Leaderboard

Popular Content

Showing content with the highest reputation on 02/06/2024 in all areas

-

MooneyMax 2024 dates September 5,6,7,8 Location will be Fredericksburg, Texas at The Hangar Hotel. More details to come shortly.3 points

-

What you described is (basically) the flooded start procedure (minus applying boost pump to make sure it’s flooded and possibly slowly walking throttle back as it cranks). I agree that will likely work, but you might look at the ignition system to see why a normal hot start isn’t working. Mine works just like @Shadrach. Very very rarely do I “miss” a hot start and have to do a flooded start.3 points

-

Next time you shut down, set it at idle (should be ~650rpm) and slowly pull mixture to ICO. Should see an rpm increase of 25-50 before it quits. If the increase is more than 50 rpm, the idle mixture is too rich.3 points

-

Your Continental fuel system bears little resemblance to the fuel system on Echo's Lycoming. Each engine probably requires its own technique.3 points

-

3 points

-

Great news! Sorry it took a while to get back but life happens. Spring was definitively the issue but also found a piece of debris on the plunger that appeared to be from the previous leather sweeper ring on the shaft that had deteriorated. Replaced with new spring and reinstalled. Used 12 step bleed method with pressure pot. Flaps are now better than I’ve had them in 20 years! Thanks again for all the help. The biggest clue was this video. My spring had no springiness left. There is no way that ball was staying in place with the way the spring was before it fixed it!2 points

-

The Mooney is a beautiful machine. It has proven versatility. One must choose which variable is to be optimized. It all depends upon your mission. If you want to get there faster, optimize distance / time (nm/hr). If you want to get there cheaper, optimize cost / distance ($/nm). If you want to log time, optimize cost (fuel burn) / time ($/hr). As missions vary, one can choose which knob to tweak. The OP wrote "I'm trying to burn as little fuel as possible so I can prolong my flights for time building." In that case, it doesn't matter how far you go or how fast. The whole goal is to log time for as little $ as possible. I've owned my '67 F for >20 years and have ~1500 hrs. in it. At 17" MP / 2000 rpm level flight, 105 mph (91 kts), I can lean the IO-360-A1A until she barely maintains altitude @ 5.4 gph. I've built ~500 hours over the past 5 years flying around southern CA in this configuration. My purpose was to build time towards my CSEL & ATP. I didn't need to go fast - just needed to log time. With avg. fuel prices ~$6 / gal., this configuration has saved me several $k vs. flying faster. Note: One can also log time while taxiing. You don't have to be burning 5-6 gph. Land long at larger airport runways and extend your taxi-back. 15-20 minutes on the ground at 1.3 gph. makes the average even lower. Of course, when I want to get there faster, I push the "Go" knob and get there at ~170 mph (148 kts). That's ~60% faster for twice the fuel burn rate. I don't think a Cub can do that. It's really nice to have the option.2 points

-

This leaning for taxi business as a potential panacea for idle engine problems just confuses the issue. Save for high DA operations, the Lycoming IO360 is designed to be ground operated at full rich and indeed it operates beautifully at that setting. Nothing wrong with ground leaning if that’s your bag. I do, depending on CHTs. However, choosing to or not to ground lean is not what’s causing the start up problem. It’s either technique, fuel or ignition related.2 points

-

@Shadrach no return line, didn't catch the lycoming. ha. disregard. making coffee now...2 points

-

Perhaps your idle mixture is on the rich side leaving more unburned fuel in the intake at shutdown? I don’t know why your IO 360 should be any different from any other. Hot starts are a non issue for my engine. Shut down at 1000rpm. On start up, treat the engine as preprimed. Leave throttle alone, crank and enrichen when it fires. It usually starts in the first 3 or 4 blades. In the rare instance that it does not, I try a second time to ensure that there is no combustible mixture in the intake. I then prime for a few seconds (3-5 depending on OAT) and try again. I’ve never failed to get it started. If that method does not work for you, somehing else is going on. What’s the status of the ignition system? SOS or impulse coupling?2 points

-

2 points

-

MooneyMax 2024 dates September 5,6,7,8 Location will be Fredericksburg, Texas at The Hangar Hotel. More details to come shortly.2 points

-

Yes, cooler engine temps allow liquid water to combine with the lead sulfates from burnt avgas, producing sludge, and gumming up oil control rings. You want 190-210 dF oil temps, and CHT's in the mid 300's as much as possible for a clean engine. Running at lower power and lower MP settings also causes reversion in the induction system. You'll find exhaust deposits and oil in the intake runners. Also not good for the engine. Fly fast! Your engine will be happier.2 points

