Leaderboard

Popular Content

Showing content with the highest reputation on 01/19/2025 in all areas

-

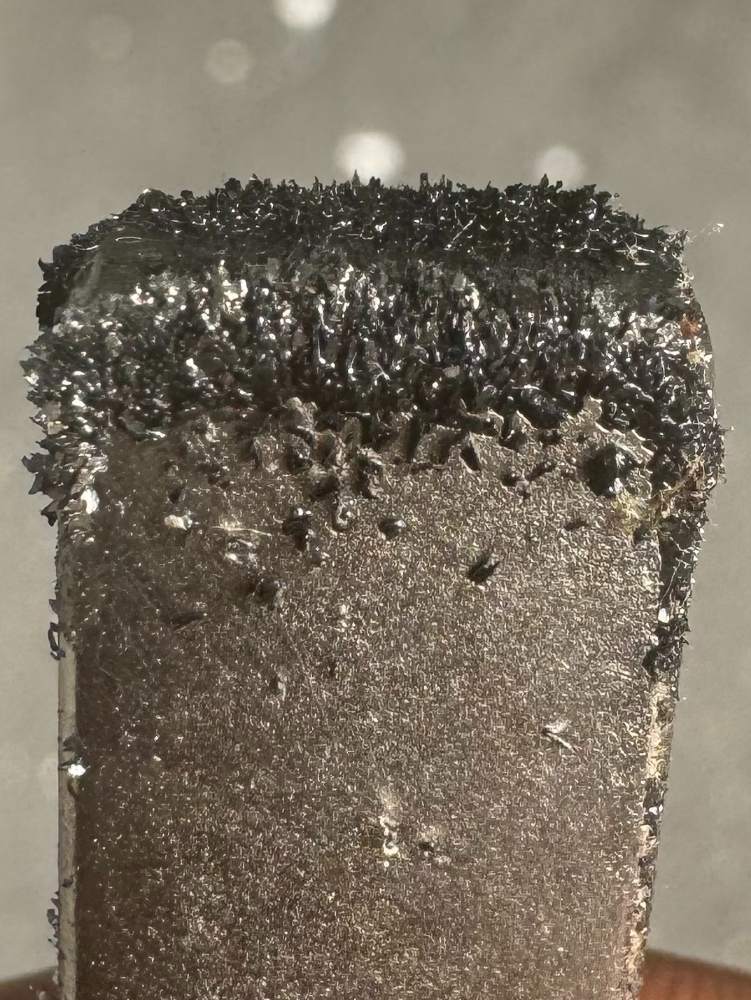

CAM LOBE CORROSION? A DULL TALE OF 1200 HRS SAFE LYCOMING OPERATION Surface corrosion noted on a cam lobe after pulling a jug isn’t great, but in isolation it is a terrible reason to split a Lycoming case – it may need overhaul soon, or maybe not... My illustrative anecdote: >10 years ago, a newb pilot/owner buys an M20C with a 600hr SMOH O-360 that had spent some time sitting and needs a little cylinder work at the outset. After pulling a couple jugs, the well-known Mooney A&P/IA who did the prebuy finds surface corrosion on multiple internal components and even some pitting on cam lobes but normal lobe height and lifter faces. The A&P sends pics of the extensive pitting and says newb owner you must overhaul. The collective “wisdom” of the internet also says that the newb pilot/owner/doctor must overhaul and asserts that he is just another vertical-tailed doctor killer-buying sucka. His demise in a smoking crater seems likely to all because he is arrogant enough not to accept A&P or internet guidance without asking questions. The sucka pilot then takes deep dive into authoritative literature by Mike Busch and others, learning that (1) there is zero danger in running it until cam/lifter truly spalls and (2) it’s easy to monitor the situation through the filter so that once it happens, further damage to the engine can be prevented. Armed with real knowledge, the arrogant newb pilot/owner pushes back hard against the A&P/IA, getting him to sign it off under some duress. Though this newb’s demise seems imminent to all, he flies regularly, uses Camguard, and keeps engine dry in winter by heating it uniformly and continuously. He also cuts and scrutinizes his filter nervously at every oil change, finding nothing for many hundreds of hours. He gets a good engine monitor, learns how to use a borescope, and learns spark plug maintenance, allowing him to monitor the top end as well. He does oil changes and oil analysis religiously but ultimately quits oil analysis after learning enough about it to conclude that it’s utterly useless for real world maintenance decisions on this engine. Finally, after flying for another 1200 hours over 10 years and accumulating ample instrument time, he notices a subtle but consistent decrement in TAS on recent flights. At the next oil change, he finds ample ferrous shavings in the filter (pic). He had become lazy recently and was only cutting every other filter, and so he pulls the previous filter off the shelf and also finds similar metal, realizing that he flew about 80-90 hours with cam lobe(s) and lifter face(s) coming apart. He flys it one last time to a major engine shop 3hrs away for overhaul, marveling at the aircraft’s fast and smooth performance during this serene flight and wondering if he is making the right decision. At overhaul, the suspected cam/lifter spalling is confirmed, and metal shavings are flushed from the oil cooler and governor. The prop is IRAN’d/resealed, and the hub is found to be in fine condition, as is the crankshaft. He’s finally back in the air and still (mostly) enjoying the continuous learning involved in the Mooney ownership journey….6 points

