Leaderboard

Popular Content

Showing content with the highest reputation on 11/12/2024 in all areas

-

6 points

-

Yes it’s easy within Schengen+EU as no immigration & customs are required * In southern countries like France, Italy…the flights are still “international” one still need to file mandatory flight plans, possibly gendec, make radio contact at borders…as these countries puts ICAO requirements above Schengen/EU laws, however, this is merely an ICAO reporting requirement: no restriction on where you can land and you don’t have to see anyone. * In northern countries like Germany, it’s easier as Schengen/EU flights are considered “domestic or national” (sub-ICAO): I flew Belgium-Germany-Austria without flight plan not talking to anyone except airport guys, this sounds more like “just go” UK (and Switzerland) need more planning: one have to comply with some immigration and customs rules like sGAR, these are not difficult once one gets used to them (it’s like eAPIS in US or Canpass in Canada) For fees (and Avgas), it’s manageable in small and medium airports in countries with light GA tradition Germany, Poland, France, Switzerland, Belgium…if you go to Spain, Italy…one tend to sick to private small airports while big airlines airports have pricy handling and are waste of time: imagine Signature price tag with bureaucracy and no red carpet. This is tough on GA flyers, you can’t fly north forever: you need to go south for sun, food, beach…5 points

-

I left Durango this month with an adult passenger, a cargo area full of bags, and 6 hours of fuel on board. Headed east, pointed straight at the Rocky mountains. Climbed 500-700 FPM up to 17,500 feet, straight over those mountains with 4,000 feet of terrain clearance, no circling required, no mountain wave concerns. Caught a tailwind of up to 70 knots, and made it to the Kansas City area in a little over 3 hours. Smooth air, no clouds, no traffic, within glide distance of multiple airports almost the whole time. Didn't even make a radio call between leaving the pattern in Colorado and entering it in Missouri. 175 KTAS at 13 GPH (TIT limited, I like to keep it under 1600). Landed with 2 hours of reserve fuel. Some days the turbo really shines.4 points

-

I’m currently supervising an annual on a plane more complex than a Mooney. Im confidant the owner is more than capable of doing the tasks I ask him to do. And I will check his work anyway. His plane is better maintained than most. It would be a travesty to make this process illegal.3 points

