Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/2024 in all areas

-

lots of facets, a turbo with TKS is able to do things that the n/a aircraft without TKS is not able to do, i.e. climb over a lot of weather and in particular icing, the question then becomes how important is it to be able to do these kinds of things, best way to find out might be to talk to one of the dealers and test fly aircraft, Jimmy Garrison at GmaxAmerican, Richard Similie at Thunderbird and Mark Wood at Delta Aviation, as a serious and funded buyer you might just offer to pay for the test flight which they will most likely decline or credit to a purchase. Once you have experience the smooth and solid climb of a turbo going through 14,000 ft the risk is you might want one. Buyer beware!3 points

-

I looked it up and according to FAR 145.219, repair stations are only required to keep records for two years. It might be a good idea to request copies whenever major work is done for your own file. I’m going to do that from now on3 points

-

Just buy one of these it will probably last 60 years like the old one. https://www.aircraftspruce.com/catalog/pnpages/11-01954.php3 points

-

I think so. Aviation Consumer Mag referred to the M20 Turbos brand as Rayjay/Consolidated. But each system differs. The original Rayjay and M20 are turbo normalized. The Turbo Bullet (an early rare Darwin Conrad creation before he set up Rocket Engineering) lowered the piston compression ratios and then overboosted to 38.5 inches. It broke crankshafts and the was an AD that restricted boost. Avoid it.3 points

-

2 points

-

It sounded like the OP was after the connector itself, not the backshell. I think he assumed the P/N on the backshell was the P/N for the connector. MIL-SPEC connectors can be a P/N nightmare. Typically there can be separate P/Ns for the connector housing, the connector insert, the connector pins (both male and female), and the connector backshell.2 points

-

Met him when he was driving the BRE Datsun 510 for Pete Brock in the transam 2.5 Litre class. He knew that trail braking and setting up for the long straight was how to get it done. His sidekick, John Morton, could make a brick go fast2 points

-

Seems like we are all happy with our choice and we are all having a good result.2 points

-

"Huckleberry" is not usually something I hear from someone down in southern CA...2 points

-

That is basically the OPP route with them YOU take a part in designing the cable via their paperwork I did mine that way. They then make it using their APPROVED manufacturing procedures. YOU have to sign the log book that you took part in the design of the part (saving the order form) and then your A&P can install it a sign it off.2 points

-

2 points

-

The fuel pickups should be 610150-001 (Left) and 610150-002 (Right) The drain valves are F-391-53-S Wetwingologist has done my tanks twice and I trust Edison not to take advantage of you on the cost of parts.1 point

-

I just balanced mine today. I bought an assortment of bolts and washers. Turned out I only had to add 1 AN960 washer to a prop spinner screw. 1 Ounce. Didn’t need to remove the spinner. It has a fresh O/H on the prop and engine so I guess I did a good job on the engine. When I picked up the prop at the prop shop, I was told to that a dynamic balance would be needed to ensure the prop had no issues. Was able to find a balancer that a guy let me borrow so it was free.1 point

-

I found one new for $80 on eBay... so I ordered that one. I don´t think it would get much cheaper than that if I got a shop to fabricate it.1 point