-

1 point

-

Found a Mooney M20A that appears to be in very nice condition however the paperwork is sketchy not sure if logbooks are available, looks like the Tachometer has been changed out but not sure if the engine and prop is at TBO , they are claiming under 2000 hours TTAF. Wood wing, metal tail ............... Can the wood wing be replaced for a Metal Wing ? Obvious issues if a wood wing but what else do I need to know, give me your opinions GOOD or BAD !!!1 point

-

Heck, I am further east and looking at making the trip. 2109 straight line. 15 hours and 174 gallons at this time.1 point

-

1 point

-

My IO360 won't reliably hot start with the leave everything alone method either. I have come up with my own variation that works everytime however. For me if I shut down with the throttle at 1300-1400 RPM (or open the throttle to approximately that position before starting), then slowly push in the mixture as I crank it'll fire up once the mixture is about 1/4 of the way in. I lack the mechanical knowledge to know what that does or why it works, I just know that it works so that's what I do. Steve1 point

-

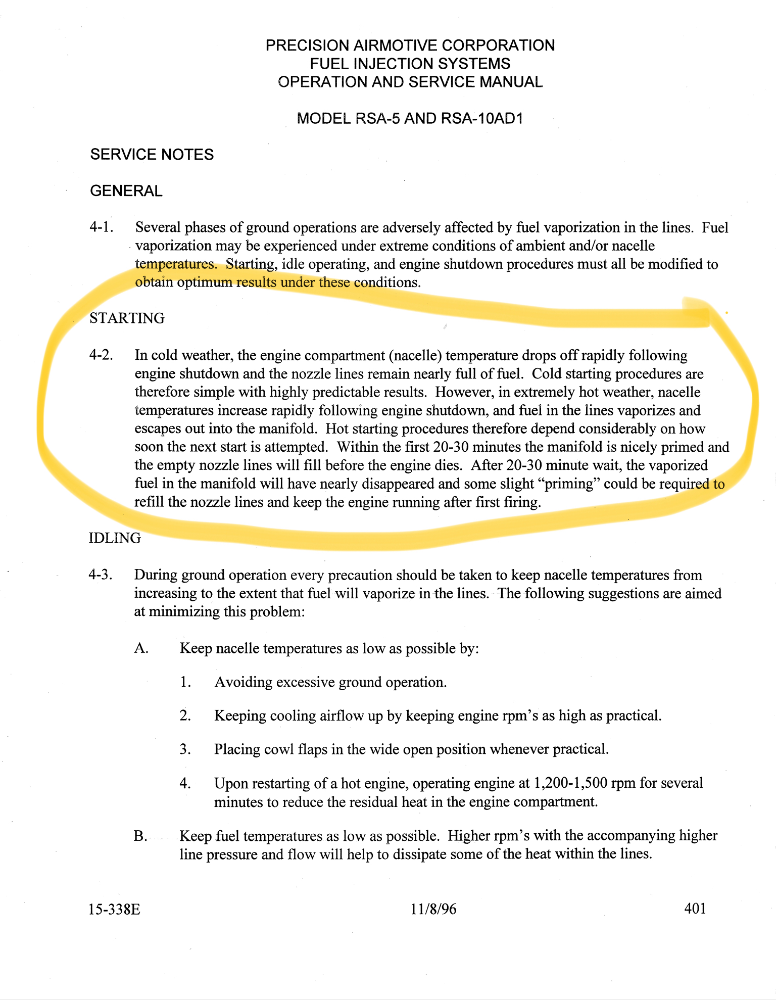

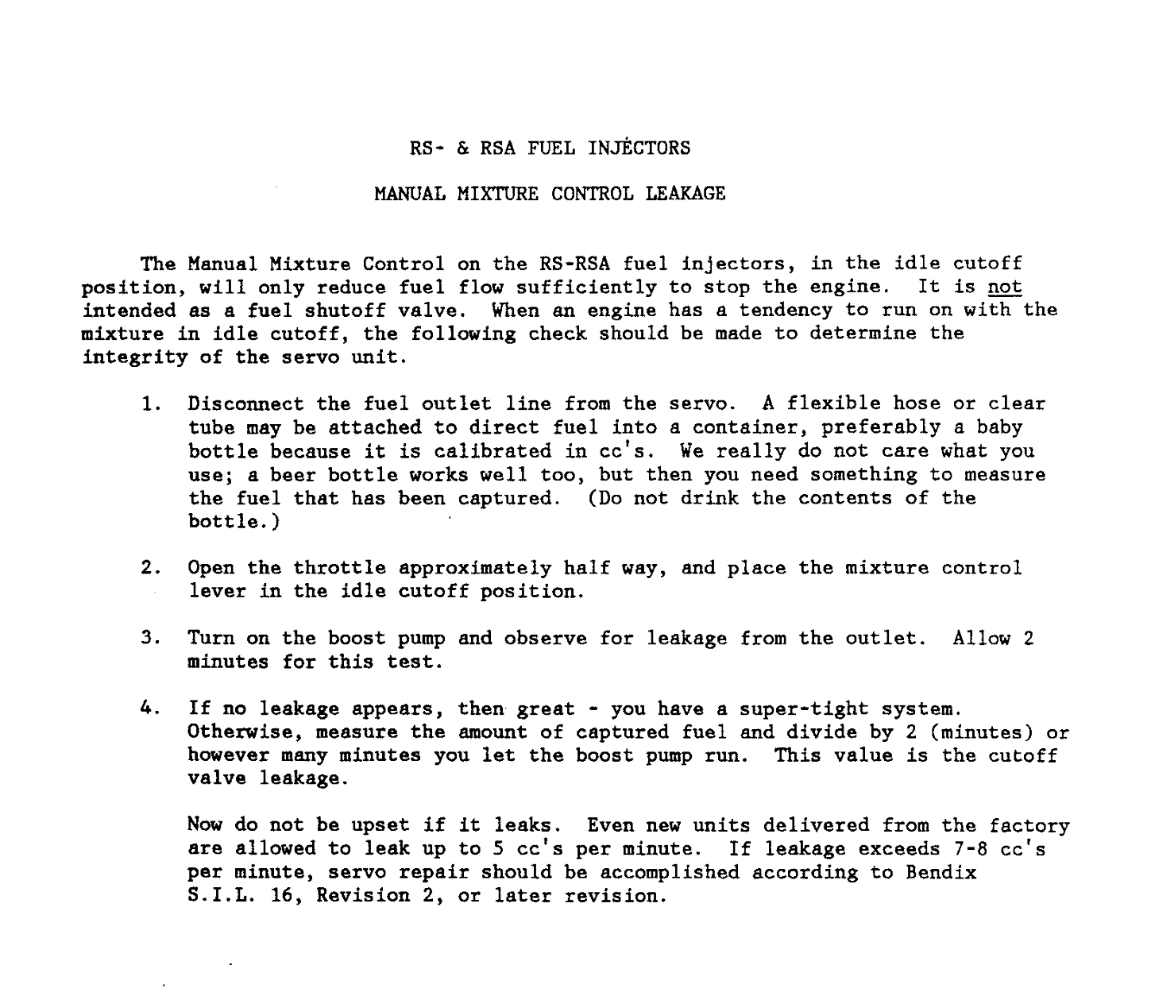

Full throttle and mixture ICO is the flooded start procedure. So, the problem is too much fuel. Assuming good mags and plugs, starting is all about getting a combustible mixture of fuel and air in the cylinders. It helps to understand what’s going on. I’ve attached the starting description by the manufacturer of the fuel injection system. The reason the procedure @SKI suggested works (usually after about half an hour when most of the fuel has vaporized from the lines) is that the heat in the engine compartment vaporizes some fuel in the line between the servo and the fuel pump. Since this fuel is trapped with no where to go, the pressure in this line increases. Opening the throttle and mixture allows this fuel, driven by the pressure in the lines, to prime the engine a bit. One variable is how tight the mixture valve is in the ICO position. The valve isn’t required to completely shut off the fuel flow and most leak a little in the ICO position. This may allow some fuel to flow through the system driven by the increasing pressure described above affecting the amount of fuel at the cylinders some time after shutdown. This might be why your engine seems to be flooded during warm starts. You can do the test described in the attached excerpt from the RSA troubleshooting manual. The procedure @Shadrach suggested works well for me. Since there is no way of knowing how much fuel remains in the lines, start out by assuming there is enough fuel to start in ICO. If not, then prime a bit. I also find that if it doesn’t start in ICO, it will usually start if I put the mixture full rich and keep cranking. I set my throttle to the point where I hear the gear warning switch click.1 point

