Leaderboard

Popular Content

Showing content with the highest reputation on 01/21/2025 in all areas

-

5 points

-

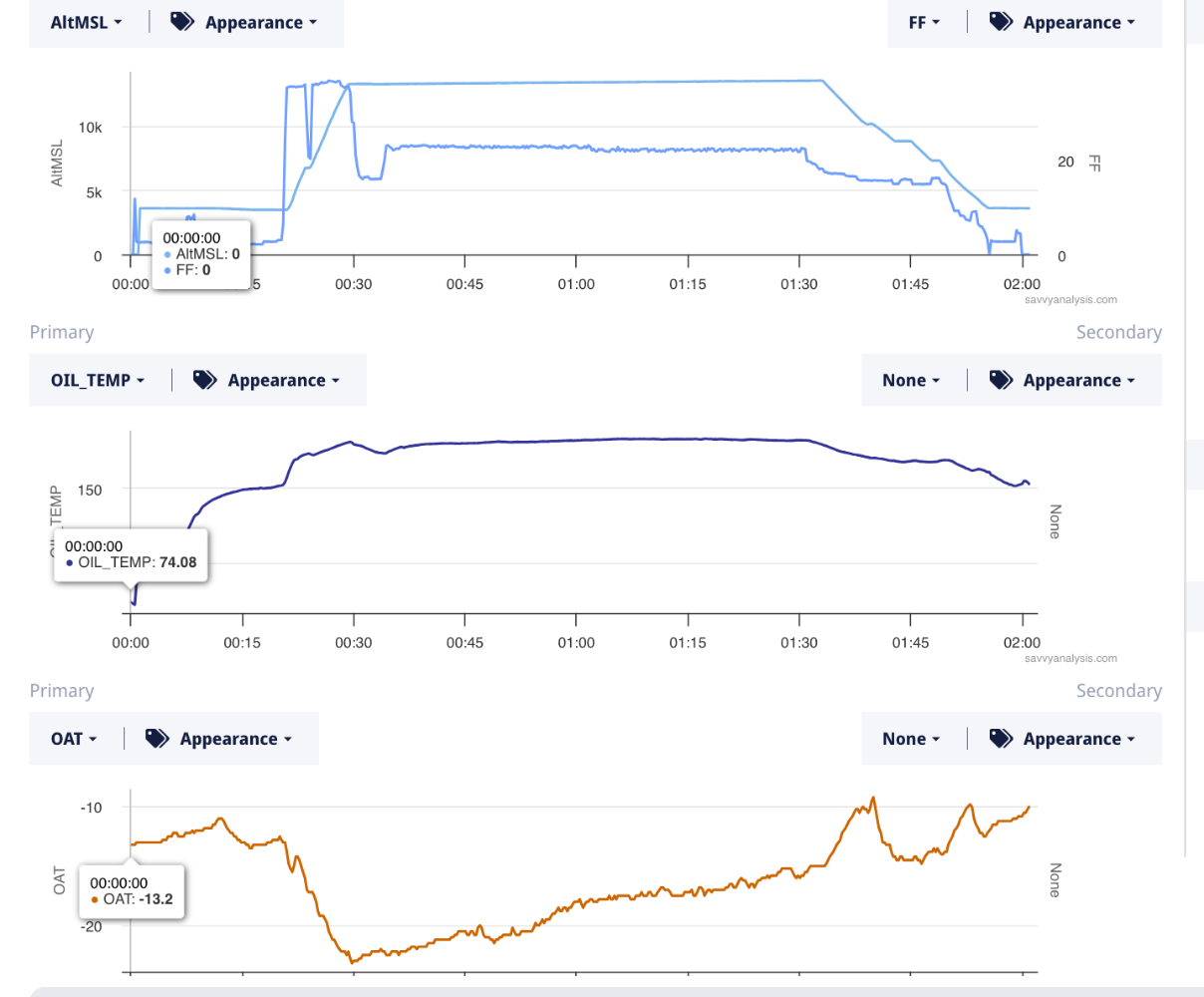

I flew to Appleton, WI yesterday, -13 below on the ground, and with my oil cooler 1/2 blocked off I was seeing 120 degree oil temp. Blocked off the cooler the rest of the way (100%) and my second flight yesterday I was just under 160 degrees. I find the Rocket really challenging to keep oil temps up in the winter. And, yes, I have removed the oil temp sensor and tested it, finding it's right on temp. On Isopropyl I have always used it in the winter on my Rocket (on my monthly trips to Florida, always up in the flight levels, I routinely see OAT's at -30F to -40F+). The one time I didn't, many years ago, I had a freeze up of the fuel spider on top the engine and coasted at an ugly idle from FL210 to 14k before it thawed enough to allow fuel flow to the engine again. I've never forgotten to add it again. Cheap insurance. Tom3 points

