Leaderboard

Popular Content

Showing content with the highest reputation since 01/20/2025 in all areas

-

I just got off the phone with Mr. Pollack (Mooney CEO) there IS an agreement that will allow for the manufacture of the 40:1 Gear Sets that we have been hoping/waiting for. The Authorized POC will be contacting me within the next couple of weeks and I will get the cost and timeline information and share with the group as well as the order process. This is GREAT news and wouldn't have been possible without Mr. Pollack's willingness to put in the (unpaid) effort to make this possible. I appreciate everyone patience and encouragement during the process that got us to this point. More to follow once I get more information. V/r Matt19 points

-

After landing I put the flap switch in up position and the flaps did not move and the circuit breaker popped. Thereafter, I noted that the breaker would pop when the master was turned on with the flap switch in up, takeoff, or down position (the airplane is a later model with the three position flap switch). I tried wiggling the flaps because some have said that got them working again, but to no avail. I'm not saying others are wrong, but the up/down limit switches ride on the acme screw barrel of the actuator which cannot be back driven due to the wheel and worm gearing of the actuator so I have a hard time seeing how wiggling the flaps can move the switches. Be that as it may, it did nothing for my problem. Removing the belly skin and inspecting things, I noticed that the actuator had overrun past the down limit and jammed the barrel. I disconnected the barrel and manually freed it and rotated it to the up position. But the breaker still popped. I disconnected the connector that feeds the motor and the breaker still popped indicating that the problem was not the motor. I disconnected the connector that goes to the up and down relays and the breaker didn't pop, so the wiring is good. Next I removed the down relay and reconnected the connectors and the breaker did not trip indicating that the short was in the relay. I took the down relay apart and found that the armature had become dislodged and that all three contacts (C, NO, NC) were stuck together creating a short circuit. The Magnacraft relay looks like a pretty flimsy mechanical design to me. I found some new/old stock online and ordered two. Hopefully this helps someone with a similar problem.17 points

-

Can’t say enough good things about Edison at KFXE. Bought my Bravo in Sept 23 and I knew there were leaks. Brian K did the best he could to patch the tanks up. I made an appointment with Paul in MN Jan 24 and looked in my calendar for the Feb appointment. No joy. Called Paul and learned it’s Feb 2026. Ugh Dec 30 I topped up and found leaking rivets in the wing walk area. Discovered bad weeping in both wheel wells. This was not going to work. I called Edison on Dec 31 at 1500 CST. Said he had 1 slot last week in Jan, 2 in Feb, 0 in March and 4 in April. I explained my dilemma in that the plane needed to be back in TX by Jan 31 for its annual. He said get it to him and he’d start it right away. 23 hours later, I pulled onto the ramp in KFXE. He planned on finishing by 1/26. It was completed 1/23. He was excellent in communicating the status, pointed out areas he found that needed attention outside the scope of the job quoted and even redid my sad looking wing walk area. He only does Mooneys and can do 4 per month. I give him two enthusiastic thumbs up. My quote, $6,800 per tank. He replaced both sump drains and repaired corroded areas. 28 nut plates, 432 SS screws and removed the interior panels to tighten L/R tank pickup fittings. $15,900. Seven year transferable warranty and $300 for any repair after that. Not cheap, but competitively priced. Sent from my iPhone using Tapatalk10 points

-

While technically not a winning bid from a salvage auction, my very good friend in Texas (Mark Hasse, sadly flew west in 2012, God rest his soul) won a sealed bid from some tiny county in the Carolinas on a '65 310K. All the listing said was something to the effect of "Seized/forfeited aircraft; Cessna 310; locked with no keys; no known records; seized in drug raid; unknown condition, sold as-is, where-is". All interested parties were to send in written sealed bids via US Postal service to the county clerk (in other words, the selling entity wasn't aviation-related at all). Nearly wincing at the potential of offending the county, he sent in a bid for $10,000.00, thinking the IO470 cores would be worth at least double that (this was in the early 'aughts). He then went about his usual business and forgot all about his bid. About 3 months later, he gets a call out of the blue from the "X County Courthouse". He was a retired prosecutor/lawyer at the time, so getting a call from a "county Courthouse" wasn't altogether unusual. He answered and the very nice lady on the other end of the line said, "Mr Hasse, congratulations, you won the bid." "What bid?", he replied. She said, "the airplane that was seized here in South Carolina in the drug raid". He then remembered his sealed bid. She told him he was literally the only bidder. Now to the juiciest parts of any similar aviation auction/sealed bid-related story you'll ever hear: Mark was a consummate A&P/IA and an extremely cunning individual. He flew commercial out to see his "new-to-him" acquisition imposed upon him by the local authorities by virtue of his forgotten-bid (evidently the listing in the aviation auction periodical where he found out about it in the first place wasn't completely accurate, or at least had scared off everyone else because it made everyone think that the aircraft had actually been used in running drugs to and fro and was thus seized during an actual drug raid--it hadn't been and suffered no such fate. It was merely owned by some local idiot who had been caught running drugs elsewhere and this was merely an asset of his). Anyway, back to the story: Mark arrives at the county courthouse to give them his $10,000.00 cashiers check. The nice lady there giving him his bill of sale then tells him "go to the airport and ask for Jed. He'll take great care of you. Thanks so much for helping us out with this nightmare airplane problem." Still thinking he got a complete piece of crap, Mark then hops in his rental car and goes to the airport where the aircraft was sitting on the ramp, still in its "seized state", all locked up without keys or "records". Mark hoped that the old wives-tale about all 1960s-era Cessna locks being identical to unserialized Samsonite luggage locks was true. By damn, it was true. With less effort spent than tying his shoelaces, he was able not only to unlock the cockpit door, he also unlocked both nacelle lockers and guess what was inside? Yep, all records, from new, with fresh annual sign-off and fresh, complete OH on both engines AND props, full-stop--the owner had evidently overspent some of that hard-earned drug running money on his own airplane and had just returned to his local airport from that lengthy, extraordinarily expensive shop visit. Icing on the cake was that the other engine nacelle locker had 4 sets of brand new DC headsets. Remember "Jed"? Well, Jed was the local groundskeeper at this tiny little county airport in the middle of fly-over Carolina and explained to Mark that the county seized all of the owner's property because he was a known, local drug dealer and hadn't paid his property taxes. This was never a "drug seizure" and the aircraft was never involved in anything nefarious. Mark corroborated this with the local FBO guy, too (Mark used his jacks and shop to do his own gear-swing and ferry flight permit inspection to fly it back to his own shop for further eval in TX). My buddy got a great twin that I flew in with him for dozens of hours in later years for about 10% of its market-value, all for responding to a no-pictures, written ad in an auction periodical from some tiny, random county in the Carolinas who truly had no idea a) how to properly list a aircraft for sale; and b) how to determine its true condition and c) literally gave zero effort to even try to unlock the aircraft and find out what was inside. The local sheriff just wanted it gone and the lovely clerk at the courthouse saw to it that it was gone with minimal effort. PS--this story is 100% true, even down to the county waving any and all ramp fees/storage and they even paid a full fuel top-off since Mark was "so nice and pleasant to deal with". With ode and respect to my great friend Mark Hasse, Rockwall, TX. A true gem, if there ever was one on this planet. May he rest in peace.9 points