-

If it was one aircraft out of 100,000 you could suppose it was just mere coincidence. I think having at least 7 aircraft with paint damage that spans at least 5 manufacturers with a hundred or so aircraft that were fueled...that's more than coincidence and deserves a thorough and close look to determine the cause. It might not be G100UL, but it certainly might be as well. The fact that an A&P (FAA certification, real person) was able to recreate the apparent damage using G100UL is not definitive proof but is undeniable that this isn't something that can be ignored as "not an issue with our product." Remember, Luvara is FAA certified and would probably loose his license if found to be maliciously tampering with evidence (at a minimum). GAMI posting YouTube videos only showing Beechcraft louvred access panels for every single "test" that they ran...that's not scientific, isn't very credible for a company that wants to have 100% of the market share of 100LL, and doesn't pass muster as "hard data". The statements that Mr. Braly has made here are very generalized "Hard proof that 100LL nor G100UL cause paint damage." Or pointing to 100LL with 29% Toulene on a single sample over a decade ago and saying that is what damages elastomers... Perhaps GAMI is investigating this behind the scenes and actually has a thorough crew of investigators from GAMI and the FAA (I sincerely hope this is the case)? But GAMI's posts on the social media outlet of Mooneyspace, BeechTalk, BackCountry Pilot, etc are so far not more than an attempt at social influencing, advertising, and damage control. If a fuel is advertised to be 100% drop in without any modification but then requires new sealant (specific new fuel resistant type) and new paint (specific new fuel resistant finish and prep), new fuel lines, and new o-rings...that's not 100% drop in as is. It's drop in with an asterisk and requires definition on an ICA/STC paperwork...(either that or perhaps an AD in the future). The fleet is a phase two of a "beta test" to uncover where issues are seen. But you have to believe the issues and adapt or else you're stuck with version 1.0.0 forever. If that's the case, this may not be a fleet wide fuel.3 points

-

Recently on a FB page somebody posted a pic of a Lycoming cam with a little bit of corrosion on one of the flat faces. Out of well over a hundred responses the majority were of the tone that 'you and everyone you love will die a horrible fiery death if you don't overhaul that engine immediately!' I exaggerate...slightly. Kudos to you for handling it sensibly. Edit: Lol...I see you posted in the same FB group. Nicely done!3 points

-

Erik: When I overhauled my IO550 in the Ovation, I used a "6 pack" of balanced cylinders from Continental and they have been good for 500 hours without issue. This was 4 years ago so maybe the quality has improved. Hopefully I didn't jynx myself so hopefully Dan and I will get longevity on these units. Best of luck with the decisioning. I also use Weber. Good gyuys. Mark2 points

-

I've updated Wikipedia's AvGas article to mention the concerns around material compatibility2 points

-

Yeah, it's funny but my temps are never really high except CHTs breaking in new cylinders ROP (expected and still only "high" using Mike Busch's 380F working limit). So it might be a bit conservative (if that's the right word). I was calculating -40F at cruising altitude had I gone today, so more heat is probably better. On the plus side, I found these guys to do my annual:2 points

-

@dkkim73 yes, you’ll want to run it hard and ROP to keep the temps up. I posted a thread awhile back where I ran lean of peak at altitude and couldn’t get the CHT’s above 200. My hang up with the IPA is that it can be hard on tank sealants, so I only use it if I’m going to go through a couple full tanks right away. If my destination is such that I will leave the plane sitting for a few days with the IPA in the wings, I usually go without. Something to keep in mind. Flying when it’s this cold out is awesome, the air is often still and crisp.2 points

-

This x100. This is just shakedown, it’s normal, even if it’s frustrating. at the end you will know your airplane better, and you may be able to help someone else later experiencing the same problems. Don’t give up!2 points

-

Wiggle lightly. I caught one loose on my 231 and was able to save it and the panel it sits on. -dan2 points

-

Thanks for the input. I agree, I need to have an A&P look at it. My primary mechanic just retired and my back-up moved away, so I'd like to do as much of the diagnostics as I can before I let someone tear into it. If anyone has any recommendations in northeast Ohio, let me know.2 points

