Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/2025 in all areas

-

The good news and the bad news. After nearly 3 hours of buffing and wet sanding and other things, Mark, at Top Gun was able to nearly eliminate the staining on my wing. If you really look closely you can still see it a little bit, but I am happy with the result. The bad news on the other hand is that it cost me nearly $500 of his time. Still less than repainting, but I'm not thrilled about it. As much as I want to support G100UL, I won't be using it. Mark confirmed it was the matt used by the fueler that caused the damage, as indicated by the pattern it left on the wing. Mark and his Dad, Tom, have maintained my airplane since I bought it 32 years ago. He personally upgraded my first engine to the Bravo, and changed out the other two himself. Needless to say he really knows engines. We talked today. I told him how well G100UL performed. He commented that it was probably great for the engine itself, but maybe not so great for other parts of the airplane. He was surprised at the difficulty he had in removing the stains, as he thought he could remove it more easily. He apologized for how long it took. There have been times when I have accidentally overfilled a tank and fuel ran all the way down the wing. I don't want to chance that happening with G100UL. It's just too easy to screw up. And so ends my experiment for now.9 points

-

The “substandard methods” appear to have been adequate to resist all factors prior to now, which would seem to at a minimum diminish your assessment of what is adequate. if it withstood all chemical and environmental conditions before g100ul, why is it now substandard?3 points

-

I owned an M20F for 20 years. I could R&R the starter in about 4 hours. But I had the sequence down cold. If I wasn’t very familiar with the E F Mooneys, I can see it taking that long to figure it out, especially if you tried to short cut it.3 points

-

I have what I think could be someone’s forever airplane. 1981 M20J, N1156P, with 1,810 TTAF, O Since major overhaul on the engine and the prop. Engine done by Flightline / Certified and the prop done by Stalling Aircraft Propeller. New engine mounts, new battery, fresh 500 hour on the mag, new style wingtips from factory and they have new lens. All new brakes and wheel bearings. Two previous owners since new and NDH ever. I have personally known this airplane since 1986. Paint: NEW Complete strip and paint in 2024. This airplane has a vintage paint scheme that is era appropriate for the plane. Midnight Blue, White with silver metallic stripes. Glass: The glass is all in excellent condition, shows like new with no checking or crazing, and the windshield was replaced at the same time the aircraft was painted last year. Interior: Very Nice - Very Ugly … Original red plaid, that’s in really good condition. It is the OEM interior that came in the airplane day one from Mooney. Avionics: Very original - Legacy, antique, how ever you want to say it, but it does have a nice century auto pilot. It does NOT have ADSB. Annual, current and recent (note no ADSB & pitot static - transponder checks need to be accomplished). Fuel tanks - Absolutely zero leaks. No stains, no runs, no drips. The RH tank had a slight seep professional repaired before the paint work was done. I will answer all serious emails and arrange showings to accommodate, or you are welcome to call me. How many TRUE 1,800 hour TTSN, NDH, M20J’s are out there today. This may well be the lowest time 1981 M20J on the market today. ALWAYS HANGARED SINCE NEW ! A full price offer includes a used, but in the box, Lynx L3 Transponder with built in WAAS. (The one with the screen) Price: $135K Thanks, Frank www.BullardAviation.com N1156P *** UPDATE *** #1 A couple of people that know Mooney’s a lot better than I do have pointed out to me that this airplane is a 1982 year model and not a 1981. To clarify, the AW date was 7/20/81, so it does have some distinguishable 1982 features that make it look like a 1982 that I guess that were not on the 1981, don’t ask me what they are because I don’t know, and if you look it up in some of the price reference books by SN, they do show it as a 1982. But, the FAA calls it a 1981 with a late July 1981 AW date. Hopefully this clears up the confusion. #2 When the engine was installed yes, it got all new or rebuilt accessories. New Lord engine mounts, a new silicone hose kit with fire sleeve, new spark plugs, and the engine mount was powder coated black. The previous owner rebuilt the master cylinders and replaced all of the brake hoses behind the panel before he would let me fly it away. We did not paint the firewall because it is perfect. It’s VERY clean with zero corrosion and looks like new. I figured why paint an OEM firewall that is still in perfect condition. #3 I added interior photos. Just like I said, really dated, but in good condition. Recover the inlays in the side panels, re-cover the seats, and throw in a SCS Interiors carpet kit, and you are good to go with a perfect interior. “I do not have any headrests for this aircraft”. The previous owner who bought it from the original owner when it was approximately three years old said that he did not get any headrests with it.2 points

-

I flew again to the pacific coast of el salvador. On my way there I overflew a volcano. What did i find in the crater? A lake!! Sent from my iPhone using Tapatalk Pro2 points

-

I have said it before, but Bill Cutter, who founded Cutter Aviation, originally made his money by building airports in or near Albuquerque city limits and then selling them to residential developers as the city grew. He was "there first" because he knew the land was not worth much at the time, but he could make money by flipping the airport as the land value grew. Yet we as plane owners want to fight this obvious fact of urban development. And yes I used to target practice outdoors within the city limits of Albuquerque in the early '60s. We used arroyos. New homes moved closer and closer to our favorite shooting spots. Of course careless shooters ruined it for everyone with stray shots hitting peoples' homes or cars.2 points

