Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/2025 in all areas

-

George, I know this is not exactly a friendly environment for you, and I'm not a proponent of how we got here, but I do appreciate you logging in. It would be easier to just turn off the computer.5 points

-

I think it is rather inappropriate to state that I give "deflective" answers to your questions. What I have provided is hard data. Exposure data with controls. There is simply not enough information about the circumstances in California with the Mooney for us to be able to do any more than speculate. We are continuing to investigate the matter. That does require some time. If I recall, one of the U-Tube reports "dropped" one day before Christmas. This is New Year's Day. What I do find somewhat frustrating is that, when GAMI does provide relevant aircraft paint exposure data - - with experimental controls - - that data is dismissed by several of the participants here, as not being sufficient to further the discussion. Regardless, as stated above, we will, with all deliberate speed, continue to investigate the matter.4 points

-

I think it would be wise for GAMI to remove this from their website: It is clear at this point that G100UL is not transparent to the engine, aircraft, and pilot. Hard data is pointing out that: Paint staining has been reported by many, in none of the cases buffing or polishing was able to remove the stains. Paint damage (as in paint peeling off) has been reported. Fuel tank seal damage has been reported. Some o-ring materials swell significantly more than with 100LL. If that generates any issue, it is still not clear. I'm not saying that G100UL is good or bad. I'm saying that it should be clearly stated in which aspects it is different than 100LL and in which scenarios (certain o-ring materials, wet wing aircraft with old sealants, paint that is not in mint condition, etc) there is an elevated risk of having issues during the transition.3 points

-

You might be thinking of the clinics that Jerry Manthey used to do. He stopped doing them years ago. Very helpful information.2 points

-

FWIW, you don't get to determine whether you come across as deflective or not to somebody. If they think you're being deflective, then it's 100% appropriate for them to say so. FWIW, I also think you're often very deflective. Your data will always be under suspicion due to the obvious conflict of interest. There have now been multiple aircraft of different makes showing photographic evidence of significant paint damage, i.e., bubbling and peeling, after use of G100UL, and those are just the ones have been shown or linked on this site. I'm sure that's not a comprehensive inventory of the entire field. The YT vid by mluvara did a good job of reproducing the conditions suspected to create the damage and 100% of the different articles tested in G100UL failed. So when you produce a single test with a single type of test item that doesn't appear to reproduce the same field conditions, then, yes, there's going to be some pushback, notwithstanding the conflict of interest. A cynic might say the test was designed specifically to not show the issue. What it needs is more independent third party testing to remove the conflict of interest.2 points

-

That’s one of the scenarios in my six “GPS Tasks Pilot Don’t Know How To Do.” If you are coming in on a NoPT transition, the hold in lieu will not be loaded. If you get an instruction to hold as published there, just reload the approach (6-10 seconds) with the IAF/IF as the transition. The hold will be there. Glad your CFI did it. It’s not an uncommon scenario. But why didn’t that CFI show you how? To your first question, TOGA gives you a 7 degree wings level climb to initiate the missed. But at some point, you need to tell the GFC what to do by selecting a vertical and lateral mode. Think about what would happen if it automated the missed: ATC: On the missed, fly runway heading. Climb and maintain 3,000. ATC (a few minutes later): Why are you making a 180 and stopping at 2000?2 points

-

A big part of ceramic coating is protecting the surface and also making it easy to clean bugs, dirt and debris easier so that you're also less likely to scratch the surface with cleaning. Of course we all pick and choose what’s important to us or not. Plenty of pilots follow minimal and limited maintenance that’s only geared towards basic airworthy…some are geared towards showroom quality or modern functionality…and lots scattered somewhere in between. To each their own. …there are plenty of people who think it’s crazy to even own an aircraft! Fortunately we all know better!2 points

-

@George Braly I posted the sealant used to reseal my aux. I can also email it to you, the work was done 9/22 no leaks until I have started using G100. Putting all the good faith aside which we all appreciate, I think the requirement of cleaning up a spill as soon as possible is quite unreasonable. While refueling, while sumping the drain valve, while just having a mechanic work on your plane, or fuel tanks leaks that happen all the time. Fuel will leak and we won't always be there to clean it up. Drain valve will leak, after sumping, there is always drops of fuel coming out. My plane doesn't have a great paint job and I am lucky enough that i decided not to repaint it last year. The bottom of my copilot wing is ruined beyond touch up paint. I honestly don't think I will repaint the plane unless I am going to forever use 100LL. I cannot foresee investing 15-20K in a paint job and then having to lose sleep at night because of G100. I am also going to have to explain this entire thread(s) to who ever is going to buy my plane when I sell it and I am going to have to take a hit on the sale price. Honestly, KWVI and Gami should have done a better job when promoting the fuel. What we are seeing here (including the green encore) is orthogonal from what it was disclosed. We were also encouraged to purchase G100. I am attaching the statement in the email. Note: "no different than 100LL". As you stated yourself there are 2 STC, one of the engine and one for the airframe. G100 is different than 100UL when it comes to the airframe. They do not operate the same Gabe2 points

