Leaderboard

Popular Content

Showing content with the highest reputation on 03/11/2025 in all areas

-

I concur, I have used both. Spirit is out in the nice suburbs, Cahokia is in a bad part of town, but it is close to downtown. I was heading to NY a few years ago and spent the night at Spirit. The next morning I asked approach if I could get a tour of Downtown. Their replay was "I need you to say you won't fly under the Arch". I said "Affirmative, I will not". They said they needed a readback. I said "I will not fly under the Arch". They then gave me an awesome tour of St Louis at 1000 AGL, right next to the Arch.4 points

-

I've got an easier way than all that- Its called DAY VFR ONLY ! :-) After 60+ years doing all the 200 & 1/2 I care to do I'm now enjoying 1500 AGL day VFR trips all over the country. Try it, you"ll like it.4 points

-

@Aaviationist It's hard to take your "advice" seriously when you seem to base it on a lot of doomsday assumptions made with very little information, and you're not reading the little information I am providing. I'm trying not to give a novel of a backstory on every question I ask but I do try to add relevant information. For example, I said the housing on the wingtip light was broken and replaced with the non-matching part, I didn't say I had the mechanic do because he had one on hand for cheap. I assume the old one got bumped at some point and it was cracked, again, no big deal. You assume this is evidence of something far more nefarious for some reason. All I asked was for advice on refinishing the housings, that's it. The trim boot isn't in great shape but it's there, and again, you're making weird assumptions about multiple paint jobs and coming up with interesting backstory on nav troubleshooting. The connector was clearly on when it was painted, and disconnected recently, as everything was clean. My mechanic opened up that area and showed me during the prebuy/annual, they must have disconnected the antenna for whatever reason and missed it when putting the cover back on. What's wrong with just saying "hey that jack screw boot looks like it's in bad shape, might want to check it out" without implying that complete structural failure is imminent based on half a photo? Maybe just chill out. The guy I bought the plane from is pushing 90 years old and he's had it since the late 90's, there's going to be a lot of little things that got deferred over the years. I have multiple mechanics that I talk to on a regular basis. I like sharing my "journey" but I don't really need or appreciate your theorycrafting nor does it add anything valuable to the conversation.3 points

-

If it was something that changed suddenly, you probably lost a phase in your alternator. Did you also notice an increase in alternator whine? This is usually caused by vibration cracking internal solder joints in the alternator. Losing a phase (1 of 6) will reduce the efficiency and total output of the alternator. Actually, there are two phase failure modes. 1. lose a diode by an open diode or an open connection and lose 1/6 of the output. 2. lose a stater phase and lose 1/3 of the output.3 points

-

Analysis will tell you the alloy. Lycoming can tell you what parts use that alloy. My mechanic likes to put the element in a big jar and fill it with solvent and shake it vigorously and then strain the solvent through a coffee filter.3 points

