Leaderboard

Popular Content

Showing content with the highest reputation on 01/03/2025 in all areas

-

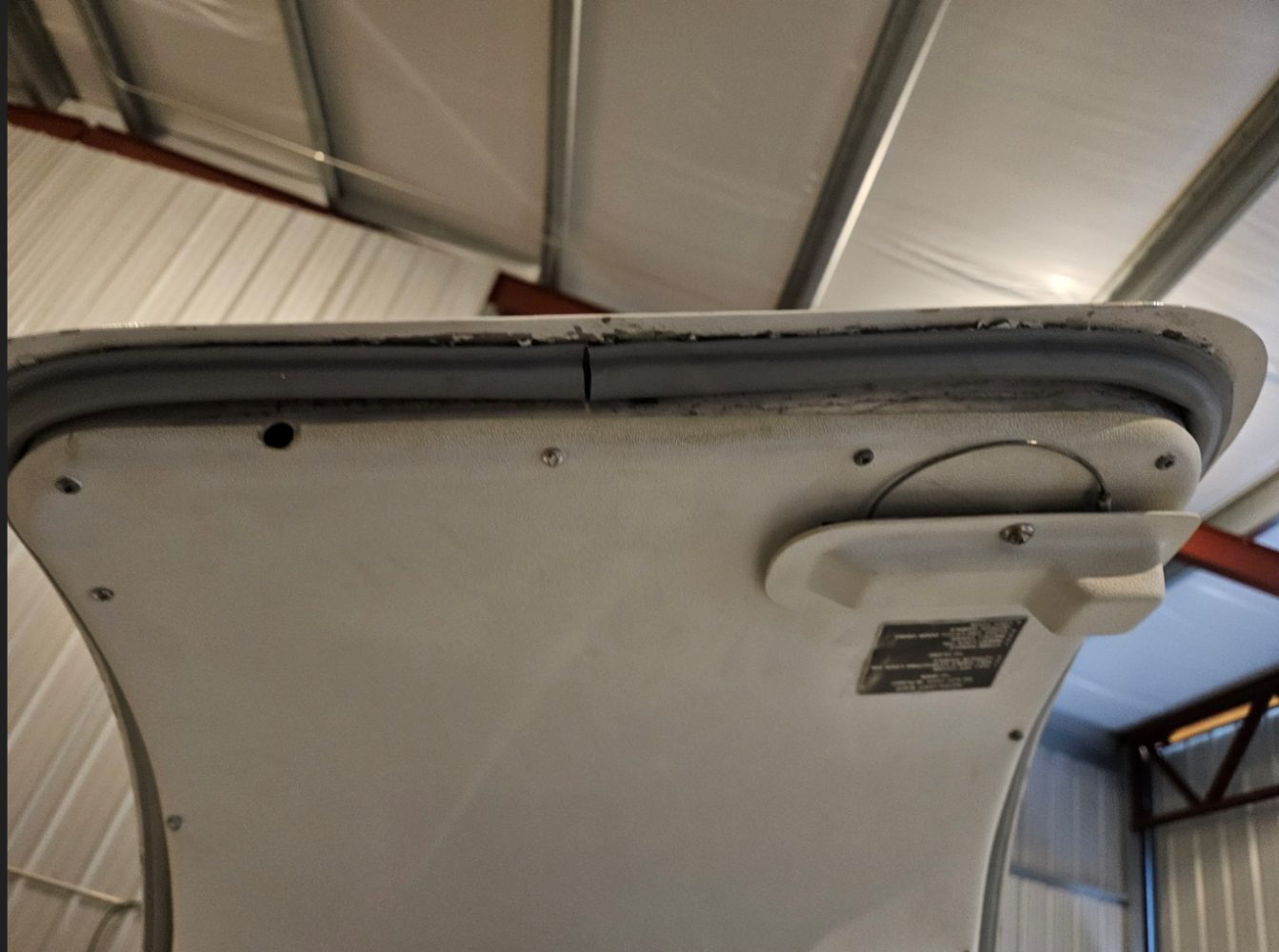

Background - it came up in another thread last year that new factory-style Mooney baggage door seals were hard to source. The Knots 2 U ones sold on Spruce and other places are made of cheap weatherstripping foam, are not factory style, and instead of attaching to the door, they go on the airframe, and therefore get scraped/damaged easily as you load and unload baggage from the plane. I'd been through several of those, with the last one not even lasting two years, when I complained here. @Gee Bee Aeroproducts stepped up, I believe bought a salvage baggage door, and manufactured a new factory-style seal out of modern high-quality silicone. I think I bought the first one. Shame on me, it took me a few months to get around to getting it on the plane, and a couple more months to post this, but it's there now. Report: The seal is great. Arrived with enough seal material to make a little more than two of them and a nice clear 2-part epoxy to glue it on. It makes a much tighter fit than the foam seal did, such that I had to lubricate the lock pins to get it to close. At first I was worried it was too tight, but after a little grease on the pins, it closes smoothly and is very snug. Before, the latch felt like it could pop open in flight if not locked. Now, I still lock it, but there's no way it's coming open unintentionally if I were to forget. I've never had a factory style seal, so I'm not sure, but suspect it's working as intended now. I also never had problems with water intrusion before, but I'm certain it seals better and tighter now. It's been on for a couple of months and has not compressed or loosened much, which is perfect. It's safe and out of the way on the door and I don't expect it to get damaged or need replacing any time soon. Thanks Guy for making a great new product for our Mooneys. A few pics below.4 points

-

It’s hard to track all the various G100UL threads but it seems like they’re all full of complaining that we need 100LL to remain available until we get a perfect replacement and then for quite a long while after that. Some of these are even seemingly directed at George Braly for reasons I can’t fathom… they’re probably better directed at your congressman, or maybe members of the incoming administration. GAMI isn’t taking away anyone’s 100LL, but it seems crystal clear to me that it’s only a matter of time before we (the GA community) lose the battle and governments (local, state, and federal) force the issue. Whether it ought to be that way isn’t terribly important, because that’s how it is. We can’t even keep our airports open and financially