-

Take it to a muffler shop, they will weld it for $20.00.2 points

-

Buffing is not rocket science. Polishing is rocket science. Words have some very specific meanings here (IMC and IFR are kinda of the same but different). I am going to regret this but here we go. 1.) Single stage paint is a layer of paint and a protective coating. Clear coat is a transparent layer put over a base color. Paint looks bad primarily due to scratches or oxidation. To fix bad looking paint you need to remove oxidation and scratches, there is no other solution other than remove clear coat or paint. You do this by cutting, sanding, polishing, etc. You are taking an abrasive and removing material to get a flat defect free surface. Determine how think the paint/coating is if insufficient you need to strip/paint. You can find a decent paint/depth gauge on Amazon for $300 If you have a lot of depth do whatever If you don't care do whatever I used Comet powder to start buffing out the boot/trunk of my 71 MGB. It was red and not original. Whoever shot it (single stage) sprayed well and deep. I could have put an angle grinder to it and had paint left. ++++++++++++++++++++++++++++++++++++++++++++ Everything above this line is dangerous. You can seriously mess up your paint with heat, abrasives, etc. If your true goal is museum quality finish you want somebody who absolutely knows their stuff. I can jet a carb but if I want to race Reno I am hiring a pro to jet my carb. For an airplane I would never recommend a paint correction (cut/polish/sand/etc.). You don't get up that close, a plane with decent paint and some wax looks good at 200 yards. If I am flying closer than 200yds to your plane we are very "good" friends... Once you have good paint the key is to protect it. I like Jescar Powerlock. Put that on. Wash it often with a neutral PH (won't strip wax) cleaner as often as you can. After first wash following Jescar put some wax on (you don't need everywhere mainly leading edges). I like Collinite 845. ++++++++++++++++++++++++++++++++++++++++++++++ The above paragraph is where everyone goes wrong. I can make a piece of paint look perfect but that is for TODAY. You cannot keep going back to sand, cut, polish, etc. You run out of paint. The key is to wash frequently with good clean mitts/rags and a grit guard. Reapply wax/etc. It is about maintenance more than anything. Polishing should and be a ONE time thing. I do a pretty good job keeping the 71 MG looking good. My Mooney it looks great from 200 yards. READ THIS - IF you spent $15K+ on paint recently please PLEASE PLEASE do not be stupid. You had enough money to spend $15K to paint a toy so you are not poor. Paint correction is really hard, I do not recommend it (polish/sand/cut) for a plane any more than ceramic coating (different topic) but if you feel the need for it, best to hire a professional. Washing (very clean mit/rags use grit guard in bucket) and waxing/buffing do that all day long. Abrasives though is in fact rocket science.2 points

-

Curt, If the hold at the IAF is a HILPT, then the hold will be included in the loading of the approach and depending on your direction of arrival at the IAF, it will ask if you want to hold there. When you push the TOGA button, the GFC 500 will go into GA mode which is a wings level pitch up of 7 degrees. This will accomplish the initial climb portion of the missed approach. To follow the navigation portion of the missed approach, you need to push the NAV button once you have begun the climb and cleaned up the plane for the missed. If there is a straight ahead climb to an altitude before turning, there will be an altitude waypoint so pushing NAV will not turn you too soon. Hope this helps. Adam2 points

-

Probably not as many full failures as there are "too worn out to use any more" due to not being disassembled and relubed as required over the years. With as little as they get used time and age have more to do with the grease drying out than anything else. Its a simple formula. Cheap annuals = no grease. No grease- No gears No Mooney specific knowledge = no gears No gears = No fly Call it price gouging, call it airplane tax, call it all you want, but the end game is the same. We fly antiques that no one wants to supply critical parts for due to legalities Why are we surprised when a manufacturer doesn't want to support something more than a half century old anymore? Does Ford still supply parts for a 63 Fairlane? Does Chevy still make exact replacement parts for a 64 Corvette? Most of our Mooneys are older than those flying them. We either cough up the money to do it ourselves OR the airplanes become beer cans (which they will eventually anyway) BTW we kill more airplanes by doing stupid stuff in them than get killed by no gears available.2 points