-

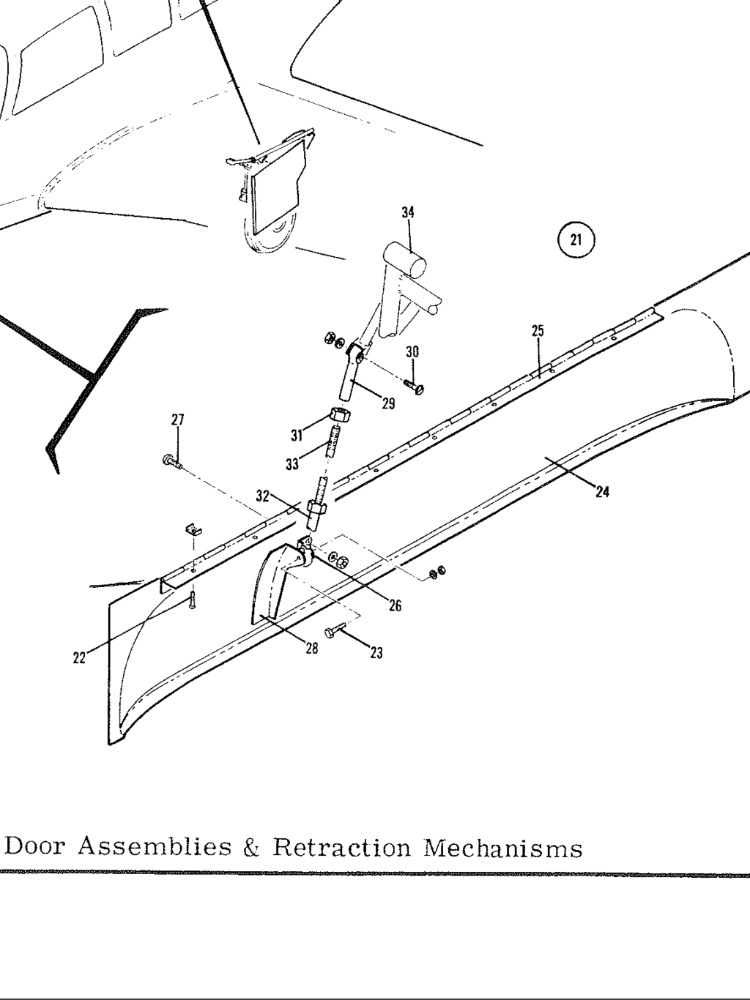

The piano hinge fingers appears to have significant wear. When the doors are are wiggled the door hinge half will move fore and aft and it might be interpreted as bad rod ends. The slop in the hinge is not that big a deal but if you want to replace the piano hinge it's a standard part and not all that difficult to replace but requires match riveting onto the doors.3 points

-

The assembly is just an assortment of spherical rod ends and the threaded shaft that connects them and a few jam nuts. Unless the shafts are horribly bent or the threads stripped completely off (both are unlikely), the shafts can be reused and just replace the rod ends. The rod ends are not uncommon and can usually be sourced from a few different places. I'd only replace the rod ends that actually have play. It'd be unusual for all of them to have play, but if they do, they're not hard to replace.3 points