solvent, let alone simultaneously fight a never ending battle against the environmental authorities. It also seems likely now there’s not any silver bullet forthcoming… G100UL has the big STC paperwork hurdle and these possible paint/elastomer issues, and reportedly the (only remaining) EAGLE candidate from VP/etc isn’t able to meet the full octane requirements. So what do we do now? Give up and hope something else emerges? 100LL extinction is coming whether we like it or not. I have my own concerns about G100UL based on the o-ring test and reports of leaks. But I think it would be useful to have a sober and objective look at how serious these problems are and whether they can be overcome. It’s highly relevant to me whether, for example, G100UL attacks and compromises even freshly sealed tanks using the sealants in wide use today, versus only older tanks with various patches, etc. Does it affect bladders similarly? Is the o-ring issue causing actual problems in the field and can Viton o-rings be sourced if needed? Does it affect all types of aircraft paint, including new paint, or does it primarily affect older oxidized paint? Yes, it would suck have to do a full tank strip/reseal just to use G100UL, but as a Mooney owner I know that’s inevitable someday anyway. It would just be good to understand whether newer sealants are more compatible or will it just leak again in short order, etc. Basically, if G100UL ‘wins’, what does the world look like for us? Also, if it really is true that the EAGLE alternative is lower octane than ‘100LL’, I don’t know that a slightly better materials compatibility situation outweighs the loss of detonation margin, especially after it seems likely that the UL94 valve seat issues were octane related.4 points

-

3 points

-

3 points

-

When I went to A&P school my instructor told the class over and over, this course is not to teach you how to weld. It is to teach the difference between a good weld and a bad one. On a certified aircraft you need a real welder.2 points

-

His point is valid, the cell was 50 years old, well beyond I’m sure it’s expected life span. It didn’t “owe” anyone anything. But it does bring up another point, does G100UL have a different effect on aged “rubber” components that have been soaked in leaded fuel for years? In truth there are just too many possible combinations to test, Africa hot, Arctic cold, Arizona dry, Florida humid? Different aged products etc, etc. Who knows how many different materials fuel cells have been made out of? All you can do is a reasonable amount of testing, then you have to field it and sit back and wait, it could even take years before problems pop up, but of course as time goes on the probabilities decline rapidly.2 points