-

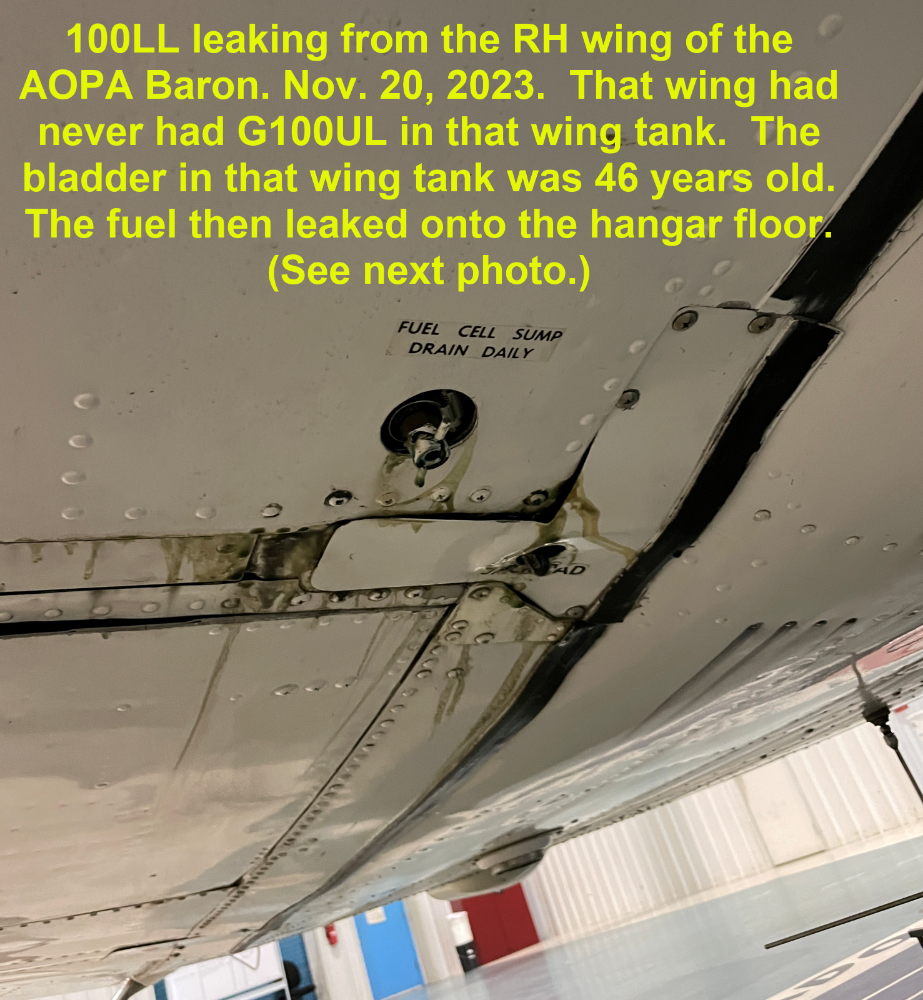

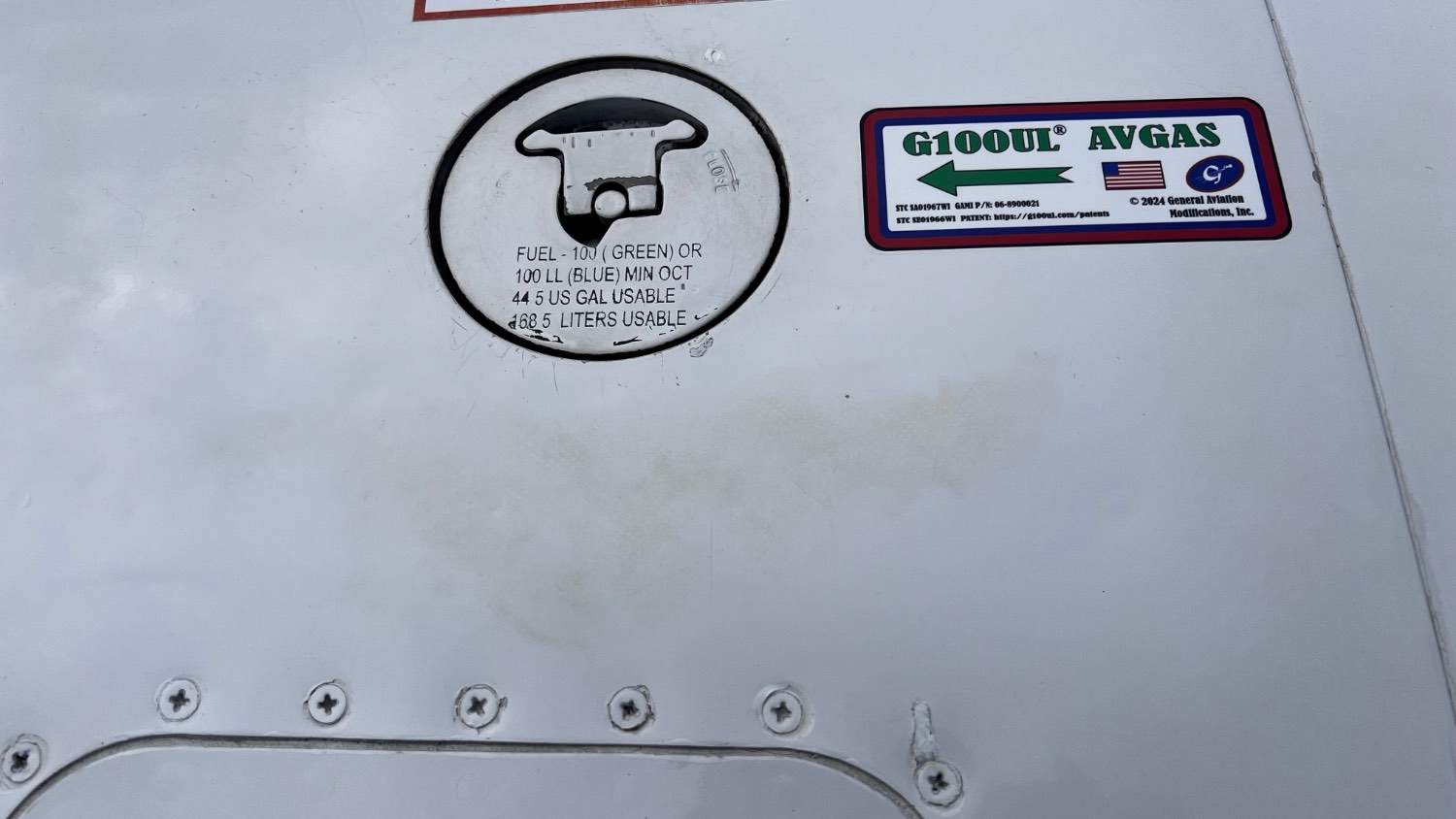

Very much appreciate the discussion and the feedback, here. Please allow me to provide a response to some of the messages. 1) I am a big Mooney fan. Flew a 67 Mooney Super 21 for nearly 2,000 hours. Commuted to and from law school in Norman, Ok. to the family Ranch (100miles each way) on a daily basis for 3 years. 2) Part I - - Some aviation fuel chemistry history: A- During WWII fuels with very large amounts of aromatics were adopted. Arguably, the Air War would have been much more costly in terms of losses for the fighter aircraft without the introduction of aromatics to aviation gasoline. The fuel approved for D-Day was "100/150" - - and used a lot of different aromatic components; B- In the ranking of the levels of "aggressiveness" as solvents, the ranking starts (most severe) with benzene. Then add a single CH3 group and you get toluene. Yes. Paint stripper you buy at the paint store. C- Add a second Ch3 group and you get xylenes (three isomers - ortho, meta, & para) Xylenes are significantly less aggressive as a "paint stripper" than is toluene. <== THAT is important. Keep that in mind. D- Many fuel bladders were developed during WWII and are labeled "approved for aromatics" or something similar. If you look closely at some of the P-51s and other planes at Oshkosh, you will see a placard that states "approved for aromatic fuels." Part II - - Post WWII. A- We had "Green" 100/130 with LOTS and lots of lead. And even purple 115/145 (with lots of aromatics) At the end of the piston airline and going into the late 1970s and 1980s, the ASTM folks decided to drop the lead content and created BLUE 100Low Lead. Still lots of lead. But much less than GREEN 100/130. B- Some of the refiners had very good "aviation alkylate" (~ 70% of some 100LL fuel formulations) with relatively high MON values for that aviation alkylate (a less than pure form of isoctane). Those refineries could make 100LL with relatively low levels of aromatics (almost always "toluene" from the paint store). Maybe 10-20%. C- Other refineries (P66 at Borger, Tx, for example) had lower MON quality "aviation alkylate" and the had to use a LOT of toluene. I can show you detailed hydrocarbon analysis (GC-FID) test results for local (Ada, Ok. FBO) P66 Borger, Tx 100LL that has 29% toluene and another 4% of other aromatics for a total of about 33% aromatic content. 3) Fleet Experience during the transition to 100LL - - A-Starting shortly after the introduction of 100LL, with high levels of aggressive toluene, A LOT of Mooney, Piper, and other airplane owners that had aluminum integral fuel tanks (no bladders) began to leak fuel out of lots of rivet holes. That started a whole new business for G.A. with companies initially specializing in re-sealing those tanks. Later, companies developed retrofit fuel bladders for those problematic "integral fuel tanks". B- A big part of the problem was the aircraft manufacturers did an "inconsistent" (careful choice of words) job of applying the polysulfide sealant to the interior (rivets and seams) of the aluminum integral wing tanks as they were manufactured. [As we have learned during material compatibility testing, the devil is in the details when it comes to the proper application of sealants to fuel tanks. ] C) Over the decades, the level of toluene from most refiners has decreased due to better quality aviation alkylate, but some refiners - - for at least some production runs - - still (from looking at their data sheets) still have a lot of toluene. 4) G100UL Avgas - - A- Uses a very high quality aviation alkylate (2-4 MON numbers higher than the alkylate used for 100LL) and then uses xylenes rather than toluene in order to achieve the 100/150+ octane/supercharge rating for G100UL avgas. The right choice of xylene isomers will have higher octane blending value than does toluene. Using "xylenes" also has the advantage of being less chemically "aggressive" than is toluene. But the high quality alkylate and the premium xylene isomers also "cost more" than the related components in 100LL. BUT - - there ends up being no lead. B- We did extensive material compatibility testing, including a whole variety of older bladders and a whole range of tests for sealants applied to aluminum. All of that supervised (in person) by multiple FAA engineers and managers and then later approved by the FAA. 5) The 100LL we have at the airport in Ada (typically Phillips from Borger, Tx) still tends to have a lot of toluene in that fuel. A- Late October of 2023, AOPA brought their 1965 demonstration Baron to Ada. Two freshly overhauled IO-520s. One fuel bladder was 46 years old and the other ~50 years old. They were supposed to have been replaced with new, prior to the start of testing, but the bladders were on "back-order". B- G100UL avgas was exclusively kept in the LH bladder and 100LL was exclusively in the RH bladder. C-Within 30 days, we noticed fuel "spots" on the hangar floor. Investigation - - we found fuel leakage and staining on the bottom of the RH wing - - which had ONLY ever had 100LL. See photographs. 