-

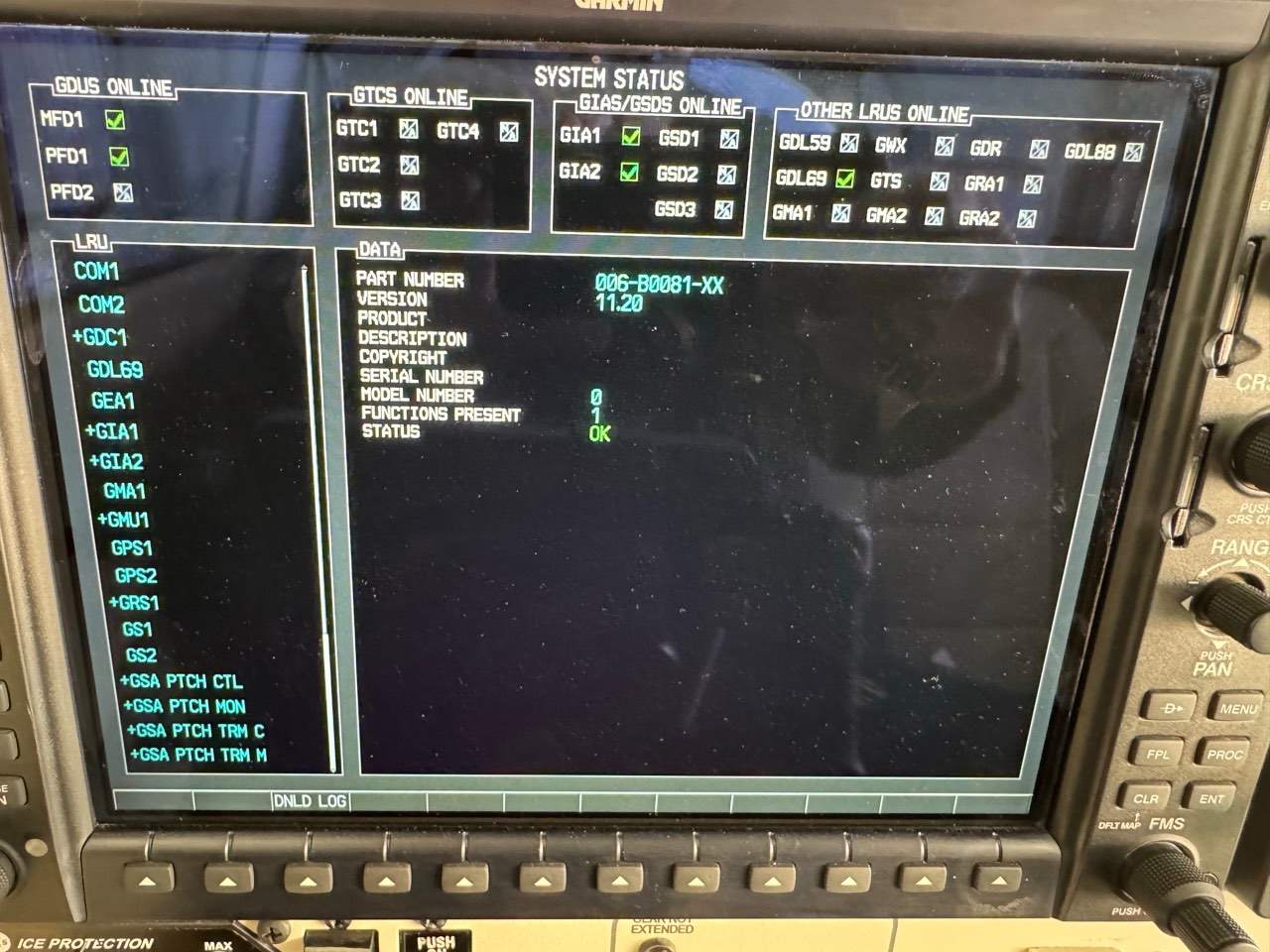

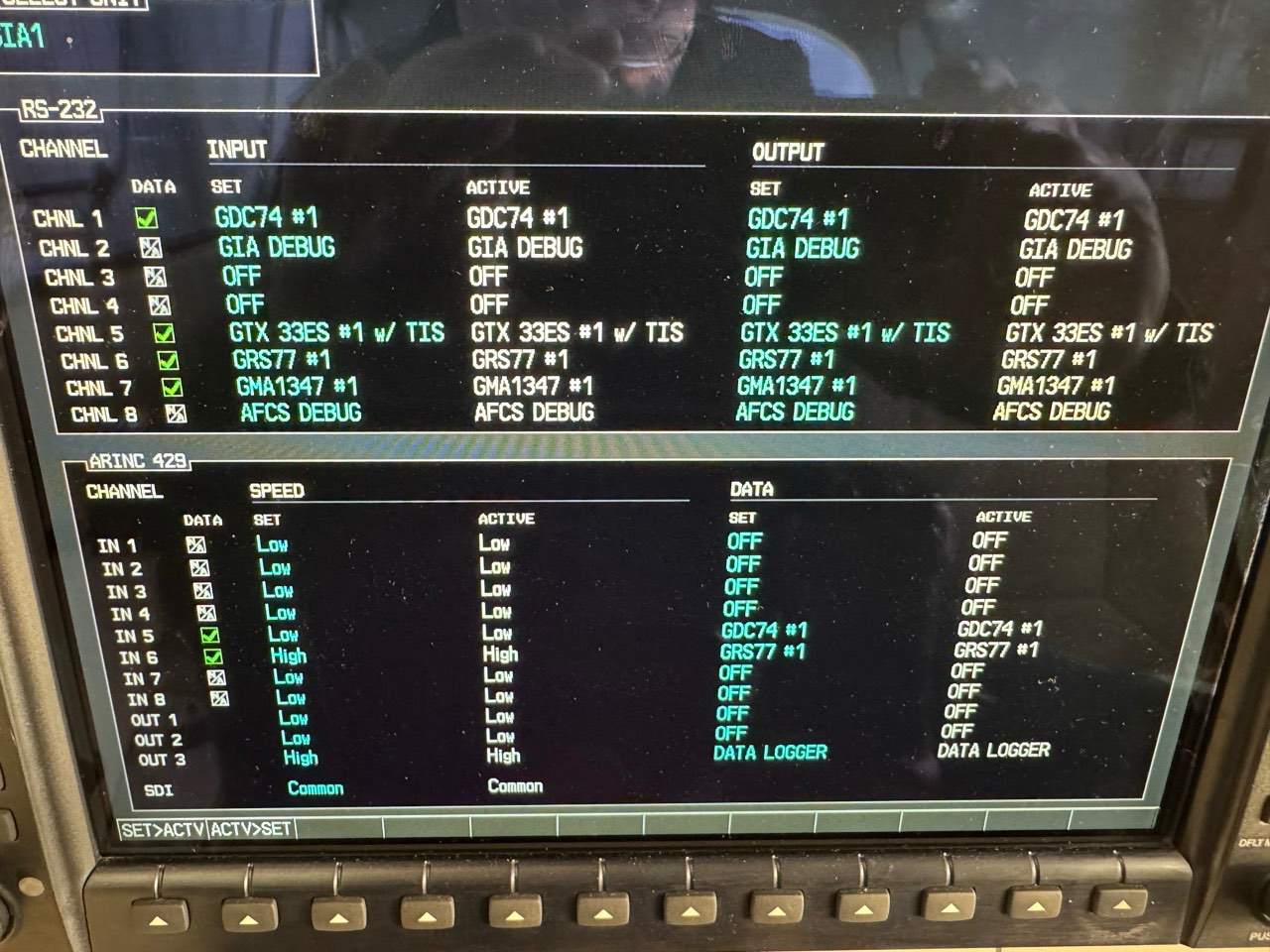

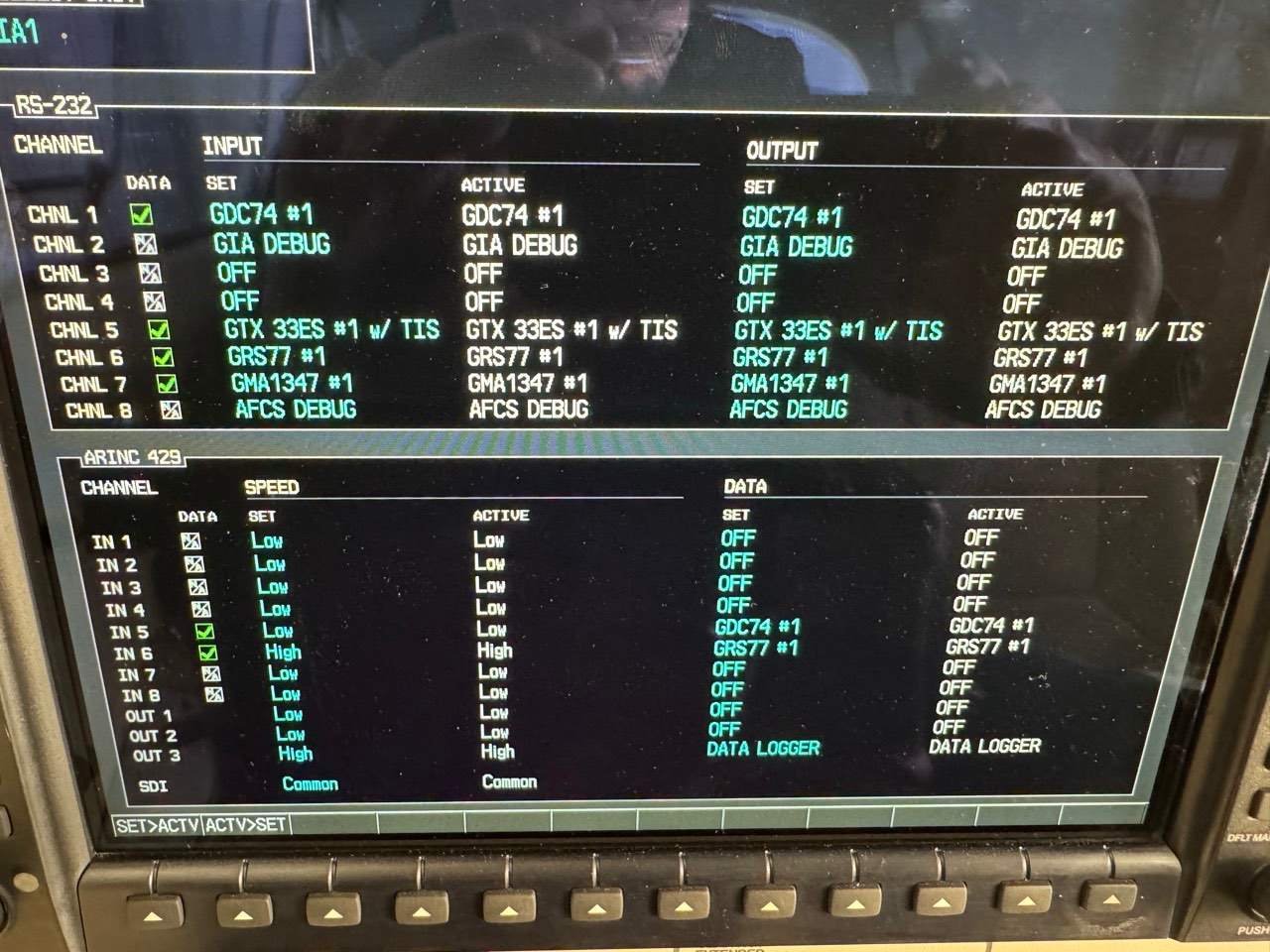

FS210 and G1000: Sorry for the delay: My Mooney was for 2 Month in AVIONIK Straubing (https://www.avionik.de) where the figured it out, the contact Persons are Mr. Schub Software, Mr. Schönsteiner Operations. The first thing was the .37 Software update. The problem when the Flightstream 210 is installed, Bluetooth is showing up, but you cannot connect to it. This needs some software adaptations. As far as I heard, Cirrus G1000 Software is involved. And there are Emails from Garmin (don't know the contact persons) that confirm the first time that it works, and giving help how it works. (as in the past the GARMIN answer always was: Is neither intended nor possible.) As I am engineer but not an avionics guy, I will send some configuration screenshots and the part number with the hope it will help you. All I can say it is absolute game changer for the G1000 in the Mooney! 22082024_AUTHORIZED RELEASE CERTIFICATE.pdf2 points

-

In a bygone era there were many 200-400 RVR night departures from KSMO with VENTURI driven gyros in a Cessna 140, to the top of a 400 ft fog layer There have been more 200/ 1/2 and CATIII approaches while in big iron than I ever want to repeat Now 20 years after the last Pt 121 landing its DAY VFR only in SE equipment.2 points

-