-

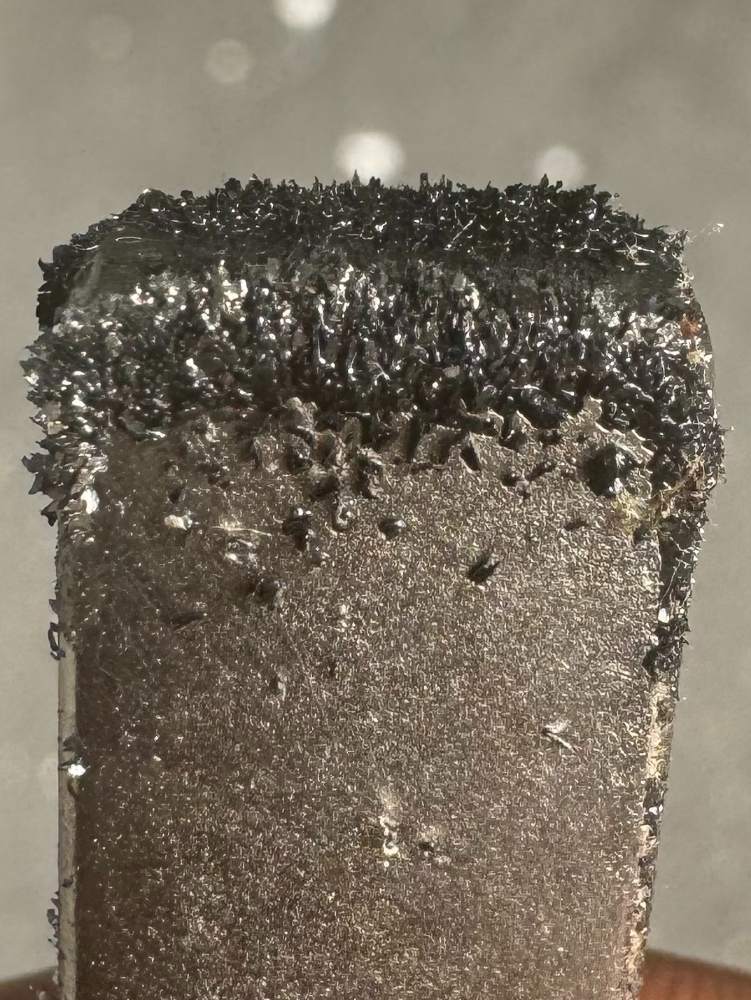

CAM LOBE CORROSION? A DULL TALE OF 1200 HRS SAFE LYCOMING OPERATION Surface corrosion noted on a cam lobe after pulling a jug isn’t great, but in isolation it is a terrible reason to split a Lycoming case – it may need overhaul soon, or maybe not... My illustrative anecdote: >10 years ago, a newb pilot/owner buys an M20C with a 600hr SMOH O-360 that had spent some time sitting and needs a little cylinder work at the outset. After pulling a couple jugs, the well-known Mooney A&P/IA who did the prebuy finds surface corrosion on multiple internal components and even some pitting on cam lobes but normal lobe height and lifter faces. The A&P sends pics of the extensive pitting and says newb owner you must overhaul. The collective “wisdom” of the internet also says that the newb pilot/owner/doctor must overhaul and asserts that he is just another vertical-tailed doctor killer-buying sucka. His demise in a smoking crater seems likely to all because he is arrogant enough not to accept A&P or internet guidance without asking questions. The sucka pilot then takes deep dive into authoritative literature by Mike Busch and others, learning that (1) there is zero danger in running it until cam/lifter truly spalls and (2) it’s easy to monitor the situation through the filter so that once it happens, further damage to the engine can be prevented. Armed with real knowledge, the arrogant newb pilot/owner pushes back hard against the A&P/IA, getting him to sign it off under some duress. Though this newb’s demise seems imminent to all, he flies regularly, uses Camguard, and keeps engine dry in winter by heating it uniformly and continuously. He also cuts and scrutinizes his filter nervously at every oil change, finding nothing for many hundreds of hours. He gets a good engine monitor, learns how to use a borescope, and learns spark plug maintenance, allowing him to monitor the top end as well. He does oil changes and oil analysis religiously but ultimately quits oil analysis after learning enough about it to conclude that it’s utterly useless for real world maintenance decisions on this engine. Finally, after flying for another 1200 hours over 10 years and accumulating ample instrument time, he notices a subtle but consistent decrement in TAS on recent flights. At the next oil change, he finds ample ferrous shavings in the filter (pic). He had become lazy recently and was only cutting every other filter, and so he pulls the previous filter off the shelf and also finds similar metal, realizing that he flew about 80-90 hours with cam lobe(s) and lifter face(s) coming apart. He flys it one last time to a major engine shop 3hrs away for overhaul, marveling at the aircraft’s fast and smooth performance during this serene flight and wondering if he is making the right decision. At overhaul, the suspected cam/lifter spalling is confirmed, and metal shavings are flushed from the oil cooler and governor. The prop is IRAN’d/resealed, and the hub is found to be in fine condition, as is the crankshaft. He’s finally back in the air and still (mostly) enjoying the continuous learning involved in the Mooney ownership journey….2 points

