Leaderboard

Popular Content

Showing content with the highest reputation on 11/13/2023 in all areas

-

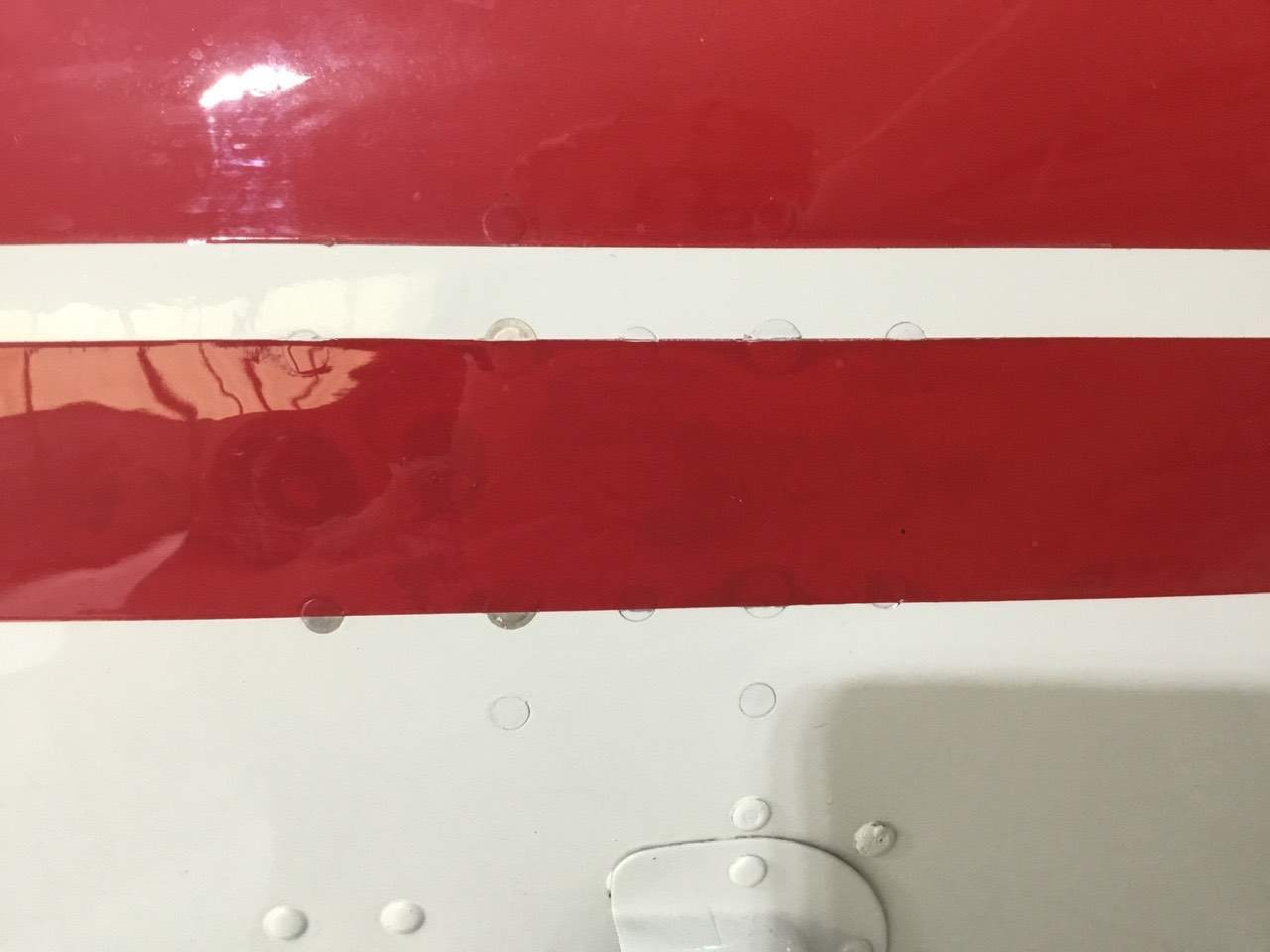

Picked up my new baby over the weekend. ‘95 Bravo, 1900TT, 10 SFOH, 10SNP. Geared up in 2021 & fresh off those repairs. Has a KFC150/297, a G600, just added an Avidyne 440/540 stack, and yes she needs a modern Engine Monitor sooner rather than later. The current AMU bill is at 24 and another 18 + labor is planned after the Maxwell’s clean up the pre-buy items. Needs paint & carpet, but the seats are in decent shape. Still working on the flare, I’m used to being 60’ in the air when the mains touch, not 2’.7 points