-

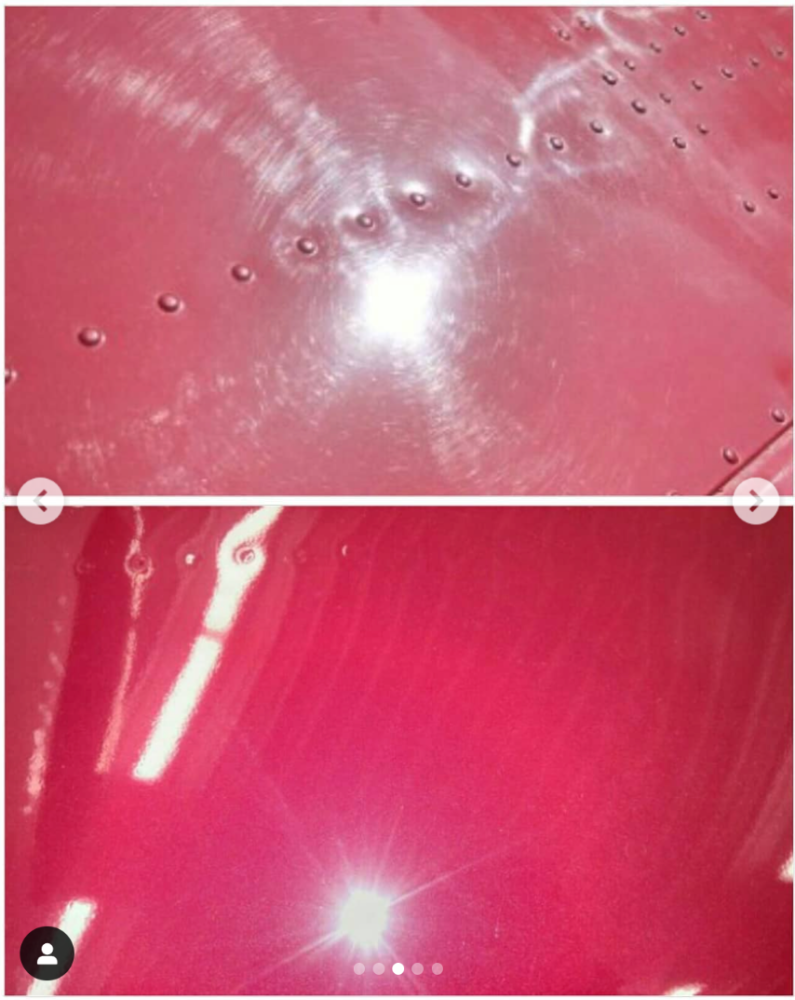

The good news and the bad news. After nearly 3 hours of buffing and wet sanding and other things, Mark, at Top Gun was able to nearly eliminate the staining on my wing. If you really look closely you can still see it a little bit, but I am happy with the result. The bad news on the other hand is that it cost me nearly $500 of his time. Still less than repainting, but I'm not thrilled about it. As much as I want to support G100UL, I won't be using it. Mark confirmed it was the matt used by the fueler that caused the damage, as indicated by the pattern it left on the wing. Mark and his Dad, Tom, have maintained my airplane since I bought it 32 years ago. He personally upgraded my first engine to the Bravo, and changed out the other two himself. Needless to say he really knows engines. We talked today. I told him how well G100UL performed. He commented that it was probably great for the engine itself, but maybe not so great for other parts of the airplane. He was surprised at the difficulty he had in removing the stains, as he thought he could remove it more easily. He apologized for how long it took. There have been times when I have accidentally overfilled a tank and fuel ran all the way down the wing. I don't want to chance that happening with G100UL. It's just too easy to screw up. And so ends my experiment for now.9 points

-

Hi All, Yes, I’m here on Mooneyspace. Never owned one, but I have a few hours in a friend’s Mooney (which was sold and is the infamous Mooney that later flew through Area 51). Anyways, I’m happy to clarify if something was not clearly stated in the videos. As to not clutter the already long thread, please send me a direct message with your question(s) over the next few days and I’ll try to summarize applicable comments in one response. I just ask that you’ve reviewed the videos (Part 1) (Part 2) to ensure your question is not already covered there. I spent a lot of time compiling the videos and it has been quite frustrating to watch comments on many forums where it is clear people have not watched the videos. I want to reiterate that my initial primary focus was on the effects & compatibility to my personal aircraft. And based on what I learned, I performed more testing and decided to share the results. I do think it is unfair to blame paint jobs being the cause, as 100LL historically seems to do very little, if anything, to painted surfaces. I’ve verified that through the course of my testing. I really want unleaded fuels to work. I’d do the same testing for any other fuel that came to market which I had questions about. Especially so since this is the application of an STC (major alteration) and the A&P/IA has to determine if the modification is compatible with the aircraft. I thought this recent commentary by Darren Pleasance (new AOPA CEO) echoes many of my sentiments. https://www.aopa.org/news-and-media/all-news/2025/january/23/presidents-position-on-unleaded-fuel Michael8 points