Have two pumps, Ideally one is a mechanical wobble pump, but either way empty the ferry tank into the main as soon as there is room to do so, if that’s how your plumbing it, that way it’s nearly certain you have enough fuel to return if you need to. Take a class on ferrying before you go and have a way to communicate, old way was a High Freq radio, newer way was a Sat phone, but heck maybe the newest is a Starlink mini now and that should give you weather too? I used to Ferry down to Central and S America lots, but haven’t in years so anything I know is surely out of date now. Oh, and of course a PLB to go with the life raft. Maybe consider hiring a Ferry pilot and go along if you want? I used to rent an Irridium Sat phone when I would ferry, no need to buy one.2 points

-

2 points

-

The opinion in Loper Bright Enterprises v. Raimondo is unlikely to have much application to the FAA regulations that apply to us in flying and maintaining our Mooneys. The holding in Loper Bright is that judges should be the arbiters of what a statute means and that a judge need not defer to regulations that purport to interpret a statute even if the statute appears to be ambiguous (although if the statute gives a specific grant of regulatory authority and that grant is constitutional, Loper Bright says that the proper interpretation of that statute is to enforce the resulting regulation). I'm a tax lawyer, not an aviation lawyer, and I can name a lot of regulations promulgated under the Internal Revenue Code that may be subject to challenge under Loper Bright. One reason for that is that there are a lot of statutes in the Internal Revenue Code, so there is a lot of statutory language for judges to interpret. Contrast that with Part 91. The authority the FAA cites for promulgating Part 91 is far more general than the Internal