-

I am hoping that with the seeming cultural shift as evidenced in the recent election, there will be a pushback from at least most of the flyover states. I am not asking that 100LL be anointed, only that any potential alternative be subject to free market forces. The ultimate 3rd party testing will be by customers.2 points

-

Corrosion is a killer. Specifically on the spar, stub spar, interior spar (under the back seats) and on the steel cage structure. Definitely check for corrosion. They are wet wings too, but those can be fixed or completely resealed if required, however it can be expensive. Looking for blue leaks is worthwhile but not necessarily a killer. Otherwise they are pretty straightforward as far as engine, landing gear, flight controls, etc.2 points

-

Good news update. Plane is flying appreciably straighter now that the flaps and rudder have been adjusted with the travel boards. Slow flight and stalls have both been easier and more predictable. Cruise flight requires much less input. Thanks for everyone’s input. Bottom line, if your Mooney is not flying straight or behaving well in a stall, it’s worth the hassle to source travel boards and get it done right. And for what it’s worth, my mechanic is not an MSC and was able to get this done in approximately a 9 hours of labour (first time doing Mooney rigging).2 points

-

I made a couple of calls, first I called Griggs who has the Mooney fuel cells now, they have no idea at all whether the Gami fuel will have any effect on their cells or not. Secondly I called Eagle fuel cells who I’ve had past experience with and respect, unfortunately the person who could speak to that issue is out and will return my call. Mooney fuel cells are made from Neoprene and Nylon, assumption mostly neoprene with nylon reinforcement where necessary. http://griggsaircraft.com/fabrication/mooney_bladders I did some looking at what the difference is between nitrile and neoprene, it seems nitrile is much more chemical resistant especially oils and solvents than neoprene If nitrile is reacting, then it seems neoprene may be worse? Maybe, time will tell. https://www.casertainc.com/blog/nitrile-vs-neoprene/2 points

-

That may be true of some vendor parts, but they still supply some parts that they get from vendors just not the very expensive parts (example: $1000+ no-clutch back springs, 40:1 Gear sets, etc). The whiteboard I mentioned earlier showed which parts were ordered when they were expected and when they arrived. If they weren't buying anything from vendors they wouldn't even have the raw materials to produce the parts they make. They are buying raw materials and some vendor produced parts. Some of what I ordered this past year were not Mooney produced parts but vendor parts, one of which had a production date of 2 weeks before I received it. I have Jonny's message on video that night at MooneyMax which primarily address the back springs. I have a video of what was said during the tour earlier that day and a picture of the whiteboard I mentioned in an earlier post on this thread but out of respect for their privacy I won't post any of that. Whatever anyone who needs parts chooses to do is up to them. This forum loves to go round and round about this. But the times in 2024 that I put in a backorder for the parts, including a vendor part that was not in stock, an MSC got them for me. They are shipping parts out five days a week out of Kerrville. I have a buddy who is the UPS driver on that route who delivers and picks up packages every day from them. Mooney specifically said during the tour in September 2024 that if you need a part, put in a backorder for it - that's how they determine what's needed the most in the field - so that's what I'll do when I need a part. Have they communicated that well to the MSCs? I don't know. Does that guarantee that they can even still get every part that was used on an aircraft made many years ago? No.2 points

-

Use the Dynon HDX (7" or 10") Use the Aerocruze for the autopilot and if you need IFR capability (I don;t) add in a WAAS GPS navigator to feed the system (you might already have a compatible one installed). I have almost 2 complete Brittian systems in my hangar (none in the airplane, not needed). I'll probably have a complete flight report next week but the first 2 check flights show good right now.2 points

-

The ISSUE is if whatever patches, new or old, are MORE affected by G100UL than by 100LL.2 points

-

^This^. I scanned my wiring diagram and I am slowly updating the electrical diagrams and leaving the avionics to another schematic. Things like, instrument cluster, fuel flow, clock, standby vacuum, strobe power supplies, etc are being erased. Only Power and ground for avionics are shown on this diagram. Lee2 points

