Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/2024 in all areas

-

5 points

-

For those of you who work on your own airplane but don't always have someone present to help you remove and reinstall the lower cowl, here is a YouTube video which shows how to do it without chipping paint or scratching the spinner. This jack makes it safe and efficient and it's easy/cheap to build.4 points

-

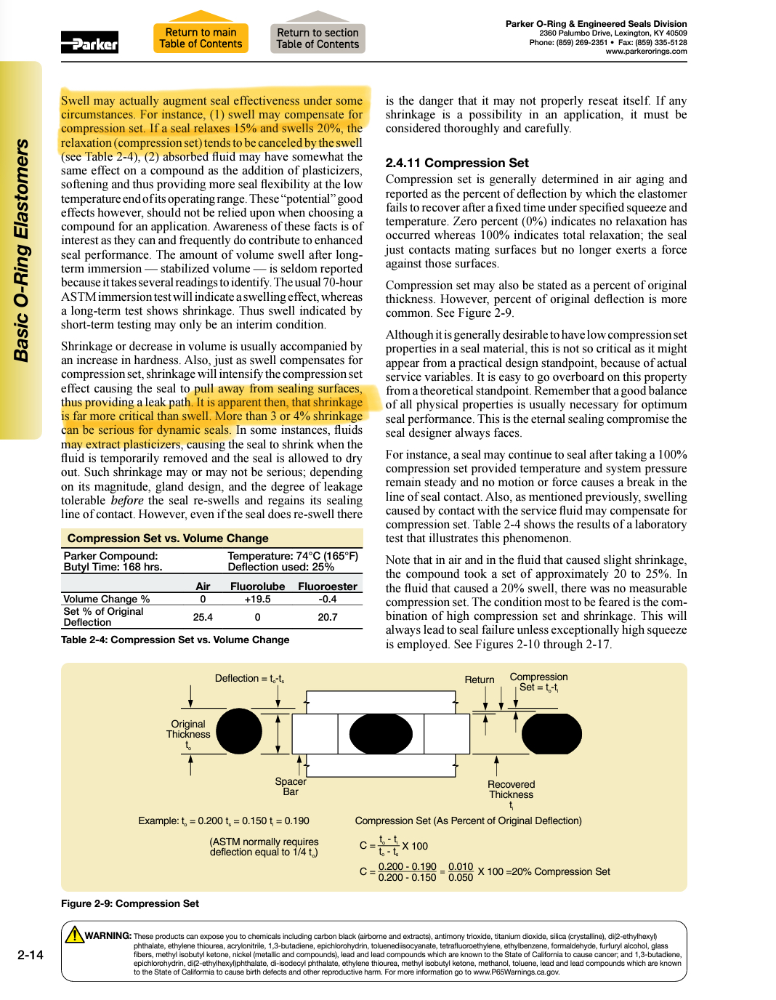

I looked at the video posted by the A&P at KRHV again. The o-rings he tested were MS28775 and MS29513 which are both nitrile which is listed in Section VII or the Parker O-ring Handbook as having only fair compatibility with 50% aromatic fuels. Also, the test may not be representative of the fuel's effect on the o-rings in service. Specifically on Page 2-7 of the Handbook, it is stated: "When deformed and exposed to a medium, rubber (Note: Parker uses the descriptor "rubber" to refer generically to any o-ring material), when confined in a gland, swells significantly less that in a free state (up to 50%) due to a number of factors including lessened surface area in contact with the medium." I just checked and SAF-AIR fuel drain valves use M83248 o-rings (Viton).4 points

-

In most of the states they've been ruled unconstitutional, and none of them have ever passed a public referendum. But red light camera companies know this, so they call it a civil penalty, and they send you some official looking fake ticket that you can usually ignore, because the whole thing is a scam. Some states, like Maryland, they can refuse to renew the Maryland drivers car registration until they pay it. So they're using the power of the state to enforce a private for profit out of state company to deprive you of property without due process. And yes, I have a problem with that, so should you.4 points