6- Oshkosh, the leakage from the LH wing tank (G100UL Avgas) was ( based on Eagle Fuel evaluation) caused by pre-existing damage to the tanks and the gaskets associated with the access panels. (In addition, there were pin-hole leaks in both fuel bladders). 7)-G100UL Avgas is NOT a threat to normal aircraft paint. A- Embry Riddle did extensive certification testing of G100UL avgas. They used G100UL in their C-172s for over a year, at Daytona Beach. They had no evidence of any fuel leaks and they had zero staining on the wings. B- As part of our due diligence, wee have deliberately spilled a LOT of G100UL Avgas onto various painted components from the many Bonanza aircraft that come through the TAT shop for turbo systems. That includes LOTs of wing tips and the lower cowling access panels, both of which are removed and replaced (with tip tanks and newly louvered lower access panels.) C- Some of that has been allowed to dry on those painted surfaces and then the process was repeated. NO SIGN OF ANY LOSS TO THE INTEGRITY OF THE ADHESION OF THE PAINT. D- We have even soaked a couple of those side panels in G100UL for a week or more. The paint was fine at the end of that. E- What does and will happen - - is if you do not properly clean up the spilled fuel, and allow it to dry, it can and will leave a light tan stain on the paint. If you do properly clean it up, it will not stain the paint - - even after repeated spills in the same location. But, to date, we have never seen any evidence of any type of "paint striping" activity to any of the dozen or more aircraft parts that were removed from our customers Bonanzas and used as "test articles." See https://g100ul.com/dl/Refueling Hygiene G100UL Avgas.pdf F- An aside - - some of the recent crystal and graphene coatings improve the resistance of aircraft paint to any damage from any variety of 100LL or G100UL - - but that is not a cure all. See the link Refueling Hygiene! 8. So "what happened" on the bottom of the Mooney wings ? A- In one case, the sump drain appears to be leaking. Likely the fittings inside the wing are also leaking. B- In the other case, there appears to be some kind of leakage from inside the wing. Not sure from the photographs. C- Almost certain that old drain valve has a "nitrile" set of O-rings. D- The paint on the bottom of the wings has likely had many months of exposure to steady drips of 100LL. In California, probably with only ~ 15% toluene in the 100LL . . . maybe. E- No information about the age of the paint on the bottom of the wings, but from its overall appearance and the multiple rivet holes that are bare and which have lost their paint - - it is likely a they are rather old paint jobs. The paint on my personal Bonanza, N11RT is about 35 years old and it is in much better condition than the appearance of the paint (away from the damaged paint). F- It would be good to know the age of the paint for each of those two aircraft. 9. What to do ? A-There is a long standing FAA / maintenance bulletin (20 + years old ???) that tells mechanics that when they find fuel leaks or deteriorated fuel lines or gaskets or O-rings, they should replace those components with parts that are made from chemically resistant materials (viton, fluorosilicones, etc.) Those types of materials are specifically stated to be for use with a wide variety of fuels, including aromatic based fluids. A lot of mechanics have ignored that recommendation over the years. Last . . . 10. I would like to have the chance to borescope an older Mooney fuel tank that has not been converted over to a bladder. A- If anyone on this forum would like to bring their plane to Ada we can do that here. You might find it interesting. If you have the STC you can probably leave with some G100UL in your tank, if you want. I hope this information helps to bring some clarity and understanding to these issues that will be the subject of conversations during the transition away from leaded avgas. Regards, George Braly gwbraly@gami.com2 points