-

I have no idea how widespread this fuel is or how many aircraft use it, but I’d suspect that before long in California it will become very widespread as other Jurisdictions jump onto the ban lead bandwagon, but never having lived there that’s just my guess. What I’m getting at is that there are several independent third party testers, the users of the fuel, if in fact the fuel is causing issues this early after it’s adoption, then the number of aircraft that are having problems will increase with the number of users. Plus and this is just from my own experience with chemicals reacting with fuel tank sealant and paint, the longer the paint and sealant is exposed if there is a problem, it will get worse. I’m thinking that if in fact there is a problem, it will become pretty apparent with the passage of time and increase in users. Mooney’s aren’t the only aircraft with wet wings. In truth I think the only real test, or arguably the true acid test is to put it out there and see what happens, hopefully nothing. By the way, what’s this selling for per gl?2 points

-

Aerocruze is built in and doesn't need an external gyro its built in but not mechanical It does require a GPS navigator either WAAS or even a hand held GPS with serial data feed out. The Dynon HDX will drive the Aerocruze with the Dynon head controls OR you can just use the Aerocruze knobs if you want.2 points

-

I am beginning to think we can't get to UL fuel without some pain. Recall the introduction of ethanol into gasoline. In tank electric pumps failed by the thousands. Boats were especially vulnerable as fiberglass fuel tanks turned to goo and aluminum tanks corroded to the point of leaking. I had to replace all the fuel lines in my 2 year old boat, because ethanol would cause them to sweat fuel. Equally so when ULSD came out, thousands of diesels with mechanical injection pumps failed. When ULSD came out with 10% bio-diesel (so the suppliers could get their federal subsidy) it gelled easily in cold temps. We on this very board have for some time encouraged the use of fluorosilicone O-rings on fuel caps. Indeed not a fuel cap thread goes by here without that admonishment. I don't think you "get there from here" without some modifications to 50 year old machines. Guys with classic cars understand that. That means some of you will likely have to hunt down all your nitrile seals and change them, like I had to change the fuel lines in my new boat. We don't know where all the nitrile seals are in our machines, but as we say in the South, "We're a fixin' to find out". Personally if I end up with using a re-formulated fuel before I call it quits in aviation, I plan to fuel my airplane, run it up so I get the fuel fully introduced through out the fuel system. Let it sit for 7 days and then inspect. I think that is prudent because like the ethanol introduction, it is not going to be a smooth "drop in" process and it never has for any new fuel. GAMI has enjoyed a Stirling reputation in this industry. I don't think Mr. Braly would jeopardize that by price gouging or knowingly selling a defective product. He knows as much about the chemistry and science as anybody out there and I think his efforts are genuine in trying to get GA where it has to go under immense public pressure that will not go away as much as some think it could.2 points

-

Nice review. Is it “P” shaped like the stock one? Almost looks like you have it on backwards, with the flat part facing outwards instead of being tucked flush under the trim panel.1 point

-

I have a little bit... I won my first blind sealed bid for a salvage J that was not repairable from a landing accident. I traveled to the storage location to evaluate it myself, and discovered the crank was severely bent on an otherwise seemingly nice 220 SMOH engine, so that devalued the salvage a good bit. I discovered some extras that were not listed in the ad copy like removable rear bucket seats and the turbo normalizer kit, that had extra value for me. I made a spreadsheet of what I didn't need and thought I could sell, and assigned value to the components/upgrades I wanted to keep to improve my plane, or stock my spares stash. I tallied all that up and bid appropriately and won! I paid to have it delivered to me, and after a few years of disassembly and selling things on the side, I actually made all my money back and a bit more, plus had upgrades and spares for my J. (My labor was $0/hour though!) I don't believe sales prices are ever disclosed... insurance companies obviously want to keep that secret as well as the salvage businesses that compete against each otehr. Over the next couple of years, I bid on 2-3 more and even traveled to look at one, but did not get them. I bid lower since they would have been nice to have but not as great of deal as my first one, but others got them of course. You're generally bidding against salvage operators that need to make money on them, so if you're doing one for your own use you can likely outbid them. I think most of the salvage folks will value what is easily sellable within some short period of time and bid based on that, and everything else is gravy but those parts must be inventoried, listed, and stored and that has expense. Some like Wentworth have taken to stripping an otherwise fixable airframe of avionics and maybe even an engine, and then listing the empty airframe on ebay... I hate that practice. If you're wanting a fixer-upper to fly again, you'll have to consider getting it transported to you in such a way that it doesn't cause additional damage, or fixing enough on-site to get a ferry permit. Both of those options are more effort/expense vs. bring a hulk of an airframe somewhere that won't fly again. If you're trying to turn a salvage fixer-upper into a flipper for profit, I suspect in most cases you'll need to get it for nearly free to make that pencil-out. If you want to do it as a way to use sweat-equity to get into your own plane and enjoy it for years, then it might be worthwhile if you have the skills and the time.1 point