-

I served on a local county board which helped evaluate changes related to our industry and make recommendations to our country commissioners. one of the issues was staff wanted to require use of a a new type of back flow preventer called an RPZ instead of the double backflow. The latter being what has always been used, and they wanted to require a new one that they claimed was safer. During one of the meetings when I was questioning the requirement, I pointed out the problems with the new type which in some instances would require a building owner to spend upwards of a million dollars to upgrade. i had researched this issue extensively prior to the public meeting so I knew the answer to my question prior to asking. When I started pointing out all of the pitfalls of the new requirement, one of the staff suggested that if a baby died because of contaminated water, it would be on my head. Which was the perfect opening for my question which was… How many documented failures of the old back flow preventer had occurred, and as a result how many of those caused illness or death? As his face turned purple he claimed he didn’t know the answer, to which I replied well I do! The answer was zero! It had never happened. The bureaucrats had made the rule already and imposed it on more than a few residents and it had to be rescinded. The moral to the story is that while there is no argument that lead is bad for us to ingest or be exposed to, the actual danger is poses as a byproduct of fuel consumption is more difficult to quantify. It isn’t as if aviation exhaust is being pumped into schools. But the “save the children argument” is foisted and everyone’s hair is on fire. That being said, high pressure direct injection, and electronic ignition on engines would render this point moot, so if the FAA and EPA were actually interested in efficacy and an actual solution, they would get the f*$& out of the way and let some real progress In engine technology occur, rather than stifling innovation. I am of the opinion that the indirect mission of the FAA is to purge GA from existence, so endlessly harping on lead is much easier than admitting they want the whole mode of travel to go away. It’s a war of attrition with your own money being confiscated and used against you. government at its finest3 points

-

I don’t trust myself to wait till 80 kts. That would mean that I am on relatively short final. I can easily see a “gear up” in my future doing that. My gear comes down abeam the upwind numbers on a visual or FAF on an instrument approach. 100 to 120 knots depending. Maybe a little harder on the gear but not as hard as a gear up landing. I simply have a profound respect for my ability to forget a crucial step. I attempt to mitigate that with unwavering procedural compliance. This is totally personal. I understand that other folks may have completely different procedures that may be superior to mine.3 points

-

3 points

-

Oh no, now you've got me thinking about soaking old Mooney landing gear shock discs in the stuff! Maybe G100UL would be even better!3 points

-

@GeeBee The other thing to note is that if there wasn’t a mandate to move away from 100LL, and G100UL wasn’t being used in California to attempt to escalate a ban on 100LL, I personally wouldn’t be commenting on these threads at all but rather just wouldn’t purchase the STC or fuel till it was proven reliable, safe, and any untoward effects were shown. Given the political mandate and currently no other UL option, I have a vested interest in a fully vetted and safe fuel.3 points

-

Couple of caveats about this. First, while the Duke's and ITT actuators are largely the same, one difference with the later ITT actuators is that they lack a Zerk fitting to add grease in situ. Thus, you can't "give it a few pumps of grease till it comes out the screw hole, while in the plane", at least not the way those with the Duke's actuators can. You can remove two of the screws and pump grease into one hole with a cone tip until it comes out the other. But I've never had much luck with this, as access is awkward and it's difficult to get the cont tip to actually seal well enough against screw hole #1 to pump through to screw hole #2. I've gotten to the point where I simply don't try to lube the gear cavity without removing the actuator from the airplane and disassembling it. I've done this enough times now that it's not a particularly big hassle. The other caveat is that if you use this technique of pushing grease through one hole (zerk or screw) until it comes out another, you've got to be sure to take enough grease out of the last hole before you reinstall the bolt, to ensure the bolt doesn't hydro-lock against the grease in the cavity, and strip the threads of the actuator. You can guess how I know this.3 points

-

So... mystery solved. I spoke to the mechanics who've worked on the plane most recently. It turns out that the oil used to recharge the Challenger air filter for the 100 hr ICA (done only a few hours ago) is red in color. The LeakTec they use is, on the other hand, the blue or green variety. I decowled the engine top & bottom today and looked carefully. The red oil is clearly distinct from the circulating engine oil, and I see the drops at the lowest point on the compressor side of both turbos. A trace along the underside of the air filter, and some lesser traces elsewhere. Nothing on the upper portions of the engine at all. My theory is that either: 1. The oil misted into the induction system and collected on the manifolds, or the compressor scroll, and dripped back down, a bit worked out along joints or the turbo housing. A trace along one of the compressor discharge hoses (routed upward) might support this. 2. It simply leaked out the air filter housing and was blown about the lower compartment, eventually collecting on the lowest points. Either way, it's very reassuring that there's no source of other red stuff (like degenerating Loctite, gasket compound, etc.). And the small amount of oil is a previously-known thing, attributed to that flange gasket or collection of dipstick drip from above. Thank you all for the inputs! I'm going to separately figure out a good cleaning solution (mineral spirits) for future use, but the current worry is addressed. D3 points

-

2 points

-

Well, damage to fuel tank sealant is a show stopper. im not putting a drop of that in my tanks until its ready.2 points