-

The two main Mooney gatherings are MooneyMax and Mooney Summit. MooneyMax is nice in that it was held in a hotel, that most everyone stayed there. Meals were included, so you literally spent several days, all day with Mooney people. But both are great fun, some great information imparted, and worth the trip. Only issue this year is, with these days, the two may end up fairly close together.1 point

-

I've used Camguard in dozens of IO-550 Continental engines accumulating 300 to 600 hours each, annually. The few starter adapter problems that did occur, have been with those that started life with the Iskra starters. Camguard is primarily an anti-corrosive agent. The anti-wear properties come from that. It prevents rust, which means the internal parts aren't losing metal and wearing down. Every time you shut down, you get a microscopic layer of rust. The next start up scrapes that off. So every time you run the engine, you're losing metal. Continentals made after 2009 seem to rust much faster internally. Especially the cams and lifters. Camguard does an excellent job of reducing rust in humid environments. I have one client who insists on using Aeroshell 15w50 in his Cirrus SR22T. (He gets a new one every three years). Everyone else uses Phillips XC20w50 and Camguard. The engine on Aeroshell is consistently rustier at annual, as viewed with a borescope. And the oil analysis confirms this.1 point

-

1 point

-

I think that’s key, staying in the green temp wise, you can run one too cold, too cold may not be as bad as too hot, but it’s not good. Even in Central Fl mine can get to the bottom of the green, and the difference in being at the bottom and near the middle for me is only .5 GPH. I’m all about being a CB, but saving .5 GPH but running at the bottom of the green is I believe being penny wise and pound foolish.1 point

-

So I recently bought a J. My transition instructor tried something the first day at lunch and it didn't work. So in my hotel that night I was searching Mooneyspace and found the below procedure around here somewhere. It's dirt simple and has worked every time I have tried it. I'm usually running in 4-6 blades. #1 Mixture, Prop and Throttle all full forward for 10-12 seconds. No Boost pump. #2 Mixture Full lean and Throttle about 1000-1200 RPM (Basically cracked open 1/8-3/16 on mine) #3 Crank till it catches then advance Mixture. #4 Smile and breath A sigh of Relief you didn't just kill your starter and battery.1 point

-

I used Dorr Aviation. They brokered the financing and got me a very good rate. And they even gave me a keyring engraved with my N number when the deal closed. My contact there was Alex Howe - ahowe@dorraviation.com1 point

-

MooneyMax is the best one stop shop for Mooney information and camaraderie. Last year was our first year going and it was a great event. Janet Maxwell does an outstanding job pulling this all together for us. The speakers are great and getting to meet so many other Mooney drivers is awesome as well. You’d be remiss to miss it.1 point

-

1 point

-

I have run my A1A 24/24 for the 6 years that I owned it. It always gets 79 or 80 on the compression tests. It is fun to do 21/21 for a bit as the plane feels completely different but this is the more like the landing speed and teaches you how it feels when landing.1 point

-

Those charts state that the numbers are for full rich above 75% and 100ROP below 75%. There is no operational advantage to operating an NA engine LOP at the altitudes in question. Of course, you’ve seen me say many times that LOP operations are better suited to altitudes where there is a surplus of air. Above 7500, operating at peak EGT (richest cylinder) makes the most sense. It puts you in the best BSFC curve, sacrifices little in the way of power while offering good temperature margins, excellent efficiency and smooth operation. It’s interesting that you feel that your airplane gets doggy at higher altitudes. I’ve always thought that the aircraft had a unique aptitude in its class for for cruising at the least busy GA altitudes (10-13K). I prefer flying high unless I am west bound. I have been fortunate enough to enjoy 200kt+ GS on many, many occasions over the years, and nearly 250kts a few times. Typically you have to fly high to catch those kinds of winds.1 point

-

Maintenance records. It will save you money over time. When I flew for a Part 135 operator, we had air Hobbs. That was what was used for maintenance. They had worked it out with the FAA to use that time plus 0.05 hr. per takeoff and landing for pilot flight time. It was a seaplane operation so we generally landed pretty close to where we docked. Most airplanes have a recording tach for maintenance because that is easy to install. The Mooneys with B&D electric tachs had a meter that looks like a Hobbs but is really connected to the tach and calibrated 1:1 at 2500 rpm. Flight schools and rentals usually use a Hobbs meter connected to an oil pressure switch because that maximizes billable time. But they will invariably keep track of both "Hobbs" and "Tach" because they use the Hobbs for billing and the Tach for maintenance. When I installed my G3X, I set the hour meter to flight time. For a while, I also hand the engine time set (calibrated to 2500 rpm) and I noticed about a 8% difference. But, it depends on the ratio of ground time to flight time. I eventually eliminated the engine timer because it confused the mechanics.1 point