-

Hello, I am posting this in the hopes that I can save someone major headaches and frustration in the future when it comes to bleeding the brakes; specifically, the copilot side brakes. From what I understand, not many of our birds have these installed, and mine happens to be one of the rarer ones that does. I've spend 8+ hours in the past few days trying to get it right so here is my writeup so hopefully it may help someone in the future. So, annual time on my Mooney. I removed the leaking parking brake for cleanup and rebuild, as well as replace one of the brake lines. Before removing these components, I decided to simply open the bleeders at the calipers to let the system completely drain. Figured I'd give it all new, fresh fluid while I was at it. After completing my work I bled the brakes as per normal procedure, ie pushing fluid from the caliper up through the system to the reservoir. My friend reported no more bubbles, cool, switch sides and complete procedure again. Afterwards I climb into the cabin to test the brakes. Pilot side feels great while copilot side goes straight to the floor. I won't bore you with all the details of the troubleshooting but it was several head-scratching hours of frustration. Rebuilt the copilot master cylinders thinking that maybe they were letting in a small amount of air (I got this idea from someone else's past post here on Mooneyspace), which did not fix it. Eventually I removed the belly panel I'd previously installed, thinking I was nearly done with my annual and didn't need access above it anymore, and traced the brake lines back to find two shuttle valves that I had previously not known existed. Apparently, part of the installation of the copilot brakes is to put these shuttle valves in; with these valves, whichever set of brakes is depressed will push the valve over and allow fluid to go to the calipers. This, of course, means that both sets of brakes cannot be used at the same time, which really doesn't make much sense to me. Maybe its purpose is to protect the calipers from too much pressure from both pedals depressed at the same time...? I don't know. But anyway... I removed the shuttle valves and made sure they were not seized/frozen. Replaced the O-rings while I had them out. Reinstalled. So here's when all the pieces came together on why the pilot brakes were bleeding fine but copilot's were not; in order for the shuttle valve to move, the pressure has to come from the pedals to push it over. Pushing fluid up from the caliper is putting pressure on the wrong side, so the fluid all goes to whatever side the shuttle valve happens to have open at the time; in my case, the pilot side. So we bled the pilot side like normal, then I took an air nozzle and shot a quick blast of air into the shuttle valve where the line to the copilot brakes should be connected. This air pushed the shuttle valve over. So then I reconnected that line and we bled the brake again, this time the fluid was directed to the copilot side. Repeat entire procedure on the other caliper. Now the brakes all work great. In my searches for solutions to copilot brake bleeding problems on Mooneys, I was not able to find anything that helped, so I really hope that someone who needs it finds this writeup someday.7 points

-

Here's a solution for all you folks that live in California but seem displeased with the state: https://www.nbcnews.com/news/world/denmark-should-buy-california-petition-trump-greenland-rcna1918067 points

-

I applaud the honest effort that was put into pursuing legal and proper methods to provide new gear sets for our birds. The "drawings" that I saw were simply sketches. They could have been sketches of anything. They did NOT have drawing numbers, revisions or approvals in the title block. Until "engineering drawings" are approved through some method, they are not truly engineering drawings. The author of those sketches could also not be held liable for what someone might try to do with that information. He did not suggest nor condone any action. He was simply providing sketches of his efforts to understand the problem. I appreciate his efforts to help all us Mooney drivers. There is no harm in knowledge. I do not fear the self righteousness, self appointed internet police. For now, it's still a free country. I am re-posting below, some sketches I found on the internet. -mark VIEWS OF 3D FILES WORM SET 7-10-24.pdf WORM GEAR DWG 7-10-24.pdf WORM SHAFT DWG 7-10-24.pdf7 points

-

So far so good with my F's bladder install. Access plates removed; vent tubes drilled out and removed; fuel cap adapter ring drilled out and removed; fuel senders removed. Removing the fuel pickup tubes should be next. Several types and layers of sealant built up over the years from patches. More to come...7 points