-

This morning, I took my wife to see her mother in central NC. The direct path is almost over ATL airport; ATL Approach guards the sacred Bravo airspace like nothing I've ever seen--in 17 years of flying past Atlanta (where my direct path lies inside the Bravo), I've never been allowed inside. First it was "remain clear of the Bravo," then it became "stay out of the Bravo." So with beautiful VFR conditions widespread across the Southeast, we loaded up and took off. My route was KALX-->KOPN-->KFAY, to stay out of the Bravo without being told. Well, about ten minutes after I got set up with flight following, ATL Center asked, "are you direct to your destination?" I said no, I was going via OPN to avoid the Bravo, since I'd not been allowed inside for 17 years. He came back with, "today may be your day, if any is." Sure enough, a minute later it was "cleared direct destination through the Bravo." So I turned from 092 to 073 and went with it. I changed freqs and confirmed clearance with that controller (VFR through the Bravo), and he said "you are cleared through the Bravo at 7500." My first ever penetration of the ATL Bravo! On Christmas morning!! It's a Christmas miracle!!!1 point

-

I think it was Maxwell who told me that in flight, that stuff goes everywhere, so it would not surprise me if enough got around the engine somewhere and was burning or steaming off.1 point

-

@EricJ I've tuned in for a couple of those; sometimes they seem geared more towards A&Ps, but usually there are a couple of good pearls in there regardless. I think that what I had in mind was what @201Mooniac was describing with MAPA and Manthey. Not sure if anyone has carried on the torch for this? Seems like with MAPA in the wind, that either the MAPASF, Summit or DMax would be the groups with the best path forward...1 point

-

Duncan is shipping my kit out today! For those curious, I purchased the flat pack. The price included a 3% cc fee, $200 STC fee, and sales tax so the total was $7926.77 (~$22 for shipping included). The Garmin GFC500 was priced at $11930.50 ( not including shipping as it depends where it is shipped from) for a 2 axis kit for comparison… The installation price is the same for both per my avionics shop - currently for my plane at around $4500.00 Garmin: $16430.50 installed NOTE: I already have G5 and GNC 355 so that cost is not included. The G5 adds about $4K to $5k more for a single G5. AeroCruze: $12426.77 installed. G5 is optional but I would want it too… Overall, ~$4000 difference -Don1 point

-

If on introduction to the general market they cause damage and create safety concerns, there ought to be pushback! Scott Manley (YT guy) did an interesting analysis of the chemical history of aviation fuels and a short assessment of where we are now. He made an interesting point at the end, that Swift has indicated that 100R is miscible with 100LL but not G100UL. The VP fuel appears, from what I can gather and what he said, is taking a similar formulation path, so the potential situation may be that 100R and VPs fuels are miscible with each other and 100LL, but not G100UL. If Swift and VP both attain ASTM standards, they will have more industrial support than G100UL. This may create a situation where people have to closely monitor whether there is any G100UL in their tank so as to be careful to not mix it with the other unleaded fuels. This could create a contracting market for G100UL, assuming it gets traction given the current environment. So I understand why GAMI is pushing hard to get first mover advantage and gain whatever market share that they can, but it looks to me like the cards are not in their favor given the miscibility issues with the others and the greater support for the others given ASTM status. The ASTM process assures the "coalition approach" features and broader support as mentioned in the Textron letters. Scott Manley's recent vid: https://www.youtube.com/watch?v=8zfIy17q9sE1 point