-

Yes, and this same problem impacts pig farms, gun ranges, racetracks, and the like. I've been talking with friends about this a lot lately due to similar attacks on airports/operators in our own metro area. The bottom line is that, for better or worse, a large contingent of the population wants to live (and work) just far enough outside downtown to be "country", but not so far that it's more than a short drive to the grocery store, the doctor, etc. The sweet spot where you can do that spreads out every 5-10 years in any town or city that's not actively dying. So until the population collapses and/or literally all the land in the country is developed, airports and things like them are always, eventually going to be at risk from suburbanites. To keep your airport, you've got to convince the population growing around it that it benefits them, at least indirectly. The good news is, that's easier to do that with an airport than it is with a racetrack or gun range. The bad news is, as a group, pilots are pretty terrible at it. Far too much time and energy is wasted on pointless whining that, "The airport was here first". The reason this argument is dumb is that it's easily defeated - the pendulum will swing as soon as some reasonably intelligent person argues, "Yes, we agree the airport was here first, but the majority of our citizens don't care. Just because our community wanted an airport in the 1950s doesn't mean we want one now. Let's talk about the future, not the past, and that future is best for our citizens if the airport is closed." If you want to beat that, you've got to focus on why the airport benefits the town, not on childish prior possession arguments that just enrage the public and provide fodder for politicians.2 points

-

I'm on my 3rd engine. With the avionics upgrade, prop and engine replacement a few years ago as the result of a maintenance issue (all zero time remans), GAMI injectors, and the new Surefly Mag, the plane is better than new.2 points

-

I called around including to RAM aircraft which had been one of the few top shops I had gotten quotes from back in April and was my near finalist. I went with Penn Yan at that stage because of their equally excellent reputation, slightly better quote and also the fact that they are just 3.5 hours drive from my house in case I had the urge to check in on them plus similarly close to Weber the R&R shop. Well I remember that RAM had quoted me also an overhaul exchange price with reasonable penalties if the camshaft and or case had problems. I called them and explained my situation and they said they do have all the necessary parts in stock and they would honor the original concept of overhaul exchange. TSIO520NB's are a bread and butter engine for that shop, so they keep stock. And I called Penn Yan and they were so generous in their interest in seeing me land well and they understood well why I was not excited to go with an AirPower new or rebuilt zero time engine. So I signed to RAM and my engine will ship to them and this project will now become a RAM engine. And just as important, this engine will be spec'ed as I had wanted it in the first place again from a different excellent shop. And of course as is only fair I will pay Penn Yan for their time and labor I am in to it so far. I was already underwhelmed by the concept of a black box continental zero time engine which is just a paper work trick to call it zero time but it is only an overhauled engine from the continental shop with unknown parts. I was more so worried abotu their cylinder quality. Well now I know ... that zero time engine I was sporting had a camshaft put into it that was literally on its last overhaul legs since it had been ground down to minimum spec at that last overhaul and was now too narrow to consider grounding down further. So I am even less impressed by continental zero time engines than the already low opinion I had.2 points

-

Yes, but you’ll need it lowered because of the left side of the panel turns down, probably to the yoke shaft cutout. Cut a piece of cardboard of the same dimensions and verify for yourself, or there’s a pdf you can print life size copies. Also having it shifted to the right makes it easier to work with, my left hand flies, my right hand does all the avionics controls. I didn’t want to have to the yoke interfere with my right arm.2 points

-

What follows would need to be confirmed by GAMI; given the secrecy with the formula and composition of G100UL, it's hard to do more than speculate. This is the part that really GAMI would have to share more information to really determine what exactly is in G100UL. Aromatic amines are toxic in general, and produce nitrogen oxides when burned. In the SDS there's mention of meta-toluidine but in the patents GAMI mentions the difficulty in getting this produced as a single isomer; so usually it's proportions of o-toluidine, p-toluidine, and m-toluidine. Ortho- isomers are even more toxic/carcinogenic, para- isomers have a high freezing point (+44C) and caused clouding of fuel at lower temps, and meta-toluidine was what they were trying to isolate. It seems like GAMI tested and developed the use of co-solvents to allow development of an "additive concentrate" of m-toluidine and p-toluidine that apparently avoiding clouding of fuel at temps similar to 100LL. Boiling point of these aromatic amines is just under 400F and it looks like evaporation is "negligible" at room temperature. UV light causes photodegradation of toluidine which can cause browning and development of more harmful byproducts. This may be the reason that you have to clean off G100UL from the wing with windex rather than just wipe away which would just smear this component and not remove but rather expose more surface area. Any residue left behind can potentially cause staining of paint or other surfaces. The solution to pollution is dilution. The interesting thing about GAMI's drip test is that they used a glove with several holes poked in it and when they'd fill up the glove it would cause drips to quickly form and under the sped up camera speed looked like it rinsed off the surface with fresh fuel. GAMI also kept adding fresh fuel to glove which then ran completely off the surface, as opposed to just adding more fuel to a container with access panel which may have resulted in higher amounts of partially evaporated fuel in the Luvara testing. My WAG is that GAMI's drip test was continually rinsing the surface with fresh fuel to dilute the partially evaporated "concentrate" of low volatility components. Whereas Luvara's test had addition of fuel for sloshing then evaporation; so my suspicion is that at the end of Luvara's test there was a higher amount and concentration of low volatility components. As opposed to GAMI's test where the total AMOUNT of low volatility compounds on the surface was much lower, and only reached higher concentration when the drips were actually stopped. I would have also like to see if GAMI then took that panel at the end of their test and left it outside exposed to sunlight/UV light how easy that staining would be to clean off. Still curious what "standard shop techniques" for cleaning the panel was. Not sure if anyone has tested G100UL staining indoors and away from UV vs outside to dry in sunlight/high UV to see what the difference in clean up and removal of staining would be?? Toluene evaporates quickly. Xylene doesn't evaporate as quickly. And toluidine likely doesn't evaporate much at all. Of course from earlier discussions, aromatics are known to affect elastomers and this is likely the root of the cause of increased o-ring swell vs 100LL. Hard to stay how much Xylene + Toluene is in G100UL...maybe up to 45+%??? (below from G100UL spec sheet). (edit: which major OEM aircraft manufacturers was this? Cirrus?)2 points