-

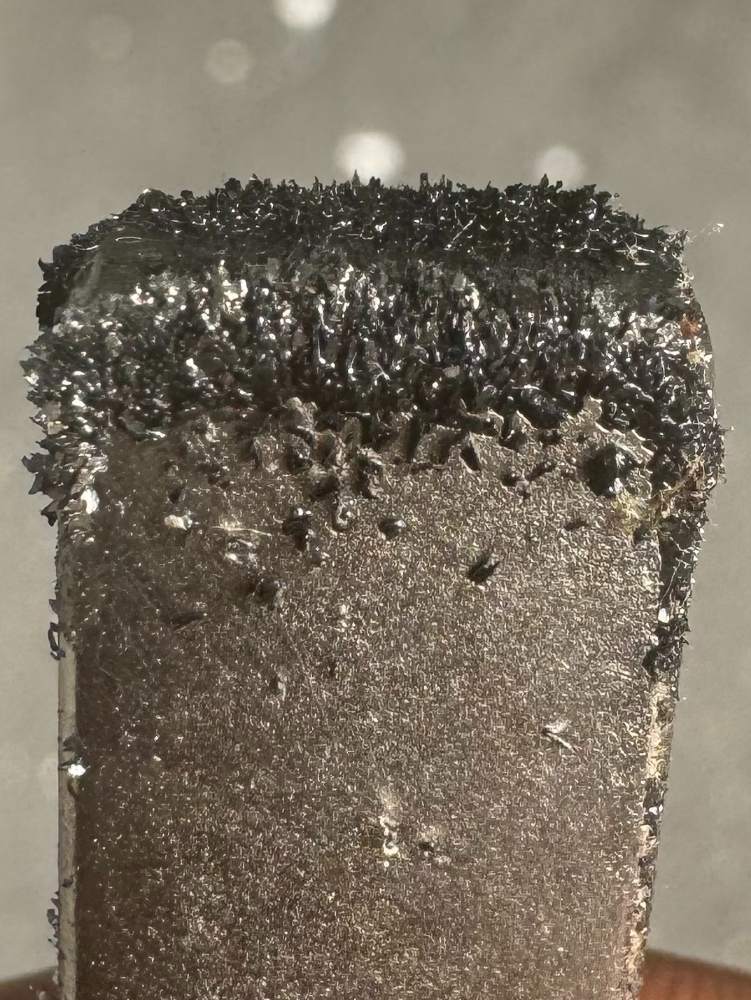

I think Lycoming's guidance is a teaspoon or two; that looks like a common magnetic retriever about 1/4" diameter, so you're still a tiny bit of the permitted amount. Watch it and see what happens in the future. Cutting the filter open at your next oil change may help, just realize that if it's at 25 hours and this one was at 50 hours, if nothing changes, you will have 1/2 of what you see here.3 points

-

Would have probably been simpler to hack off an antenna or get a 1mph speed mod to justify it being a 2023 points

-

2 points

-

Just began on my last flight. Cranking was normal. It dipped just below 12 on the taxi out and taxi in. There is a whine that I just recently noticed in the headset, so could be the alternator going. Thanks for the ideas2 points

-

Apples to oranges. You have a K with a Continental that uses a "coupler". The OP has a J with a Lycoming that uses a V-belt.2 points

-

I rarely use my brakes other than engine start, runup and stopping to park. I do brake gently when exiting the runway, but rarely feel pressure to make any particular turnoff; at home (5000') there are now only three runway exits--at each end, and one spot off-center since the FAA made everyone remove ramp entrances to the runway. When landing uphill on 36, it's an easy turnoff, but going downhill on 18 I often just roll to the end, as the exit is closer coming that way. In 1000+ hours, I've replaced my brake pads once that I remember. At 2575 gross, though, I'd expect much less wear than a long body with one third higher gross weight.2 points

-

So I just completed a basic training with a new student who bought an Acclaim Type-S. He had just gotten his Private license a few weeks earlier. I didn't have the time to teach him about the LA area so I referred him to another good friend and 787 Captain for additional training in the LA area. My friend objected to several items from my teaching: First, he wanted all trims set before taxiing, and second he really objected to my teaching where the aim point should be, about 400 feet before the threshold. That all sounds reasonable, right? Wrong! Set the rudder trim full right before taxiing and the plane will want to go right all the way down the taxiway because the rudder is connected to the nose wheel in the Mooney. Aim for the threshold and you'll have difficulty landing on a very short runway such as Oceano (L52) with the long body Mooney. I always teach to land assuming a short runway. Unless you have an extended amount of time teaching in such planes even a really good non Mooney instructor really wouldn't know that. I have a few hours teaching Mooneys (see https://donkaye.com/flight-instruction). Personally, I don't know of anyone else with more Mooney teaching time. I've specialized in Mooney instruction nearly full time for the past 31 years. I know how to control speed down to the knot and slope to less than a degree and I teach the same. So when I say the pucks need to be changed in the long body Mooney with the old 2 puck braking system about every 70 hours, it's not because I come in too fast. There was a reason Mooney changed to the 4 puck system. 2 pucks on a 2740 pound airplane are quite different than 2 pucks on a 3368 pound airplane. Of course you could land and not apply brakes and chew up a lot of runway. Of course you could aim for the threshold and sometimes due to obstacles you have to. But most of the time you don't have to. The 4 puck braking system on all long body Mooneys starting with 27-107 (mine is 27-106. I just missed it) was a big benefit and a worthy upgrade. I agree with the Rolls Royce comments having owned mine since 1979.2 points

-

Nav1 GS/VOR antenna connectors were reversed, and the coax at the tail was disconnected. VOR/ILS/GS on both radios all testing good now. Wasn't worth spending to rearrange and remount the radios flush right now, I'll just hold off until I do a proper upgrade. Has anyone stripped and buffed Whelen wingtip strobes? I have new tip sight lenses coming and one side doesn't match (replaced a broken housing). I was thinking of removing both to paint strip, buff and put them back together with fresh gaskets. I do have a little spare paint in a can and there seems to still be liquid in there, no idea if it's still good though.2 points