-

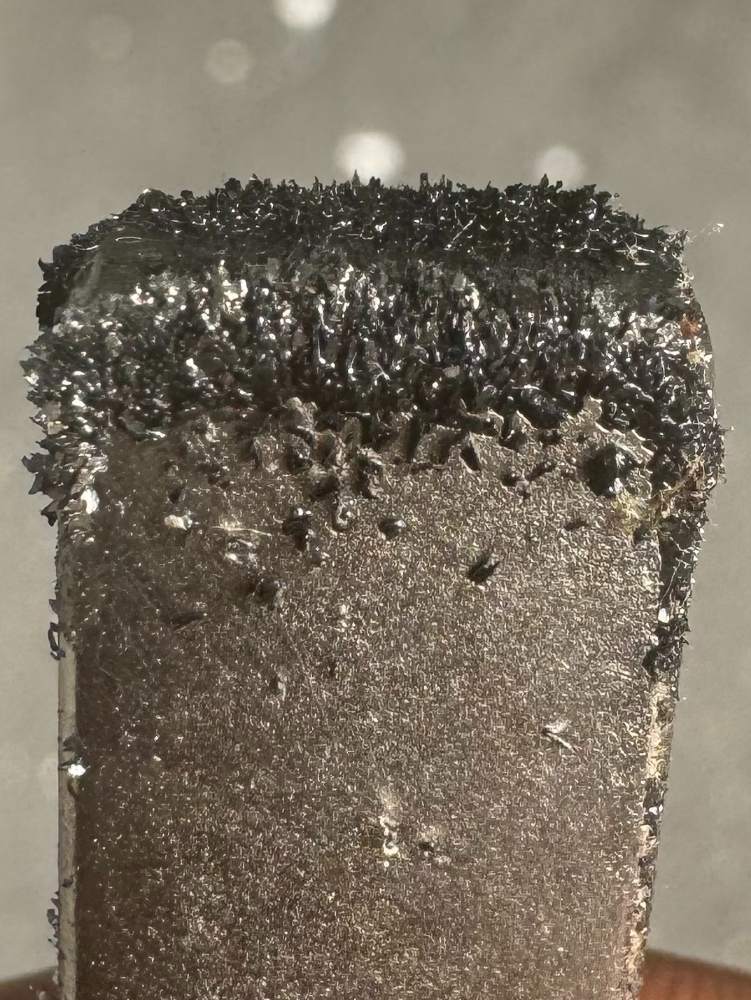

CAM LOBE CORROSION? A DULL TALE OF 1200 HRS SAFE LYCOMING OPERATION Surface corrosion noted on a cam lobe after pulling a jug isn’t great, but in isolation it is a terrible reason to split a Lycoming case – it may need overhaul soon, or maybe not... My illustrative anecdote: >10 years ago, a newb pilot/owner buys an M20C with a 600hr SMOH O-360 that had spent some time sitting and needs a little cylinder work at the outset. After pulling a couple jugs, the well-known Mooney A&P/IA who did the prebuy finds surface corrosion on multiple internal components and even some pitting on cam lobes but normal lobe height and lifter faces. The A&P sends pics of the extensive pitting and says newb owner you must overhaul. The collective “wisdom” of the internet also says that the newb pilot/owner/doctor must overhaul and asserts that he is just another vertical-tailed doctor killer-buying sucka. His demise in a smoking crater seems likely to all because he is arrogant enough not to accept A&P or internet guidance without asking questions. The sucka pilot then takes deep dive into authoritative literature by Mike Busch and others, learning that (1) there is zero danger in running it until cam/lifter truly spalls and (2) it’s easy to monitor the situation through the filter so that once it happens, further damage to the engine can be prevented. Armed with real knowledge, the arrogant newb pilot/owner pushes back hard against the A&P/IA, getting him to sign it off under some duress. Though this newb’s demise seems imminent to all, he flies regularly, uses Camguard, and keeps engine dry in winter by heating it uniformly and continuously. He also cuts and scrutinizes his filter nervously at every oil change, finding nothing for many hundreds of hours. He gets a good engine monitor, learns how to use a borescope, and learns spark plug maintenance, allowing him to monitor the top end as well. He does oil changes and oil analysis religiously but ultimately quits oil analysis after learning enough about it to conclude that it’s utterly useless for real world maintenance decisions on this engine. Finally, after flying for another 1200 hours over 10 years and accumulating ample instrument time, he notices a subtle but consistent decrement in TAS on recent flights. At the next oil change, he finds ample ferrous shavings in the filter (pic). He had become lazy recently and was only cutting every other filter, and so he pulls the previous filter off the shelf and also finds similar metal, realizing that he flew about 80-90 hours with cam lobe(s) and lifter face(s) coming apart. He flys it one last time to a major engine shop 3hrs away for overhaul, marveling at the aircraft’s fast and smooth performance during this serene flight and wondering if he is making the right decision. At overhaul, the suspected cam/lifter spalling is confirmed, and metal shavings are flushed from the oil cooler and governor. The prop is IRAN’d/resealed, and the hub is found to be in fine condition, as is the crankshaft. He’s finally back in the air and still (mostly) enjoying the continuous learning involved in the Mooney ownership journey….7 points

-

As the tapes come out I notice two things which really stand out to me. 1. The acceptance of visual separation by the helicopter. I guess for helicopters, not unusual but at night? I never accept a visual separation at night. Too easy to call the wrong aircraft or get lost in the lights. Depth perception is also difficult so judging distances and closure rates much more difficult. In this case add in NVG and stir well. 2. One controller, two frequencies. In one tape you can hear the controller talking to both aircraft but you don't hear the Blackhawk. I assume he was on Uniform. Whenever I hear a controller talking on two frequencies, the hair on the back of my neck stands up. I see this often with a controller handling two runways with different frequencies. It should be banned. Everyone should be on the same "party line" with a given controller. It used to be many military aircraft did not have Victor radios but I know that has changed because the size of radios has changed greatly. In airspace like DCA, everyone should be on Victor and on the same frequency if the paths are going to cross.6 points

-

6 points

-

This issue needs a novel approach. the FAA needs to get its head out of its 18th century ass and make it easier to certify a new engine, that can have variable electronic ignition and eliminate the need for leaded fuel. Designing a new fuel is obviously a poor solution/approach we have the technology already…6 points

-

6 points

-

I will never hesitate to take a flight on a CRJ. Any airplane that you can crash that bad and everybody walks away, seems like a great airplane to me.6 points

-

I have a friend Lori who was in my old speed skating club. She was a serious competitor. After 9/11 she was mad and joined the Army. She was almost 30 years old at the time. She trained like crazy before going to basic training. She was crazy buff right before she left. We emailed a bit while she was training. She said she finished all the running and hiking ahead of all the guys. If anybody would have been carrying anybody else’s stuff, it would be her. Last I heard she had been to Afghanistan 5 times. She told me the story of her first deployment. They didn’t have separate tents or facilities and her group was coed. They did everything together sleep, eat dress and use the latrine all coed. She said there were no issues. If someone would have tried something with her, she would have kicked their ass. About a month later some officer came by and insisted they have separate tents and facilities. She said there were more problems being separate. She also told me the story about her rifle. She said about every other month some officer would say either all the women must carry a rifle or cannot carry a rifle. She said whenever she got into a HUMVEE or a helicopter, somebody would hand her a rifle. She ended up running the post office for the Army in Afghanistan. She told me once that she knew more about where everybody was deployed than the generals did. She told me once she was really pissed because the bad guys were shelling her base and blew up the new Pizza Hut.6 points

-

This is really the only sensible approach. There’s no way that GAMI expected the fuel to eat through tank sealant and ruin paint within weeks of the event at RHV. I’ve got to think that they expected happy customers. I’m super appreciative of the time and effort that @mluvara has put into his evaluation, and I hope that it helps identify areas of concern that can be addressed by GAMI moving forward. We all benefit hugely from unleaded avgas availability, and we all ultimately want the UL effort to succeed in one way or another.6 points