-

For me, remaining runway must include time to descend, land and stop. My home field is 5000', so by the time I'm much above treetop height, I'm not going to be able to land and stop using the overrun area. So take off, verify in control per the Owners Manual, verify positive rate on the IVSI, then Gear Up.2 points

-

2 points

-

I wound up down a bit of a rabbit hole yesterday and inadvertently discovered that o-ring swelling was researched quit a bit in the context of the Sustainable Aviation Fuel program that was investigating alternative fuels for airliners. Much of the data is not necessarily relevant to our situation, since turbine fuels and avgas are not completely comparable, but the amount of work that was done on the topic indicates that concerns about o-ring behavior in the presence of alternate formulations was a big concern. Swelling is the main effect that was studied, to assure that there was enough swelling to assure a seal, and that there was not excessive swelling to cause degradation. We have the same basic concerns, but insufficient swelling doesn't seem to be an issue based on the video, but excessive swelling does appear to be a genuine concern. The main issue is for Buna-N (nitrile) gaskets, seas, and hoses, since it is more susceptible to excessive swelling than other materials. Fluorosilicone and Fluorocarbon (e.g., viton) are less susceptible to swelling issues, but exhibit other tendencies that sometimes make nitrile preferrable. e.g., fluorosilicone tears more easily and generatlly isn't used for dynamic seal applications. Since nitrile is used in many places and may still be installed in aircraft for some applications where other materials have replaced it, it is still a concern for aircraft in the fleet. Amongst a plethora of various academic and industry analyses, there were two papers that were pretty throrough in their analysis. Although much of the discussion and results aren't necessarily relevant to avgas applications, some things in them were still useful. The two papers, for those who would otherwise complain about the lack of reference: Elastomer O-Ring Seal Swell Measurements for Sustainable Aviation Fuel Material Compatibility, a graduate honors thesis at UDayton, and very thorough and nicely done: https://ecommons.udayton.edu/cgi/viewcontent.cgi?article=1380&context=uhp_theses The capability of organic compounds to swell acrylonitrile butadiene Orings and their effects on O-ring mechanical properties, a refereed paper published through Elsevier: https://www.triceceramics.com/uploads/9/3/8/9/93899770/49_oring_article_2019.pdf Anyway, a couple tidbits out of those (and other stuff that I slogged through) were interesting. From the first paper: "Currently, there is no certified ASTM test method associated with measuring o-ring seal swell." Both papers (and other material I found) use an optical method to scan the size of an o-ring before testing and then periodically in the presence of the fuel to measure the increase in size. The o-ring is unconstrained for these measurements. This suggests that the significant increase in size shown in the video is relevant for a basic assessment of swelling. It also raises a question about how testing and verification was done for avgas applications and how much. My main takeaway from this was that there was a lot of attention paid to this sort of detail for the SAF program for airline fuels, so it's not a trivial thing. It appears that we may need a comparable level of verification for avgas applications. Maybe that's what's contributing to the delays with other applicants.2 points

-

2 points

-

The rudder looks like a later model too — I’d check the logs. Not sure about this one — lots of $ to get it going… -Don2 points

-

Depends on your definition of captive. Lead has around a 1 month half-life in blood, 2 months in soft tissue, 2-3 years in the brain, and 20-30 years in bone. Other interesting info: 1) OSHA PEL 8-hour shift atmospheric workplace limits are <50 ug/cubic meter. 2) SoCal AQMD ran a study at Whiteman airport (KWHP) with the following results (note these data are in nano-grams/m^3, 1000 less than micro-grams/m^3!):2 points

-

2 points

-

My partner made it back. We flew together a couple of days later. The turbo was turboing. All is well except my bank account is sad.2 points