-

With your Garmin G500 display you either have a GAD43 or a GAD43e. If you have the "e" you have pre-select built-in. If not, you need to keep the KAS-297B pre-select for your KFC150 autopilot. (https://www.garmin.com/en-US/p/62760#additional) Looking at your panel (https://www.aircraft.com/aircraft/228929665/n9153z-1996-mooney-m20m-bravo) it looks like the only vacuum instrument you have is your backup attitude indicator. You could get rid of your vacuum pump (and backup vacuum if you still have it) by installing any approved electric attitude indicator, which would be much less expensive than a GI-275.1 point

-

I used this toggle switch as well. I like it better than the old knob. It’s a switch on the dash and now I have a ppt on the yoke.1 point

-

I manufactured aircraft for years with wet wings, 114 gl per side, I’m very familiar with wet wings. One of the reasons I bought my airplane was it has bladders, bladders last decades longer than sealant. Don’t worry about whether they will be available, there are several companies that rebuild bladders. Here is a good one https://www.eaglefuelcells.com My airplane’s bladders only hold roughly 55 gls, I could add the extra ones to increase capacity but I don’t have the need.1 point

-

It is probably not your instrument cluster. There are 2 fuses between the shunt and the gauge. They don’t normally blow, but the wires that attach to them often break.1 point

-

Forgot to add- I shortened the threaded portion of the link rod to accommodate the closer mounting of the servo to the connection point. This HAS to be done carefully and by shortening BOTH ends so as to keep the required 12 threads engagement required by the STC as the hole does not go all the way through the threaded link rod. Also be aware that on the early short bodies (up through 68) have an unbalanced throw of the elevators (10 down and 24 up) instead of the balanced 22 each way for 69 and on so for the early ones the at rest setting for the arm on the servo will be off set from equal throw between the hard stops on the servo to accommodate this anomaly This is done with the length of the treaded link rod. I strongly suggest that a practice threaded rod be made (utilizing the actual rod ends) to play with this adjustment before the actual part is cut to size. Its a trial and error effort. You will need to check and recheck that the MAIN elevator stops hit first BEFORE the hard stops on the servo touch It is a close fit but can be done THIS IS THE MOST IMPORTANT PART OF THIS INSTALLATION I would highly recommend that a check of the proper elevator throws on the airplane be done according to the maintenance manual BEFORE the pitch servo is installed. This can only be done by jacking the airplane to level and using travel boards. This step is a glaring omission on the STC paper work This will entail having the proper tools and understanding of how to do this job to check this item off the list. I would definitely NOT install the pitch servo without making sure the elevators are actually moving the correct distances up and down per serial number I have seen too many airplane out of rig to not do this important step. Only the full elevator rigging procedure should be done No short cuts.1 point

-

With no options, local hangar fairies in my vicinity would be hard at work fabricating a pointer1 point

-

Wow. I just can not comprehend spending 1500-5k on a guy to polish my plane. Thanks for motivating me to spend $50 bucks to purchase compound and waffle pads to do my plane myself. Honestly my plane looks great from 10'. Really not a high priority for me, but an excuse to fire up the heater and hang out with my plane.1 point

-

There is no certification project in the history of the FAA that tests every possible combination of events that are related to the product being certified. That is NOT how engineering is done in the real world. The best practice is to identify the boundary conditions that are safety related and to make sure that each of those is fully tested. Example 1: If there is no detonation using the fuel on an engine with 8.7:1 CR and CHTs at 500 dF and 24 degree timing and operated at 130% of rated power - - then there will, with a high level of certainty - - be no detonation on any other 8.7:CR engine operated at 22 degrees timing and 100% of rated power. Example 2: GARMIN does not test a new radio in every aircraft. They pick representative aircraft. Based on the results of that testing - - they obtain approval for use on an Approved Model List of aircraft (AML). The FAA followed the same kind of logical engineering approach to G100UL avgas, as it did for the mogas STCs, 20 years before.1 point

-

For preheating - I got a 30$ space heater from Amazon, some 4 in dryer duct, and a flange with a round 4 inch transition. screwed the flange to the space heater outlet, connected the duct and put it in the cowling. Will hear me to 80 in no time at 15f. total cost about 50$1 point

-

I prefer an on/off toggle switch so I used this one https://www.aircraftspruce.com/catalog/elpages/togglevalve11-12168.php1 point