-

It did. The M22 resulted in the Mooney 301, which lead to today's TBM series from Daher/Socata. During the brief Mooney/SOCATA partnership, the name “Tarbes Built Mooney,” or TBM, emerged and has remained to this day. https://www.planeandpilotmag.com/aircraft/mooney/mooney-301/3 points

-

The “eight second ride” is about a nose wheel caster adjustment on pre-1977 airplanes that may not have been set up correctly at the factory. It is covered by SBM20-202.2 points

-

Sounds great. None of this is ever cheap. i had had my Ovation for four years and still working on flare. Nail 75 kts. hold it off stay stable, no changes and be patient. Mooneys like to float. you cannot force the landing. so much fun AlAN N913ND2 points

-

2 points

-

I'd get whoever wrote that note to tell you what they'd replace or adjust or fix if you approved the work, i.e., where they think the play is coming from. There's more than one thing that could be "addressed", and it may or may not help, depending on where any issue may actually be. Do you have any trouble taxiing? Does it make clunky noises sometimes? If your airplane isn't having trouble, you can probably leave it alone. There's a steering horn that can get sloppy with wear and can be improved with shims. It's fairly easy to determine if the horn is sloppy, you can grab it and see if it wiggles around. There are also steering rods with spherical rod ends that can wear and get sloppy. There's also a potential issue with the front pucks mount as well. There's also a certain amount of natural slop tolerance just due to how the thing is designed and how old the airplanes are. Six+ years ago Maxwells did the PPI on my airplane and indicated that the steering horn was getting sloppy and was going to need a shim soon, but that it was okay for the time being. I just reshimmed it this fall, so "soon" turned out to be quite a while. You can ask for clarification from the author of the note, and/or get another opinion.2 points

-

You guys aren’t understanding the purpose of Experimental, there are two reasons that come to mind. First of all there are several different versions of “Experimental” like market survey for example which allowed me to fly an uncertified aircraft pretty much anywhere in the US to allow others to see and fly it. Or a way to fly Warbirds that were never Certified and in fact don’t have a Type Certificate. But very often it’s one of two. 1. Gives a manufacturer and or others a way to develop aircraft or it’s subsystems. 2. A way that an individual can build their own aircraft. It’s not a way for someone who doesn’t like the FAA rules and doesn’t want to put the work required to build their own a way to take a Certified aircraft and do as they want. From my dealing of selling aircraft and providing maintenance support in over 85 Countries I can tell you that the US regulations are pretty much the most lax in the World and give owners rights and privileges that the majority of the World can only dream of. If you don’t like dealing with FAA rules and regulations, sell your Certified aircraft and you don’t even have to build your own, your allowed to buy one, and without looking very hard it’s not hard to find very new low time home builds, it’s pretty obvious that some pretty much manufacture kit planes as they build and sell them on a regular basis, which isn’t allowed of course but the FAA looks the other way, like the two weeks to taxi programs, anyone who honestly believes a person can actually build 51% of a decent airplane in two weeks is mistaken, yet such programs exist. The FAA is pretty much bending over backwards to allow individuals freedoms in the US that just don’t exist in most of the rest of the World. Trust me, the majority of the FAA wants to wash their hands of our old, single engine toys and concentrate on what they see as providing service to the taxpayer, the Airlines. In private most will admit that they see oversight of little airplanes as a waste of taxpayers money for rich men’s toys. Some of course understand that our little airplanes are job security for a whole lot of them Every year that goes by, Experimental makes more and more sense, parts are usually available and if not just build your own where possible, our aircraft get older and parts less and less available at any cost. Try to find a new landing gear actuator for instance. To be truthful if I wasn’t an IA I wouldn’t have considered a Mooney, and even then I almost bought an RV-7, and whenever I have to search for almost non existent part I think I should have. I often think I should sell while selling is good, because I think when 100LL goes away, my airplane will lose a huge amount of its value.2 points