Revenue Code. It's just a handful of statutes: 49 U.S.C. 106(f), 40101, 40103, 40105, 40113, 40120, 44101, 44111, 44701, 44704, 44709, 44711, 44712, 44715, 44716, 44717, 44722, 46306, 46315, 46316, 46504, 46506-46507, 47122, 47508, 47528-47531, 47534; Pub. L. 114-190, 130 Stat. 615 (49 U.S.C. 44703 note); Sec. 828 of Pub. L. 118-63, 138 Stat. 1330 (49 U.S.C. 44703 note); articles 12 and 29 of the Convention on International Civil Aviation (61 Stat. 1180), (126 Stat. 11). The statutes tend to contain broad regulatory grants of authority. For example, section 40103(b)(2) provides: "The Administrator shall prescribe air traffic regulations on the flight of aircraft (including regulations on safe altitudes) for— (A) navigating, protecting, and identifying aircraft; (B) protecting individuals and property on the ground; (C) using the navigable airspace efficiently; and (D) collision between aircraft, between aircraft and land or water vehicles, and between aircraft and airborne objects." If you run afoul of the regulations that apply to buzzing your neighbor's house, you're not likely to have much success pointing to Loper Bright and saying that the regulations are not "law" because they are not the best interpretation of this statutory language. I'm not saying that there can be no challenges to FAA regulations under Loper Bright. Congress did set out specific statutory rules regarding ELTs, and enforcement via civil and criminal penalties, and a short list of other topics. But I would be very surprised if Loper Bright could be wielded to challenge most of the regs that apply to us.2 points

