Leaderboard

Popular Content

Showing content with the highest reputation on 10/14/2022 in all areas

-

Oh man. Great find. Can you please share your mechanics name because I’d fly just about anywhere for that kind of individual. Also, he needs a bottle of scotch when she flys again.6 points

-

Mooney Family! I have some good news! The primary mystery is solved - the likely cause! When the engine was overhauled last year, the prior owner declined servicing the fuel system. That is one of the dominos in this chain. My mechanic, after a number of inspections at the engine area, began training from the fuel & fuel tanks-forward. Approximately in order: Fuel - out to the lab, awaiting word. Airframe fine mesh screen - no debris. Fuel selector/gascolator - No debris, clean screen, nothing out of the ordinary. Elbow before electric fuel pump - INTERIOR RUSTING Electric fuel pump - INTERIOR RUSTING Elbow after electric fuel pump - INTERIOR RUSTING Coarse screen filter after fuel pump - no debris Fine mesh screen inside fuel servo - BINGO. Significant amounts of fine rust particles, sufficient enough to significantly and variably reduce fuel flow. Combine this with the fact that we went to higher-flow air filter (PowerFlow Challenger K&N style) and higher-flow exhaust (PowerFlow) - increased air flow. Secondary mysteries are: Why was the prior flight ok? Total extent of damage. So it seems that this aircraft had sat with water at times and may not have been regularly sumped by the prior owner... who also saved several hundred dollars, leading to a situation that caused loss of effective engine function, potential loss of life, and significant costs. As my mechanic feels that he should have spotted this, he is covering all labor, cylinders, pistons, rods, bearings, bolts. I am voluntarily covering a couple overhaul items, noted below. Plan: Oil has been sent to the lab Oil filter paper portion sent to the lab Fuel from each tank separately sent to the lab Cyls 1 & 2 turning into trophies for the fireplace Cyls 3 & 4 going out for inspection Bearings being inspected right now. May be some marks in the babbit material. Replace mechanical fuel pump (precautionary) Overhaul electric fuel pump Inspect and replace all connectors and elbows that may contain rust Overhaul fuel servo (precautionary)6 points

-

4 points

-

Sometimes being located in California has its benefits, and today provided one of them. In the summertime coastal fog provides a good opportunity to go out and practice approaches in actual conditions. Although unusual, this autumn day was even better with a thick layer of fog. With a nearly 30°F inversion the cool fog was held in in the Monterey Bay and tops were 1,700 feet with bases from 500 feet near Monterey to 700 feet near Salinas. With four airports nearly on top of each other the opportunity exists for a whole range of approaches. What really surprised me was that there was not one other airplane taking advantage of this day. That meant I had one controller nearly to myself. After doing a couple of new LPV approaches to minimums at Salinas and the required holding, I made things more interesting with the full VOR approach into Salinas, own navigation. A friend of mine told me that fuel prices at Marina were $6.00/gallon (who would have believed a year ago that that would be the lowest price around), so I ran the LNAV approach and broke out at near minimums for a full stop landing. Once on the ground I advised ATC to close my flight plan, told them I was stopping for fuel, and asked them if I could just pick up a clearance from them when I was done without filing, since they would be working me for my next few approaches into Monterey. They said that would not be a problem. That was the first time I tried that, and it came off without a hitch when I was ready to leave. It was sort of like a pop up clearance, but on the ground. Marina is usually a small quiet airport, but this day a big hangar was open, 50 or more people we hanging around, and I saw a huge electric helicopter in there. I wish now I had thought about taking a picture, but then again, maybe that would not have been appreciated. Once ready to go, I called for my clearance, was given a void time, and, shortly thereafter was released. I finished off my 6 approaches with a couple of ILSs to minimums into Monterey. After that, I got a clearance back to San Jose. Approaching the final approach course for the RNAV Y Rwy 30L, ATC queried my on my speed which was 160 knots. For the second time this day they told me to slow down by 20 knots (the first time it was 40 knots), an unusual request, since I'm usually requested to "keep your speed up". Having upgraded the LHS 100B to the LHS 200C yesterday, I got the altitude callouts, and touched down at the 0 foot callout. Taxiing back to my hangar, I was thinking of the great instrument flying day, and all those who missed the opportunity to sharpen up their instrument skills.4 points