-

2 points

-

I would check the door fit. Over time, the hinge wears and gets some slop and the door can sag and when you open and close the door, the door and fuselage skins can touch in this area. When you latch the door, it will pull this edge forward and there will be a gap. When you unlatch the door, the skins can touch and then when the door is opened it could catch the fuselage skin if it’s not flush.2 points

-

OK I finally get it. Ovations and poor man's Ovations ie The Eagle are freaking fast. Picked it up yesterday flew 800 miles home in 4 and half hours. Made it south across East Texas in an hour. Mooney Zoom. Oh there is a F model with Dynon Skyview for sale.1 point

-

Got a loaner from the shop - seems this is not unusual for the GTX 327. Mine lasted 4 years since the last Garmin repair. This one totally died…Auto Pilot is gonna have to wait a bit… Got to fly a couple of hours so more engine break in. In 6 hours total so far, added 1 quart so it’s stabilizing… -Don1 point

-

And not be able to use Foreflight This goes round and round every few months on Mooneyspace Sent from my iPhone using Tapatalk1 point

-

Wow, it's come down. My first iPad mini (and my only iPad ever( was $300-$350 more than the wifi version. But for that $150 difference, you can get a Samsung wifi tablet with GPS . . . . And still have whatever the apple costs still in your pocket.1 point

-

The cellular version iPad is $150 more - when you sell it after a four years you can get at least $50 more for it. $100 over 4 years is $25/year (roughly $2/mo) for a ton of convenience in flying and in day-to-day life. I add it for $5 per month to my Go5Next plan. So $7 per month. Not a huge decision.1 point

-

The whine is the obvious clue you’re looking for in the alternator going bad. Just make sure that the whine isn’t coming from a passenger1 point

-

was this plane at Skywagons? If so it is a nice looking plane! good luck working through the few small items we all find with a new plane!!1 point

-

@Ragsf15e While I have an F, not a 252, the small line out of my air/oil separator goes to a 'Y' fitting on the rocker cover drain back tubes; i.e., back to the sump.1 point

-

It is. Sometimes essentially ripping the engine off its mounts. The attached report from memory rendered the aircraft unable to maintain altitude because the engine was mostly ripped loose and hanging down or sideways maybe but whatever it created a large amount of drag. https://asn.flightsafety.org/wikibase/36677 The cause of this prop failure was traced to “reactionless mode” and I think this high profile accident is what caused it to be addressed, essentially reactionless mode is a harmonic that causes extreme stress and therefore blade fatigue, what’s so bad about this mode is when it occurring there is no vibration felt, it’s actually very smooth, hence the name reactionless, but it’s why yiu hear some Pratt four and five bladed aircraft with such high ground idle speeds so high they sound like Garrett’s. I dealt with it by having the MVP-50T flash yellow if you were in the range instead of turning the idle up real high. https://hartzellprop.com/FAA/NE-06-13.pdf1 point

-

In a previous life I owned a Cherokee which I kept tied down outside. After a period of heavy rains I found quite a bit of water in the fuel, and discovered that the filler neck on one side was pitted. Immediately replaced the gaskets, and my mechanic did two things: 1) Sanded down the pitting till it was more or less smooth, but while being very careful to not get dust into the tank (I don't recall how he did that part). 2) Put some Dow Corning #??? on the lips of the filler necks and on the gaskets of the caps. (I don't know the exact DC number, maybe someone else here knows; it was a clear greasy substance.) This DC grease was reapplied at every annual, and every time I stopped by for other maintenance issues. After this I no longer had any problems with water in the fuel, even though I still kept that plane outside for a few more years. May be worth doing as a temporary measure, since it was a small ticket item. Could prevent bigger issues like what @cliffy said.1 point

-

Yes you need to run a strong rare earth magnet across the entire surface of the filter - you will likely find lots more. I bet what you have already is 40+ pieces though. This is what my magnet looked like when I had one cam-lifter pair spall...they are small flecks, likely very similar to yours on closeup, but very hard to count. Note this phenomenon may decrease considerably if you run it long enough to keep wearing down the cam lobe, and the only operational difference you may notice is subtly decreased power. BTW I do all my own oil changes, but when this happened I had gotten lazy and was only cutting open every other filter. I pulled the previous one off the shelf and found the same thing. I flew it one more time after that, to the engine shop.1 point

-

@jeremyc209, you might want to reach out here for the fuel filler parts:1 point

-

Again, based on your findings, it sounds like you are at the beginning of your maintenance journey. must have been some hangar! id strongly recommend you check all the controls and surfaces for proper assembly. What you found suggests those connections have not been assembled properly since it was painted. And nobody bothered to check. get someone to look at this airplane VERY closely.1 point