-

Depends on the plane. I recently quoted insurance for a prospective purchase Cessna 340 to a very active pilot in his mid-70s at very good rates. Below $250K Hull there are generally insurance options (sometimes, but not always, good quality insurance policies) for almost any mass-produced piston single for pilots prior to age 80. Recent pilot hours are helpful to the cause (50+ in previous 12 months is good, more is better). The insurance market is softening. Underwriting seems to soften first, followed by rate. In a claim-inflationary environment, flat rates are effectively rate decreases.6 points

-

I don’t feel the need to get in a back and forth of who’s more experienced. Like I stated, you get to choose what you like or what you think is best for you. Thankfully, I get to do the same. I have ACF-50 in stock and use it as needed. My Mooney isn’t based on a carrier or getting a saltwater bath any time soon.6 points

-

6 points

-

Shop is close to startup! Here are the expected costs: ~$9800 for 4 new Millennium cylinder kits, piston pins/caps, new cam, DLC lifters, gasket kit, new alternator belt, quick drain(I bought and supplied) ~$2700 for all main and rod bearings, 8 new plungers (lifters), 8 new tappet sockets (plungers), 8 new rod bolts, 8 new rod bolt nuts, 4 new pushrods, 2 new lower engine mount bushings, oil and filter, new spark plug wire, incidentals/shop supplies ~$10,500 labor for annual, remove/reinstall engine ($3250), IRAN engine ($5000), IFR certification ($425), R-N-R electric step, flush oil cooler/lines, running /final engine configurations tax ~$220 Total so far is ~$23,220 for this year’s ‘annual’. Give or take a couple hundred more. Hoping that is it for now but that is an approximate cost based on shops current estimate. Once initial run is completed I’ll know for sure. -Don6 points

-

I flew again to the pacific coast of el salvador. On my way there I overflew a volcano. What did i find in the crater? A lake!! Sent from my iPhone using Tapatalk Pro6 points

-

6 points

-

Honestly, from a professional pilot perspective, I wouldn’t think twice about taking off at night into 400 ovc/br. They had two pilots and a capable aircraft. I don’t know what avionics, but some type of autopilot as well. Seems like we always want to blame spacial D (it is sometimes the cause) because it’s easy to say “ I wouldn’t do that” or, “it wouldn’t happen to me.” I think there’s more to this story.6 points

-

A few comments as a Retired Army Rotary wing pilot, but Retired 22 years ago but I don’t think much has changed equipment wise. 1. Some time before 1982 when I Enlisted ALL Army Rotary wing have VHF and UHF radios, we always used VHF when communicating in the Civilian world, AF I believe many only had UHF. 2. There is Military and there is Military, my world was tactical combat units, our job was to fly, this was not what this UH-60 was, my bet it was a White top, that is a pretty painted non tactical VIP transport, I believe there were likely two pilots, one I thought an LTC and a Warrant, at least the Comissioned Officer was a staff officer I’m sure, pilot barely, not with a tactical unit, but likely Pentagon. To get flight pay you have a min number of hours to fly, often put with an Experienced Warrant. If so this 60 was essentially single pilot. Don’t take me wrong you let them fly, but they are barely proficient at best. My last couple of years I was promoted out of a line unit to Brigade Maintenance Officer, so I often flew Staff for them to get their hours, usual mission was from Savannah Ga to Daytona Fl, eat at Hooters and return, they never participated in the flight planning etc, just rode. Again I let them fly if they wanted too, most didn’t. 3. I believe it’s a VFR helicopter corridor, not a Military corridor, as such at 200 ft or below what other clearance could be issued for 200’ and below other than visual? I bet if you looked it was mostly used by police, Medivac etc. but that’s just a guess. Other than VIP transport, what other military mission could there be in DC? 4. Clearly the 60 F’d up, they were high, if at assigned altitude I doubt there would have been an accident, but accidents are chains, the 60 being off of assigned is one link, ATC was obviously another, first I don’t think he told the RJ about the helicopter, then as I believe collision was imminent he didn’t say Army Left turn 30 degrees now, or traffic at 12 O’clock 1 mile etc, he asked do you have the RJ in sight and said pass to the rear. I think the poor RJ was just a victim myself, I don’t even think he had any idea there was a helicopter out there, and I think the 60 never saw the correct RJ either but a different aircraft. 5. Every Army helicopter I’ve ever seen has a Radar altimeter, when low level you always fly the RADAR alt, never the pressure altimeter. So pressure altimeter shouldn’t have been an issue 6. Googles are a poor choice in City lights, any bright light especially a red one shuts them down, yes you can look under them, but as you have been looking at a pretty bright TV screens, your eyes are not night adapted so you can’t see very well unaided. Field of view in the Goggles I flew was 40 x 40 degrees. There is binocular vision so there is distance estimation, what I flew only has one eye so no depth of field, but that can be overcome with training and experience, many people fly that only have vision in one eye. 7. Should have put this up in the accident chain as another link, but putting a helicopter VFR corridor less than 200’ under short final approach is stupid, if for example the pilot flying the 60’s googles bloomed out, and there was a startle response it only takes a few seconds to climb 150 - 200 ft or so, and most just by instinct if flying low lose vision, instinct is to climb, just one possibility. Daytime this corridor would likely be OK, but night? No. In summation in my opinion, the 60 drivers were at fault, ATC has some liability, but whoever allowed a VFR helicopter corridor that close also has blame, my opinion that was the worst. Poor RJ drivers were just victims I think. All this speculation and opinion, I guess we will know in several months when the report comes out? Oh, and except for Test Flights, ALL Military flights are training, Don’t know about VIP transport, we didn’t do any of that with Apache’s6 points

-

If fuel has historically never stripped your paint, and a new fuel is represented as being essentially a drop-in for the old fuel, but it does strip your paint, I don't think the leaks are the issue. Tanks will develop leaks, whether they have bladders or wet wings or integral tanks or whatever, and if the new way of finding a leak is that that paint gets stripped off, I think that's a highly undesirable feature of the fuel.6 points