-

3 points

-

3 points

-

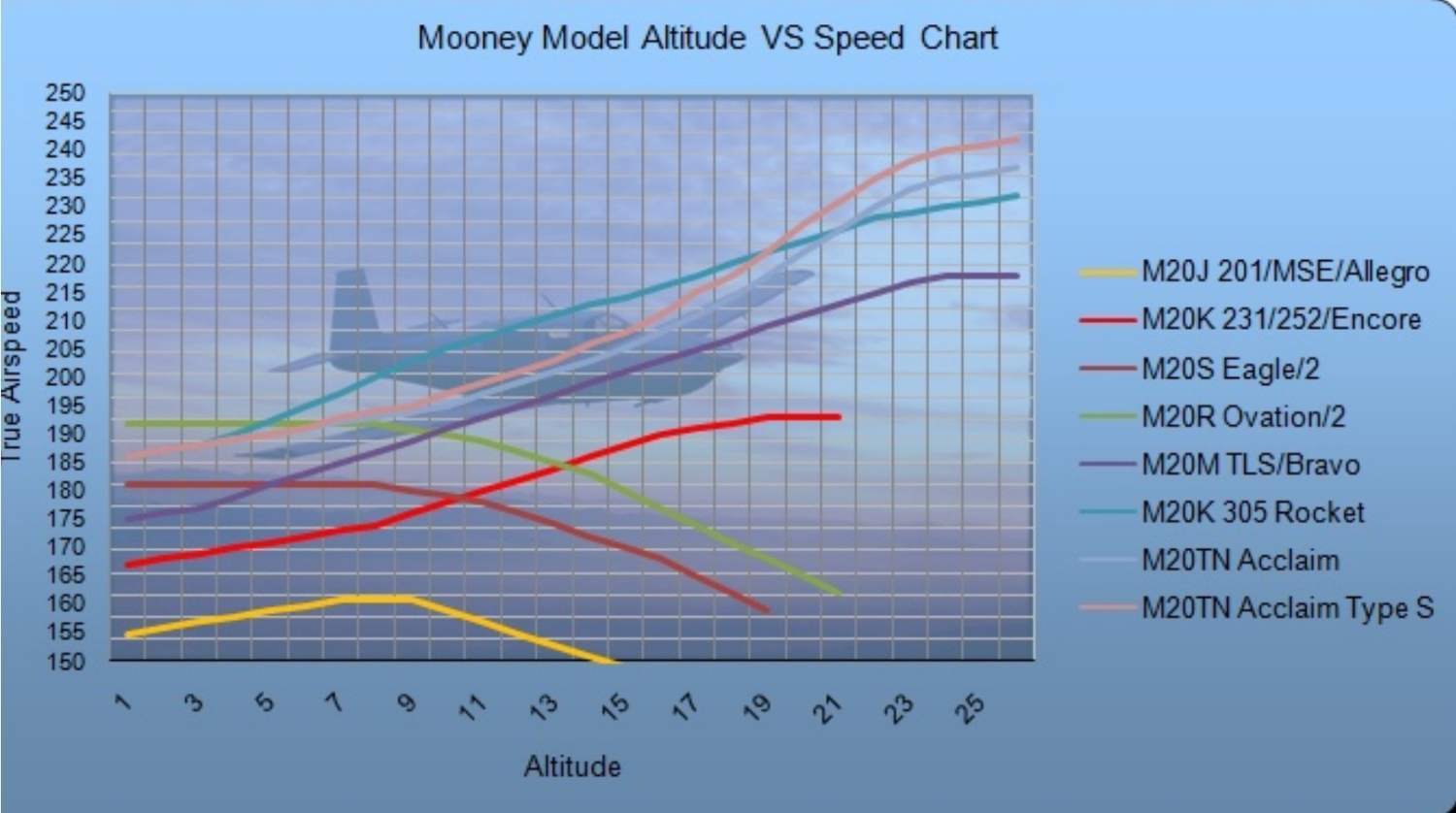

A factory poh won’t have many of those answers because most are modifications or implications of… overhauls are definitely more and you have turbos and exhaust maintenance, but if you divide that over a tbo and all other costs of ownership it is probably 5-10%. hangar, insurance, basic maintenance, upgrades, fuel etc. yes appointments are options, AC, FIKI ect Mooneys, at least long bodies will always be flying at or near gross, but with an ovation you can keep more fuel and it’s a little more efficient. I have had long range tanks in two of my planes. I did not need it enough to pay for the modification myself, but wouldn’t mind the option. It requires more attention to managing fuel because of how the gauges read as the tank empties, but more fuel is always a desirable option. My point was that everything in aviation is a trade off, and your mission, personality and budget will all play a role in your priorities. If you can own and maintain an airplane you could justify the extra for a turbo if you wanted to, it isn’t an order of magnitude more to own. If performance and speed is really important to you, you will probably always long for a turbo. It may only save 20-30min over a 3+ hour trip and for me that’s big, but in the grand scheme of things isn’t as important to others. I like the climb, the versatility to take advantage of favorable headwinds, getting through bad layers, and love seeing the 200+tas. There are lots of good arguments for either perspective, but they usually boil down to the trade offs that make sense to you.3 points

-

This occurred before the election following an effort spearheaded by Jeff Simon of Social Flight and Mike Busch of Savvy Aviation. There’s a number of Social Flight video segments with Jeff and Mike discussing how it all came about and why.3 points

-

The rigging looks good. The engine is new and makes static rpm and the climb is good. Sounds like instrumentation. The standard "pitot-static" check really only checks for static leaks - the pitot connection is just to balance pressure on the pitot to avoid damaging the airspeed indicator. It's easy to check the pitot system for leaks. Just pressurize the pitot somehow. The standard way is to use a long piece of surgical tubing and roll it up. I found that difficult to manage and bought a large diameter syringe and connected it to the pitot tube by a short piece of vinyl tubing with a few wraps of electrical tape at both the syringe and pitot to avoid any leaks. Be sure to cover or plug the pitot drain hole. This makes it very easy to set 150 kts on the airspeed indicator. Then note how well it holds for one minute. The spec in my M20J service manual is not more that 10 kts drop. If the pitot system is tight, it will do much better than that.2 points