-

my rocket seems to use pads too, 100hrs they are done and its possible to kill them in 70 as I did my first year. when the mid body rocket is heavy the brakes are entirely inadequate for an emergency stop or anything like that. I would imagine a long body would be even worse. go and get in a Cessna and apply the same pressure everything in the plane moves forward !!!1 point

-

Well, the short and simple story is one would be lucky to get this plane truly airworthy for $120K cost plus $80K min, which puts the purchase into a whole 'nother level, so it would be better to just start looking at $200K+ airplanes (which I'm just not needing to do! :D) Of course, one might get lucky and it's a lot easier than that, but this plane seriously exceeds my mission needs. The extra complications and costs come with drawbacks as well as benefits. Back to looking for a J or similar NA plane. Or just upgrade my wholesome little C!1 point

-

The most obvious answer is that the shop probably hasn’t been cutting open your filter. Or if they have been, they are expecting not to find anything so they don’t look very closely. $75 to have the filter analyzed is nothing in aviation dollars, But doing everything you’ve done so far with the filter may alter the results that they would find. If it was me I’d still send it and the next one to see what they find. I’d also sample the oil and send it off. I wouldn’t just assume it’s the new chrome cylinder breaking in. Pure chromium is not magnetic, but the alloy that they use in cylinder I believe has a weak magnetic attraction. The engine making metal on Lycomings is usually the cam lobe or lifters coming apart. Assume the most likely, hope for the best.1 point

-

My old one had been repaired with what looked like liquid firesleeve: https://www.abthermal.com/firesleeve-open-end-liquid-dip-paste-sealant-rtv-contamination-protection.html It might also have just been orange RTV. It didn't look great, but may have been functional for a while. It had been worked down into the cloth material and seemed to be a decent patch. Sorry to hear the boot has become hard to get. I did talk to the parts department directly at Mooney about it before I got mine. He told me they had some (4 I think?) in stock at the time but that I had to order it through a MSC. You could try calling them direct and see if you get a different answer today.1 point

-

Historically yes as FAA rules for licensing, operation and maintenance were lighter and pragmatic for private operations, the JAA/JAR required compliance with airline rules. Less advantages now as new EASA rules were tailored for GA operations and they have mirrored FAA rules when it comes to non commercial operations (NCO, Part-ML...are now in force since 2020) Pilots can have N-Registered aircraft based in Europe as long as they have "dual papers" for EASA & FAA licences1 point

-

Every 70 hrs? You're landing too fast and stay off of the brakes!!!!! (as I can hear my mentor saying even today 60 years later :-) As Jimmy says- " What could possibly go wrong?" :-) :-) Unused/low use airplanes suffer the exact same fate as low/unused Rolls Royces - exactly the same fates. Everyone wants that museum quality garage find airplane (Rolls Royce) with low time for a bargain price but they usually find the first annual makes up for the low initial buy in. (and I know Rolls Royces!)1 point

-

Looks to me like it's $3K for O2, and $12K for the new, larger brakes. But what do I know, my C doesn't have either, that's just how I read it [item(price) + next item(next price)].1 point

-

I wouldn’t call that “too much”. Pull your filter the next 25 instead of 50 and see what you e got.1 point

-

1 point

-

I'm typically not one for 'overkill' solutions, but I'd NEVER trust that engine again, even after a complete overhaul. I can't imagine the over stress placed on EVERYTHING, engine cases included.1 point

-

Parker since I already signed on the dotted line, I’ll hit you up next year, I do work for the Maxwell’s and your highly recommended and spoke of D1 point

-

Wouldn’t they have had to do the conversion in 1998 at the tear down, or when they topped it in 2008? They said the Lycoming factory did the tear down. That may be an error in the brokers listing using the old engine model. Everything in aviation is a trade off. Even if someone were to choose to put the 400 it takes to restore this plane, they would end up with a nearly new plane, outfitted to that individuals tastes and specifications. It comes with a premium for sure, but if you own and fly it for ten years that premium is somewhat irrelevant. There are probably cheaper candidates out there, but there will be compromises with all of them, pick your poison….1 point

-

On another forum, a pilot friend of the mishap pilot reported that (paraphrasing): the mishap pilot thought he lost a cylinder at 3500’, was astonished at the vibration, and immediately shut it down. He dead sticked it to that landing. Well done. Along that route, it looks like the prop picked the best available time and place to depart. I’m not a socal flyer, but from ForeFlight, the coast looks pretty inhospitable for a forced landing. -dan1 point

