Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/2025 in all areas

-

My crystal ball says they will want you send in all the parts of your system for repair/reconditioning.3 points

-

I hold 104.937472727 MPH but I have a really supple wrist.3 points

-

2 points

-

Very happy. High quality and a made-exactly-for-the-job tool. No messing with trying to get a torque wrench and socket behind the filter with no room. Pre-set torque and works to remove the filter, too. I paid $85 from Spruce when I bought it 6 years ago. I'd pay $100 now, no question.2 points

-

The March 2025 AOPA Pilot magazine got me thinking: I wonder why it seems so hard to understand how our wings produce lift? Bernoulli? Newton? Both? Neither? It's not as hard as we make it, but it is not intuitive and trying to make it match our intuition seems to me to be what trips up those that try to explain it in simple terms. Consider Bernoulli. Yes, the air flowing over the top of the wing speeds up and produces a lower pressure. But why does it speed up? It is NOT because the air above the wing is funneled through some sort of half venturi. This is easily shown by the fact that a flat sheet will generate lift at a positive angle of attack, but, since there is no camber, there is no half venturi. Consider Newton. Lift is not created by downwash. Downwash creates drag. Downwash is due to the tip vortices of finite span wings. 2D airfoils generate lift but have no downwash. Ground effect reduces downwash with the effect that drag decreases and lift increases. If downwash was responsible for lift, lift would decrease as we neared the ground and our Mooneys wouldn't float so much. There are two problems that impede our understanding of lift. The first is that many of the drawings of streamlines flowing past an airfoil are incorrectly drawn. An airplane wing actually affects the airflow at a considerable distance ahead, above, below and behind the wing. The second problem is that we are used to simple systems that have discernable cause and effect. But fluid dynamics isn't like that. If the air speeds up, is it because the pressure changed? Or, does the pressure change because the air speeds up? What is really happening is that the wing presents an obstacle that the air must go around. And, there are laws of nature that the air must obey in so doing. The air must change direction to get out of the way. Air has mass so changing its direction requires a force. Force on a fluid such as air is a pressure. So, as the air flows around the wing there will be pressure gradients. And pressure gradients cause the air to speed up or slow down. It's not correct to say that the pressure causes the direction and speed changes or that the direction and speed changes cause the pressure changes because all three parameters are part of one system.1 point

-

Even with Right Pattern, I'd still sidestep to the right. Only need to move far enough to see the runway, should be well inside pattern distance. Then climb out and away, re-enter and try again.1 point

-

For incompressible flow (M<0.3), streamline curvature explains >95% of the pressure distribution on an airfoil, with viscosity (vorticity) playing a minor role. Downwash has very little to do with lift produced by a wing. Lift results from either angle of attack and/or asymmetry in the airfoil itself. An asymmetric airfoil like the one on our favorite airplane in normal cruise has 0-degree angle of attack! How much downwash do you think that is that causing? As Skip pointed out in the wind tunnel photo above, which is a symmetrical airfoil at a high angle of attack, the net vertical velocity component around it very nearly zero. In the case of a symmetric airfoil at 0-degree angle of attack, the lift is zero because the streamline curvature is the same on both upper and lower surfaces. But as the wind tunnel photo shows, angle of attack greatly modifies the flow field and results in a lot more streamline curvature above the airfoil than below it. That's all there is to it. No magic. Once you get into the compressible flow regime, then the magic starts to appear along with a few demons.1 point

-

1 point

-

This. So many people have died within a quarter mile of an airport trying to save the airplane. if I have an engine failure, I care nothing about the airplane. Whatever consequence comes, I’m fine with it so long as I’m sitting at my dinner table that night.1 point

-

Does a propeller create thrust by creating lower pressure in front of it or by moving the air from in front of the propeller to behind it! A propeller is a miniature wing. Lift is created by forcing air downward. The significance of the lower air pressure above the wing is that the air is being sucked downward and therefore is creating extra lift through the direction change downward. The process of changing the direction of the air creates drag. This explains ground effect perfectly since the downward moving air is now hitting a solid surface and the air can’t move as freely as it does at altitude. Without forcing air downward you can’t push a plane up. It really is just that simple.1 point