-

6 points

-

The “substandard methods” appear to have been adequate to resist all factors prior to now, which would seem to at a minimum diminish your assessment of what is adequate. if it withstood all chemical and environmental conditions before g100ul, why is it now substandard?6 points

-

6 points

-

What we're seeing was: 1) discussed and brought forth by PAFI in their testing and development of fuels and was discovered and warned about with use of higher content aromatics (PAFI Lessons Learned); 2) paint damage has been shown to occur in at least 7 aircraft that have been fueled with G100UL release in California, usually in response to marked leaks that show signs of escalation in leak location and amount of leak, but also paint damage has been shown in the form of staining with any spill/splash or drop not immediately cleaned with a product such as Windex; 3) GAMI/Braly has reacted defensively making initial comments that issues seen are due to high aromatic 100LL and not due to even higher aromatic G100UL; 3a) Cirrus finds that G100UL may not be compatible with their sealant and issues service advisories stating that G100UL is not approved to be run in their aircraft and this may void warranty. GAMI releases a series of YouTube videos and commentary on their website in response; 3b) Textron keeps G100UL off their approved fuel list; Continental and Lycoming keep G100UL off their approved fuel list; 3c) PAFI candidate reports that creating a truly "drop in fuel" (fuel without any requirements of modification) is likely impossible; 4) a video surfaces performed by an engineer/A&P where he uses G100UL initially from the pump, but then also tests that were from the affected aircraft that demonstrates the process shown in the affected aircraft (Luvara video 1) (Luvara video 2); 5) GAMI releases a series of YouTube videos that don't use the affected aircraft, doesn't use various test cases, and solely focuses on one model of aircraft and paint to present "hard data" to make a statement that G100UL doesn't affect paint and shows how "easy" it is to remove staining from paint with "standard shop techniques for cleaning up paint" (G100UL soak test) (G100UL drip test); 6) AOPA Baron makes the statement, "G100UL tends to stain paint, hangar floors, and anything else it touches. Pilots and aircraft owners can take precautions by applying protective coatings, but G100UL doesn’t wipe away or evaporate like avgas. Inadvertent and relatively small fuel spills must be cleaned immediately and thoroughly to avoid staining." And in fact, if exposed to UV light the stains are very difficult to remove (AOPA Baron Lessons Learned); 7) FAA is investigating affected aircraft and have taken fuel, oil, and paint samples; 8) These test cases and issues seen have all occurred within about 2 months of the introduction of a new fuel to California; 9) Said fuel is still being sold and is currently marketed as "basically transparent to the engine, aircraft, and pilot. No mechanical modifications are required" other than placards; 10) some who haven't used the fuel are proponents of GAMI/Braly and have come to his defense out of faith that surely the proper testing and FAA certification means that the product should be trusted; 11) many who haven't used the fuel are fearful to use a new fuel without more testing and transparency to determine the merit of the issues shown in California. 12) This would be a simple case of vote with your wallet and either buy the new fuel or dont, however the current political climate (especially in California) has continued to escalate pushes to ban 100LL; due to this the apprehension to use this product is tempered with the fear that this will become a mandate to use this fuel if nothing is said. Proponents of G100UL should fly to a location and fuel up. We fly one of the best traveling, single engine piston aircraft in the world. Either your help disproving the concern, or proving it, would be greatly helpful for the fleet! Good luck!6 points

-

So, just an update...I spoke with John Smoker (COO) at LASAR who is finalizing a licensing agreement to allow for the manufacturing and sale of the 40:1 Gear Sets. LASAR is currently working with the manufacture to update the licensing agreement so it will take a little time before they can take orders. Mr. Smoker will be contacting me, at a later date, to provide me the information regarding costs, lead times and minimum run requirements and once I receive the news I'll provide an update. I would anticipate that we should hear something within the next 30-45 days. I wish I had more information for you, especially those aircraft that are currently AOG searching for options or those individuals that have already undergone modification to keep their aircraft flying. I've been assured that the cost of the gears will be significantly less than the cost of a used actuator. Also, LASAR is currently working to find a means to have the Actuator Motors repaired, so more good news for those with electric landing gears or those wanting to upgrade to electric landing gears. Once again, would not have been possible without the efforts of Jonny Pollack (CEO, Mooney). V/r matt5 points

