip to our local Class B airport. The air/oil separator generates moisture. The moisture all froze, blocking the breather. I got unusual temp readings during a takeoff, returned immediately for landing, and had oil streaks about 18" wide running down both sides of the aircraft. The fix for this is to dawdle before first takeoff, keep the cowl flaps closed, spend about 10 minutes on your checklist and runup. Have not had a problem since that episode many years ago now. I have operated in extremely cold temps because in the 231 I can fly in the flight levels. It is almost always below zero up there. I made a very fast trip from Williston ND to Minneapolis once at 21k with the temp at -54 dF (great tailwind). It was so cold that with the heater and defroster full open, all the windows were frosted and I was operating on instruments. However, I kept the engine amply warm and had no problem other than the cold in the cockpit. I have not used ISO in the fuel for many years, but it is probably a good idea. We have had several discussions on the board about the problem of fuel line freezing at high altitudes. It appears to happen when a plane is fueled on the ground in higher temps and humidity and then is flown in the flight levels in below zero temps, because the fuel at ground level can carry moisture. I have not had any problem fueling around here in MN in the winter and then going up high. That said, there have been a couple of incidents where others have experienced fuel line freeze so I am going back to putting a bottle of HEET in each tank during the winter if a high altitude flight is planned. 1-3% is ok, or so I have been told by the experts. Lastly, if I am flying up to International Falls or some other place that is foolishly cold I always plan ahead. I carry at least a 100' extension cord and call ahead to find out if there is a way to plug in. On occasion I have run a cord from the tarmac through the door or window of a rural airport building to plug in, but many in MN have outdoor plug-ins the same as cars. Need to do this if you want to get back home before spring thaws the plane out.1 point

-

Did a 3 hr round trip and found tings working well right now BUT I haven't tried to "de-select" to use the Dynon heading bug yet. That will happen on the next trip. After takeoff it grabs heading and climb rate nicely when engaged and climbs to preselected altitude and levels off within 20 feet of selected altitude (CAUTION - you MUST sync the altitude reading of the AC 100 with the reading on your altimeter AFTER you set it to the current altimeter Hg setting. This is spelled out in the manual) . The altitude reading of the AC 100 goes back to 29.92 ref every time it is shut off. Just a quick setting every start and every altimeter change. The trim indication will bother you for a couple hrs until you learn how to check it by tapping the control wheel. Descents are easy as you just set the bottom altitude and then the rate making sure the rate is ZERO before setting the bottom altitude. Levels again within 20 feet every time. Stays within 20 feet during level turns Buttonology will have you thinking for a few hours. Follows flight plan in Dynon perfectly and I had an occasion to need a heading for a while so I transferred from Skyview mode to GPS mode and used the AC 100 control head for the heading control and it works perfectly. Had to reselect altitude hold though. Again buttonology to get used to. At this point with about 5 hrs of time behind it I'm very satisfied. I have a hangar neighbor with a G model who is now going to install one also and get rid of his Brittian. He'll use his G 430 for a AIRINC drive for GPSS steering. As he has a G he has no modifications to do to make it fit with the install kit now supplied, Sure wish it had happened 5 years ago.1 point

-

Bend spring back and forth while adding washers in the space between coils. Very easy and effectively lengthens the spring so you can attach without damaging you or the plane. Swing gear and washers fall out to be retrieved with a magnet. Be sure to count the washers first.1 point

-

I used 1" dia steel bar through the hole in the gear truss, scissor jack from my old car that was high enough to lift the wheel and change tire and a jack stand for added security in similar situation.1 point

-

That's going to be an amazing panel! As an aside, I don't understand why Garmin makes the GNX375 but doesn't offer transponder in either the GTN750 or 650 variants. Sure they have the remote transponder for the GTN as an option, but it makes panel planning hard.1 point

-

I spoke way too soon... While I did receive one email attempting to resolve the tax issue, it completely missed the mark. I have not received any reply since (despite promising answer within 48 hours). I also can't seem to get to a human being on the phone. Sigh.0 points

.thumb.jpg.ae084ff98f2eda1b3f595ed45b9592c9.jpg)