-

Tension should be adjustable. Reach behind the panel and loosen the nut a turn or two, then tighten the nut on the front of the panel to take up the slack. Thanks to @M20Doc for this one!3 points

-

Hmmm, I read it as 13.7… All of my Apple products auto correct to make me look as dumb as possible. Perhaps your quote was caught in the cross fire.3 points

-

Got this from my old EAA chapter, I didn't find it while searching the forums so hopefully this isn't old news FAA NPRM NOTICE OF PROPOSED RULEMAKING (NPRM) Part 0, Section 000 (a) 1(c) Section I - No pilot or pilots, or person or persons acting on the direction or suggestion or supervision of a pilot or pilots may try, or attempt to try or make, or make attempt to try to comprehend or understand any or all, in whole or in part of the herein mentioned Aviation Regulations, except as authorized by the Administrator or an agent appointed by, or inspected by, the Administrator. Section II - If a pilot, or group of associate pilots becomes aware of, or realizes, or detects, or discovers, or finds that he or she, or they, are or have been beginning to understand the Aviation Regulations, they must immediately, within three (3) days notify, in writing, the Administrator. Section III - Upon receipt of the above-mentioned notice of impending comprehension, the Administrator shall immediately rewrite the Aviation Regulations in such a manner as to eliminate any further comprehension hazards. Section IV - The Administrator may, at his or her discretion, require the offending pilot or pilots to attend remedial instruction in Aviation Regulations until such time that the pilot is too confused to be capable of understanding anything.2 points

-

Understood. Fuel flow was lower than it should be but not apocalyptically horrific. Maybe we will learn more with the cylinders 3 & 4 inspections as well as the fuel & oil lab tests.2 points

-

Quite possibly, but I suspect he was not watching. Unrelated note - He only took over servicing of this aircraft 2 weeks before the incident flight. His checklist now include inspecting for rust in steel components and inspection of every...single...screen. He is a very smart dude with an excellent memory... and clearly an honest person and person of integrity. He has my trust.2 points

-

I would just use the nut and bolt hardware from the newer design. I would hope the follow on SB would address that. I was wondering if LASAR wants you to fly your airplane there so they can inspect it and tell you it's grounded.2 points

-

Definitely have the servo overhauled, and check the flow divider as well for junk/trash. I had similar issues and an engine failure (total power loss, though, not just lean) due to junk in the servo, evidenced by a finger filter full of rusty crap. It actually had failed three times, intermittently where we thought we'd fixed it until it failed completely. The overhauler said it was "full of grit". I think if crap gets inside it and the diaphragms get sticky it can misbehave without warning, sometimes fix itself, etc. Glad you found a culprit, and very glad to hear your mechanic is stepping up, which sounds like an incredibly solid move on his part.2 points

-

@Pineconebeat me to it. I just looked through the 900 manual and didn't find anything about seeing a change in % power from ROP to LOP. But on Page 47 they show the engine constant setting and mention 13.7 for turbo or 14.9 for normally aspirated. That must be for LOP power calculation. Next time you're at your airplane check with the lean find, then push the LOP and see if it changes your % power. Cheers, Dan2 points

-

There is a setting for this in the 830 Page 58, Engine Constant https://www.jpinstruments.com/wp-content/uploads/2012/07/PG-EDM-730_830_851_740-Rev-F-TB2.pdf They show a default setting of 14.9, which is in the ball park for many NA engines. There is also a setting for Horsepower Constant on Page 50. That seems to be for ROP2 points

-

Removing the lead from the fuel will make the engine last longer. Lead is incredibly harmful to the insides of any engine. Lead's only purpose is to ward off detonation, more cheaply than refining the fuel to the next higher octane level. Lead, in combination with combustion byproducts, corrodes valve seats and anything else it touches. Lead sticks to the valve stems, causing stuck valves (morning sickness). Lead forms sludge in the oil passages, and clogs up the piston ring lands and oil scraper ring drain ports, leading to high oil consumption. Your engine will thank you for switching to 100 UL.2 points