-

The lower cowl on an F is significant. Especially if you want him to be careful with your “unobtanium” rubber intake duct.2 points

-

Starter and alternator or generator… are the only simple automotive style add on things under the hood… if you have changed out these devices on a car… (60s and 70s auto technology…) these are quite similar… if it takes all day to get right… call it good! if you end up bending/cutting sheet metal, riveting in place… replacing felt seal with a silicone seal… it will definitely take extra time… in the end… you are going to love the high speed starter, compared to the original… Best regards, -a-2 points

-

I asked him if his invoice had a typo. He revised the invoice down to 8 hours. Still sounds like a lot but I'll take what I can get. Does anybody have instructions or a video on how to remove the cowling on a '67 F? Mine is bone stock, no modifications other than a panel upgrade and avionics last year. I'm tempted to start doing the r/r of the cowling myself if I can do it in an hour.2 points

-

I don't see that it fits the FAA definition of "major alteration" quoted above. It's a factory part for a different model Mooney, but the only physical difference seems to be the handle on the outside; otherwise, the dimensions are the same; the fit to the airframe is the same; mounting is the same; latching mechanism into the airframe is the same; the outside handle and the part number are different. To me, this is A&P signoff.2 points

-

What we're seeing was: 1) discussed and brought forth by PAFI in their testing and development of fuels and was discovered and warned about with use of higher content aromatics (PAFI Lessons Learned); 2) paint damage has been shown to occur in at least 7 aircraft that have been fueled with G100UL release in California, usually in response to marked leaks that show signs of escalation in leak location and amount of leak, but also paint damage has been shown in the form of staining with any spill/splash or drop not immediately cleaned with a product such as Windex; 3) GAMI/Braly has reacted defensively making initial comments that issues seen are due to high aromatic 100LL and not due to even higher aromatic G100UL; 3a) Cirrus finds that G100UL may not be compatible with their sealant and issues service advisories stating that G100UL is not approved to be run in their aircraft and this may void warranty. GAMI releases a series of YouTube videos and commentary on their website in response; 3b) Textron keeps G100UL off their approved fuel list; Continental and Lycoming keep G100UL off their approved fuel list; 3c) PAFI candidate reports that creating a truly "drop in fuel" (fuel without any requirements of modification) is likely impossible; 4) a video surfaces performed by an engineer/A&P where he uses G100UL initially from the pump, but then also tests that were from the affected aircraft that demonstrates the process shown in the affected aircraft (Luvara video 1) (Luvara video 2); 5) GAMI releases a series of YouTube videos that don't use the affected aircraft, doesn't use various test cases, and solely focuses on one model of aircraft and paint to present "hard data" to make a statement that G100UL doesn't affect paint and shows how "easy" it is to remove staining from paint with "standard shop techniques for cleaning up paint" (G100UL soak test) (G100UL drip test); 6) AOPA Baron makes the statement, "G100UL tends to stain paint, hangar floors, and anything else it touches. Pilots and aircraft owners can take precautions by applying protective coatings, but G100UL doesn’t wipe away or evaporate like avgas. Inadvertent and relatively small fuel spills must be cleaned immediately and thoroughly to avoid staining." And in fact, if exposed to UV light the stains are very difficult to remove (AOPA Baron Lessons Learned); 7) FAA is investigating affected aircraft and have taken fuel, oil, and paint samples; 8) These test cases and issues seen have all occurred within about 2 months of the introduction of a new fuel to California; 9) Said fuel is still being sold and is currently marketed as "basically transparent to the engine, aircraft, and pilot. No mechanical modifications are required" other than placards; 10) some who haven't used the fuel are proponents of GAMI/Braly and have come to his defense out of faith that surely the proper testing and FAA certification means that the product should be trusted; 11) many who haven't used the fuel are fearful to use a new fuel without more testing and transparency to determine the merit of the issues shown in California. 12) This would be a simple case of vote with your wallet and either buy the new fuel or dont, however the current political climate (especially in California) has continued to escalate pushes to ban 100LL; due to this the apprehension to use this product is tempered with the fear that this will become a mandate to use this fuel if nothing is said. Proponents of G100UL should fly to a location and fuel up. We fly one of the best traveling, single engine piston aircraft in the world. Either your help disproving the concern, or proving it, would be greatly helpful for the fleet! Good luck!2 points