-

Bladders add 37-40 pounds, but they effectively end the risk of future fuel leaks. Plenty of airplanes on here lamenting fuel leaks, but none lamenting bladders leaking. Theyre made of really thick rubber, about 3/16". and theyre durable. We just did a set of fuel bladders for a PA30 Twin Comanche. The bladders in these are very thin and flexible. About 1/32" thick. But guess what, 3 of the 4 were original 1969. One was leaking a little, so we did the whole set. I had the 10 gallon add on kit added to my plane a couple years ago. This requires removing the outboard bladder and gluing a nipple onto it to connect to the new bladder. Still supple, still great condition. It was installed in 1992. So I guess were good for a while. We do patch wing tank fuel leaks occasionally. You'd be surprised the crap we see. People use non-approved sealants, or they dont mix the approved sealant properly. They dont prep the work, they dont find the leak, they smear it with their gloved fingers. We recently fixed a wing tank that the client paid amost 3K to a well known east coast MSC. The sealant was light gray and it was gooey like putty, it was the wrong stuff, not mixed right, or both. The tank was leaking again after half a year. We've got a 177 Cardinal in our shop right now actually, it was leaking from the outboard corner of the wing tank, the owner is working with us on this, he pulled the top cover off, was sealed with orange RTV and it was gooey and smearing off because it's not supposed to be there, the end board corner of the tank had at least two different kinds of crap smeared all over it, and it was leaking underneath that. After spending the better part of two days, stripping and scraping and stripping and scraping, it's cleaned up enough where we can probably put sealant on it now. Point being, sometimes properly and accurately fixing a wet tank Mooney leak can get very expensive. One client just paid nearly 30 grand to get his 100 gallon tanks stripped and resealed. Prayer is not a strategy. I'm not saying take your plane to O&N and have bladders put in it, but I would say that if the plane has bladders and they're not leaking, that is one $20-$30,000 repair job you're probably not gonna have to ever worry about.1 point

-

Brian my Bravo was one that ran ok LOP but I lost considerable true airspeed, on long trips I just dialed it back to say 24/2400 and 15 GPH for good range, my Acclaim is opposite loves LOP. Although the continentals top are suspect. All a trade off.1 point

-

Just a curious thought- Did the landing fees go up AFTER the contract was signed with Vector? Is there an "administrative fee" attached to the bill? who pays Vectors "cut"? The airport sponsor or us through a additional fee? As one who ran a Pt 139 airport for a short while you have no clue how "clueless" most city councils (cities are the airport sponsor in most cases) are on anything let alone running an airport. All they see is the ability to collect revenue and nothing more. Beyond that they have blinders on. In some cases the FBO leases the ground for the tiedowns and ramp from the city. In some cases not. If they do I can see them wanting to recover those costs If not, its a financial gain using publicly paid for property (the ramp, FAA grant). If the city is part of the later then they are complicit. Every city wants an airport, not many want to pay for same. We pay fuel taxes for airport improvements (ramp resurface), do we then have to pay again to use that improvement (FBO access fees)? Airports CAN charge a landing fee IF they want. Many cities don't so as to attract business to the city. Every city that accepts Fed funds has some sort of study compiling the value to the city that the airport represents. It is still my opinion that IF the airport sponsor accepts Fed funds to keep the airport alive then they should have to provide a set number of tie down spots, rest room access and gate access on and off the airport as a condition of Fed fund acceptance. If they want to limit access to their city through a private company (FBO) with an exclusive contract for the entire airport then then the "gate fee" should be controlled by the city council and not the FBO. If the city wants to charge a fee so be it. At least an elected body is the determining factor. If the city (another name for Airport Sponsor) wants to charge BOTH a landing fee AND a 'Gate Fee" so be it, It should be transparent that is the city doing it. having the FBO do it only transfer the angst away from the city (which is what they want as elected officials). I started a conversation with Baker many years ago about FBO fees and the locking up of airports to no avail. I've been an AOPA member since the 1960s and I support them just because we need all the voices we can get BUT I think they have gone too far into a merchandizing company than an advocate for GA. JMO As to the analogy of fees for state parks think of it as the park is a "destination" in it self and not just an access point to a city. Park fees are fine IF I WANT TO GO TO THAT PARK. If I want to go to a city I don't pay a fee to get off of a Federally funded highway to enter the city- DO I?1 point

-

Even an annual can be misleading. The plane I recently purchased had what I would classify as incompetent maintenance. They didn’t do any SB’s, a lot of things done improperly, and a lot of things well out of spec. Original landing pucks from 2006, original brake fluid, original mags one of which has never been overhauled, the list is not short. Same 3 or 4 shops did all his annuals, none of them mooney’s service centers.1 point

-

All too common. It seems many new Mooney owners get their initial instruction from their Cessna or Piper instructor with very little Mooney experience and are taught to use much too fast of a final approach speed. We see it at PPP’s too. The same poor instruction leaves the new owner deficient in learning to properly trim the aircraft leaving them unable to slow the aircraft. I expect the complaint about RPM was a red herring. Not going to be able to get the rpm much lower going over 100 kts with the airspeed turning the prop till the plane slows down. Add in leaky brakes, worn pads and a tail wind and it just underlines the need to go around when not properly established and stabilized on final. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Those of us in the Socal area having been dealing with this for over a decade. It’s old news and the discussion reminds me how many of felt about this years ago. I am a bit surprised how much this is expanding. But we’ve always been use to paying fees of some kind, such as ramp or facility fees and really i don’t see any difference here when the airport is collecting it. It seems they have the right to do it and frankly we take it for granted how good we have it here versus outside of the US. FBO have to make millions in infrastructure investments to get their lease so we can’t really deny them from being able to charge for their use. Our first airport to do this was SMO and it seemed as much as method to discourage using the airport as much as anything and more recently Torrance started it too to discourage traffic. But Catalina has always been charging but different since a private airport. Sent from my iPhone using Tapatalk1 point

-

1 point

-

G100UL is what it is. It isn’t like George is going to fix it. It seems to burn well in out engines, but eats our paint. I hope flying with paint stripper in our tanks isn’t our new reality. If it is, we will eventually learn to deal with it. And we will have to pay for the mitigations. Sucks….1 point