-

If the engine goes cold you won't have the time or the inclination to be fumbling with an iPad trying to find your speed Have one number in your head and just fly the airplane and look out the window. The ground will be there a lot quicker than you think right now.1 point

-

Latest RC Mooney refurbished plane. Originally built in the mid 1990's. Thanks for watching!1 point

-

YUP I use it also Worth every penny. Good mechanics buy good tools Its a mind set Start with a good base and you do good work. Start off sloppy or cheap and that's what you produce.1 point

-

Make sure you have the latest software installed. There is a known bug where they don’t turn off all the way and drain quickly. Other than that it shouldn’t really be a big problem.1 point

-

No bueno if you are not instrument rated and current. Just ask for a VFR practice approach.1 point

-

1 point

-

Another break in flight today - almost 2 hours - lost the alternator due to broken connector so cut it short. Found the broken connector and will fix it tomorrow. Gotta figure this will happen since all the removal/installing of the older connectors. Takeoff, cylinders 1 and 4 were hottest but once I got moving they tamed down well. Had to add a quart of mineral oil and will be monitoring that. Planning on flight tomorrow after fixing the broken connector. -Don1 point

-

Wow! Glad I dont fly an F! Why so fast? In my C, short final is a max of 85 mph, down to 70-75 just before pavement, and on go arounds I aim around 85 initially (seriously), unless I'm still a couple hundred feet high, then I just maintain standard pattern speed of 90 mph. Then again, not much arm strength is required with only 180 hp. Good thing, too. I also don't use full nose-up trim, usually landing somewhere around the Takeoff mark. Trim is just another flight control to use to hit my intended point of landing, just like rudder, elevator and ailerons (which I also rarely move to their travel limits while landing); I just trim away the yoke force. Flaring is done by pulling gently on the yoke, and that close to the ground, I'm not letting go of the yoke to reach down for the trim wheel.1 point

-

So, not really. The air is stationary (sort of) and the wing must pass through it. But your analogy does not make the analysis incorrect.1 point

-

1 point

-

That is a pet peeve of mine; not clearly announcing your intentions. Always say "Full Stop", "Low Pass", or "Touch and Go" when you make any/all of your pattern position calls.1 point

-

He also said the Cessna was doing touch and gos. So if this is true, it looks like the Lancair is way more at fault here. Who would overtake an airplane doing touch and gos doing a low pass. That is nuts.1 point

-

Blocking a vent should not change level indication, unless and this would be an extreme event but unless it was blocked and over time the pump pumping fuel out pulled such a vacuum that it collapsed the bladders. I have seen a metal fuel tank crushed from a blocked vent though so it can happen.1 point

-

+1 to all the cautions about skydivers I fly frequently to an airport with jump operations. The skydiving group is on the west side of the field - that’s where they do training, that’s where their LZ is, and that’s the expectation that all pilots have when flying in the area (pay careful attention to the jumpers on the west side). On a recent flight, we were in communication with the jump plane and had visual contact with the jumpers…….. but then suddenly there was a jumper coming down through the traffic pattern on the east side of the field. Fortunately he was nowhere near our position, but when we landed he was walking across the middle of a very active runway while carrying his chute and gear. We radioed the jump pilot to let him know that one of the jumpers was walking from east to west across the runway, and the jump pilot basically said “er.” Anyway, when you’re at an airport with skydiving operations - especially where they’re training students - be very careful. Heads on a swivel. And don’t assume that they’re going to be in a particular place just because that’s what the AFD or NOTAM says1 point

-

This one checks all of your boxes, the asking is $105k, but that doesn't mean you won't be able to snag it for $100k. The only thing not mentioned is how frequently it is flying. https://www.trade-a-plane.com/search?category_level1=Single+Engine+Piston&make=MOONEY&model=M20E+CHAPARRAL&listing_id=2439515&s-type=aircraft1 point