-

I just got off the phone with Brian Kenndrick! I'll be taking the plane to him next week and he'll be working on it February 232 points

-

Better solution would have been to install a breaker. But fuses are much cheaper and are easily installed inline. I despise hidden fuses A fuse does nothing that a CB can’t do, difference is of course a CB is resettable a fuse means you have to carry spares which was required back before breakers, probably a Commercial rule like the 2D cell flashlight was. Where the CB is has nothing to do protecting the device it’s connected to, but where the CB or fuse is important as the wire up to the device is unprotected, but it’s not prior to the device For this reason any device connected to a battery for continuous power when the aircraft is “off” like say a clock requires for example that the protection device be within 1 ft of the battery, either way the clock is “protected” but being close to the battery means only 1 ft of wire that could cause a fire isn’t. But I am confused how a CB or fuse protects a device, protects it from what? Internal shorts? It’s broken then, Anything else that I can think of that will cause excessive current to blow a fuse or trip a breaker means a wire is shorted, the device is broken and drawing excessive current of the protective is incorrectly sized.2 points

-

Unfortunately I really doubt the A&P here will sign off on anything not done by them. Feels like a cash grab (but it could be for liability which I also understand). He already told me that he would have to put it up on jacks and swing the gear to check the door closure as well if they were to do the work, so I don’t think I’m getting a quick sign off. They’re doing a full engine swap on an M20K that bit the dust here, and all 3 of the FBO’s planes are down for maintenance, so I’m pretty low on the totem pole of profitability and priority with this job for them2 points

-

This is the easiest fix ever. Even if you’re not too mechanically inclined, order the heim joints, install them and have your mechanic take a look and sign it off when you’re done. Advise him first and see if he agrees. If not, find any other A&P to just look at your work and sign. Im not that great a mechanic, but I disconnect those parts (not tge ball joint part though) each annual to free the gear doors so I can access the inspection panel screws close to them. Don’t lose the tiny spacers in there!2 points