-

If you are into BMWs you will like my play car. 1995 BMW M3 LTW.2 points

-

I had the Schroth ASM 4-pts in two different track cars. One of the shoulder belts is designed to yield under tension so that one shoulder moves forward and keeps you from submarining the same way a 3-pt belt works. They have to be worn correctly, though, with the lap belt *very* tight so that it stays on your pelvis and doesn't move up into your soft middle bits, and the shoulder belts not so tight that they pull the lap belt up. A 5-pt doesn't restrain you from submarining with the 5-th (or sixth) straps, instead those straps are there to keep the lap belt low on your pelvis, and that restrains you. Single seat/open wheel cars where you're much more reclined need the 6-pts so that they go into tension and pull the lap belt down and rotate your pelvis up immediately on a forward impact. I spent way too much time learning race safety engineering when I started racing, but that was back in the era when they were just starting to really get serious and scientific about race safety (middle 90s, early 2000s), and everything was evolving pretty quickly. It was an interesting time for all that. I did learn at the time that some of the better research that had been done on belt/strap material was done by the Army for helicopter restraints. They were worried about material degradation since their aircraft are generally stored outdoors with sun exposure. Some of the SFI standards came from that and it apparently influenced FIA standards at the time as well for materials and longevity. GA aircraft belts that are stored outside and get sun exposure should be inspected carefully periodically, especially for belts over ten years old or so. Anyway, it's just a topic that I spent a lot of time on over the years. I got a back injury once after a crash where the belts didn't work properly due to a suboptimal lap belt tensioner design. I found out afterwards that the problem had been previously identified by a California race shop, but they weren't able to get the manufacturer to acknowledge the problem. I stopped using that manufacturer's stuff after that. It's worth taking this stuff seriously.2 points

-

When I first got my 231 it was obvious the engine had been run on the hot side. It had 646 hours but the turbo needed to be replaced nearly right away and it leaked quite a bit of oil, mainly at the rocker covers. At around 1200 (these are all Hobbs hours) I had to do an emergency descent to a landing from 19k (not due to how the engine might have been run). The problems worsened after that and I had the engine IRAN’d. Determined to find a better way, I went to the APS class in Tulsa and learned a lot. However, the advice from George B., Walter A., et al. was not perfect for me. I got the impression it was mainly based on experience with NA engines, which mine is not, and/or big bore engines, which mine also is not. So armed with the theories they taught, I set about to come up with a way to operate LOP that worked for my engine. I did quite a bit of experimenting and learned quite a few things. First, it is not accurate that LOP results in a power loss compared to ROP. That may be true for NA engines because it is not possible to add more air to lean the mix, MAP is capped at ambient, so your ability to add enough air to run at higher power settings while LOP may be limited. Also, lots of people run at 65% or just under because of the advice that you cannot hurt the engine regardless of where you operate it, LOP or ROP. Sure, if you have been operating ROP at 75% and then because you are afraid of what will happen to the engine if you operate LOP, you always do it at or under 65%, you will have a power loss. However, in my experience with my engine that power loss is in your head, you are the person who has elected to operate at a lower power setting, LOP operations do not require it. I have a JPI930 which is quite a good monitor and I am able to see quite a bit of information. The theory I came up with was that if you wanted to operate at more standard cruise settings (i.e. >65%) while LOP one way to do it is to add more air. LOP after all is an air/fuel ratio, it is definitely not just a matter of running the engine at less than 65%. The setting I use is 34” MP and 11-11.3 GPH. This gives me right around 71% power and nifty speeds. 71% seemed to be the practical limit in my aircraft, TIT tends to be higher by very roughly 100 dF, and I just do not like to operate with a TIT above 1600 even if the POH allows it. TIT also goes into a long slow climb in my engine if power is higher than 70-71% and especially if OATs are high, and adding more air does not help. If that happens I reduce the fuel flow but 10.9 or 11 is all it usually takes. I cannot maintain this in the high altitudes during summer. The TIT starts a slow climb and I just have to reduce fuel flow too much, so above roughly 15-16k I fly ROP. In the winter with cold temps I can go higher and stay LOP. Obviously this is a cooling issue. I experimented enough to know what MP and fuel flow works. During the experimentation I use the APS advice to operate degrees LOP from the last cylinder to peak (EGT). Now, however, I just watch the TIT and if it climbs up above 1600 I make an adjustment. The control systems on the 231 are not perfect and the fuel flows, and therefore the temps, may move around a little, or fuel flow may increase over a long period of time. Don’t know why. But when that happens I just adjust the fuel flow back to where it was. Among other things I learned that the aircraft was actually faster this way by quite a bit compared to my previous ROP operations at what were supposed to be the same %power settings. Previously I had been using charts supplied by the intercooler manufacturer, Turboplus, to determine ROP power settings. The charts turned out to be very conservative. Assuming the formula APS puts out that %power equals a constant (13.7 for my engine) times fuel flow in GPH divided by rated HP, I was sure I was operating at 71% HP at my LOP setting, but the plane was faster by at least ten knots than if I set for 71% ROP using the charts. That told me that the ROP setting that I thought was yielding 71% really wasn’t. Generally, I get about 145 at 3,000 MSL, closing in on 160 at 10k, and in the higher altitudes before I must go ROP I will see speeds in the 165-175 range (all in nm/hr). So what about the engine, operating that aggressively at LOP must be tearing it up? Currently it is very smooth, runs clean, CHTs are lower than ROP by quite a bit. The tbo is 1800 and I am at 2355. I wouldn’t ordinarily wait that long just because I am conservative about engines and safety, but it turned out last year when we inquired about a reman, that Conti now has a delivery delay of about 9 months, so we ordered one in April and it will hopefully show up at the end of the year. I intend to abuse it the same way I have the current engine, starting from day 1. The turbo which was overhauled at 645 has not been touched since, and now has about 1700 hours. Since around 1200 hours, the majority of cruise operations have been LOP at my preferred setting. Fine wires are a must. GAMI’s are a most likely. Regular attention to the magnetos and the spark plug harness are a must. Most issues with a rough running engine, if you have gotten the fuel flows evened out with GAMIs, are going to be related to the spark. One nifty thing about the 231 is that it has an interlink between fuel flow and MP. If I set my 34/11.1/2450 and then want to reduce to approach speed of about 120 kts. I can just pull the MP back to 24.5 - 25, it varies a little depending on the day temps. The fuel flow comes with the MP and I will be operating at 9 point something GPH. When I am on final I pull the MP back further and the fuel flow drops with it. So all downward power adjustments will be only with the MP. If I want to increase power for a climb I always go full power, full rich. Works for me.2 points