-

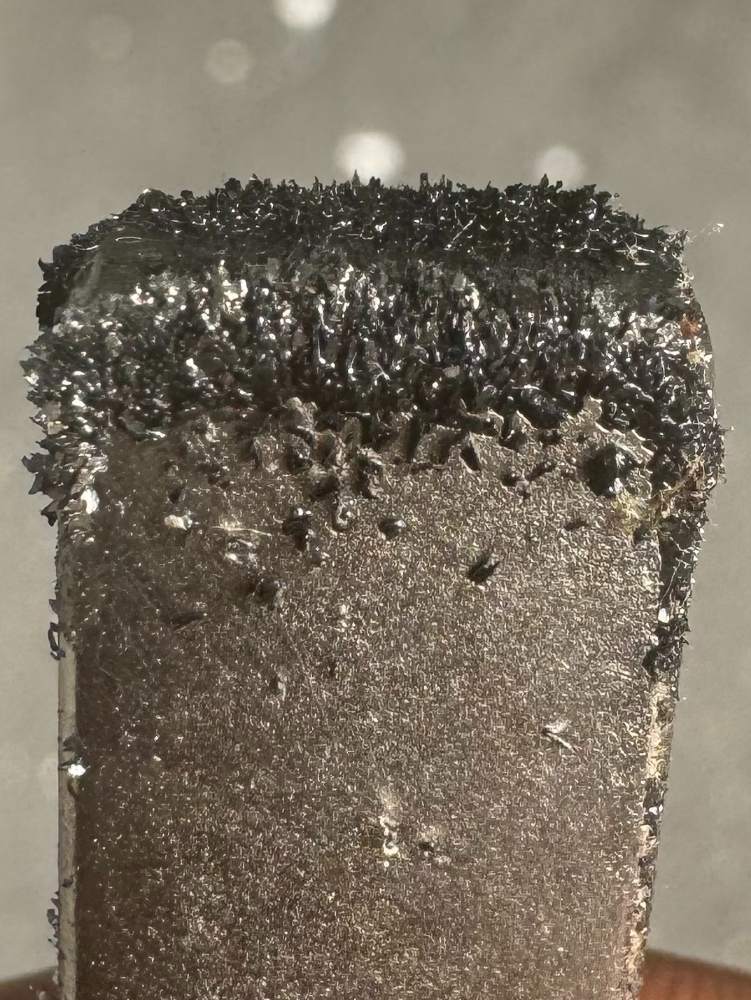

CAM LOBE CORROSION? A DULL TALE OF 1200 HRS SAFE LYCOMING OPERATION Surface corrosion noted on a cam lobe after pulling a jug isn’t great, but in isolation it is a terrible reason to split a Lycoming case – it may need overhaul soon, or maybe not... My illustrative anecdote: >10 years ago, a newb pilot/owner buys an M20C with a 600hr SMOH O-360 that had spent some time sitting and needs a little cylinder work at the outset. After pulling a couple jugs, the well-known Mooney A&P/IA who did the prebuy finds surface corrosion on multiple internal components and even some pitting on cam lobes but normal lobe height and lifter faces. The A&P sends pics of the extensive pitting and says newb owner you must overhaul. The collective “wisdom” of the internet also says that the newb pilot/owner/doctor must overhaul and asserts that he is just another vertical-tailed doctor killer-buying sucka. His demise in a smoking crater seems likely to all because he is arrogant enough not to accept A&P or internet guidance without asking questions. The sucka pilot then takes deep dive into authoritative literature by Mike Busch and others, learning that (1) there is zero danger in running it until cam/lifter truly spalls and (2) it’s easy to monitor the situation through the filter so that once it happens, further damage to the engine can be prevented. Armed with real knowledge, the arrogant newb pilot/owner pushes back hard against the A&P/IA, getting him to sign it off under some duress. Though this newb’s demise seems imminent to all, he flies regularly, uses Camguard, and keeps engine dry in winter by heating it uniformly and continuously. He also cuts and scrutinizes his filter nervously at every oil change, finding nothing for many hundreds of hours. He gets a good engine monitor, learns how to use a borescope, and learns spark plug maintenance, allowing him to monitor the top end as well. He does oil changes and oil analysis religiously but ultimately quits oil analysis after learning enough about it to conclude that it’s utterly useless for real world maintenance decisions on this engine. Finally, after flying for another 1200 hours over 10 years and accumulating ample instrument time, he notices a subtle but consistent decrement in TAS on recent flights. At the next oil change, he finds ample ferrous shavings in the filter (pic). He had become lazy recently and was only cutting every other filter, and so he pulls the previous filter off the shelf and also finds similar metal, realizing that he flew about 80-90 hours with cam lobe(s) and lifter face(s) coming apart. He flys it one last time to a major engine shop 3hrs away for overhaul, marveling at the aircraft’s fast and smooth performance during this serene flight and wondering if he is making the right decision. At overhaul, the suspected cam/lifter spalling is confirmed, and metal shavings are flushed from the oil cooler and governor. The prop is IRAN’d/resealed, and the hub is found to be in fine condition, as is the crankshaft. He’s finally back in the air and still (mostly) enjoying the continuous learning involved in the Mooney ownership journey….1 point