-

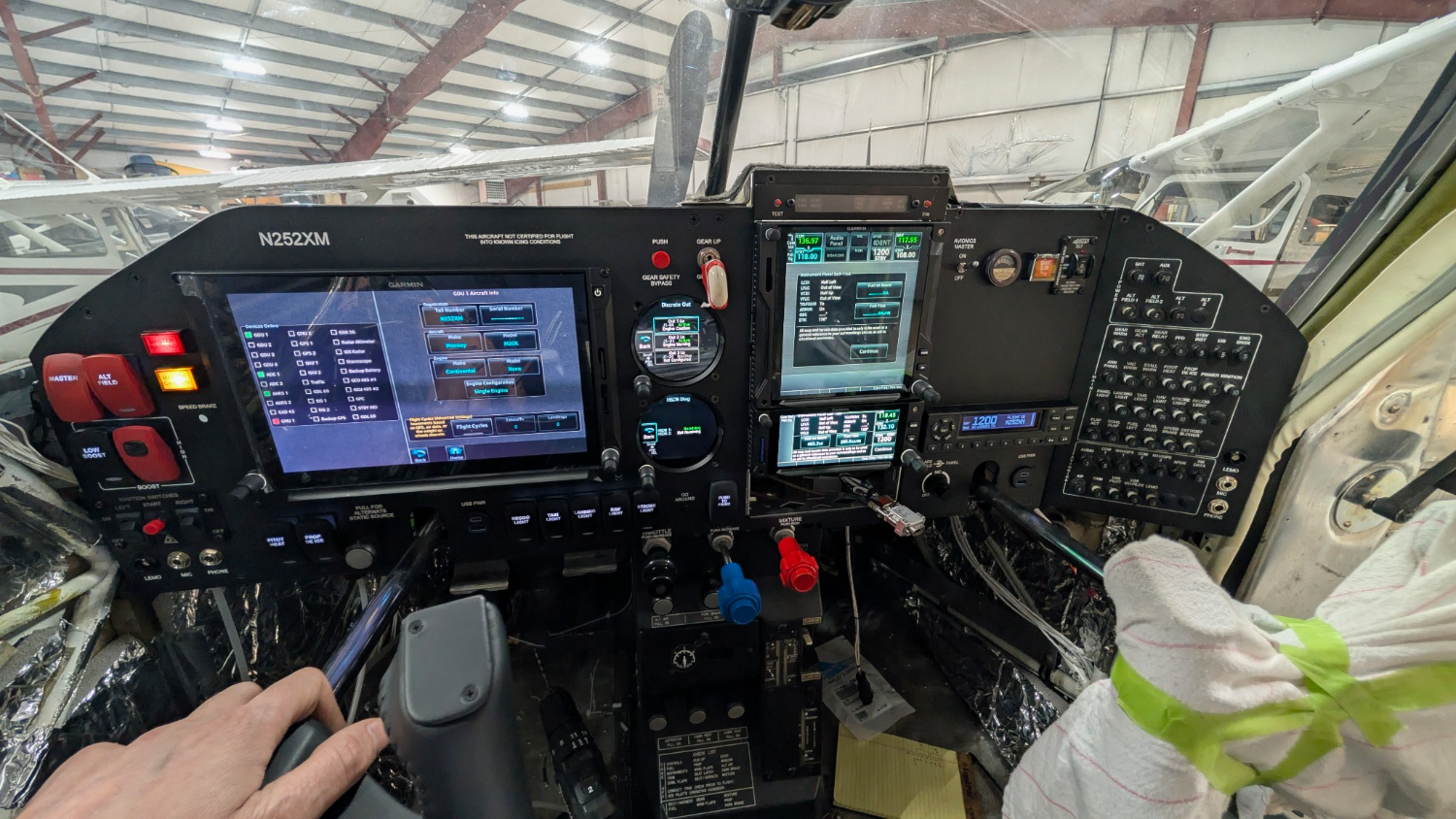

Mine isn’t, but it does result in the HSI being centered when in dual screen mode, which I always use. This was by choice, it also allows me to push it up higher.2 points

-

We had one last year. They had fantastic metal numbers, but we wanted to change a cylinder and my coworker ran the bore scope down the top of the cam and the very last cam lobe was about half the height. The cratered lifter literally polished the lobe down over the course of probably a couple hundred hours. Interestingly, the previous annual, a MSC put a longer pushrod on the exhaust of #4 because they said the lash was way too great. That was a missed opportunity. This engine had 1200 hours on it.2 points

-

I can see that perspective for as much flying as you do. I find that, despite having learned the sight picture, if I'm only making one landing per flight I tend to notice the quality of my landings suffers a bit; especially if I'm not flying often. When that happens I find it valuable to perform a few T&Gs and get 'back in the groove'. It works for me but, as you say, 'what others do is up to them'.2 points

-

I flew again to the pacific coast of el salvador. On my way there I overflew a volcano. What did i find in the crater? A lake!! Sent from my iPhone using Tapatalk Pro1 point

-

Thank you for that explanation. It helps me a lot. I agree, these can be difficult aircraft to work on. I'd love to do an owner assist annual but my only time available is weekends and of course the shop is closed on weekends. I know it would help me out a lot. Maybe some day. The description of the intake boot r/r makes a lot of sense. Yeah, it was very generous of him to knock off 4 hours. I actually do feel bad. But the bill for 12 hours labor had me saying some things while sitting at my desk at work that had my coworkers asking if I was OK. lol This is the second plane I've had this shop take care of for me and they've always been really good to me so I don't foresee taking my plane anywhere else.1 point