-

MooneyMax 2024 dates September 5,6,7,8 Location will be Fredericksburg, Texas at The Hangar Hotel. More details to come shortly.1 point

-

MooneyMax 2024 dates September 5,6,7,8 Location will be Fredericksburg, Texas at The Hangar Hotel. More details to come shortly.1 point

-

CAM Aircraft at Fort Worth Spinks did my panel and autopilot. I think they did a nice job at a reasonable price. The work came in at the quoted fee on all of the work. They have since gotten new owners but the new owners were avionic technicians for the original owner who retired. They bought the shop. But they were the guys that did all of the work. The owner had a maintenance side to CAM aircraft that was more of his thing but apparently that is being shut down and all they will be doing is avionics. CAM Aircraft1 point

-

Typically, in Mooney's, if the OAT is 59 degrees Fahrenheit or above you can get a low-pressure indication due to the viscosity of the fluid. @amekler I sent you a PM.1 point

-

I would use a drill bit to clean out the vents. It will pull the mud from the mud daubers down and out as you spin it. Just use your fingers to spin it. After you get a hole in the mud, use wet pipe cleaners to clean the last bit of dirt out of the vent.1 point

-

Good Morning All, I have an update that is mildly encouraging. I spoke with John Paul at GAMI and he confirmed that GAMI is working with a machine shop and the FAA to manufacture v-band clamps under an STC. He seemed to think that it could be as little as two months before production starts, provided the process continues to flow without issues. That probably means more like 6 months but, hey, it's somewhat encouraging.1 point

-

I bought one off a member here about 6 weeks ago. My hangar is also slightly up hill and only 40' wide so I needed a controlled way to get my J in. I paid $1500 and I think new they are about $2200. Even if you need to pay the $2200 I highly recommend them. They are worth every penny in my opinion. Hanger rash on a wingtip or a screwed up back is way worse than paying the money in the grand scheme of aviation.1 point

-

I would not change the material from fiberglass for several reasons, Glass, kevlar and Carbon have all been around about the same amount of time, but carbon is "sexier" but not the right choice in this application, nor is kevlar. This part is made of very light glass cloth. This was done to allow maximum conformability. If you use a heavier weight cloth you will need to vacuum bag to get the right shape etc. you need to be an expert to pull this off in heavier weight cloth. details matter. The carbon can be much harder to work with and again, less easy to find in light weight. Kevlar is for high abrasion application or tensile strength applications but neither of those applications apply here so again, wrong materials. One major mistake is not using RTV when installing the lower half to the upper section (male to female overlap joint). The result will be fretting or vibration which chafes through the glass and puts silica into your oil. you will see this immediately in your oil analysis. the correct application is a finger wide thin film of rtv inside the female section on assembly so it's both airtight and vibration free. don't use too much or it will be too hard to take apart. I would focus less on the "fire" risk of polyester and worry more about the usability issues with novice folks using poly vs epoxy. Epoxy can be more forgiving in a tricky layup or for the inexperienced. The repairs take some care but anybody skilled with quality glass repair can do a nice job. sand and spray paint with high temp silver paint.1 point

-

Give it a good 2700rpm & WOT until it screams and burn all the moisture, lead and sulfure, you need to warm up your oil/cylinders past 200F/300F and fly that for while, then you can bring it back to 20/20 LOP cruise What you can’t do is fly it 20/20 all the time, this gets you the same result as people who are doing ground runs instead of flying, that does not get cylinders and oil hot enough and likely more bad for the engine… In any case, flying at 20/20 is better than no flying1 point