-

2 points

-

Let’s not get too much of the opinion that there is a set order as to whether gear or flaps should come down first as it’s entirely model specific set by the Vy speed limitations. As @Hank just pointed out in the C models the flaps speed is higher than gear speed so flaps will be used to help slow to gear speed. But at least starting by the midterm J models that reverses and gear speed is higher than flap speed so the gear will be used first. As models get younger the gear speeds get higher and higher to ~140 kts while flap speeds remain the same near ~110 kts. So with the late Mooney’s there is a very sizable buffer between gear and flaps speed. As always it depends on your v speeds. Sent from my iPhone using Tapatalk2 points

-

2 points

-

Rigging can be performed without the boards. The control surface angles are described in the TCDS. A protractor or digital level/protractor can be used effectively. The boards just make it easier.2 points

-

Lets digress a little here- Yes an A&P can make some "parts" that conform to some "approved" method. (accepted? -) In the two items you cited, ribs and cables both are covered by the "approval" of 43.13 Accepted Techniques and Practices But even with that there is the limitation of- This advisory circular (AC) contains methods, techniques, and practices acceptable to the Administrator for the inspection and repair of nonpressurized areas of civil aircraft, only when there are no manufacturer repair or maintenance instructions. This data generally pertains to minor repairs. It goes on to state - The repairs identified in this AC may only be used as a basis for FAA approval for major repairs. The repair data may also be used as approved data, and the AC chapter, page, and paragraph listed in block 8 of FAA form 337 when: a. the user has determined that it is appropriate to the product being repaired; b. it is directly applicable to the repair being made; and c. it is not contrary to manufacturer’s data. SO while yes an A&P CAN "make" some parts they are always made to some kind of approved or accepted data. And it is always in the realm of "REPAIRS" to a particular airframe. No A&P can make parts (say a rib) in bulk and sell it on the open market. A&Ps do repairs - they don't "manufacture" parts. The connections you cite for P&W and GE are way beyond the scope of this forum. We are confusing "parts" for repair and parts for manufacture and sales. The "Type Design" package that describes every bolt and nut on any complete airplane is the property of the Type Design holder. That "package" of data is submitted to the FAA for approval so the manufacturer can make exact copies of the airplane for sale. Every airplane made is compared to that data package to make sure it "conforms" in every way to the approved data ""Type Design" Any changes to that data require some sort of approval. Every part, item, screw or nut in that package is verified to the approved design on every produced airframe. Each part has a drawing describing exactly how that part is to be made. What material, what process, what heat teat, etc. If you don't have access to that approved data you can't make a part conforming to the approved data. One can always hire a DER to design a part and APPROVE a part and that also works when the original drawing is not available. As I noted in some instances the FAA will open a Type Design package for a request to make a part available but this is a rare occurrence. In short = the Type Design package that the holder owns is protected property by the FAA and not usually released As to the PMA holders- YES they can make any part they have the capability to make YET they still have to make it to an "approved design drawing". they can't just pull the design out of thin air, It has to have 'traceability" back to the original drawing OR be approved by some other manner such as a DER. Think of a PMA as approval of your quality control process rather than an approval to make a particular item. A PMA approves the process and not the part.2 points

-

I remember a class mate in USAF UPT rolling off the perch on his first solo in the T-37. Over his "Gear Down" call, one could clearly hear the gear warning horn. I am a HUGE fan of the LHS system. With the C model, you get a "Check Gear" voice prompt at 200 AGL with the gear handle in the Up position.2 points

-

I have AdLog on both my planes. But @jetdriven, who does my annuals, has his own form to track ADs.2 points

-

2 points

-

I don’t see how you could really, for example Repair Stations and manufacturers labor force is overwhelmingly people with zero FAA Certification. When pushed my Inspector told me the reason I had to issue “repair station certificates” was only so the FAA would have jurisdiction over them. The Certificates were worthless otherwise. But then the people on the factory floor had no such Certificates and therefore weren’t subject to FAA being able to “touch” them. MIDO and FSDO differ significantly. If supervision were to be disallowed then no aircraft could be manufactured and every Repair Station would have to shut down, and no one could get their A&P based on experience, except prior Military, because how could you get the experience? I think the number of A&P’s that didn’t go to school is higher than many expect, especially your local A&P, the school guys usually go to the Airlines etc. I do think that the intent was to prevent ridiculous claims of supervision like show me the repair on your phone etc. and in my opinion that nonsense should be disallowed.2 points