-

I asked him if his invoice had a typo. He revised the invoice down to 8 hours. Still sounds like a lot but I'll take what I can get. Does anybody have instructions or a video on how to remove the cowling on a '67 F? Mine is bone stock, no modifications other than a panel upgrade and avionics last year. I'm tempted to start doing the r/r of the cowling myself if I can do it in an hour.1 point

-

I don't see that it fits the FAA definition of "major alteration" quoted above. It's a factory part for a different model Mooney, but the only physical difference seems to be the handle on the outside; otherwise, the dimensions are the same; the fit to the airframe is the same; mounting is the same; latching mechanism into the airframe is the same; the outside handle and the part number are different. To me, this is A&P signoff.1 point

-

If any work has been done on the mags or switch or wiring, I would check that the mags are wired to the proper switch position.1 point

-

Try switching the probe with another cyl and see if the problem moves.1 point

-

1 point

-

It was this part https://www.mouser.com/ProductDetail/785-12TS15-71 point

-

Fore-aft slop in the piano hinge can sometimes be cured with a little bit of safety wire in one or more of the gaps. Gets rid of the slop.1 point

-

We can continue to disagree, You don’t see any fuses on Military aircraft and I’d bet Commercial Jets for a reason. You do see them on old aircraft, just as old houses had fuses. Fuses are like vacuum tubes Fuses are cheaper, easier to implement and take less room1 point

-

That's only a 2% difference, or one gallon per side, which is easily within a margin of error of differences in how line guys top off an airplane. It wouldn't concern me. Eventually the transducers slowly fail. The Service Manual says that the life expectancy is 1500 hours on the transducer.1 point

-

I wasn't a fan of Cannon who did my L3 NGT9000 ADS-B install in 2016. From being way overcharged for the install to shoddy workmanship to avoiding me for warranty work. I believe they had sold business previously a couple of times. I heard they were good, apparently before 2016 they had gone downhill. Your new panel looks nice glad came out the way it did. Enjoy it. James '67C1 point

-

The slop is MOSTLY from the rod ends. All 4 have pretty bad wear in my opinion. There is some slop in the hinges too without a doubt, but I’d say it’s 85% rod ends, 15% hinges. Transparently there was a bolt and nut that held one of the linkage brackets to the door that was loose, and that caused the door to have a lot of play, that’s been rectified, but it brought the attention to the rod ends. I think once the rod ends come in (got them ordered) I’ll have them installed by an A&P and get their opinion. Another operator at our base is supposed to open a shop in the next month that has a Mooney expert as their lead mechanic, so I’m counting down the days until that happens1 point

-

I don’t have a good image of mine, but I have a spaces in front of and behind the ball joint on the door side. Looking at the image it looks as if the front bracket is bent and you have 2 washers as spacers on the rear and on the front the 2 washers are not being used as spacers as they are not between the bracket and ball joint. With the spacers installed there is no play between the door and the lower ball joint. This alone could be the main source of slop. (My spacers look like 4 small pieces of tubing, 2 in front and 2 behind, they are small, each is about 3/16 in length) small trick, I would always have to search for one when I would disassemble, I installed heat shrink tubing around the 2 pairs. Now it goes together with ease, and if I drop one of the spacer packs the blue heat shrink stand out on the ground.1 point

-

You should definitely swing the gear afterwards. I don’t see why some play in these rod ends should make the airplane unairworthy (which would be the only reason to “ground”it) but if your CFI really believes that he should refuse to fly it without obtaining a ferry permit. I would either obtain the parts and have your local A&P install them and swing the gear, or I would fly it to another shop. No need to get your CFI involved (and pay his fee) assuming you are current in the airplane. A lot of mechanics will not sign off the work of owners unless they know the mechanical abilities of the owner. It takes time to build up that level of trust.1 point

-

Because fuses except for those with regulated blow times such as slo-blow have higher response times. Other reason is unless the C/B is trip free it can be mismanaged by the user (i.e. resetting it too many times or holding it in to prevent tripping) But the biggest reason is fast response. Most C/Bs are thermal and reaction time is often based upon ambient temps the C/B operates in. I am willing to bet the C/B for that trim is in the cabin where as the fuse is in an area of high variable temp, especially to the low side.1 point