-

2 points

-

Funny story: you need to know your systems. I didn't know that the overhead vents don't pass through the heat exchanger. That ignorance was rewarded with a memorable flight2 points

-

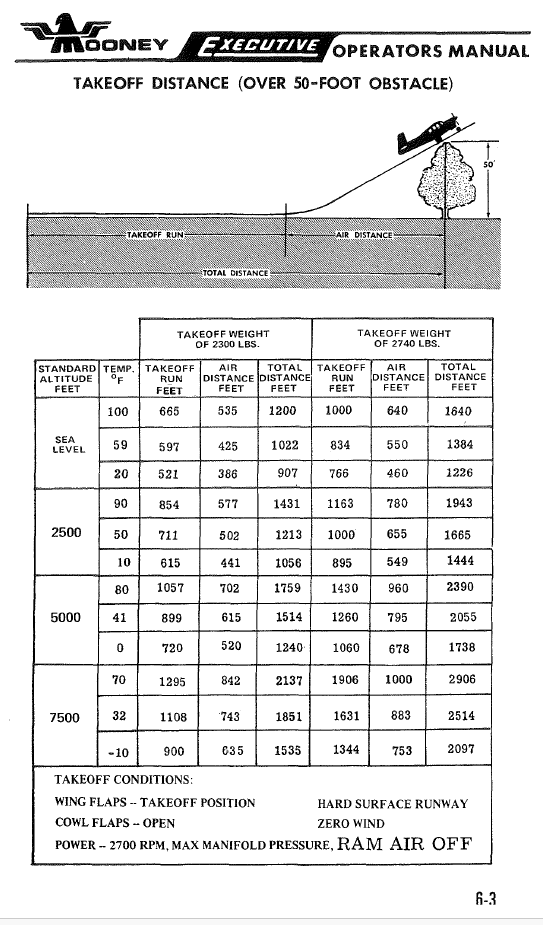

Not sure what version of the M20F POH you're looking at, but the 1975 edition has takeoff and landing data up to 7500' at 70 degrees F, which is about 10,000' DA. Takeoff distance chart is pasted below, landing distance is shorter than takeoff distance for all cases. Real world performance of any stock, airworthy M20F is not meaningfully different from these numbers.2 points

-

I'm a week out from dropping off my 1989 J model to start its panel upgrade. The before picture is below; I'll have a separate post in a few weeks in the Classified section for anyone interested in legacy equipment that's being removed. I plan to post updates as the avionics shop makes progress. The project includes GFC500, G500TXi, GI275 backup, GI275 EIS, GTN650Xi, GNX375, GTR205, yoke Aera 760, Carling switches, Cies senders, LHS, and LED nav/strobe. Many thanks to @donkaye @shawnd @Lois @201 RedTail for sharing their panel experiences and providing advice during the planning stage. John1 point

-

If it’s ever proven that they are at fault, yes. I believe Mobil did for the oil problem regardless of engine age? However I believe the owner is a Lawyer, so surely he’s covered pretty well. Way I see it as a Layperson, is that there really is a compatibility problem, or it’s one heck of a coincidence. I have no way of knowing which it is, but I believe two things. 1. If I was using it or even used it once, I would have that documented by every means that I could starting with receipts and if I lost it, because I have never kept receipts I’d ask for one 2. I’d not use it until the issue, if there even is one is solved. Personally I’d never use it because we are certain that it reacts negatively with Nitrile, and my fuel bladders are apparently made from Nitrile. Everyone keeps saying O-rings, and they are not that big a deal, but they may be the canary in the coal mine. The bigger deal is fuel pumps, fuel flow transducers, pressure transducers, fuel servo, fuel spider on top of the engine, who knows what else, there are plastics and rubber throughout the fuel system, heck even the fuel quantity transmitter floats and they probably have seals too. O-rings aren’t really the issue because in most all cases they aren’t really that exposed, they are in grooves that when the part is assembled there is very little in contact with the liquid, but seals etc are exposed and I don’t know where Viton replacements can be sourced for those components I listed above. But then, maybe this will all turn out to be a non issue. Having worked a lot with the FAA myself I know their overriding concern is “can this reflect negatively on me?” I’m actually surprised that they haven’t stopped the sale of the fuel until the investigation is completed myself, the fact that they haven’t indicates something I think, what that is I’m uncertain1 point

-

@CCAS I configured my stack just like your first example, GMC 507 on the top and GMA 345 on the bottom, and I really like it. I have my G5 between my PFD and the radio stack and use it for altimeter adjustments, and use the heading and altitude knobs on the GMC 507 right beside it for those adjustments rather than the knobs or the touch screen on the PFD. The audio panel on the bottom has worked out great as well, especially with the frequency color coding on the PFD to show me which radio/freq is active. I'm starting to transition to the PFD touch screen (I have a G3X) for the autopilot controls, and already use it for all of my radio freq changes. Eventually I'll get to where the G3X and the G5 are my primary interfaces and the radio stack is secondary, excepting the audio panel and flight plan manipulation on the 650Xi. But right now I'm still using familiar button operation on the GMC 507 most of the time until I get more comfortable doing everything on the G3X.1 point