-

We are currently offering rebates on our most popular engine monitors. Now would be great time to save a bit on that early Christmas present you've been thinking about! EI Rebate1 point

-

It would be helpful to have links to he Savvy data. It’s hard to get a precise look at FF from the pics. Fuel flow may be suboptimal but was it different from the previous flight?1 point

-

Mike Busch says, as a general rule, if you are having trouble starting and it's cold out you are probably not priming enough; if it's warm, you are probably over priming. Of course none of that matters if you have wiring issues or bad mags, regardless of when they were overhauled.1 point

-

What I remember is that once you switch to LOP you then can’t switch back to ROP unless you shut the engine monitor down, so you are basically stuck with the LOP mode for the rest of a flight. Maybe that has changed. At any rate it never occurred to me to make the switch in flight. I just noticed that in Lean mode the %power number always matched the formula for LOP ops.1 point

-

I have the same sketchy feeling generally. It had 2 prior overhauls and is roughly 22 years old with ~2.5k hours Some people are trustworthy, some are not. It's hard to know the difference when I am getting 2nd hand info through my A&P. If the airplane was closer I'd probably be working on it myself with an A&P, vs letting someone else handle everything.1 point

-

1 point

-

That's because fixed wing helmets look cooler. And I have personally stress tested a fixed wing helmet and it did a fine job of protecting my head. And the newer ones have a more shock absorbing liner. As for legacy, the A-10 is same vintage (within a year) of the F-16 and F/A-18, and only the F-22 and F=-35 are newer. And about the same intro date as the M20J.1 point

-

Thank you gents! Cash is good… it keeps things running Sharing knowledge helps as well…. It keeps things interesting… Find something every day… add to the conversation… Best regards, -a-1 point