-

5 points

-

If you are interested in reducing wind noise in flight there really is no better option than installing a Bob Fields inflatable door seal. There has been a lot of discussion regarding this modification and I wanted to dispel some myths and clarify a few other items. The most difficult part of this process is the removal of the old seal. For this task I would recommend a brass wire wheel for a drill or hand grinder. Remove as much of old the seal as you can by hand and with a plastic scraper prior to using the brush. I would recommend that you open the door, remove your interior door panel, and remove the arm closer. This makes it much easier to get to everything for the install. The install directions say to remove the door from the airplane. This may make it a bit easier but is completely unnecessary. With the wire wheel, it’s important to use brass to prevent damage to the back sides of the rivets, you can clean the entire door in less than 30 min. Tape off the cabin, and mask the painted edges of the door to prevent accidental damage with the brush, and keep the debris from getting in the plane. If I ever do this again, I will do this part outside the hangar! After removing the old seal, clean the door with acetone, and then grease and wax remover. This ensures good bond with the adhesive. The directions suggest the inflatable nipple of the seal, be placed on the front side of the door but this isn’t possible with the door on the plane. I elected to drill the hole on the bottom forward corner of the door, where I could reach with a drill . With the interior of the door panel off, drill the hole for the nipple to pull through for connection of the pump bulb. Once again, I am going to contradict the instructions, install the interior door panel BEFORE you glue the seal in place. The reason for this, is that there are areas where the door seal actually laps over panel, which is important for the seal to completely contact the door jamb. The instructions also suggest trimming the door panel. I do NOT recommend this, at least not for the newer style panels. The door seal comes with a long section of hose which allows a lot of options for placement of the hand bulb. Connect this hose to the door seal and bulb while the glue is still wet and get inside the plane with the baggage door open, you will exit this way after installing the door seal. The adhesive sets rather quickly, so be prepared to move quickly. The only three really important points to monitor, one is where the nipple enters the door, two is the stud clamp at the top of the door and three, the bottom of the door where the door closer arm must pass between the door and the seal. Be careful when setting the seal that these areas won’t chaffe or pinch the seal. With the seal all glued, immediately get into the plane and slowly close the door making sure there are no pinch points or areas chaffing. Close and latch the door and then pump the ball about three or four times. This basically forces the seal into a tight fit. At this point, the ball is not mounted and has the long hose attached, so you can drape the hose with the extension out the vent of the pilots window and climb out of the baggage door. Allow a few hours for the glue to set, release the pressure of the seal and open the door. Now choose your mounting point, screw it down and you are finished. Geebee aeroproducts has mentioned on several occasions that this seal can damage door hinges. I can say with 100% certainty that this is not possible with the non electric model. Not only do you not need this much pressure to create the seal, it’s not possible to put much more than probably 10-15psi by hand with this equipment. I do believe it has a high likelihood of leaking while deflated in the rain, so if you are permanently on a ramp and do not have a water tight cover, this will be a big consideration. Some have said, just give it a few pumps prior to closing and this isn’t an issue. I don’t believe I will use this method. One because my plane is hardly ever on a ramp overnight, and two, I will do what I have always done with my Mooney, which is carry a roll of blue tape and cover the door gap and fuel caps if I’m on a transient ramp. I did not do a very good job documenting my work with photos, so I’m sorry I don’t have good visual aids, but I do have photos of the completed install and will be happy to discuss with anyone considering the install. The pics show some areas where the seal laps over the panel. What I found was that these areas had excessive gaps between the door and jams and laying on top of the panel helped fill the void. NOTE: I did NOT glue the seal to any part of the interior panel. Lastly, while some models are not listed on the STC, it is acceptable to install as a minor modification logged by your IA. This is a really easy install if you know the right process. I sure hope you find this helpful! One final note, don’t worry if the seal isn’t perfect and needs to be adjusted after install. It is not difficult to break the bond and re-glue!5 points

-

As the crack has run it’s course, I’d leave it alone, I believe anything you do other than replacement is going to make it look worse. I assume thin CA (super glue) would seal it, I’ve never tried, MEK is so thin I’d want a syringe or something as an applicator, even one drop is going to run I think. I’d practice on scrap first though. In the mean time maybe a strip of clear tape to stop the whistle?5 points

-

5 points

-

Well, now all the drone guys don't have to read them any more. I feel safer already!5 points

-

I appreciate the offers. I never envisioned that a quick look at the effects of the fuel on my personal aircraft prior to application of an STC would lead to this effort of testing. At this point in time, I don't anticipate taking on additional testing and hope that those with the real testing tools and capabilities would perform any of that. It's likely this may already be occurring with some of the affected aircraft. As to composition, I think one can glean enough from the SDS to make a reasonable guess at the percentage of elements, even if you took a mean value or slid them to one side. In the end, it all has to add up to 100%. Michael5 points

-

5 points

-

Here is an update on testing and issues in the field.5 points

-

WOW !! Thanks for the recap. Considering that our engines are antique technology these prices are just insane. So my engine has 500 HSMO and $60K added into the panel in the past 5 years and an airworthy air-frame wrapped around it... why are planes like mine selling for a $100K at best?? I think we are all nuts. Nothing like enjoying a hobby that costs about $10K a year even if you only fly one hour, and can get you killed if you don't do everything just right. Just sayin... I think we are all nuts.5 points

-

Bend spring back and forth while adding washers in the space between coils. Very easy and effectively lengthens the spring so you can attach without damaging you or the plane. Swing gear and washers fall out to be retrieved with a magnet. Be sure to count the washers first.5 points