-

Make sure you look at the tube structure in the fuselage BEHIND the sidewalls for evidence of water leaking through the side windows and running down on the tubing and rusting the tubes. There is a SB on this and a newer sidewall insulation that should have been put in. If you can remove the interior side walls for a prebuy then you might run it near a wash rack and run water down the sides over the side windows watching inside for any leaks. There is also SB to check the bottom rear ends of the tubing frame by removing a bolt each side and checking for rust inside that tube. Corrosion on the main spar between the main wheels (and under the rear seat on metal wing Mooneys) is another big issue as are fuel tank leaks showing up in the wheel wells on the main spar (blue stains soaking through the rivet)s Be prepared for a high $$$$ first annual next year. This is a fact most of the time on this website with newly purchased Mooneys. New airplane owner gets hit with high $$$ annual first time in the shop because of "differed" maintenance by the previous owner not disclosed at the purchase. I'm not trying to scare you off but you have to be aware of the pitfalls of ANY airplane purchase. You don't know what you don't know. As my second caveat on any airplane purchase- NEVER TRUST ANYTHING SAID BY THE OWNER OR THE SALESMAN, PERIOD! Check everything out yourself with the help of a Mooney knowledgeable mechanic. EVEN down to the data plate on the engine and the serial numbers on the prop to make sure they all match the log book entries. Just things to bear in mind as you look at candidates to purchase. Cool your jets and take your time Below is a prebuy check list I made up years ago for Mooneys Check that all the model numbers and serial numbers match on everything with the log book, engine, prop, airframe, I do radios also. Actually read the data plates and compare to the logs. Check that the parts actually installed match what is contained in the TCDS and/or the logs show an STC change for the big stuff and changes for radios and electronics. Anything added like engine monitors, fuel flow gauges, etc should show an STC listing in the log books. Pull the rear seat bottom and open up the inspection holes to check for corrosion on the spar caps. Look at the spars real well in the main wheel wells for same. As noted fill up fuel tanks the night before and look for leaks the next day. If you can jack the airplane do a gear over center torque check. Make sure the A&P has the correct tools to do it. While on jacks, move the main gears in and out toward the wing tips for excessive movement. Lift the main wheels to check for play in the donuts. The donuts should expand enough after 5 mins unloaded to not have much movement. Check the mouse boots for condition in the main wheel wells. While down by the main gear look at the spar bottom between the fuselage and wheel wells. Look for smoking rivets there. The rivets that hold the spar sandwich together. That can be a big $$$$$$. I found one in AUS with almost every rivet loose on the bottom of the spar. It was grounded by the owner when Kerrville said it had to be repaired. Nose gear area - if on jacks this is easy- twist the nose wheel left and right to check for excessive play in the steering linkage. More than about 10-15 degrees either side of center before tightening up on the linkage is too much. You will see the slop way at the top of the nose gear on the rod end linkage up there. Most important on the nose gear! Look and feel for dents where the steering system touches on the tubing for dents where it touches. Turn the wheel by hand and you will see where it touches and stops. MAKE SURE THERE ARE NO DENTS THERE! The limit is 1/32" depression. Any dents and the nose gear comes out for repair $$$$ On the tail surfaces grab the tip of the stabilizer and try to move it up and down and fore and aft. If it moves or clicks you might have work to do. Limits are about 1/10th of an inch either way. Usually fixed by changing out the "close tolerance bolts' in the hinge. As noted lift up on the rudder to check for play in the jackscrew. Same limit about 1/10 of an inch. Lots of times it is wear on the 2 bolt hinge bracket at the aft end of the jackscrew and not the jackscrew it self. I found one stabilizer that moved 1/2 inch either side of center! Look over the outside surface of the entire airplane for dents, filliform corrosion, hangar rash (the elevator tips seem to be especially susceptible to this damage and NO repairs are allowed to control surfaces (no patches, partial skin replacement, etc). The FAA in one case here on MS made a big thing out of this stuff on a routine ramp check on one of our posters. Basically they said it didn't come that way from the factory so fix it. I check all the exterior control surface rod ends to see if they are loose enough to move or if dry and frozen. If dry and frozen I start looking at the logs real close to see if the lube and gear swing AD had been being done. One item missed almost always due to the effort but it can cause big headaches, is pulling the sidewalls inside and actually looking at the steel tubing frame for rust. If the windows are not sealed well, water gets in there and runs down inside on the tubes and rusts them. The insulation SB aside. There is actually a SB describing how to check for leaks by pulling the sidewalls and directing a water hose at the windows looking for leaks. Make sure everything, and I mean every switch, knob and button works as designed! Put power to it and try all radios in all modes, all lights, all warnings (landing gear warning horn, stall warning horn, etc), all exterior lights, everything that can be turned on or off or moved in and out. There was one write up on here a while back where someone bought a Mooney and the stall warning didn't work nor did the gear warning (IIRC). That makes the airplane unairworthy. If on jacks (and it should be) do a gear swing and make sure the gear works properly. I've seen them signed off 3 months ago and they hang 3" from the wells when sucked up. If its electric gear do a manual drop also to make sure it works. Had a couple on this board recently that went in for annual and the manual gear drop didn't work. So check it out. Look to see if the gear actuator has ever been removed, cleaned, checked for proper gear lash and relubed. If it hasn't you may be doing that on the next annual yourself It's that important. Disregard if its a manual gear. It goes without saying that a full log book check is required for all applicable ADs and required inspections even though the annual has just been done. The logs tell a story and knowing how to read them is a skill. Make sure you know what to look for or have someone that does. The engine stuff is the normal stuff. Compression check, oil filter inspection, looking for leaks, cracks, anything not normal. Pull the plugs and read them, they too have a story to tell. My caution to any whom I help buy an airplane? Trust no one selling an airplane period. Take nothing for granted. Don't trust anything even though it just had an annual. If you do, it will bite you in the arse. Check and verify everything before money changes hands. Once you pay for it , its yours! Good luck and show us pictures even of the prebuy! :-) :-)2 points