-

1 point

-

1 point

-

I was in a meeting with a local airport manager recently, and just saw a communication from another. The airport managers see this as a vital tool to help keep their airport open in the face of increased cuts to funding and grants, etc., especially at the state level. At least one of the busy GA airports in the Phoenix area has started using this to track, at the moment, commercial traffic for assessment of existing fee structures. Many busy GA airports in the US get federal grants based on the number of operations, so being able to accurately track that is beneficial to the airport and may not involve any fees to users. There's only one airport in AZ that I'm aware of that is using it to collect fees, and they've made an exemption to anyone who buys even 1 gallon of fuel at their pump. They're a smaller airport who gets their grants based on the number of aircraft based there rather than operations, and their expenses were starting to get dominated by traffic from the large flight schools who do numerous touch and goes and never stop. Since the big schools around here have bulk agreements with fuel vendors on their fields, when they go somewhere else, they won't buy fuel there. Evidently they got tired of expenses for things like replacing struck runway lights, etc., with no benefit from the traffic. So the service itself seems to be useful to the airport managers, and since they're the customers to the system it seems unlikely to go away. Whether and how it is used to collect fees from Part 91 GA folks seems to be TBD, at least around here.1 point

-

Years ago I bought this really high end Italian oscillating belt sander. It worked really well for a few years and then the oscillating part stopped working. I took the machine apart and found this helical worm gear made of bronze. I hunted for the company only to find out they had gone out of business years ago and if I couldn’t get the gear the machine was scrap. Well, a new machine of this size and quality was over 20k so I started looking… I ended up finding a shop in Columbia (the country) that would to produce the part for $75. I ordered three of them and zip tied them into the machine near the gears… I’ve used one more set of them and apparently this was a part designed to wear to spare the more expensive parts. sorry for the tangent but my ocd required me to complete the story… point being, I’m not going to retire any machine I own for some part that I know I can figure out a way to replace. I understand there are some things on the plane like a turbo housing, or a crank that are far too complex and critical to produce yourself, but the FAA treats too many things as critical, that just are not so on our little planes. Good machinists all pride themselves on being able to do complicated things, and they are extremely knowledgeable about metal and its properties, those gears are not that hard to manufacture, and I’m willing to bet if you knocked on enough machine shop doors you would find somebody willing to make them.1 point

-

Speaking on behalf of every American GA pilot , we are not accustomed to it in the US and are enthusiastic about not becoming accustomed to it.1 point

-

I think the leaks and stain should be separate questions.1 point

-

I would want to have, in my scan, an AI that's failing and tumbling in IMC while my autopilot is following it.1 point

-

Welcome to MooneySpace. We love it when vendors hang out with us. You may take flak from some, but there is a larger number who will read and learn from your posts.1 point

-

CB opinion here: Save your money and polish/buff/wax yourself. My plane was painted with Imron back in the mid '90s and still shines nicely after buffing and waxing. Does it have the 'mirror look' of @exM20K's? NO. But, I'm only out 0.2 AMU (including the cost of the Home Depot buffer).1 point

-

1 point

-

1 point

-

So I got a Starlink mini (mainly for Hurricane Preparation here in Florida) and I decided to temporarily upgrade to the $250 plan and throw it on the glareshield of my Mooney. Heading north (Orlando to Charleston), it worked perfectly. Over 100 Mbps at times. I didn’t find it to be in the way at all. Heading south, this evidently didn’t provide enough northern sky view so it would get stuck and refuse to initialize fully (“Calculating orientation”). I decided for fun just to hand hold it up to a side window and point it as north and east as possible. And it finally connected. But the interesting thing was, once it connected, I was able to throw it back on the glareshield and use it just fine! It held connection that way with no noticeable drop in speed for close to another hour, including a few course changes. If anyone else decides to try this, try that if it gives you trouble. I sure wish the mini had been available when I went to Alaska. Wasted $600 on a used Iridium satphone and $500 or so on 200 (very slow) data minutes to get in-flight weather in Northern Canada. I’m willing to bet Starlink would have worked much better!1 point

-

Hey JT! I wanted to thank you for your kind note and words of encouragement. In fact, I located this post on my own a while back and meant to respond but as you can imagine it was easy to get sidetracked. So please accept my apology for the long delay. To your point, I think it's important that the Mooney Community have access to the company. As a Mooney owner I never felt a connection to the company even though I relied on the engineers, metal workers, electricians and other artisans every time I turned the key in my 201 or Acclaim. I'd like to change that dynamic and as you've probably gleaned from my interviews, reconnecting to the Mooney Community is a priority. In the coming weeks we'll be building out a new website and it will allow me to communicate with Mooney owners and advocates more directly. Eventually, the site will also invite participation from the Mooney Community so everyone can have more of a seat at the table so to speak. As you correctly pointed out, we're working to get over this "first hill." I'd be dishonest if I told you it was easy. There is a reason Mooney finds itself in the position it's in and it will take an awful lot of work to undo some of that and get us going in the right direction. But the one thing I am confident of is that Mooney is still the best single engine piston out there and always will be. "Like flying a Ferrari in the sky" I like to say. That reputation still has some gas in the tank and I promise to do my best so that Mooney can rise again. In the meantime, we'll keep the parts going and look to offer improvements to the fleet. I probably won't have time to respond to all the questions and suggestions I expect will be posted, but I promise, I will read each and every one. Thanks again, JT Best, Jonny Pollack1 point