-

1 point

-

Flight went well today. Much better choice than the widespread IFR and changing lowering ceilings yesterday. Oil warmed up and stayed pretty warm. No hiccups. Did have to run ROP to keep in the green (went around 29"/2500/lean then switched to rich as expected). Temps in cruise around 180F at OAT -22C at lowest, warming up going west, actually all warmer than forecast. (I am told there is an oil cooler winterization kit with a bracket... I wonder if that's it in my earlier picture, and if there's a specific "block" that's supposed to slide in there). Quite pretty:1 point

-

1 point

-

Not sure exactly why the OP did it, but I can tell you it won’t be noticeable in your scan or flying. My F had dual G5s that were offset similarly because there isn’t quite as much space directly above the yoke and that space pushes everything to the left. Anyway, it seems weird, but you don’t see it at all when you’re flying, and I’m pretty anal about that stuff.1 point

-

Ouch. Well you definitely have a smoking gun if you're having multiple spring failures on that cylinder. Dry lifter lash needs to be checked. See if you can find a part number on the spring to see if it's the right one, etc.1 point

-

Was finally able to hook up with member Ricky_231 and get a tag along in his M20S Eagle last week. What a great plane and a good day for flying. He showed me around the plane and answered any questions I had. We went for a flight and the "S" did in fact climb like an eagle. I am used to little Cessnas, so the climb at 1800+ fpm that never seemed to drop was amazing. We cruised out over the coast for a bit and talked about planes. What could be better than that? Thanks so much for your time Ricardo. It was an enjoyable flight.1 point

-

Yeah, it's funny but my temps are never really high except CHTs breaking in new cylinders ROP (expected and still only "high" using Mike Busch's 380F working limit). So it might be a bit conservative (if that's the right word). I was calculating -40F at cruising altitude had I gone today, so more heat is probably better. On the plus side, I found these guys to do my annual:1 point

-

Sounds like the typical multi-tasking vs no multi-tasking question. I have had CFIs chide me for writing down a clearance while taxiing. And I do admit that it does take a little thought and eye movement to re-set the flaps to the take-off position (assuming you landed with full flaps) while rolling exactly on the center line. Yes, there are potential risks with any distraction, but yes, in real life we sometimes have to deal with distractions, so perhaps we ought to practice distractions.1 point

-

I do touch and goes for instrument currency, running along the runway at idle while resetting trim before powering up to head for the next airport. Sometimes I even do a touch and go on an IPC. What's the point in purposely avoiding touch and goes? My minimum for TnG is 5000' of runway and not landing long, otherwise I'll stop and taxi back.1 point

-

Wiggle lightly. I caught one loose on my 231 and was able to save it and the panel it sits on. -dan1 point

-

Keep it in the plane for when a TKS stall strip breaks loose. NB: “When,” not “If.” Enjoy your trip. -dan1 point

-

1 point

-

Shocking! I made a round-trip to Houston, VFR both ways! I've usually been above a pretty solid layer with no ground visibility. This is crossing the Mississippi, looking towards Natchez on Tuesday. Coming home today was smooth sailing at 9500, just had to duck out of an MOA that two F-35s entered about 4 minutes after me, and about 15 minutes after Center confirmed that it was cold . . . .1 point

-

It only has to do with where the fuse/CB breaker is placed, through the mechanical size of those different devices may dictate where they wind up. Otherwise, there is no truth to this idea that one type of circuit interruption device is designed to protect wiring and another to protect the appliance the wire connects to. That's just not correct. Both types of interruption devices can protect both wiring and appliances. Both types of interruption devices provide more safety when placed on/near the bus bar than on/near the appliance being powered. This is due to the nasty failure mode of a power wire which chafes and shorts to ground between the bus bar and the appliance, and winds up carrying more current than it's rated for. This type of failure tends to melt the insulation, dribbling hot, waxy gobs of plastic-like material onto surfaces like clothing and carpet that are prone to catch fire. It's nice to protect the appliance too, but the failure mode of an internal short in the appliance tends to simply burn out a component that's encased in a metal box. It could still hurt you or start a fire, but that's much less likely than an over-current wire. If you can only place one circuit interruption device in the electrical path to an appliance, putting it near the large, robust (cool) bus bar is good because it means most of the wire that might melt is "downstream" of the circuit interruption device. If you instead put the interruption device near the appliance, most of the wire that might short is "upstream" of the interruptor. That's true regardless of whether the poorly-placed interruption device is a breaker or a fuse.1 point