-

This is exactly the reason that you find disclaimers on products everywhere. If you didn't say "use caution with wet wings as this may accelerate leaks and lead to paint damage" and instead said "will be invisible to your aircraft or engine compared to 100LL"...you might have a civil problem. Heck, they have disclaimers not to allow babies to play with plastic bags. But keep in mind, NONE of this is already decided and no one has clearly defined where liability coverage is found with G100UL. Until we actually have actual hard scientific data it's limited observational data with LOTS of speculation all the way around.1 point

-

I’d have done what you did. No reason to tear it down if it’s not making metal. I would use x/c victory oil and be especially careful about cold starts if I had a cam that was beginning to show signs of distress, but I’d just watch it until I found metal in the filter.1 point

-

@0TreeLemur, just wow! On my side of the state, the nearest A&P to my base (the IA who now does my annuals) signed off on the ferry permit and off I went to see Joey Cole. No problem, he charged me for an hour of his time. Life is good in the country! War Eagle!1 point

-

I suspect if you do that then your Continental Warranty (18 months) will also immediately be void. When you add up the cost of extra shipping, Extra labor to pull and reinstall all cylinders (even on a crated engine), the cost of the new cylinders (seriously doubt that you will break even - even in this market waiting for cylinders - you offer no warranty on the cylinders that you are "reselling" even though they are new). Then you have the risk that the "new" new cylinders were installed correctly. And you said earlier you wanted a Superior camshaft - that would mean splitting the case - even more cost and issues. If you have any infant mortality issues with your overhaul both Continental and Superior will just shrug their shoulders and say it is your and the other company's problem. And then you have the extended down time of shipping to a second shop for a "Top OH" on the Rebuild from Cont. This sounds completely nuts. If the custom build specs on overhaul are most important to you (ignition, cylinder, cam, etc), then why don't you just bite the bullet and continue with Penn Yan? Yes it will cost more than a Rebuild Cont from AirPower, but you will be spending way more money (and importantly way more time) if you go this second route.1 point

-

1 point

-

I know this is a very subjective thing, but my GFC control head is at the bottom of the radio stack. It makes one-button changes easy while my hand is resting on the throttle. I can see the logic in having it at the top, but with the other AP annunciators already in front of the pilot it’s redundant and less convenient.1 point

-

Take yours apart, clean the contacts and put it back together again. Don't mess with the bumps on the bottom just clean them with solvent. Use fine sand paper on the U shaped pieces to smooth out any pitting, then polish them till shiny. Reassemble with DC4.1 point

-

They approve those all the time. You just need an A&P to sign off that it is safe to fly.1 point

-

Crudest way to check fuel flow is take injectors out stick each into measuring cup, run boost pump with full throttle mixture rich for let's say 1 min and compare cups, if this does not show anything do lean test at 24" record fuel flow for each cylinder egt to peak, make sure mags are wired correctly, one mag fires bottom plugs on one side, top plugs on the other side, persistence wil get you a perfect running engine1 point

-

We’re now an all-EV household, and the EVs cover our 95% use case (including a 100-mile RT daily commute). For a road trip of any significant length, we just rent a car. The fuel costs for two EVs on a ToD electric plan are under $40/mo, which more than pays for the occasional rentals. I’m a fan of renting cars for road trips anyway (had too many bad experiences getting stranded with a personal car waiting on a repair shop in the middle of nowhere), so we would be renting for most of these trips even without the EV thing. (Sorry for contributing to the thread drift, just wanted to chime in on EV practicalities. To each their own, of course, but it’s really not bad.)1 point

-

I've never heard of an Airport that charges landing fees to not charge the landing fees if you do a T&G. Wheels touch the ground you pay the fee. The other stuff is all about ADS-B not being corrected for the current Altimeter and they show you were at 0 ft AGL (or maybe even below the Apt elevation ) So that's were you have to make sure the actual Client is aware so they can get on Vectors case. Or avoid the airport all together.1 point

-

Matt, Hopefully your flight home went well! One recommendation for departing at high altitudes (ok, maybe two) 1. Only take the weight you need, so 40 gallons of fuel is much better than 64 if you’re going to make a fuel stop anyway. Weight is key. 2. During the early takeoff roll, adjust the mixture to ~1220 egt (they are all a little different, but pick one). That’s roughly your max power, climb mixture setting. If you’re leaner than that, it’s very easy to get hot CHTs very fast during takeoff and initial climb. Richer than that is less power. The F does well at Colorado altitudes, but I always tried to leave by ~11am or earlier in the summer.1 point

-

No offense taken, and no apology warranted. Seth is the guy who machines cylinders for Gann and other well-regarded engine shops. His website is herePerformance Aircraft. Really personable guy. He ports, polishes, balances, and grinds the valve seats with precision. His work will void the CMI warranty, but really, who cares? If a cylinder has to come off my Acclaim, it’s potentially a new V-band clamp plus all the labor. In my dream world, I’ll buy an engine core, send it to Gann, Powermaster, Victor, or similar, and have them build me an engine to a higher standard that I can swap on my schedule. But with a little luck and frequent flying, that is a few years away. For now, I just topped a 1750 hour engine, which might seem nuts to some, but it works for me (I hope). I’m not planning on selling the Acclaim any time soon, so a top not being accretive to the plane’s value matters little to me. -dan1 point