-

This morning, I took my wife to see her mother in central NC. The direct path is almost over ATL airport; ATL Approach guards the sacred Bravo airspace like nothing I've ever seen--in 17 years of flying past Atlanta (where my direct path lies inside the Bravo), I've never been allowed inside. First it was "remain clear of the Bravo," then it became "stay out of the Bravo." So with beautiful VFR conditions widespread across the Southeast, we loaded up and took off. My route was KALX-->KOPN-->KFAY, to stay out of the Bravo without being told. Well, about ten minutes after I got set up with flight following, ATL Center asked, "are you direct to your destination?" I said no, I was going via OPN to avoid the Bravo, since I'd not been allowed inside for 17 years. He came back with, "today may be your day, if any is." Sure enough, a minute later it was "cleared direct destination through the Bravo." So I turned from 092 to 073 and went with it. I changed freqs and confirmed clearance with that controller (VFR through the Bravo), and he said "you are cleared through the Bravo at 7500." My first ever penetration of the ATL Bravo! On Christmas morning!! It's a Christmas miracle!!!1 point

-

This had my laughing...until I realized I did a flight from CT to NJ last weekend. Wonder of Bruce's Custom Covers is starting to make flack jackets for the cowlings...1 point

-

1 point

-

POH 7-16: BAGGAGE COMPARTMENT The baggage compartment is located aft of rear passenger seats. The standard compartment has 20.9 cubic feet (0.59 cu.m.) of baggage or cargo space. A maximum of 120 pounds (54 Kg) may be loaded in this area. There are floor tiedown straps provided. Passengers should not be allowed to occupy this space. Additional cargo space is available by folding rear seats down. To fold seats down remove rear seat bottom cushion. Pull seat back release handle and fold seat back forward, pull Velcro attachment loose, and slide seat cover UP and OFF frame. Fold the seat backs the rest of the way down. Store the cushions as desired. Reverse the procedure to re--install. Seat back frames may also be removed for additional space. To remove frame fold rear seat back forward, pull Velcro attachment loose, and slide seat cover UP and OFF frame. Pull the lock pin on the left side of each frame then pull seat frame from pivot rods. Pull seat back release handle UP and push pivot rods forward & down into seat cushion cavity. Reverse the procedure to re--install.1 point

-

You can do this, the 530W will work fine with the G3X/GFC system, but of course you won't have VNAV which you probably already know. That KX170B is ancient and takes up a ton of panel space. I would see if you can't find something, anything, better than that. Whatever you're putting in the future will be way smaller than that. I assume you also won't be able to have the G3X show the NAV2 CDI from that either, but I admit I am not knowledgeable about the old analog stuff with the G3X. I would vote at minimum you try to pick up a used Garmin SL30 or something. (The only old radio I kept in my upgrade) It's a great unit, small/thin, and can be easily replaced down the line with the GNC215 (was designed to replaced the SL30 in fact, but not pin compatible). The SL30 will at least interface with the G3X in every way except flip/flop of the frequencies. I would also strongly consider the G3X EIS. I am super happy I have EIS on my G3X. It is very nice to have everything on the same PFD, and engine parameter alerts are displayed front and center. Additionally, since you're doing a G3X, that is basically a full panel overhaul, and now is the time to also ditch the analog legacy gauges, which you can do with the G3X EIS. The GTX335 and GMA340 are fine as-is. I am told the yaw damper is also easy to add. I plan to add it to mine later. There is a spot in the servo mounting bracket for it already. (It comes that way) That being said, a G3X + GFC + install including a full new panel is going to be probably 70%+ of the cost of your full system.1 point