-

That's a bit of an oversimplification, I think. Some swelling is expected, and beneficial, but excessive swelling (as seen in the vid) is detrimental, as described in the linked document. For an o-ring used as a static gasket, 20-30% swell is acceptable, but for a seal (dynamic), only 10% or so is allowed. Swelling also weakens the material and makes it more susceptible to tearing (for a seal) or extruding out of the groove for a gasket. The issue as noted in the vid is that the swelling was significantly past acceptable limits, especially for a dynamic seal. Mooney fuel systems have dynamic o-ring seals in the fuel selectors, gascolators, carburetors, fuel servos, etc. An excessively swollen o-ring in any of those may restrict or seize the motion of the sealed shaft, or may tear when the sealed surface moves, resulting in leaks. None of that is good, and excusing excessive swelling as just "it'll seal better" is ignorant at best and disingenuous at worst imho.2 points

-

The problem is not finding people who have been exposed to lead. But to find those with NO exposure to show that the lead is the cause. Just because everyone who is exposed to lead has X issue, doesn't mean the lead caused it. You need to show that those not exposed don't have X issue.2 points

-

My guess is that there are a few in the FAA that are saying Uh-Oh, can this get me in trouble?2 points

-

All too common. It seems many new Mooney owners get their initial instruction from their Cessna or Piper instructor with very little Mooney experience and are taught to use much too fast of a final approach speed. We see it at PPP’s too. The same poor instruction leaves the new owner deficient in learning to properly trim the aircraft leaving them unable to slow the aircraft. I expect the complaint about RPM was a red herring. Not going to be able to get the rpm much lower going over 100 kts with the airspeed turning the prop till the plane slows down. Add in leaky brakes, worn pads and a tail wind and it just underlines the need to go around when not properly established and stabilized on final. Sent from my iPhone using Tapatalk2 points

-

This morning, I took my wife to see her mother in central NC. The direct path is almost over ATL airport; ATL Approach guards the sacred Bravo airspace like nothing I've ever seen--in 17 years of flying past Atlanta (where my direct path lies inside the Bravo), I've never been allowed inside. First it was "remain clear of the Bravo," then it became "stay out of the Bravo." So with beautiful VFR conditions widespread across the Southeast, we loaded up and took off. My route was KALX-->KOPN-->KFAY, to stay out of the Bravo without being told. Well, about ten minutes after I got set up with flight following, ATL Center asked, "are you direct to your destination?" I said no, I was going via OPN to avoid the Bravo, since I'd not been allowed inside for 17 years. He came back with, "today may be your day, if any is." Sure enough, a minute later it was "cleared direct destination through the Bravo." So I turned from 092 to 073 and went with it. I changed freqs and confirmed clearance with that controller (VFR through the Bravo), and he said "you are cleared through the Bravo at 7500." My first ever penetration of the ATL Bravo! On Christmas morning!! It's a Christmas miracle!!!1 point

-

I think this is one of the issues of pursuing an unleaded fuel independently outside of working with current airframe and engine manufacturers. It also highlights that in order to go alone, GAMI should really be freely sharing their data and test findings. The only stamp of approval for G100UL has been from the company selling it and the "court of public opinion" in terms of a fan base. So if detrimental things happen, fingers are pointed not based on fact but based on assumptions. The only people who know the data and what data was actually obtained, are the ones not openly sharing it. And since this is outside of a third party consortium there are no other airframe and engine groups to review, audit, and approve the testing data and results/conclusions. "If you want to go fast, go alone. If you want to go far, go together."1 point

-

I would look at the check valves before I would do anything with the turbo. A brand new turbo will do that if the check valves start leaking.1 point

-

Plus 3 months (minimum) to get a shop opening, plus a month in the shop, plus 5-10k for the problems they find, wiring, static system, antennas, etc.1 point