-

Glad you're okay and able to share the story. That appears to me to be the usual Swiss cheese accident, where multiple unusual factors piled up to conspire against you. Can happen to any of us, and I'm glad yours wasn't worse. FWIW, and for anybody else in a similar situation, if you can't hear but you can transmit, it's always okay to transmit anyway, and end your transmission with "in the blind" or "transmitting in the blind". That tells whoever can hear you what your intentions are and that you probably won't be able to hear them. Since you didn't have a transponder you couldn't squawk 7600, so that's a way around that. +1 that distressed aircraft always have right of way, so when there's a situation with an increasing number of Swiss cheese holes, do what you need to do. It's one of those times when it is better to apologize than to ask permission. Thanks again for sharing. It sounds to me like you did a lot of things right, and I'm sure you don't need anybody else to beat you up about the preventable parts.2 points

-

On the test flight, it felt "normal" but as I am just learning Moonies, not quite sure if it should be better than "normal". No control concerns, and definitely no shimmying in the limited time in plane. Thrilled that the annual is getting done in lieu of a pre-purchase inspection. Rob1 point

-

As I mentioned before I tried to contact them but they never returned my calls, emails or texts1 point

-

Bet the first thing they do is trace out the wires and find they basically go nowhere and are tied off someplace behind the panel.1 point

-

My M20K has been a solid and reliable performer with reasonable maintenance expense over 18 years of ownership. I love the flight envelope options afforded by the turbocharger, and I would never buy a NA Mooney after experiencing the benefits of flying in the mid-teens.1 point

-

Well, obviously if it shimmies, or directional control is compromised, it should be fixed. But that is something that will be obvious and doesn't come on suddenly. The OP wasn't complaining about steering issues but asking what to do about a notation that a maintainer made that the steering has "excessive" play. The truth is that they all have some play in them even when new because of the design and there is no spec on it and so how much is too much is determined by the owner and the maintainer.1 point

-

Reading thru this thread again makes me so thankful for the shop that takes care of Myrtle. I couldn't be happier with the guys that keep her in great shape. The only bad experience I have had is with the shop that did my avionics upgrade...and it was a very painful experience indeed.1 point

-

That sounds about right from back when i flew my 231 without the Merlyn, but @jlunseth has a lot of time in a 231 and maybe we can get him to chime in1 point

-

Good advice. I'll try to scope the leading edge and go from there. Still waiting to hear from my AI. He's MIA.1 point

-

oh yeah...when the engine quits a life has gone....you only want that to happen on the ground1 point

-

Okay guys…I’m the first to admit I’m naïve about many aspects of Flying, still relatively new and wanting/willing to learn so constructive feedback is always humbly appreciated.1 point

-

Most likely the transducer or the wiring going to it. Here's a 'cheat', swap the fuel pressure and oil pressure transducers, see if the red X goes away or moves? Don't start the engine with transducers swapped, they are different pressure ratings.1 point

-

1 point

-

As previously mentioned, I am having a heck of a time getting them bled. My mechanic insisted on doing the same thing over and over.....that is another discussion. I think the problem is that the dual brake systems during traditional bleeding simply passes the air bubbles from side to side. What eventually worked is forcing fluid from the caliper up and out from the reservoir, I removed the master cylinders and allowed the air to flow upward, just doing that I could see the bubbles move up and out, shook them around a bit as well and that made some difference.1 point

-

I would start from the engine, wiring of the sensor can be broken by careless maintenance, then check the connections of the sensor wires to the wiring harness. The wiring into the display is the last thing I would check unless you have had some work done behind the panel recently.1 point