-

EricJ: Wonderful information!! Thank you for sharing it. From what I heard from the servo overhaul shop, the screens are plain steel - and so they rust. I also understand that the boost pump is a vane-type pump with a steel sleeve that the vanes ride on; perhaps with ingress of water (which then sits for a while, depending...) that steel sleeve rusts a bit. I have had one party recommend rebuilding or replacing the boost pump as it may fail (and yes - mine is old too - I think it is an old Dukes, but haven't looked...). Thanks again!!1 point

-

Kind of like people that are SCREAMING on their phones as they walk down the street... Then claim it was a "private" conversation.1 point

-

@Yetti I honestly can't believe you think it's a good idea to suggest that someone who has never welded go out and buy a cheap HF welder and 'learn' on his Mooney. Sorry, NOT a good plan.1 point

-

1 point

-

I suspect that if it’s $1 more than 100LL that very few will buy it if they can buy 100LL. Only way it will be a success is if 100 LL isn’t available. I would hope that before 100 LL is banned overall, that ADI will become widespread in STC’s, I would also suspect that on a Mooney to burn car gas that it might take an electric fuel pump running continuously, possibly not our current boost pump, but if 94 UL becomes widely available that it wouldn’t. Only the high compression or turbo motors need 100, the rest of the fleet doesn’t, pretty much anything with a Carburetor doesn’t need 100, not 100% but most. There used to be three grades of Avgas, then two, then for some reason only one. I assume the reason 80 Octane went away was profit motive as it was significantly cheaper. ‘I hope and think that the incoming Fed administration isn’t as Green as the outgoing, so I hope from a Fed perspective that 100 LL may stay for four years, much of that I think may be whatever AOPA’s position is, they have more pull with the FAA than you might think.1 point

-

Just a moment ago I edited my above post: The base is already in your airplane - all you need is the relay. If you have a bad base socket it looks like that last company I linked might have one for the relay.1 point

-

I'll have to check my paperwork but I'm 95% sure that's what CAV told me to do. Leave it alone and replace it on condition when you get a high pressure alarm. Otherwise, the filter is working fine and its better not to touch it.1 point

-

My guess is most likely one of the fuses. Mine has two. Very different fuses. Located near the ammeter. Little short stubby ceramic cylinders. If you are diligent, you can find replacements at quite reasonable prices.1 point

-

Most A&Ps can't be counted on to be good welders. Welding is a skill that has best results with regular practicioners, and most A&Ps don't weld regularly and some haven't ever. We did a little bit when I went to A&P school and it was nowhere near enough to be proficient, and it was only gas welding. Welding is usually the sort of thing that is farmed out to a competent practicioner and "supervised" by an A&P. Results are much better that way.1 point

-

1 point

-

My point was how many FBOs will front some $100K (IIRC) for another tank/pump/etc setup for another fuel? How many pilots will buy it, even if it is 10% more than 100LL? So how long is the payback on that fueling rig? No, I read it. THE VAST MAJORITY (no percentage) will not need mods. But the others will require unspecified mods. At what cost? And at no point have I advocated shutting down 100LL production. I am saying that just offering it will not result in wide range availability.1 point

-

ETA: to be clear it is often light rime or short bursts of moderate... No SLD or hanging out forever without a plan.1 point

-

Exactly. A very conservative person can field a FIKI bird and use it only for inadvertent icing. But in many places you *will* find ice. The question is outs (above, below, turn around, elsewhere), severity/inciting conditions, duration, etc. I could not fly my commute many times without the ability to confidently penetrate some (reasonably forseeable) amount of ice. It removes an immense amount of worry to have a countermeasure. Gives you time and attention to worry about the turbulence, routing, and other hassles.1 point