-

Even an annual can be misleading. The plane I recently purchased had what I would classify as incompetent maintenance. They didn’t do any SB’s, a lot of things done improperly, and a lot of things well out of spec. Original landing pucks from 2006, original brake fluid, original mags one of which has never been overhauled, the list is not short. Same 3 or 4 shops did all his annuals, none of them mooney’s service centers.1 point

-

That’s all great except the airport was/is paid for with federal money. Your examples are all city or state not federal. Toll roads are for the new roads they build. I have yet to see a toll applied to an already developed federally funded road. So not the same comparison. And at least with the toll roads i can choose to use that new part of the road or stay on the free federal road. For an airport to charge for their funded part of the airport fine. But for them to charge for use of the federal part of the airport is nothing short of stealing and should be prosecuted at a federal offense. Like vandalizing mail boxes is a federal offense.1 point

-

Yes, some swelling is expected in many materials and is calculated into the design when sizing o-rings and materials for seals and gaskets, etc. And, yes, there are assumed limits as well. The issue in this case is that the swelling appears to be way beyond what is generally allowed. For an o-ring used as a static gasket, 20-30% (you often hear 25% cited) is generally allowed, and for a dynamic seal, about 10%. For a dynamic seal if swelling gets excessive the issues may result in resistance or seizure in the sealed shaft, or damage to the o-ring via a split or tear that results in a leak.1 point

-

When I did my panel upgrade in 2017 before I wired anything I drew schematics for everything. It made the install much easier. I have an old copy of Altium Designer I used for the schematics. I was doing the annual on a 310 recently and I had some questions about some of the new wiring. The owner said "I think I have that". He produced a complete set of schematics for the latest avionics upgrade. They were very well done. So, a good set of schematics are not unheard of.1 point

-

Back to two pumps, on different busses, but losing a Mag could also, or a clogged fuel injector or strainer or any number of a great many other issues. I would tell you that the likelyhood of a fuel that causes O-rings to swell is far more likely to cause an engine failure as there are a great many “rubber” and plastic components in an aircraft fuel system. My C-140 would likely be OK as the only plastic or rubber in it is the fuel level indicator floats and maybe a cork gasket where they go into the tank, but my Mooney is full of the stuff from the servo, fuel divider, fuel flow transducer, both fuel pumps, strainer, fuel selector to say nothing of my bladders or everyone else’s sealer. O-rings are I think the least of the possible problems Unless the guy who did the video snuck in MEK or something into his tests those simple backyard tests are enough to keep me away. If I lived where it was the only option I’d pull my fuel trailer to where I could buy 100 LL, sell the Mooney or quit flying Certified aircraft I guess or buy something Certified to burn car gas. I think Rotax are allowed?1 point

-

That is entirely possibly. History is full of changing from one product due to hazards only to find out later that the new product is as bad or worse. I have never said that lead from aircraft engines is a hazard. But that will not stop people from using it to rile up others to close airports. History is also full of examples of over reaction to a minor or limited hazard.1 point

-

Definitely true, it happened to me. My checkout was with an instructor who kept telling me to keep my speed up and I couldn't land the plane safely until I flew with Don a few months later. It definitely pays to have an experienced Mooney instructor for transition training.1 point

-

A hangar neighbor was doing landing practice at a field south of here. He told me about a Mooney with a student and an instructor. They went around 3 times because they couldn’t land on a 3500 foot runway. The blind leading the blind.1 point

-

My point exactly. so how can the FAA issue an STC for the type design of an airframe?1 point