-

Probably pressure sensor on the firewall or the wiring into the display.1 point

-

Congratulations! Nice airplane and a lot to work with there to make it your own. I was in the same position as you and I installed an LHS and placed it on the "experimental setting" with 1 foot call outs. Really polished my landings. The other day I landed after some avionics work and realized after landing the LHS was off, yet I greased it so the "training wheels" are no longer needed. It still is valuable for those dark and stormy nights after breaking out.1 point

-

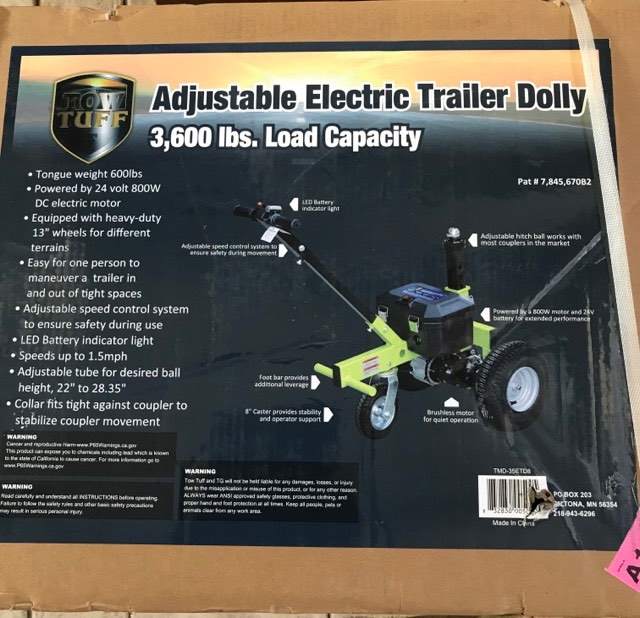

There is already a tab on my browser open for one of these. Just a matter of survival until I put it in during the next annual.1 point

-

1 point

-

The nose wheel steering is not one of the strong points of the Mooney design. There is no spec on the play that I’m aware of. Blocking the pedals is part if the rigging procedure and not normally done during inspections. If you are happy with it and your IA considers it airworthy then leave it alone. The worse that happens is that you have to do a lot of footwork to taxi straight. if you want to fix it, it’s fairly simple to put it on jacks and replace the parts with the most slop. In my case, I greatly improved it by taking it to an experienced MSC. They shimmed the steering horn and replaced a couple of rod ends. Didn’t cost much and it taxis much better now. Skip1 point

-

Man, things are just funny sometimes… Changed the oil today just to get that done. While I was in the area, I looked over the hose that goes to the fuel pressure gauge. I notice it appeared a bit loose so I tightened it up. Did a startup - fuel pressure was @ 6 PSI - seriously. Ran it for a few minutes @ 1000 RPM. Shut it off, slow bleed off. ‘Well , that is normal…’ I said. Got out, checked things over for no oil leaks, restarted it, 6 PSI - normal again. Switched tanks - still normal (5 to 6 PSI). Ran it 5 minutes, shut it off, slow bleed off of pressure- its back to normal again. I still want an A&P to verify pressure. So strange but, she did sit 3 weeks. I guess I’ll keep an eye on it. I’m going to do a full run up next and then pattern flight to confirm - if the run up shows normal… -Don1 point

-

Too bad you didn't fly a pattern to draw little hats on them- it would look to me like "Spy vs. Spy"1 point

-

I guess this is the time for MP/FF or FP gauges to fail. Someone else (guess on FB) was just asking. Mine failed recently and I could not find a replacement or parts anywhere. Someone told me about Aerospace Logic. They have MP/FP (also MP/FF) gauges. A couple of gotchas to be aware of: Transducer: The device can only be installed with THEIR transducer, so if you have a JPI or any other device with Fuel Flow you CANNOT piggyback on their transducer. My mechanic put in an extra log piece of fuel line and put my old transducer inline and did some fuel flow tests and signed off on it. Long line was to make sure there were no flow issues to mess up the other transducer. Dimmer: The unit was originally certified for DAY VFR so they never installed a photocell or any dimming capability. And it is VERY bright. So if you do go with them, be sure to get their optional Dimming Package for a few extra bucks. https://www.aerospacelogic.com/engine-instruments/fuel-and-manifold-pressure/1 point