-

I went with a custom overlay (will dig up thread). While I'd hoped to have a proper replacement sooner, it is holding up well...1 point

-

1 point

-

Would ceramic coating provide effective protection for paint against the effects of G100UL? At least the staining that's been reported? While it's important to know the potential drawbacks, let's also talk about solutions. Lots of people were, and still are, against ethanol in mogas but it's been introduced and is here to stay. For the most part, we have adapted to it. If G100UL becomes the prevalent fuel, it would be good to find solutions to the issues that are being presented. I suspect many people would still be willing to adopt G100UL even under the worst case scenarios that are being presented here.1 point

-

Marc, I am back in country. Please feel free to contact me about follow up on this effort. George1 point

-

Well said. And I agree. Also, with ethanol in fuel, there was a movement to increase it from 10% to 20%. That would have been a mess because about 1/2 the cars on the road would have fuel system problems.1 point

-

The problem is, it will not happen on its own. It will be by mandate. And thus in the hands of the government (local, state, and Federal) and they will move on whether there is ANY substitute.1 point

-

Thanks, George. I genuinely believe you have developed G100UL to help keep our fleet flying in the face imminent government-mandated requirements to phase out lead additives in fuel, and that you have been very forthright during the entire process about the development of G100UL and testing you have done. That you are willing to post here on our Mooney owners forum is a further testament to your openness and service. I'm a long-time scientist near the end of my career and learned long ago that you need to understand the experiment to understand the result. The tests posted online by YouTuber mluvara seem to do a good job of replicating the effects of a seeping fuel tank on a wet-wing bird like our much-loved Mooneys. There does seem to be a difference between soaking panels in a large volume of G100UL and mluvara's test letting the more volatile components evaporate leaving behind components that more aggressively attack paint. Perhaps you could replicate mluvara's test? Again, I believe your intentions are altruistic and you truly want to find a solution. I heartily thank you for your multiple contributions to the welfare of general aviation. - v/r, AJ1 point

-

I’ve occasionally had this problem with my TSIO-360-MB as well. Fully agree with the advice to check whether either the oil supply or scavenge valve is leaking by. Sorry to say, but, this could also be just operator error. Turbocharged engines don’t like being idled at very low RPM. Mine doesn’t like idling at less than 1000 RPM. If I idle it at less than 1000 RPM just before shutdown, I get greeted by a mess similar to what you’ve illustrated here at the next flight. Another possibility is that the scavenge line has come loose and is leaking somewhere between the turbo and the scavenge pump in the starter adapter. If that happens, the scavenge line will leak air INTO the scavenge line, interfering with the turbo oil scavenging, and resulting in a turbo oil leak. I’ve had that problem at the connection between the scavenge line and the starter adapter. I fixed that with a ~$2.00 seal from Spruce. Don’t have the part # or link for it handy. I’m away from home & my laptop which has that info. Warning: Overhauling a turbo because it’s leaking oil is the wrong thing to do. According to an IA renewal instructor at OSH, the shaft seals in a turbo are intended to keep the exhaust out of the oil, not vice-versa. If your turbo is high time, such as more than 1000, then, maybe, yes, overhaul it since high time turbos have some rather non-benign failure modes, to put it mildly. Don’t overhaul it just for an oil leak. BTDT, fortunately Western Skyways footed the bill for that worthless op. —Paul Keller1 point

-

Its probably easier to exclude those who you do not want to do business with. From my experience, the mechanics and avionics guys are the worst thing about aviation ownership.1 point

-

Some previous owner probably read on some internet forum that the alternator should be loose.1 point

-

GAMI addressed this. See post in the long thread. They state that while the O-rings may swell, there is no adverse effect on their functioning. In fact, the swelling may help worn O-rings seal better. When full synthetic oils were introduced in autos, the advice was to not switch to them in an older engine run on dino oil. The reason was, dino oil contained a small amount of light fractions that caused the seals to swell, and they wore a bit. If you switched to full synthetic, the seals shrank and leaked. So the manufactures adding a small bit of light fraction to keep the seals swollen like with dino oil.1 point

-

You need "I will not use G100UL until forced to"1 point

-

1 point