-

You guys are all getting along really well lately… There’s even a Brice sighting! Must be something in the coffee…. Anyone work with somebody that had high lead levels for extended periods of time? There were a few cases of fuel tanks that leaked lead based auto fuels into the ground water system…. Into neighborhoods that used shallow wells to get drinking water… The EPA has also generated new rules for underground storage tanks since then…. One thing that is different… Lead has a huge affect on young students growing up… something related to brain development is at risk… As adults, our brain development isn’t very high so it may not be very noticeable… Sooooo…. The people that grew up next to a gas station… are at a higher risk than those that grew up near an airport… Hah! Take that… main stream media! Best regards, -a-1 point

-

I got an email from LASAR today saying they could fix this problem. The ad had a picture of a Cessna on it.1 point

-

1 point

-

What did you race? I ran Spec Racer Ford in the 2000s. I need to get the car upgraded to Gen 3 specs. SCCA requires belts to be changed every 5 years.1 point

-

If you have a strong forearm you can just brace yourself on the dash.1 point

-

1 point

-

Not the same , The G1000 is a much more integrated system , Apples and Oranges1 point

-

Please don't home-cook anything with this, MS friends. Control balance is nothing to mess with. There are planes popping up with this issue all over the place. It amazes me that these things haven't been caught in shops up until the factory saying something.1 point

-

That's wild, I have an 830 and never noticed that (I never use Lean Find, though). I've never seen it documented either. I'll have to test that this weekend.1 point

-

I think that's kind of the point of the data out there--there is no insignificant amount and any amount produces measurable negative impacts (at least in the contamination amounts we've seen throughout the last 100 years). Nowadays, it is at least less frequent and less severe, but still measurable.1 point

-

There was a webinar a few months back with one of the controllers from the SoCal TRACON that was excellent. It is a couple hours long but was full of information to help better understand what is happening on the other end of the radio.1 point

-

If fuel was removed for calibration and temporarily stored at the shop I wonder if it is possible that it was contaminated there? Maybe solvent unnoticed in the storage container? Preignition can be stopped by reducing the power. But if your event was a case of detonation caused by fuel contamination, I don’t think it likely that you could have saved the engine from damage given the low altitude when it occurred. Skip1 point

-

1 point

-

This may be the ultimate answer for me. Fly puppies instead.1 point

-

1 point

-

1 point

-

1 point

-

At $30k buy it and fly it. Have something in reserve just in case it starts making metal. After sitting three years there's a good chance that after getting used again it will make metal and need an overhaul. Of course you could get lucky and not need one, but have the money set aside just in case.1 point

-

Beautiful panel. Glad you made it back safely. You’re alive and engines parts can be replaced so it certainly could have been worse.1 point

-

If you know everything then why would you need our help? There are some of the nicest, kindest people on Mooneyspace, but telling people what they can and can't tell you after they try to help you isn't going to win you friends on any Internet forum, especially this one.1 point

-

We don't have to agree on everything. We can still be friends. We both want lead out of avgas. You are willing to pay more, I am not. No biggie.1 point