-

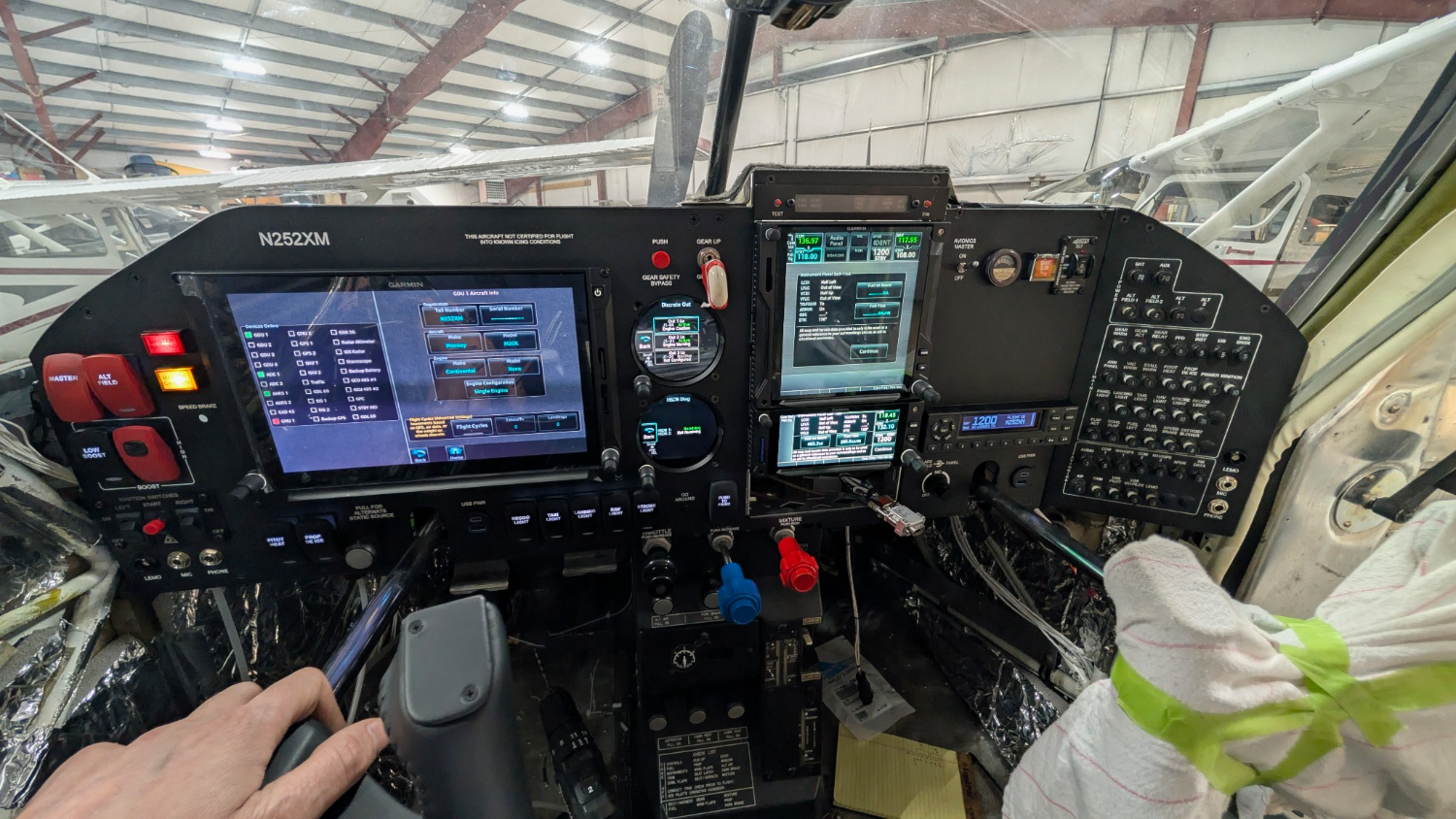

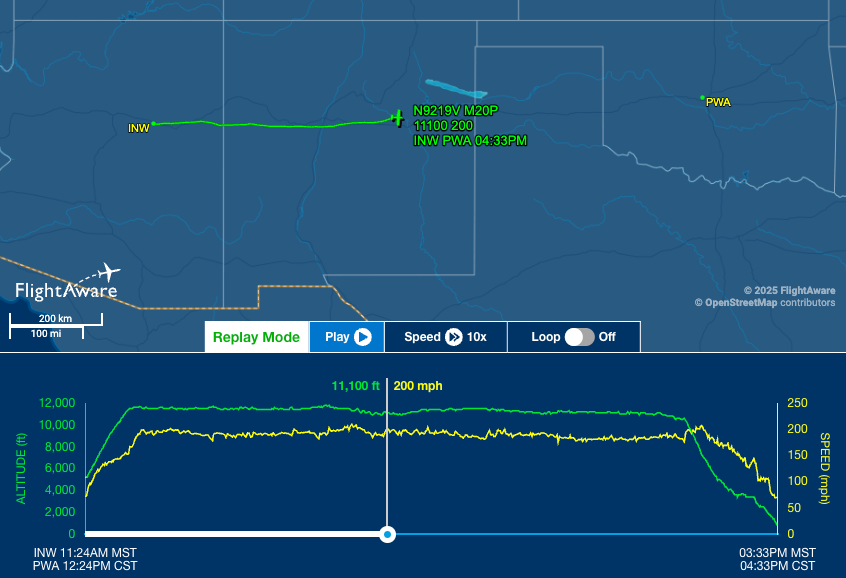

After owning my Mooney for about five years, my flights have more or less limited to California. This is the first time I took my Mooney across the country, or at least half way. 1100 nautical miles from California Central Valley to Oklahoma City with only one stops. 65.5 gallon total. Converted to statute miles, that's 19.3 mpg. Incredible flying machine. Of course 20+ tail wind helped a lot. At times, I was cruising at 180+ knots ground speed!!5 points

-

Mostly from a long XC on the 13th (KFFL to 2S0) but the last picture of an undercast was on the 15th taking off from 2S0 to KTTD for annual. If you look closely at the fuel planning on the 750 in the cockpit picture you'll notice I only have a 20 minute reserve at my destination. Also, I'm at 8,000'. So you should expect me to be IFR. Well, the short version is that I ended up changing my destination to stop and get fuel earlier. As it turns out though, I didn't need to, because as I went further West the headwinds got lighter so I would have had plenty at KBYG, as was calculated by ForeFlight to begin with. But sitting there for an hour looking at the fuel remaining being that low got the better of me and amended my flight plan. Then I was too proud to go and change it back. hahah. The two 'dark' pictures are at night, it was the full moon then and with the snow and full moon, it was plenty bright to see everything!5 points

-

While price is one of the most important data points, what this tool doesn't do is evaluate coverage quality. While most auto insurers have fairly common policy coverages, aviation coverages can be substantially different from insurer to insurer. Some important items: Is Non-owned hull & liability covered? To what limit? $100K? The value of the insured aircraft? A percentage of the aircraft's value? How many seats maximum? What about emergency landing expenses where there's no damage to the aircraft? $10K? $25K? Up to the value of the airplane? Hail damage limits for cosmetic hail damage? 10% of the agreed value minus a deductible? Or is all hail damage covered? What about getting that written off the policy if you primarily hangar your plane? Crew bodily injury exclusions? Someone gets a low price on insuring their Mooney Acclaim, but did their agent tell them that their insurer excludes crew bodily injury? So if they're receiving training and the CFI is injured in an accident, they policyholder will be defending themselves if the CFI brings a demand/suit. Does the tool just use the baseline of $1MM Each Occurrence for Bodily Injury and Property Damage limited to $100K each passenger bodily injury? We really like to see $200K each passenger (this usually only costs $70-$300 more per year).5 points

-

@AndreiC most of the money you spent towards the labor of the actual paint correction. The coating most likely took about a 1/5th of the time and the cost of the coating itself couldn't of been any greater than $200. You're still in a good spot really. Since the paint correction has been completed, and you have protection applied, your paint will continue to look good. You could apply another ceramic coating on top of the poly earlier than a year to ensure continued protection without having to get a full paint correction as well. Coming from a guy who has done a paint correction or two ...5 points

-

4 points

-

I love reading about this kind of troubleshooting -- way easier reading about it than actually having to do it.4 points

-

Send me the two thousand bucks and I’ll see about it4 points

.thumb.jpg.ae084ff98f2eda1b3f595ed45b9592c9.jpg)