-

Ah the dreaded VFR into VMC scenario... Other than the poor planning, very well handled by the student pilot and controller. Good on him to fess up and ask for help! Goes to show that just because it's legal VFR doesn't mean it's a good idea to be flying in it. For you non-instrument rated pilots out there, keep in mind that just cause some marginal VFR conditions are legal, doesn't mean you'll be able to see anything. At 3 mile visibility from 6000ft, you can only see about 2 miles ahead on the ground which is only about 1 minute ahead. You could be inside the delta of a towered airport and still not see the runway.1 point

-

My mechanic and I swapped a Delco Remy to a Skytec 149 NL outside on the ramp AOG in Tucson in ~ 2 hours (Bendix bushing blew up). We had limited tools and had to drop the lower cowl. No way I’m buying its an 8 hour job inside a shop with everything available.1 point

-

Permatex Aviation Form-A-Gasket #31 point

-

1 point

-

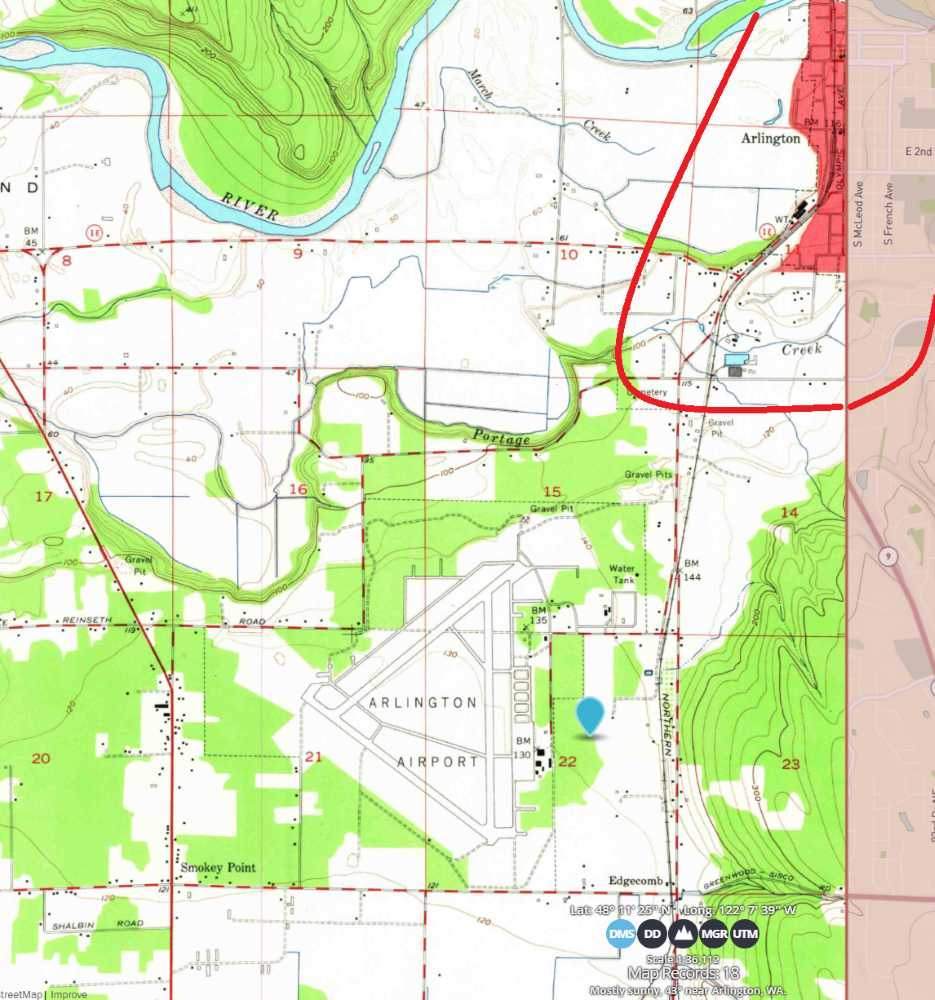

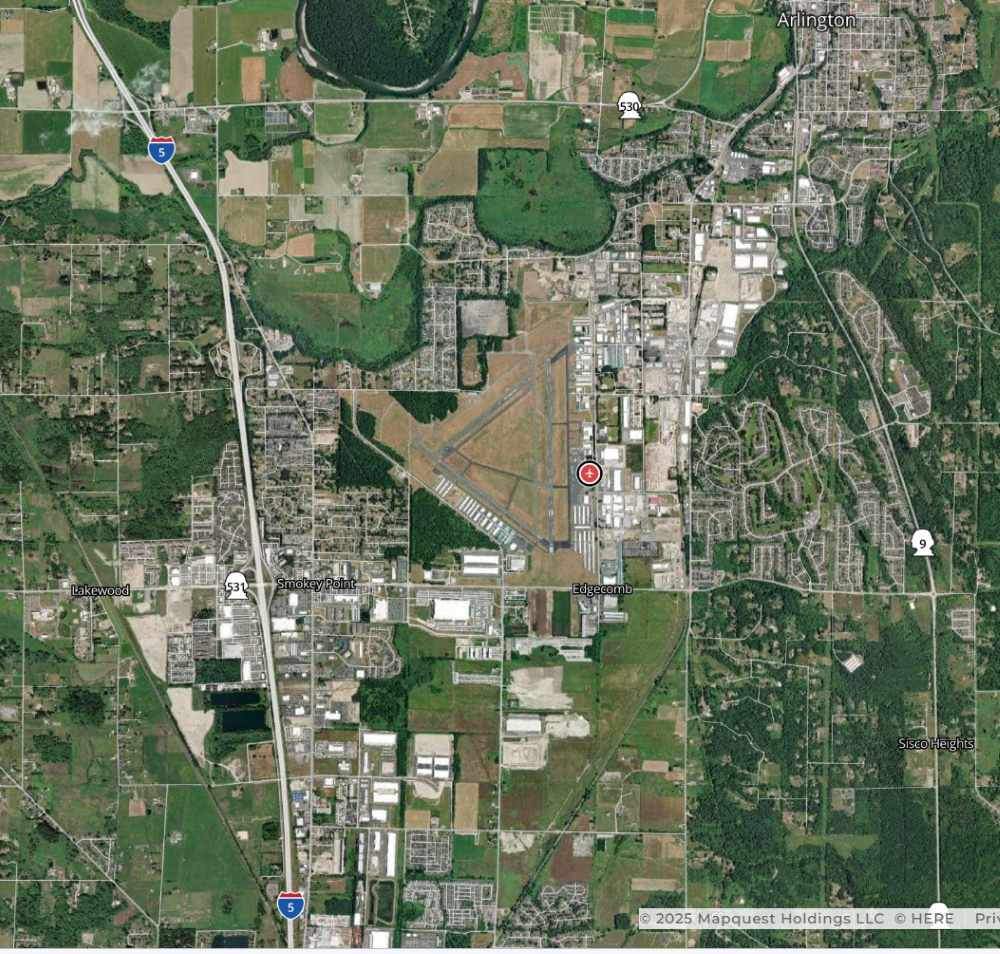

I think everyone has missed the bigger issue here. This is the classic problem of city sprawl and encroachment upon an airport. KAWO was built during WWII as a reliever airport for Seattle to the south and for military training. It was located about a mile southwest of the city of Arlington, WA built on unused or farm land at the time. Even by the mind 60's there was not much near the airport. There was growth in the 70's and beyond. But the urban growth around the airport has really taken off on the last few years. The largest Amazon Fulfilment Center in the State of Washington was built literally across the street from the airport. It was opened last year and employs 2,500 drawing a lot of people to the area. The 5 story apartment building where the plaintiff lives was built in the last couple years at the same time as the new Amazon center development. Even the Google satellite and "Street Level" pics are behind don't show the explosive growth. I bet every scrap of land around the airport will be built up in the next few more years for both residential and commercial. The land upon which the airport sits will become more and more valuable for commercial development and less valuable as an airport. The runway patterns, which were once over nothing but farmland, pasture and forest are increasingly over congested area. If it isn't this lawsuit it will be something else. What might happen? The City might displace the thresholds to keep the patterns closer within the airport perimeter. Of course that will reduce the usefulness of the airport. All the newcomers are also voters. I could be wrong but I bet few of the newcomers are interested in aviation as a hobby. Support and funding for the airport may decline. 1966 Mapquest Satellite - 20231 point