-

Contact the nearest EAA chapter and tell them what you have.1 point

-

I always have an iPad in my lap with EIS via Garmin Pilot. So if the LCD craps out, GP is an easy backup.1 point

-

Welcome! It's a terrific plane that fits your mission. There's TONS written here about prebuys here on the Vintage birds. Google Mooneyspace prebuy (or similar, the search function for the website sucks). Make sure key components of the airframe are corrosion free first (wing spar, steel cage for cabin). If it checks out, then move on to evaluating the rest. If you can find one with good avionics, it will save you a ton of money and time upgrading, but focus on the basics first when assessing a plane.1 point

-

I have a 30,60 and 160G Turtlepac, take your pick and send me a PM. I also have documentation that might help with the installation approval. Aerodon1 point

-

You are a class act, Andrew. It has been a great pleasure knowing you. Even if only virtually here on MooneySpace. God bless and Godspeed. Jim1 point

-

How far do you plan to go, and starting from where? There are several shops, often near the coast, that support ferry tank installation. This global flight started with a Turtle-Pac installed by Air Mods in NJ: https://www.pieternel.net/rtw/the-round-the-world-aircraft-n5810t/ - makes the reference on this page Some others get tanks installed in KSMX Santa Maria, CA before launching over the Pacific. Not sure the vendor there. Skyview Aviation at Tracy Municipal Airport installs ferry tanks, and may give advice, too.1 point

-

It's the first time I've read this thread and so sad to hear the situation. But you're right, Andrew, you've had an amazing life and gratitude (and love!) is what makes all the pain worthwhile. Thank you for being part of our airman and Mooney community. Thank you for sharing your trials and triumphs. Thank you for sharing your adventures restoring G-OBAL. You're leaving behind a plane that will continue on to be loved just the way you have loved her. Have faith. Be strong. God Bless, God Speed, and - Clear skies and tailwinds, AJ (another Andrew)1 point

-

How you are handling yourself at this time, and for the last year and a half or so, is remarkable, and quite an inspiration for the rest of us. I enjoyed meeting you at the Mooney Summits, and our online interactions here. We will all miss you, Andrew.1 point

-

1 point

-

Crash into a school and kill 9 kids: you wont be around anyway!1 point

-

It’s hard to track all the various G100UL threads but it seems like they’re all full of complaining that we need 100LL to remain available until we get a perfect replacement and then for quite a long while after that. Some of these are even seemingly directed at George Braly for reasons I can’t fathom… they’re probably better directed at your congressman, or maybe members of the incoming administration. GAMI isn’t taking away anyone’s 100LL, but it seems crystal clear to me that it’s only a matter of time before we (the GA community) lose the battle and governments (local, state, and federal) force the issue. Whether it ought to be that way isn’t terribly important, because that’s how it is. We can’t even keep our airports open and financially solvent, let alone simultaneously fight a never ending battle against the environmental authorities. It also seems likely now there’s not any silver bullet forthcoming… G100UL has the big STC paperwork hurdle and these possible paint/elastomer issues, and reportedly the (only remaining) EAGLE candidate from VP/etc isn’t able to meet the full octane requirements. So what do we do now? Give up and hope something else emerges? 100LL extinction is coming whether we like it or not. I have my own concerns about G100UL based on the o-ring test and reports of leaks. But I think it would be useful to have a sober and objective look at how serious these problems are and whether they can be overcome. It’s highly relevant to me whether, for example, G100UL attacks and compromises even freshly sealed tanks using the sealants in wide use today, versus only older tanks with various patches, etc. Does it affect bladders similarly? Is the o-ring issue causing actual problems in the field and can Viton o-rings be sourced if needed? Does it affect all types of aircraft paint, including new paint, or does it primarily affect older oxidized paint? Yes, it would suck have to do a full tank strip/reseal just to use G100UL, but as a Mooney owner I know that’s inevitable someday anyway. It would just be good to understand whether newer sealants are more compatible or will it just leak again in short order, etc. Basically, if G100UL ‘wins’, what does the world look like for us? Also, if it really is true that the EAGLE alternative is lower octane than ‘100LL’, I don’t know that a slightly better materials compatibility situation outweighs the loss of detonation margin, especially after it seems likely that the UL94 valve seat issues were octane related.1 point

-

Yep. He’s gotten enough airplay on the forums this week that I’m sure he’ll surface somewhere. I really wish he would have yanked the mixture after touchdown just to get the prop stopped, but he was deeply into “resignation” at that point and just riding it out. Obviously lots of mistakes here, but I’m sure each of us is glad that our worst aviation moment isn’t on YouTube1 point

-

I suspect he's feeling pretty bad and kicking himself. That stuff is often much clearer after the fact.1 point