-

Prior to the current plane, I had only a few hours in a 182 turbo (a nice late 80's or 90's model) and I loved the power on demand... everything else was normally aspirated. Now, 120 hours later, I wouldn't go back. It is more complex mechanically, but the Acclaim's TSIO-550G turbo design is pretty sound (used also on Cirrus FWIW), and the actual management is much simpler in my opinion (MP is settable arbitrarily up to the critical altitude). The ability to just keep climbing through weather and select arbitrary altitudes is huge. Terrain? Push it up and go... But I also live in the mountains with MEA's routinely above 10k. I came into a cloudy valley with some light ice on Sunday at 17k, had climbed up in a few minutes from 14k to minimize icing (TKS was keeping up but always better to have less), dropped down to 9k in a hold with TKS as needed, and shot the approach. I wouldn't have made the trip without TKS. I think I could get by with an Ovation here, but the diminishing climb rates up high would limit options in some cases. East coast does not have the terrain issues, but might have the weather which also benefits from climb in some cases. Others here @Schllc? can weigh in on the utiility of a Stormscope too in the southeast (lots of convection at times). The XM weather downlink is great and does most of what you need, but just another thing to consider since this is a bit of a clean-sheet/blue-sky discussion. HTH D2 points

-

It ain't over yet. Last paragraph: This stay does not represent a conclusion on the contents of that interpretation and will be effective until such time as the agency issues new or supplemental guidance.2 points

-

You'd spend more renting a complex plane to gain RG hours than you would just paying the higher premium for the first year. We can get you covered in a Mooney as a brand new private pilot with one or two quality insurance companies.2 points

-

Thanks Mike, yep I should have started with the J's. Plus you have the later F which has the increased gear speed from original F's at 105 mph to 120 mph in 68' So its really not till the J model that they reversed. J model flap speed stayed at 110 kts but the earliest J's gear extension speed started at only at 104 kts (below flap speed) but soon increased to 132 kts (well above flap speed) before the last topping out at 138 kts (sn 3000 on)1 point

-

What do you expect to gain by taking your gear doors off? Those help a lot with speed and climb, even if they're a bit out of rig.1 point

-

1 point

-

Just got a call from LASAR. They are shipping out my intake duct today. So I guess everyone who ordered one can expect them soon.1 point

-

It looks like your prop and throttle controls are full forward at 9500 feet and it's only making 2500 rpm. That doesn't look right. Your mixture is pretty far forward, too, for that altitude. I'm wondering if you don't have an engine rigging problem.1 point

-

That's not what I meant... you cannot use any of the free EFB products to get the data into your IFR navigators that the plane actually uses. Charts and plates that you use, absolutely, but you still need to pay $300/yr or more to somebody to feed a GNS, GTN, IFD, etc. (I use FltPlan Go for a backup EFB myself, and their web planner is fantastic)1 point

-

Go do this at 3-4k and 7-9k: True Airspeed Calculator VIA GPS Just because you have a digital readout doesn't mean it is accurate. After that, then you likely need to check the mag timing, and maybe go deeper and measure the rocker arm/valve lift and see if your cam has lost it's profile. That could very much be in play if it has been sitting. Great looking Mooney!1 point

-

The Miata comparison is slightly off target. More correct would be a Miata (or other 2 seat sports car) with the top UP or the hard top installed.1 point

-

I recall seeing something about why American did not paint their planes in the past. The savings was hundreds of pounds for the paint.1 point

-

If you go up to ~9000’, you can just leave the throttle full and play around with it to get a good feel for how it plays out. At that altitude, you can’t get more than about 65% anyway and you won’t hurt anything by going slow with the mixture as you lean and watch your egts. If you know the ff specifically for the power setting you want, pulling straight to that is great, but I like to see where peak is and watch each one peak, so that’s what I do. So just start leaning with or without lean find. Watch each cylinder peak, stop just after the last one peaks. Should be around 8.5-9gph for 65% power. Look at your chts, they’re cooler than 100rop. If you stop right at peak on the last one, that might be cool enough as well (and you’re running “peak egt”), but say you’re chts are around 380 and you want cooler, go slightly leaner. you’ll want to stay pretty close to peak because power drops off quicker on the lean side of peak. I disagree with not using lean find and just doing a big pull until you’ve played around with it a lot, got a great feeling for your engine, and know your exact lop power settings. Just play around up high enough that you’re below 65% power. Leave throttle full, lean to get lop and then to control desired cht. If you’re down lower, just pull the mixture back to 9gph or less as that’s 65% power. If i was learning, I’d go up higher so I could play around without worrying about hurting anything.1 point