-

1 point

-

Instead of getting into a fight, one way to avoid the question is to not use the word "inspection" either spoken or written. Call it a pre-purchase "examination" or some other word you are comfortable with. And since the pre-purchase process is undefined, the buyer must specify everything they want examined, and what kind of report they want following the process, and who will have access to that report. As much as we talk about this, you would think "pre-buy" would be well-defined -- but it isn't. It's tempting to ask for an "inspection" because that has more meaning. For example the process of an "annual inspection" is defined by the FAA (or at least the minimum). But I wouldn't use the word "inspection" if I wanted an expert opinion regarding the condition of an airplane I was thinking of buying. And the seller probably should be clear that no "inspection" is being done. And of course, many buyers will arrange with the mechanic to convert the "pre-buy" into an annual inspection if the purchase is completed.1 point

-

Removing the lower cowl does take some time. You haven’t seen to disconnect the landing light, cowl doors, oil cooler, oil line clamps, oil line heat shield. Disconnect the inlet boost duct. Remove bolts at lower firewall. All of this in a very tight space. It does take quite a bit of time to do that and reassemble.1 point

-

I know nothing about lawsuits or laws, I'm an Engineer and I want to stay away from courts as much as possible. My question is, reading at the claims made by the plaintiff, it looks like that is *very* easy to win for the defendant, I wouldn't even hire a lawyer. I would reply, item by item, with my own knowledge. For instance, the plaintiff claims that the defendant, on purpose, flew circles over his home but looking at the ADSB data is clear that it's just regular traffic patterns. The same goes for flying at an altitude lower than 1000ft, it's clear that the pilot was in the landing or taking off part, which allows for altitudes lower than 1000ft AGL. You can make the same statements for using lead fuel. G100LL is only available at a very reduced of airports, it has an ongoing investigation from the FAA regarding material compatibility, and requires a major modification to the aircraft (STC). I know, the STC is just placards, but technically, and STC implies major modification. And I can keep going, some of the claims are merely opinions, such as "the pilot and operator doesn't care about people", that you can easily make your case that those are opinions and not facts. Am I completely wrong?1 point