-

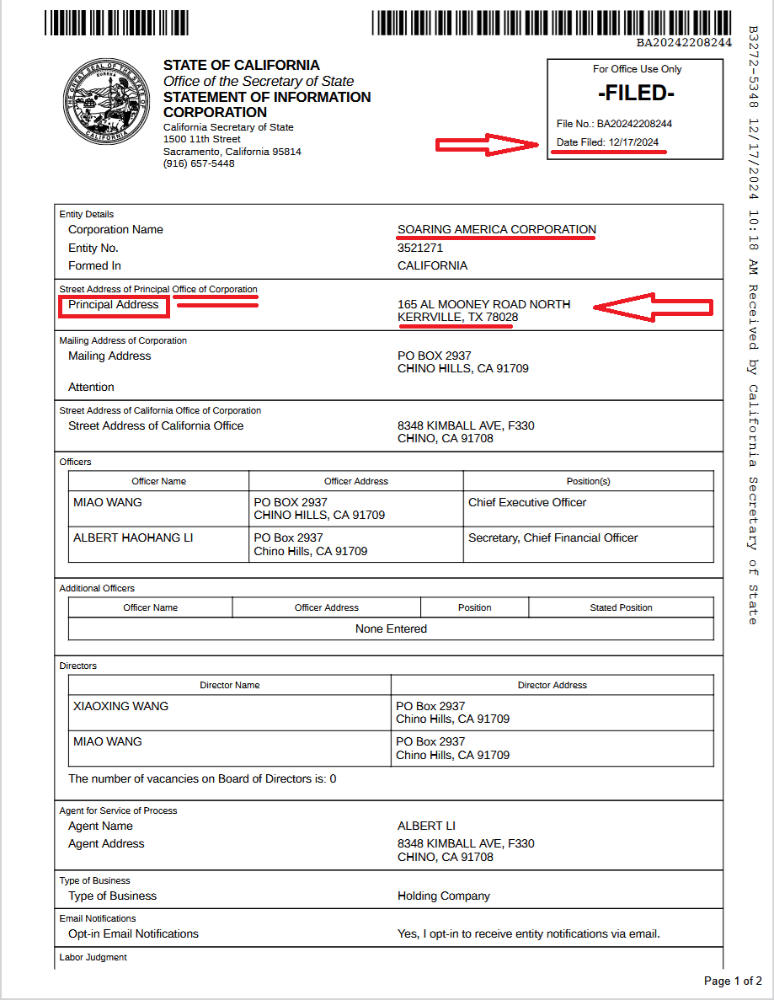

Not exactly right. In October 2013, Mooney Aviation Company was bought by Soaring America Corporation, Chino, CA, a US subsidiary of China’s Zhengzhou-based Meijing Group (which is a real estate and import/export company.) The Mooney company was renamed "Mooney International Corporation" This was well documented in Mooney Flyer November 2013 on page 7 https://themooneyflyer.com/issues/2013-NovTMF.pdf http://usa.chinadaily.com.cn/business/2013-10/17/content_17040096.htm https://opencorporates.com/companies/us_ca/3521271a In September 2020, after considerable cash investment in Mooney only to cease operations in 2019, Meijing Group sold 80% of Mooney International Corporation to "U.S. Financial LLC, WY" Soaring America (Meijing Group) retained 20% of Mooney and retained the right to manufacture Mooneys in China and Africa. This is well documented in the October, 2020 Mooney Flyer on page 3 and in the Aviation Week "Sounding Board: Five Minutes With Mooney International CEO Jonny Pollack". Present Position Sounding Board: Five Minutes With Mooney International CEO Jonny Pollack | Aviation Week Network I don't think anyone would argue that Meijing poured a lot of cash into Mooney. I suspect that Meijing put it on the Mooney financial books as loans....and loans that are secured by assets of Mooney like the Type Certificates, designs, engineering data, Intellectual Property as well as factory assets. That is what any smart financial advisor or attorney would recommend. If any of you followed the bankruptcy of Vans Aircraft you can see the obvious parallel. Founder Van Grunsven (and family) had supposedly sold the company to the Employees. But the company needed cash loans which Van Grunsven provided. However, he secured all the valuable assets, engineering data, designs, certificates, manufacturing assets and building to those loans. When Vans filed Bankruptcy, he stood at the head of the line for claims and the entire company came back to him like a big rubber band or yoyo. Upon exit of bankruptcy, the Van Grunsven family now owns 100% of Vans Aircraft. The employees' "investment" got hosed. Everyone wonders why Jonny can do a deal with Lasar on the Eaton "no back spring" but can't do anything with the Dukes actuator w/Mooney designed gears. It is likely because he cannot trade away the "Dukes IP" because it is secured by loans from Meijing and he cannot do anything without their approval. The "no back spring" was likely an Eaton design that they would rather not make any longer. Hence they were willing to work with Jonny. But when it comes doing anything that requires a concession by Meijing I bet his hands are tied. Additionally, Likely Jonny is desperate to avoid bankruptcy because Meijing will get all the secured assets. The factory building (leased from the Kerrville Airport Authority which is co-owned by the City and County) will go back to the Airport Authority. U.S. Financial will likely lose everything. Soaring America Corporation - the US subsidiary of Meijing - which owns 20% of Mooney is alive and well and still actively exists. Soaring America Corporation (A California Corporation) shows its principal corporate address (that is Soaring America's corporate address - not it's investment or subsidiary address) as 165 AL MOONEY ROAD NORTH KERRVILLE, TX 78028.. Meijing Group may have unwisely invested in Mooney but I doubt that they are stupid..1 point