-

If the government is "trimmed down" or at least boundaries are reiterated (a la Chevron) then maybe it is part of the political atmosphere. But I kind of wonder if GA is niche enough that good advocacy will primarily depend on a few good advocates, e.g. like James Inhofe used to be. This never used to be partisan except when viewed with a "Green" spin, and aside from the usual stereotypes of "the rich" and lead phobias, I'm not sure it's on most people's scopes... Generally safetyites and anti-freedom types fear GA, but it's not an issue with visibility outside those who bought a house next to the Inner Marker and immediately started writing letters to the paper I wonder what will evolve. Montana's new senator has aviation industry experience and has flown GA; he seems like a potential advocate from my impression. D1 point

-

I bought my F at 100 hours and it was the best aviation decision I ever made. Insurance was too bad, but it is something to check. Nothing like having your own airplane!1 point

-

This is not my first repaint I’ve stripped and repainted three planes in the last 3 years, I’m just not sure it’s worth the labour to completely strip to repaint. If the existing paint is in good shape but worn thin, I’m thinking a clean up and repaint will work.1 point

-

1 point

-

To do it right you need to strip it and acid etch it and alodine it and then prime it with some epoxy primer and then paint it. Think about this, if you’re gonna scuff it and paint over what’s already there, you’re betting that’s gonna hold onto the metal but that paint job may be 30 years old. The paint shop is not going to warranty it. If you don’t wet sand the previous stripes, you will see those through the new top coat. And if you’re gonna spend enough time to knock all the edges off the stripes, that costs real money too l…it comes out of the savings that you saved from not stripping it. And how much are you really saving? Two or 3K? Is it really worth it?1 point

-

I completely agree with what @Fritz1 said above. All 3 of those gentlemen are very knowledgeable and enjoyable to speak with, and very knowledgeable about market specifics (leads on particular planes, trade-offs, etc).1 point

-

That chart for the 231/252/encore is actually just the 231 with its fixed waste gate. 252 or encore should not be included on the same line. Their line would continue paralleling the bravo like it does in the teens and keep going up to 24k then slightly increasing after 24k as that is critical ceiling on the 252 encore is at 21k but has more speed in the high teens compared to the 252 (guess that 10 extra hp helped) from another chart i saw of just the differences between the 252 and encore.1 point

-

It's also just a different mindset to existing within the system, complementary to the VFR world and skillset. There are pilots who fly VFR only who are masterful in many areas (mountain flying comes to mind), but even a beginning IFR pilot in training develops awareness that complements what he or she already knows as a proficient beginning VFR pilot. It's kind of like learning a foreign language or (I would imagine) getting a law degree and never practicing. You "get" the framework and can muster up enough to get by where you need a few phrases. Most of us who fly IFR (and aspire to be better all the time) are VMC most of the time. OTOH there are people who fly mostly VFR and are hell-on-wheels in the backcountry, tailwheel, floats, etc. Lots of places to go with aviation. Instruments is useful for almost all of us who travel with any constraints, and fun for most regardless. D1 point

-

1 point

-

The only time an ovation is “faster” than an acclaim would be on takeoff if the ovation has the 310hp stc. The acclaim is as fast or faster than the ovation at all altitudes and all configurations other than takeoff. At least that has been my experience with owning two ovations, flying eight or so others, and owning seven acclaims and flying twelve of those. I think what may skew some people’s understandings of this is the appointments. if you have an acclaim with tks and an ovation with neither AC or tks, the ovation may be faster below 8k. But if they are identically appointed the acclaim is still as fast or faster at any time. On my average mission the acclaim is about 30-45min faster and uses about 5-10% more fuel. That is the main difference. The difference to maintain an acclaim vs an ovation is a rounding error. Insurance may be a bit more but once you get good experience, even that isn’t much different.1 point

-

Fuel Pressure is not an option available on an EDM830. Time to upgrade to an EDM900. Aerodon1 point

-

1 point

-

I’d work on getting your instrument rating, by the time you complete that you should be insurable.1 point

-

One of our members flys a Mooney and operates a prop shop -- get in touch with @Cody Stallings.1 point

-

The Piper latch I used was actually a little bigger overall; thicker and wider anyway. Feels more durable.1 point

-

Got my balance done today. Went from .51IPS to .05. I can read my compass now.1 point