-

2014-06-01 Cylinder Work - Be Afraid.pdf1 point

-

When I said above that it would take longer if you tried to short cut the jab, that meant not removing the lower cowl.1 point

-

I ended up leaving the duct attached to the cowl and removing the bolts from the servo. They are easier to get to. There are only 4 of them and they are less traumatic on the boot.1 point

-

Does the lower cowl really need to be removed, with the induction, cowl flaps, etc., disconnected? Or could it be lowered onto a towel? That's all I've ever done with my C's lower cowl, dropped it down but left everything hooked up.1 point

-

Early E’s & F’s are brutal!! 8h is a fair outcome. What starter came off? Baffling changes required if anything other than the NL starter. Mine is sealed tightly, removing the FWD baffeling is really tough. I’d rather pull the prop. The starter lead doesn’t fit the new stud sometimes as well. Even going from an LS starter to the NL starter. I have never had my lower cowling on and off in the same day for perspective. You should try the R&R for practice. -Matt1 point

-

That is exactly the analysis I ended up using. Went with 0.5% anhydrous(ish) IPA. I think that was your ratio? @carusoam Warm clothes, yes. I was a bit of a nerd about it. I wore an underlayer and boots fleece and core survival stuff in a vest (thanks @Rick Junkin) in case I had to ditch quickly. Had an A bag with the rest of it in the back seat. The Acclaim does have a heater muff on the hot-side crossover pipe, and also a feed from sonic nozzles on the high pressure side. It actually all worked pretty well. I did both hangar storage (heated) and Reiff XP overnight. Taped oil cooler as above. Do you know where I can get that oil cooler blocking panel (that fits in the shelf)? Thx D1 point

-

I doubt it, 100LL leaves very little residue. Experiment would be to put some on a mirror, let it evaporate and see what’s left, do the same with the Gami fuel. I’ve never seen the stuff but suspicion that they way it stains is from whatever is left behind being concentrated, so a leak keeps concentrating something that doesn’t flash off as quickly as the rest. The mixture doesn’t stain if cleaned off quickly? It stains if left on? If I had to guess and it’s absolute speculation with zero evidence, but I’d guess that the Gami fuel mostly evaporates, but leaves some liquid behind and it’s whatever is left that causes the problem, maybe why soaking in the mixture doesn’t cause a problem but intermittent wetting and letting it dry does, it’s similar to a leak. The same way a tiny 100LL leak leaves a very concentrated blue dye. Wasn't that pretty much what was done in the test? The Youtube test, Gami’s test was I believe different? Again pure speculation it could be the difference in temp, humidity, what kind of wax was on the paint or who knows.1 point

-

I just replaced mine. It took my son and I 2 hours. Maybe another hour for the cowling, but yeah, 12 hours seems high if it was a direct replacement. I believe we have the same engine.1 point

-

1 point

-

Sumping is not enough. It only drains free water. All fuel contains entrained water to some degree or another. In cold weather your only choice is isopropyl alcohol. Used sparingly it should not be a problem.1 point

-

Thank you for that anecdote. I've had a lot of people say "you don't need that" locally (at least if I sump religiously, which I do, and include the gascolator in the winter), and the board is skeptical due to sealant issues. But then again we read about these weird fuel icing issues. I would probably be more worried coming North from FL due to the change. D1 point

-

It's important you brought it up with them and also that you got the expletives out of your system before doing so. It's rather tricky when a mechanic or shop known for reliable work seems to overcharge. The number of qualified A&Ps available to help with our planes continues to shrink, and I tend to give the benefit of the doubt and prioritize maintaining any working relationship...unless they've done something willfully and egregiously fraudulent. Fortunately that has been confined to a single experience for me - charging >1amu for tightening an alternator belt - It was fortunate in retrospect that no punches were thrown by the shop owner and there is no lien on my plane after I refused to pay that bill. I definitely can't set foot in that shop again though...1 point

-

That's not a bad outcome, I think. FWIW, my airplane is a J model, so it's only a couple of minutes to decowl it completely, and the baffling is different than yours. So my experience may not be relevant. That's a good idea, so you have a future reference. I've never done it on one of the earlier, metal-cowled airplanes, but I've always heard it's a bit of a pain.1 point

-

Fore-aft slop in the piano hinge can sometimes be cured with a little bit of safety wire in one or more of the gaps. Gets rid of the slop.1 point

-

1 point

-

Yeah Cannon was the shop where I took it first to install 2 GI-275s. Needless to say, it's in much better hands now. If you ever want to swap stories, PM me.1 point