-

Two weeks ago spring arrived and our skiing went to crap. Decided to go visit my parents down in Nevada. First trip in the new airplane and must have been doing something right because we had a tailwind both down (Fri) and back (Sun). Only 20kts on the way down though, the way back was even better!! Apparently we even did an aileron roll!1 point

-

Just a word of caution until you get the gas cap rim changed If water can get in then gas can get out on the low pressure area of the wing You might find on an upcoming flight that you port overboard a lot of your fuel from that tank all of a sudden. Being that it is the right side you won't see it until its too late. Out of sight out of mind during the flights. Don't get caught running out of gas.1 point

-

Last fall I reserved N201Y. The FAA approved the change so I spent today painting white where I'd sanded off portions of a "2". My J had N202Y, which is ok, but kind of like a vanity plate that just doesn't quite make sense. Tomorrow I paint the blue portions of the "1".1 point

-

Maybe I'm misinterpreting your statement and reading it through the lens of the attitude I've gotten from others here. If so, my apologies. But what it sounded like you were doing was complaining about the effect on your insurance rates of those that want to "experience" these kinds of places that you don't. Your statement reminds me of the guy who says that everyone who drives slower than him is an idiot and everyone who drives faster is a maniac. There is no reason to fly a Mooney at all for most folks. Or to get a $100 hamburger to begin with. Most people in the world would consider flying any aircraft high risk. Flying as PIC or SIC when you are over the age of 65 is such high of a risk the FAA has banned it for air carriers. Why don't we complain about how all us old people are ruining the rates for those young folks? It sounds like you want to exclude any activity that you don't personally partake in because the activities you choose not to do have 'no valid reason'. In other words, you want to be the riskiest person in your insurance pool. From a pure financial perspective I'm right there with you. I want to be paying the least and to be the most likely to collect. But from a reasonable risk management perspective we should all expect to have some that are riskier than us. All of our expenses related to light GA aircraft are 100% optional. If the insurance costs are taking someone over the edge of financial capability then this hobby is out of their budget to begin with. For commercial aircraft that are US based air carriers, the people who think it's risky are 100% wrong but that doesn't affect this argument. Also, the vast majority of medivac flights are a huge waste of money and the patients had no health benefit to being flown Vs. transported on the ground so those are actually 'no valid reason' too.1 point

-

I know this was touched on briefly by a DER for gears post but not specifically the path I took . My gears were not quite on their last leg but well used as the actuator motor was as well; so my A&P and I asked the engineers at Mooney if it was possible to engineer or draw engineering plans to install the whole electric gear retraction assembly including emergency gear extension from a model J/K or later for my F model. In our thought process this would eliminate the emergency hand crank and clutch, the inevitable gear replacement issue and the frequent inspection requirements of my F model. Similar to a DER this is not a group endeavor because it is based on each model type and is assigned to each aircraft serial number. The FAA had to approve and reissue the emergency extension section my of my specific Operators Manual. But having said that the ground work has been laid for a "better" retract system for our "vintage" Mooneys by Mooney. The process did take a bit of time and of course money, I did purchase a very nice entire gear retraction system out of K model and had to pay for Mooney's time and effort as well. So I'm not sure if this an answer to everyone's issues but I really think it will work well for we Vintage Mooney owners moving forward. I have to thank my A&P and the two gentlemen in Engineering at Mooney that helped us get things moving forward and through the finish line of Mooney and FAA approval. Now it is out with the old and in with the newer system.1 point

-

something similar happened to me in my Mooney...Just stay calm1 point

-

In my experience the amount of crosswind a given airplane will handle varies directly with the speed flown during final approach. The faster the speed, the greater the rudder authority, and the more crosswind that can be handled. Barry Schiff wrote an article that I read a long time ago. He posited that with proper technique, almost any crosswind can be successfully handled. What Barry advocated was an approach with the upwind wing low and enough top rudder to maintain runway alignment. Approach speed is whatever necessary for sufficient rudder authority to maintain runway alignment. This is not a full stall landing but rather one where the plane is flown onto the runway, upwind main gear first. Ailerons into the wind until speed decays and the downwind man gear is on the runway, followed by the nose gear. I tried this technique in a short rudder C and it works. This is not a technique for a short field because the touchdown speed may be higher than normal. You may also decide to leave the flaps up.1 point

-

This is what we used to snake the sync wire of my last airplane’s LED install. We snaked this thru the wing grommets. Cen-Tech 65327 3/16" x 11' Fiberglass Wire Running Kit https://www.amazon.com/dp/B001RV4T3U/ref=cm_sw_r_cp_api_i_c7FaBb9DNZ2JX1 point