-

They have a fairly extensive collection of used parts. I’ve purchased parts by mail from them. They recently relocated. I’ve never had work done there but I’ve never heard anything negative.1 point

-

I didn't do it. i just fuel the plane and fly it. United Flight Services did it in KWVI.1 point

-

the rear piece is 2.5" x 36, the front is 2", not as sure the length, 24" IIRC is a couple inches short.1 point

-

Consider for a moment that there is no right and wrong. There is only Alive and Dead. Fly like that.1 point

-

I have counted 93 different kinds of screws, 70 kinds of bolts (5 proprietary), and 51 kinds of nuts (4 proprietary) in my AF parts catalog. Al Mooney was a freak.1 point

-

1 point

-

Do you have engine analysis data to share?1 point

-

I'm in the middle of a plastic repair & restore process right now. I recommend S.E.M. products, specifically their soap, adhesion promoter & paint. My results have been great. Just follow their directions. By all means get a respirator AND goggles because the adhesion promoter & paint fumes are horrible. You'll need nitrile (or neoprene) gloves and unless you want your finger to cramp up get a "Can Gun" aerosol spray trigger from Aircraft Spruce. Paint on a calm day ideally between 70* to 85*F. It's best to apply several very light coats (up to 7 or 8 in my case). It dries very fast but wait the directed amount of time between coats. If you've never spray painted before watch a YouTube video for proper technique. It's not difficult but I practiced on an old cardboard box just 3 times until I had it perfected. Leave your finished work to cure for a day or two before handling. Most if not all odors will have dissipated by then unless the ambient temperatures have been cool. Fun Facts - S.E.M. paint is expensive but totally worth it. IIRC McFarlane sells a limited number of colors and had it for a good price. Unfortunately, not the specific color I wanted. O'Relly Auto Parts was pricey and had supply chain issues. Amazon saved the day and was by far the least expensive but be aware they don't have returns on paint due to it being HazMat. Calculate your square footage necessary and order conservatively knowing you can always order more if needed. For cracks in the plastic, I initially tried "Satellite City" instant glue, specifically their "Hot Stuff" and "Super 'T'" product. It has the viscosity of water which I found difficult to control and the results were not what I'd hoped for. I ended up using 7 Quarical Easy ABS Repair Tips for Easy Plastic Solutions which is an all-in-one pre-mixed ABS solution which proved to be outstanding. My headliner had some very bad cracks, splits & holes The ABS resin resembles tar and is applied from the back so no will ever see it. Time will tell if it holds up but I'm very optimistic. If you need more specifics just send me a DM. It'd be easier to explain it on the phone. BTW great looking Mooney. Wow!!!1 point

-

^^^. THIS. ^^^ I figure both back pockets are going to be touching each other if I have an engine failure...No way I'm risking any more of a helmet fire by trying to optimize glide speed based on exact weight and trying to figure out wind speed and direction at several altitudes below me. I've got Foreflight set to 10:1. My biggest fear is going for an airport close to the edge of the glide ring vs. accepting a for-certain makeable off-field site.1 point

-

You should use the speeds in Section III of the POH/AFM for your airplane. Best glide occurs at a specific angle of attack, so the airspeed will vary with weight. This is because lift = weight and if the angle of attack is constant then CL is constant so the airspeed has to be variable. The heavier you are, the faster you need to fly and the faster will be your descent, but the glide angle will not chsnge.1 point