-

Saying that 85 other countries have even dumber rules than our FAA doesn’t really make them good, it just means they may suck a little less. Regulation is obviously a necessary evil, and I don’t object to regulations, just the nonsensical foolish ones. The FAA is spending tens, maybe hundreds of millions of dollars, trying to thwart warbirds from being enjoyed, and even when they discovered the horrific unintended consequences of their folly, they doubled down instead of adjusting. Meanwhile, they ignore basic things that could actually make aviation safer. They are a gigantic, bloated, feckless bureaucracy that is so convoluted and filled with dead weight employees it’s arguable that it does more good than harm. Under the FAR concerning experimental, you could technically take that plane apart to the point it satisfies the percentage of building regulation, modify and restore however you want, and then register it as experimental. The point is if that is possible, why not allow conversions of planes that have no support? I seriously doubt most people with the intelligence and funds to build an airplane are trying to avoid maintenance, but who wants to pay more for something just because? Look at the cost of an experimental avionics vs certified. There is NO difference whatsoever in how those units are made, nor how they function, they are identical, yet one is an order of magnitude more $$$. The vast majority of the rules appear to do little for efficacy, safety or economy, most seem to be just for the sake of a rule, as useless and arbitrary as it may be… perhaps some of them made sense 50 years ago but many of them are obsolete now There are many simple rules that would make aviation safer overnight, such as requiring all planes to have a radio. This is not a hardship today, but would make uncontrolled fields a lot safer. They could also mandate Adsb in and out for every plane so traffic was available. The challenge is that the FAA uses “safety” as a shield for all of their idiocy, just like every other bureaucracy, they get caught in the petty power struggle rather than efficacy, and they have no competition, and no ability to self regulate or evaluate. All they do is pile new dumb rules on top of old dumb rules… The FAA need a genuine overhaul for, top to bottom.1 point

-

I’m going through this right now. I just finished resealing both master cylinders. One has been weeping for a while. Not as bad as what you’re dealing with, just enough to form a thin sticky line of 5606 on the outside of one cylinder. I elected to do the parking brake as well since I was draining the system completely to make the switch from 5606 to Royco Synthetic 782. If you’re doing it under supervision, be sure to mark or measure the location of the rod ends before disassembling the shafts.1 point

-

1 point

-

That dent would be insignificant on a Thrush, but we used a NACA 4412 airfoil with a 1.5 degree washout, that’s a very conservative relatively high lift but pretty high drag airfoil that has exceedingly good tolerance for things like dents, ice build up etc. Very forgiving. However the Mooney airfoil I’m sure isn’t nearly as forgiving, because it’s so efficient TANSTASFL Only reason you would need a factory skin is if you don’t have access to a roller to roll the leading edge shape, rollers are pretty common. This shouldn’t be a difficult repair but will be a labor intensive one. Oh, there IS guidance it’s AC 43.13, newer aircraft have structural repair manuals, older ones relied on FAA guidance. The FAA has been pushing manufacturers HARD to publish structural repair manuals, because they don’t want the liability anymore and have been gutting 43.13 of a lot of the most useful data. They, the FAA have tried taking the interesting tact that without a structural repair manual which among other things list whats acceptable damage, that without that, that means NO damage is allowed, which is silly. On edit, I believe the location of the ribs is easy to determine by the rivet lines. I believe if I were doing the repair I’d cut out the damaged area out and roll a flush patch to fit, with just a little skill a flush patch is invisible, most bad leading edge dents on Ag planes are flush patched if it’s a nice looking airplane. I had two great BIG Vacuum venturi’s on my 140 that I removed, left screw holes and a 1” hole. A friend who is talented cut out that section and put in flush patches that when painted disappeared without even body putty, and this is on the beer can thin C-140 fuselage skin. See pic, it’s been 15 years and for some reason the white paint didn’t bond to the rivets, poor prep I’m sure. With just a tiny skin coat of body putty you would never know the rivets are there and you can’t see the patch even without putty.1 point