-

Happy new year to all Mooniacs ! First flight in Mooney (second flight of 2025): quick trip to Amiens (LFAY), cold weather here in Normandy but nothing compared to “freezing bones” in Chicago The first flight of 2025 was Wing-Shift ULM (sort unregulated LSA), takeoff on skis at 9500ft elevation on top of Alps, a very short flight though: at -15C, this is the best fun one can have with LOT of their cloths on, it did not last more than 15min my wife complained about flying in freezing cold on “something that looks like motorcycle”, I reassured her that it makes us younger: the cold help to preserve meat for long conservation, this analogy did not go very well1 point

-

We each set our own minimums but the whole point of FIKI is to dispatch into ice. If it is 1000’ overcast with a 3000’ layer of light/moderate ice to CAVU on top, I am going and that is what FIKI is for.1 point

-

Engine Preheat is a must, seal the wemac vents on the sides real tight, you can tape over the pilot side, seal any leaks in cold air ducts on the copilot side, in the heater box on the copilot side there is a butterfly valve with pass through holes for cold air, you can tape them over for max heat, I use an alien 1500 W heater to preheat the cabin, Reiff with two pads on the oil pan and one on the oil cooler and heat bands on each cylinder, if you don't have a defrost blower use anti fog spray on inside of windshield, dress warm, I have flown the Bravo into -40C weather, but always put in heated hangar the night before and run engine and cabin heater, the defrost blower keeps the windshield clear during taxi, heat is marginal during climb but quite sufficient in cruise, I never covered the oil cooler since Bravo oil gets plenty hot, you may try covering half the oil cooler. Preheat as much as you can, that will help during taxi1 point

-

I’ve done hundreds mostly during training. I imagine with as much helicopter time as I have I have way more landings than normal. I have more tailwheel than nose dragger time too, and there the concern is ground loops, it really does require more skill to land a tail dragger and once you feel comfortable in one I believe it makes nose dragger landings much easier. Most all of my touch and goes are in my tail dragger just because they are more challenging. Back in the day as in 40 or more years ago when there was sheds lot more flying going on people would go to the airport just to do touch and goes. I guess it was just something to do, or maybe everyone else did so they did too. Or maybe there were many more new pilots as a percentage of the population back then? Or maybe as landing was the most critical phase of flying that it was practiced the most? I don’t know why but it wasn’t uncommon at all for several to be in the pattern just doing touch and goes back then. I can see the argument in a complex airplane to not do touch and goes as it wears the gear, but if you feel that you should brush up on your landing skills, then I think you should go out and do some, but just as an excuse to fly, maybe not. The argument that there are some accidents that occur with touch and goes, so therefore you shouldn’t do them, is as logical as saying that the aircraft should never leave the hangar, because flying causes accidents, in my opinion. From what I have read the overwhelming majority of landing accidents come from pilots that apparently don’t have good skills, and when I watch Mooney’s landing it seems that there are quite a few that would benefit from the practice as I watch them float down half the runway then touch down in a three point and often bounce and have directional control issues. Those seem to be where the accidents come from, perhaps they should be doing touch and goes until they become proficient? From this accident as accidents almost never have one cause but a chain of causes I’d bet age was a contributing factor but I bet lack of recent experience was also and maybe others like weather, fatigue who knows? Plus once in a blue moon, we all make stupid mistakes for no apparent reason, the FAA years ago commissioned a study to determine why and never could, just came up with the acronym of SLOJ or sudden loss of judgement and I bet as I grow older the likelihood of SLOJ striking increases. We all are subject to things like trying to walk through a door that opens the other way etc1 point

.jpg.6f9fd1fa29d6d243ec60ccd0eaa2b031.jpg)