-

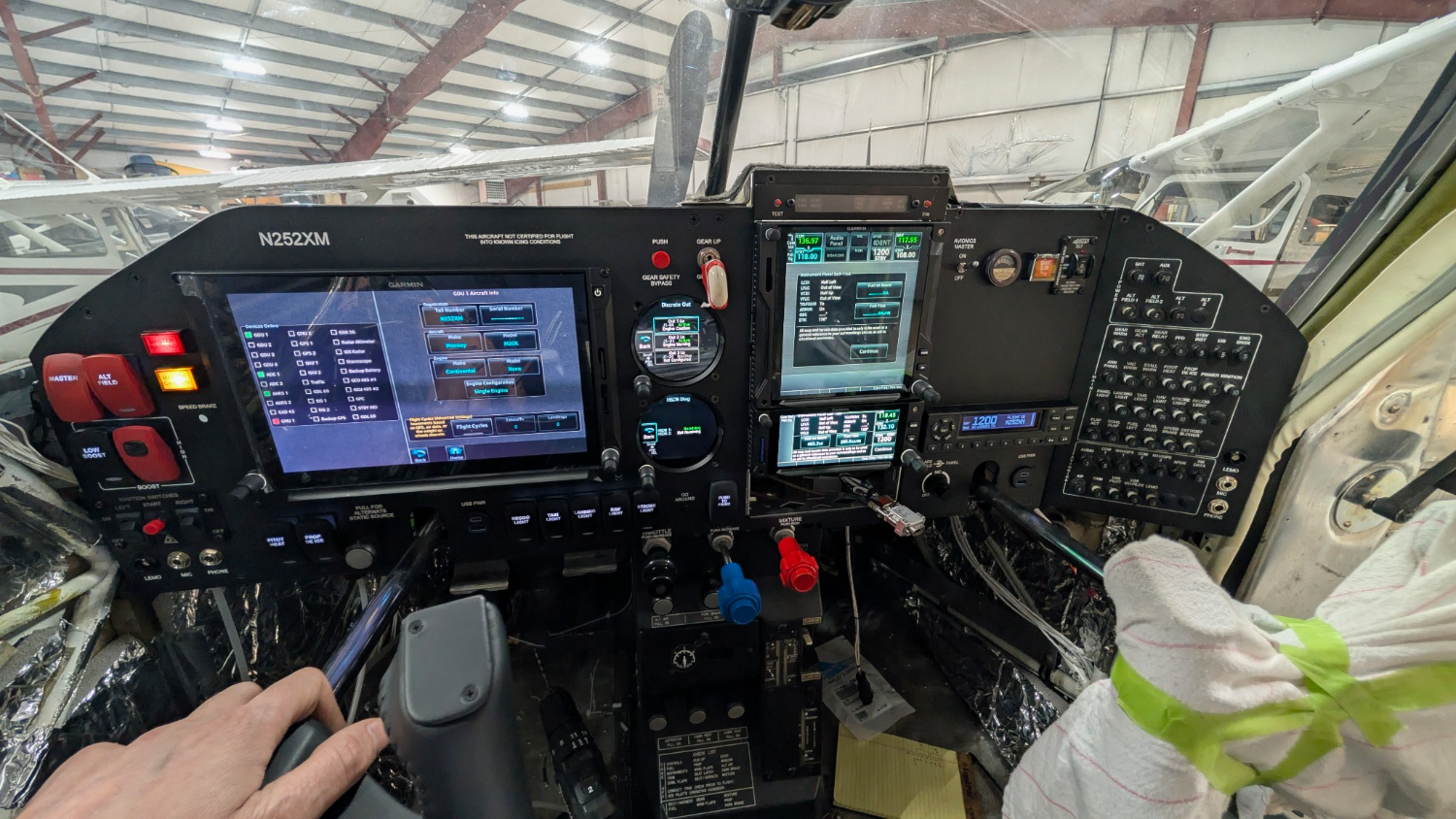

I am still going through my avionics install, and as part of it, issues were found that has resulted in almost new harness all the way through except for some underbelly connections. I, like Skip, provided the original M20K Mooney schematics to my shop which was very useful to diagnose the problem. Which proved that having reference diagrams are crucial and can save you significant time and money down the road. My plan is to redo the wiring schematics with the new avionics in KiCad so that I myself can reference it for troubleshooting or provide it to the next shop for the next upgrade. I tried other software but KiCad seems to win from the feature set perspective and also it’s free!1 point

-

I think you’re spot on. They probably work long after you go unconscious. The cigarette version is loud enough to stir the dead.1 point

-

To add, beside the reiff Xp system, i have another 1500w buddy heater which i stucked under the cowl open to provide additional heat. i do have a digital carbon monoxide detector from aircraft spruce in my plane too. It came factory calibrated and im pretty happy with how well it worked.1 point

-

A must all year round. Even have one in my road vehicle, saved me from a bad day1 point

-

The inboard senders are just in front of the rear seats, OP might be able to just pull the corner of the carpet up to check the floor to see if any blue stains from fuel dripping from the senders without removing any panels.1 point

-

One sender is in the root; the other is at the outboard end of the tank. Either can cause an odor in the cabin. The one at the root is obviously in the cabin. But there is a path along the leading edge of the wing for the gas to go downhill into the cabin. I’d check outboard first because you don’t have to remove interior panels. Look for blue fuel stains. Skip1 point

-

Update: I finally got my "Old Girl" back today. The actuator and motor were sent to LASAR and the problem was indeed, the brushes. I got some explanations, but they were in different languages and so I didn't really understand it. I don't even understand it in English, but I did understand "brushes" and "inconsistent contact." Did one Touch 'n Go and one full stop and everything worked perfectly, except the pilot who was very rusty after two months on the ground1 point