-

1 point

-

Anything for me next year, since I passed 1000 hours this summer? Should reach 1000 in my Mooney by renewal, if I can keep both of us airworthy.1 point

-

Your concern for a threat that didn’t really exist led to you giving up on your primary duty - AVIATE. Really, that was your only duty. You didn’t have to communicate. You didn’t have to navigate. You never left the pattern. Your primary job is to fly the airplane. You don’t need radios to do that. Look outside. I’m sorry your plane was destroyed, I’m glad you weren’t injured. You reached in with both hands and grabbed a pile out of your luck bucket. Shove that into your “I learned about flying from this” bucket and use it.1 point

-

Aviate, navigate, communicate. If I’m in an emergency situation, especially at a controlled field, the last thing I’m going to worry about is traffic and ATC. That’s what they are there for. To figure out what’s going on a keep everyone safe. It sounds like they were doing their job, when they said you were number one for the runway without you asking. I would have done a normal pattern entry at pattern altitude like at an uncontrolled field and announced my turns and such hoping the tower and other airplanes can hear you. Just like at an uncontrolled field, your best chance of seeing and avoiding other traffic is when everybody is where they are expected to be. Also remember, it is your job to see and avoid other traffic, it is their job to see and avoid you. Especially in an emergency, you shouldn’t be worried about doing their jobs. Im glad it worked out as well as it did and everybody is safe.1 point

-

1 point

-

Certified planes cannot be converted to experimental and be used as a conventional GA plane for business or personal use like experimental amateur built planes can be. Certified planes are temporarily moved to experimental for things like STC development, R&D, exhibition, etc. Those categories come with restrictions about when and where they can fly, who can go, etc, so it removes almost all of the utility that we enjoy with regular Mooneys. Sent from my motorola edge plus 2023 using Tapatalk1 point

-

I recommend it to everyone with whom I fly. One of the best "bang for your bucks" in aviation today. With it you can forget the "bang" when it comes to the actual landing. Nidal is also totally responsive to any question you might have.1 point

-

1 point

-

I think there may have been a bit of an "I can't have her anymore so no one will" sentiment. This guy still felt sharp when he hung it up. He quit flying because he lost his stomach for the risk of instrument flying and VFR only flying was so boring to him that it was not worth it to continue. As much as I like XC travel, the most fun you can have in an airplane is in a low powered, tail dragger...preferably with tandem seating and the wings on top. I feel sad that he was blind to the absolute joy of flying for the sake of flying.1 point

-

The reason to connect the pitot during a static test is so the ASI doesn't overspeed, i.e., wrap around past redline, as you take the altimeter up to 20kft or whatever your guy does during the test. The way this is done is just to connect the pitot to the same pressure the static port sees during the test, so the ASI always reads zero during the test. Yanking the pitot part of the tester off before the static ports come back up to ground pressure will yank the entire system from altitude back down to ground (because it is just like popping the entire tester system off at once). The first thing to go will likely be the VSI which might peg past the down limit. On my tester there's a valve that separates the pitot side from the static side, and two pumps. If you shut the valve off so that the pitot and static systems are separate, you can use a pressure pump to pump the pitot side up above the static side and do a pitot leak check. The static side is kept open to ambient pressure during this test. After that test is done you turn the pressure pump off and bleed down the pitot pressure so the ASI returns to zero. Yanking the pitot test tube off before the pressure is bled down can definitely damage the ASI. You can then open the valve that separates the pitot and static sides and turn on the pump that pulls down the pressure (on both sides, since the valve that separates pitot and static ports is open) and the ASI will stay at zero while the VSI indicates climb and the altimeter winds up to the desired altitude. If somebody started off with the separating valve closed while pulling down the static pressure the ASI would start winding up and can go past redline pretty quickly if you're not paying attention. If they then go, "Oops..." and just open the separating valve to fix the mistake, it slams all the air instruments around a bit, particularly the ASI. Similarly, mine has valves between the system and the two independent pumps to control the rate at which they pressurize or pull down the system, and if you turn either of those the wrong way or too much during operating it can go badly. There are also "bleed to ambient" valves on each side, that if you turn too fast or the wrong way you can cause problems. I bought my tester as a derelict off ebay and rehabbed it with new reference instruments, replaced some valves, fixed some leaks, and just generally got it working again. You can block the test ports and fiddle around with it to get an idea of how to operate it, which I did quite a bit before ever taking it near an airplane. The number of ways to screw up a test and damage an instrument is very large, and I'm not at all surprised at how often it happens, since failure modes that can damage instruments include not only mishandling or operating the machine, but if a test line pops apart or disconnects somewhere at the wrong moment or falls off the static ports or opening the alt air static port or whatever. I get the jeebeez a bit whenever I have to do it. My transponder cert guy, who was also my DME, suggests one way to mitigate risk is to disconnect the static line in the tail and use a threaded fitting to connect to the tester. This can also be done at the pitot tube with a little more work (and apparently often is with the weirdo pitot-static masts like Pipers, et al, have). So, yeah, it's a risky operation on a good day, and an inexperienced or marginal operator or marginal equipment or just bad luck can make it worse.1 point