-

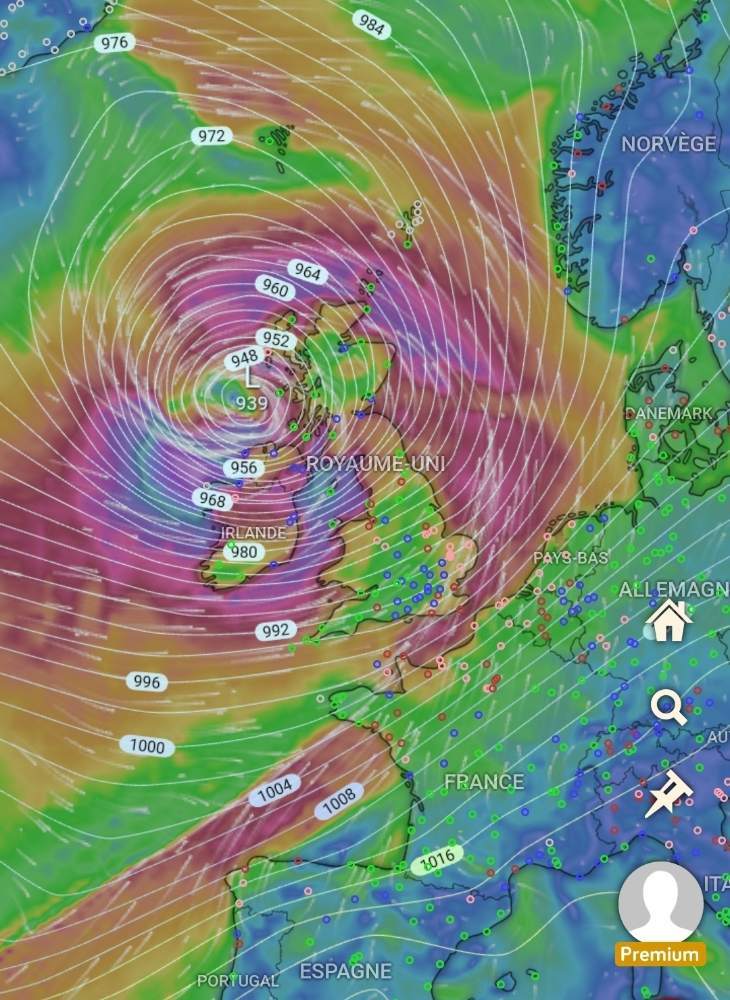

Dropped Mooney for it's annual plus right side rank reseal at the MSC shop in Netherlands, it was a quick trip from France with 80kts tailwind (we had 940hp or 27.72" depression over UK), bumpy surface wind but aligned with runway: I probably used less than 400ft for takeoff and landing ! In the hangar, I saw what it looks like an unwanted child from an affair between GeeBee and J3Cub? flying is getting expensive: downsize from J3 to single seater version this one looked very cold and tiny1 point

-

In one of Mike Busch's articles he mentions a guy who had a similar issue. Ran it out of oil just before landing. The A&P was adamant that he needed to "tear it down." Mike suggested a multi step detailed gound run, oil drain, analysis schedule. The guy followed this carefully. No excessive wear was observed in the oil analysis, and after some of thsis he did some short flights, still doing the anlysis regularly, but gradually increasing oil change back to normal. I don't think a knee jerk "tear it down" is necessary.1 point

-

Lack of oil pressure affects each part differently. Cam and crank bearings turn slowly, and there is plenty of oil left around the journals, and in the galleys, to provide enough lubrication to prevent seizing or galling for some time. Cylinders will suffer more quickly, since they run the hottest and the scraping action of the rings will clear oil much faster than other parts. So I would not panic about this particular loss of oil pressure. I would evaluate it carefully before making any decisions. Setting aside cost, downtime, and liability. It's either OK, or it's not. So one day's worth of inspection should tell you whether it's OK, or it has to come apart. As another data point, I reviewed flight and engine data for a plane that had an oil pressure indication problem. It flew for 10 minutes on approach with the gauge going from 60 to zero and back, then to zero. The pilot landed, and then disconnected and reconnected the sensor, and verified the sump was full. He started up, saw 50 PSI, departed, flew for 5 minutes while the gauge went back to zero, and the engine threw a rod. So this engine was operated for 5 minutes at full power on a hot day, after running 10 minutes at low cruise power, with no oil pressure, before it suffered damage. It takes a lot to harm these engines.1 point

-

Looks to me like he was trying to make a short field landing and ran out of energy just before the threshold.0 points

-

0 points

-

IF it were rebalanced when the servo was installed it should be a little nose heavy, which is conservative for flutter0 points