-

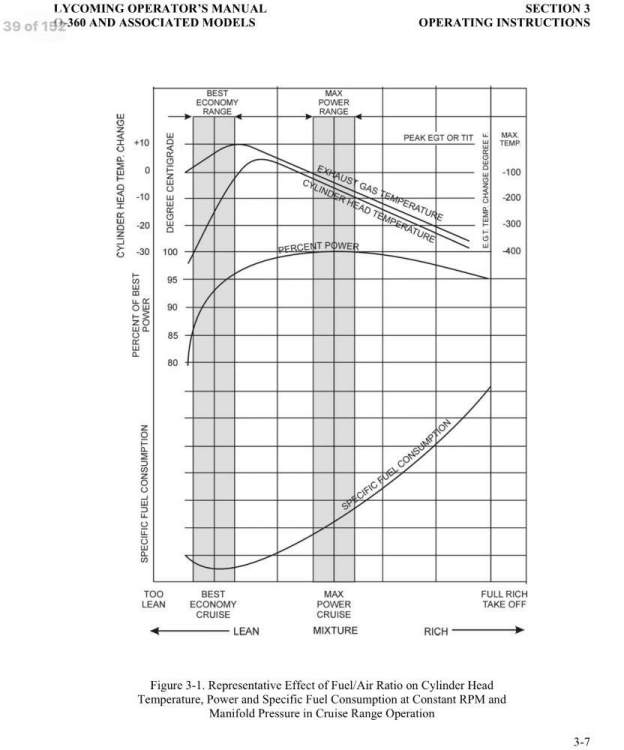

As Lance says above, this engine is known to be a challenge to run on the lean side of peak. I don't know what Lycoming's official stance is today, but they acknowledged years ago that LOP was a perfectly acceptable place to run an engine in the document “EXPERTS” ARE EVERYWHERE TO HELP YOU. It was printed in 2000 and was in my opinion, a cheap shot at George Braly, Gami, APS and anyone else that believed that there are scenarios where LOP operations are more practical, efficient and healthy for an engine. I won't get into analyzing Lyc's document. John Deakin (Pelican's Perch columnist and APS instructor) wrote a pretty thorough rebuttal. Those were heady days in the ROP LOP debate...Good thing we've come so far in 22 years. There is still a lot of misunderstanding in the pilot community about combustion science and therefore a lot of well intentioned misinformation. In the early 00’s, I was fortunate that Walt Atkinson (RIP) an APS instructor whom I became acquainted with online was kind to me, a then 20 something just starting to fly high performance singles. He answered a lot of my questions both in forums and via email. I will forever be grateful for his generosity. There are two graphics below. One is a conceptual chart published by Lycoming. The other depicts the actual internal cylinder pressure (ICP) of a Continental six and was taken from an excellent article written by Mike Busch. It is worth the short read. As you can see from both graphs peak CHT, peak pressure, lowest detonation margin etc... all occur about 50° rich of peak EGT. In the past both manufacturers recommended cruise settings of 100° ROP. There is no setting on the lean side that is as aggressive as that setting from an ICP standpoint. "Running LOP too aggressively" is not a real thing. Lean mixture ratios are more difficult to ignite than rich mixtures. They are also more resistant to detonation, not less so. An engine will not detonate if all cylinders are on the lean side of peak EGT under any practical scenario. So regardless of what Lyc says, their graph shows that all LOP settings are cooler than their recommended setting of 100° ROP. . Below is a graph taken from the aforementioned Mike Busch article. This is actual data as opposed to Lycoming’s theoretical/conceptual depiction. This is a more sophisticated analysis that shows actual cylinder pressure in relation to crank angle (which is crucial to extracting energy from the combustion event). CHT‘s are driven by cylinder pressure. Here we can see that every setting on the rich side of peak (including full rich) has lower detonation margins than Peak EGT, going leaner only increases margins. We can also see that from peak to 50° LOP the slower burning combustion event produces a more ideal pressure profile in relation to crank angle. The pressure drop is less steep producing similar mean cylinder pressure over the power stroke but with a lower peak and less severe pressure drop after peak. This is best BFSC range. The engine is extracting the most mechanical energy from a unit of gas and generating less heat/peak pressure in the process. Read the above linked Savvy article. It's short and to the point and will clarify some of the well intentioned but less than factual guidence that you might find here and elsewhere.1 point

-

My hangar elf built my aluminum hubcaps with a hole (properly located for the valve stem) that is covered by a "snap-in" plug (available at Home Depot, etc.). Then use a short extension on the stem for adding air. Thus no need to unscrew mounting screws for the hubcap. (Take a look at my album)1 point

-

1 point

-

Welcome aboard ROF! Congratulations on your first question… Anyone that has bought a Mooney in the last 23 years has been through this a few times… and that was before MS…! Rule one… don’t bend any metal if you don’t have to… Rule two… most things that need to be replaced… come from various manufacturers… Rule three… the pandemic is winding down…. The supply chain issues are following the pandemic…. Interest rates are climbing and there is a probable recession expected over the horizon… Then hasn’t been a better time to have a Mooney than today… The higher the fuel prices go…. The more you will tell your friends what great fuel mileage your Mooney gets compared to their Slowboat 180… Bone up on what PPIs are all about… don’t buy something that needs to be fixed unless you know where the source of that fix comes from… I’ve been a Mooney owner since Y2K… started with a nice (ly run out) M20C…. Enjoyed maintaining it for a decade…. I think you will really like the M20J. Best regards, -a-1 point

.thumb.jpeg.7ba106fbf2b10cba03047ba965aecd84.jpeg)