-

After retuning the plane to service after changing the oil sump gasket a couple of years ago, I thought I noticed the oil pressure running higher than I remembered. Near top of green, higher if not fully warm. I removed all but one washer from the pressure regulator, but it still remained high. I assured myself that high was not a bad thing and kept on keeping on. But the gnawing question is if there is any “bad” thing it could be pointing at. Oil analysis and filter cut has been normal. On an unrelated note (I think), a spike in oil consumption led me to pulling #4 cylinder, finding a broken top ring. Reworked cylinder (Phil’s) and finally flew the first hour of run-in yesterday. This morning’s inspection happily shows negligible oil consumption and for the first time in a long time, no drip puddle under the breather. This is on my 2300 hour engine. While the cylinder was off, internal inspection of the cam, etc., looked very good. It was never my intention to care for a geriatric engine, but apparently it is doing better than I am.1 point

-

1 point

-

I’m not doubting your statement, but I am curious where you found this information?1 point

-

1 point

-

I would run it at 19/19 and lean it as lean as you can get it without it running rough. If you are concerned about dehydrating your oil, change it more often or fly at high power every now and then. I would say any time spent flying is better for the engine than time spent sitting on the ground. No matter what power setting.1 point

-

I'm staying clear or any RPM restriction on my prop (I think that's at 2000-2350). What do you mean by "105 would seem slow"? I could cruise even slower if I wanted to pull more power, but the gear warning alarm would trigger and make the flight unpleasant. I'm trying to burn as little fuel as possible so I can prolong my flights for time building. If I wanted to get somewhere faster, I could cruise at 65% or 75%, but that's not my "mission" all the time. I purchased the plane so I could get the best of most worlds and get to choose to burn less fuel for time flown when flying locally and take the 600 mile trips in 4 hours when I need. I just wanted to make sure that low power wouldn't cause other issues, but it does sound like it will unfortunately.1 point

-

I managed to get the Rocket & Missile articles and brochures scanned into 18 separate PDF documents for the archives. Includes at least one M20K 252 article. Hopefully they can be downloaded. If anyone wants these emailed, please send me a message. Missile MAPA 5765.pdf Missile Living MAPA.pdf Missile Firepower Sep 94.pdf M20K 252 Apr 99.pdf M20 Missile Mar 03.pdf Mooneys Dominate Oct 92.pdf Muscular Mooneys Sep 94.pdf Rocket Along P&P Sep 94.pdf Rocket Contract.pdf Rocket Demon Sep 93.pdf Rocket Document List .pdf Rocket Flying AP Sep 92.pdf Rocket Irv Feher Brochure.pdf Rocket Irv Feher Local .pdf Rocket Log .pdf Rocket Me Jan 94.pdf Rocket P&P.pdf Rocket Pocket P&P Oct 92 .pdf1 point

-

Funny how these things happen. My century 41 started to poop out this past year. With century going out of business and the outlook for parts for the next 10+ years only getting worse I decided also to take the hit and replace with Garmin gfc500. I considered the G3x path but just couldn’t get there with the budget. There’s a lot of “while you’re in there” paths you can take! Mines currently at Don Maxwell’s getting the hook up now. Looking forward to the new functionality.1 point

-

https://www.lycoming.com/sites/default/files/attachments/SB480F%20Oil%20ServicingMetallic%20Solids%20Identification%20After%20Oil%20Servicing%20and%20Associated%20Corrective%20Action.pdf Page 2 on that SB Also the Mooney Maintenance Manual for the M20M on page 4 of section 12-10-04 specifies 25 hour oil changes on this engine.1 point

-

If you’re in Southern California hit me up. I Can get you a few ounces just about every week of Matterhorn white jetglo (or Imron for that matter) rather than using car paint. That or we can spray it for you as a courtesy if you’ve already prepped it at no cost in between other jobs.1 point

-

wasn't meant to be anonymous i had to pick a user name. I own Blue Skies Aviation my name is Shaune Maycock and what i said is the complete truth. You can say one sided I don't really care. As of today I no longer hold Don in high regards. My name Mooney Builder is as such because I use to work ant Mooney. No suck thing ans libel when you are speaking of a Business and when what is said is the truth. If you use your name as your business name then be prepared for people to discuss all avenues, good or bad, about your business. Call it "slamming" if you want its the truth and I was very disappointed about it. I also never heard anything negative about Don Maxwell, that's why I said "WOW". This is not a rant. Maybe he does not act that way to customers, but I am another shop and I think he was offended when I was asking for clarification about how he described items, and no I was not rude when asking questions. I was very polite because I respected his reputation. I know you want to defend him, and that's fine. I am only describing how I was treated. I made a correction to my original post...darn auto-correct.... So don't think I am trying to slam Don Mawell. I have a right to tell the community my experience.1 point