-

Maintaining an airplane is a hassle. These things were designed 70 years ago and many are at least 50 years old. As one mechanic once told me, "When they fly, they break. And when they don't fly, they break." Here's how I do it (and not without some pain ) 1. I have always done as much supervised maintenance myself as I can. This includes annual inspections. It helps me stay up on the status of everything. 2. I try to fix every issue as it occurs because I know from experience that each one may involve unforeseen complications and take a lot longer to resolve than expected. I like to focus on one problem at a time. 3. The annual is the annual. The airplane gets inspected and serviced. The only things that get fixed during annual are discrepancies found during the inspection. If discrepancies are not airworthiness items and cannot be fixed expeditiously (perhaps because of parts availability) they get scheduled for a later date. 4. I maintain good relations with several shops. I know which are the best for certain types of problems and take it to the shop best suited to deal with that issue. Not every shop is uniformly good at everything. I also keep up with the maintenance literature from Mooney and Garmin. It's hard for a shop that maintains multiple brands to keep current on them all, and I find that they always appreciate it when I have done the research. Skip1 point

-

Before you sell and plan to do all your own maintenance, find a shop that will let you help on current annuals. Then take 3 or 4 days off and do everything you want, and supervise what they do. It’s really the best of both worlds because you know everything that’s done, yet you don’t have to do anything you don’t want to or don’t have as good of skills for. But you can personally do everything you want to your specifications. And you get an appreciation for how long it might take to do 100% yourself.1 point

-

Yea, The above story got even worse... I discovered that the instrument lights they were supposed to fix (and claimed they did and charged me for it) still do not work.. So I still have 3 instruments that have no lighting and cannot fly in the dark. I don't even know what to do now as it requires removing my instrument panel to fix the lights. I didn't bother posting about it because I am completely dejected about the whole thing. In 4 years my situation is going to change and I will be abandoning certified aircraft for experimental, this is no longer tenable being at the mercy of bad maintenance. Hope you have a better experience.0 points

-

@Alan Fox @Deb @carusoam @Hank @LANCECASPER @mooniac58 @Marauder @Skates97 @gsxrpilot @bradp and lots of others. May I all ask you please to send me an E:mail on Andrew@andrewhyett.com, include your telephone details as well please. 3 weeks ago I was happily flying baby, when I got a call from my Doctor telling me I had anemea, following a routine blood test. Referred to the relevant clinics and a quick Biopsy revealed the worst. We went to the consultants on the 24th October thinking "oh a bit of chemo and it will all be well", but were told "I might make summer, your TP53 genetics are broken as well, we have no cure." I basically have MDS and AML (the doctors amongst you will understand) Needless to say Andrew and I are heartbroken as we were planning our retirement in France etc. If you can all drop me a mail, Ill add you to a mailing list so we can keep you updated on stuff. You have all been great friends to me over the years and Ill miss you greatly, but as the Doctor says "its just S H I T ". Ill never forget the support you gave to me in the refurb of Baby nor the same for when we got married. Lots of love Andrew PS Sorry to put this on here like this, but i cant seem to be able to do private message anymore.0 points