-

Imagine spending a decade trying to push something through the FAA and then single handedly force it into the market, against all odds, against Pafi, against big oil. If you know the story just a little bit, what he’s overcome, the guy is a certified bad a$$ that is for certain, having gone through all the thorn bushes that he has. When you have that much heart and soul into seeing it through, it would be realllllll tough to do anything, say anything, that might torpedo the whole initiative if you can manage to minimize the ill effects.1 point

-

If the airport is privately funded i could see that but charging for an airport that was paid for by tax payers dollars and then u want a fee because you setup a camera is theft and should be a felony since it involves federal resources. And if I’m flying a cross country flight and half a dozen airports start charging me fees when I didn’t land there I’m not going to pay.1 point

-

Actually they are not. They are subcontracted by different airports around the country to collect their landing fees, nothing else. To me it's irrelevant if letter with bill comes from them or airport i landed at. I only got a bill recently for being at Santa Monica (KSMO) which i know it has nominal fee and I was expecting it. I believe the fee was for Take-off (?) which I found strange but I would need to check. Problem for some people, I suspect for is using ADS-B data for collecting but to me it's irrelevant. It similar as collecting toll on some roads here using cameras. Believe me, it's much better and efficient then stopping and dropping quarters in the baskets. And you can't get ambushed like Sonny in Godfather...1 point

-

I’ve been hit by the fees when I’ve landed someplace and I’ve paid those. I’ve been hit by the fees when I’ve done an approach someplace and not landed. I complain and they have always been reversed. I suspect in this case ADS-B works in my favor, since I can prove I never stopped…. We had one local airport who stopped having an attendant and went to Vector. I’ve only randomly received bills…and they are not on the list above…. I think the frustration is fees on fees….and our inability to decode what is a legitimate bill for the upkeep up an airport or simply a bill to line someone’s pockets. At a minimum, one would expect the fees to be posted in facilities directories and flight planning apps….and they should identify who will send the invoice and how they determine an operation. Like all, I fear this will become out of control.1 point

-

I feel it’s a rip off scheme especially if i do not use their service. At KDTO for example there are 2 FBO and there used to be free transit parking in front of the tower. It’s a bone of contention when i want to pickup someone that comes to the airport and does not use their facility in anyway shape or form for them to come out and expect a fee from me. It’s the equivalent of going to a restaurant and self parking in the parking lot but i still have to pay a valet person?!?! No if i didn’t use their valet then I don’t pay. The FBO doesn’t own that tarmac the tax payers do and for a FBO company to come in and then claim that part as theirs to charge a fee is wrong. Now if they build a new complex and new concrete in front of their business and you park there sure. But it would be like me setting up a toll fee in front of my property on the road that goes in front of my house when the tax payers paid for the road already. It’s not mine to charge for nor is it the FBO’s to charge for either.1 point

-

All this sounds like a communist country (or at least state). Forcing a market to switch to a monopoly is the perfect recipe for corruption, abuse, and kill competition. Lucky for us, it looks like Swift 100R might be relatively close (2025?) to be an alternative, with ASTM cert. Maybe G100UL is just a bleep in the transition to unleaded fuel.1 point

-

I did not see any mention of cost/pricing in the Consent Decree. Please point it out because calling something "Commercially Available" without consideration of commercial cost comparison is pretty oxymoronic! How about $200 per gallon? That's certainly "Commercially Available" Oh, yeah, I'm sure the FBOs/suppliers weren't subject to any coercion before signing. Kind of like your constant reminder that no one will force anyone to buy G100UL in the future because we're all free to produce our own avgas if there is no other choice available!1 point

-

Thanks for the photos. I'm no ME, but I believe the scalloping is by design for a 90 degree worm gear. I'd hate to think some A&Ps are condemning gear sets over that! As you said, it's the backlash that is critical.1 point

-

Jake, will you please send me the old gear set so I can have them sent to a metalurgist for destructive testing to determine the type of steel and hardening process? I have the 3D CAD drawings of the gear set but not the metal specs...I'll contact Mr. Pollack tomorrow to see where we are on getting a batch made up, probably no closer than 3 months ago but I'll try...looking to go the OPP route and once I get the metalurgy report done, my plan is to share the info on mooneyspace...unfortunately it won't help you currently...please let me know if you are willing to send me the worn gear set. V/r Matt1 point

-

Chris, Nice pirep for Jimmy! Thanks for sharing it… Just one inaccuracy… early 50s is NOT late in life… You are only at the halfway mark…. Life is short, fly fast… (just not that short) Best regards, -a-1 point