-

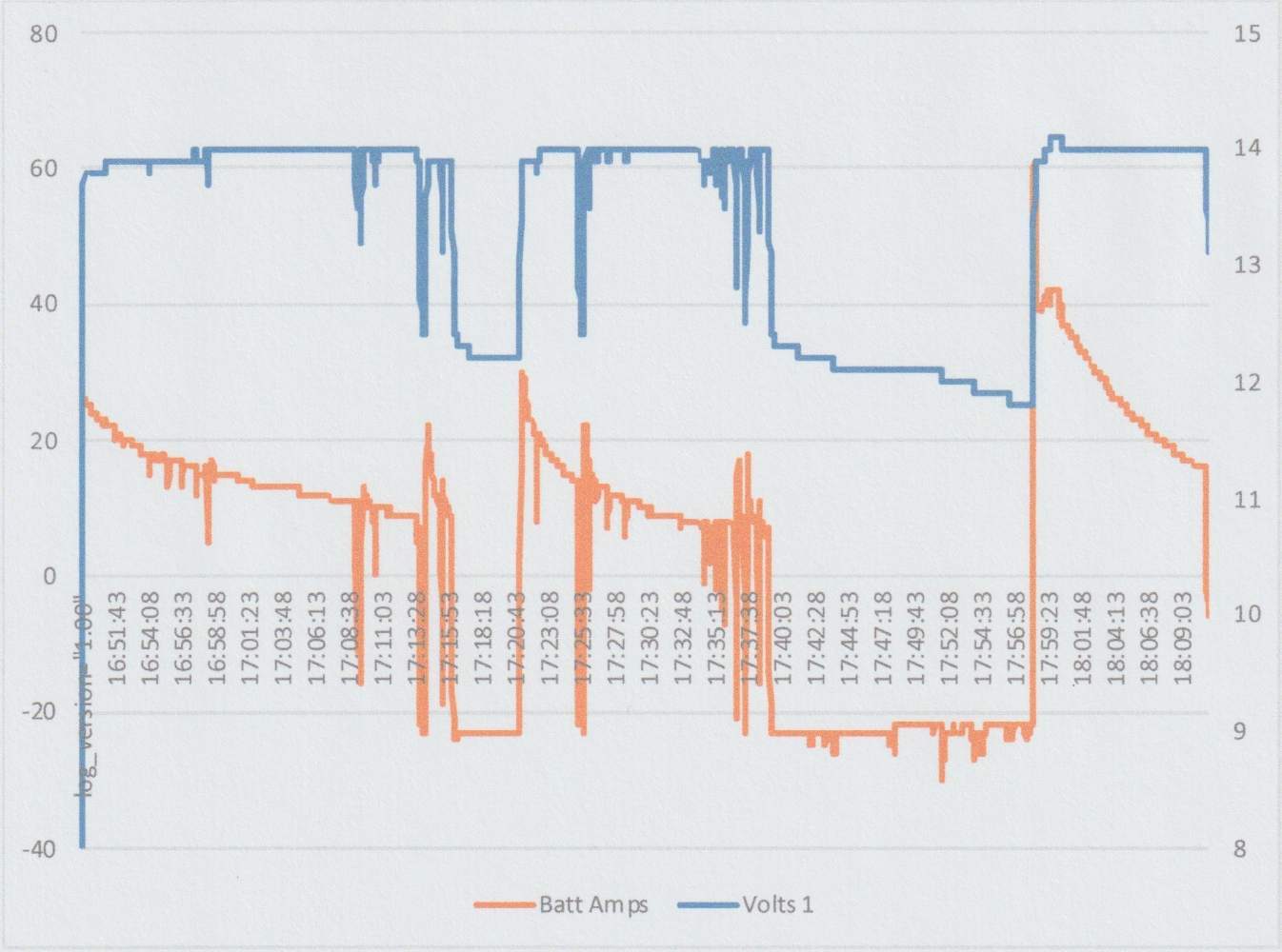

I'd check all the wiring for poor connections before spending money on parts. The way the traces look it smacks of an intermittent electrical connection. Maybe the field wire; it opens and the alternator output is going to go to zero and the battery is going to supply the load current (the -22 Amps), then it comes back and the current stabilizes at around 10 Amps after initial spikes to 25-30 Amps.1 point

-

1 point

-

https://www.aircraftspruce.com/catalog/inpages/canonplugms3106a.php1 point

-

Try looking for a MIL-DTL-5015 connector that mates with what you have. Or, you might just contact an Amphenol rep.1 point

-

That looks like a very poorly done repair. I don’t think that grounding strap is original either. I’d remove the hinge and take it to a machine shop and see if they can duplicate it. Mooney won’t release drawings, but you can call a MSC and get a quote on price and delivery for a new one. Probably a lot more than the use one at BAS.1 point

-

So, the nut plates are just standard nut plates, with a couple of notches ground in the sides with a Dremel. They will probably be $200 each from Mooney, Or you can make them for $5 each. What is wrong with the pickup tubes? I would glue the finger screens back on with sealant.1 point

-

The front Mooney cockpit is a lot more spacious than people make it out to be, tons of leg room and headroom. It's the rear seats that get cramped in older Mooneys, not the cockpit. The difficulty for larger people isn't the cockpit, it's getting in and out of the airplane IMO, kind of like getting in/out of a Mazda Miata.1 point

-

Swap bulbs and make sure the issue follows the socket and not the lamp. Sent from my iPhone using Tapatalk1 point

-

Personally I think they qualify as small standard parts (the base should be BA15S or BAY15S or similar, anything with a compatible base will plug into the socket). Most these days are fairly quiet from a radio perspective, the main risk seems to be whether they're bright enough or not.1 point

-

1 point

-

One potential issue with cheaper LEDs is that their controller or power supply can blast out significant RF interference, and negatively impact your COM and maybe NAV radios. Many or most on this forum go with Whelen, and it's made easier by one of our members who is a distributor for Whelen and other aviation-related equipment. Let's see if @OSUAV8TER can advise you.1 point

-

I think that someone should contact centex aero and perhaps made to sample Good Luck1 point

-

There are approved areas to add weight to the backplate and unapproved ways. Make sure your tech knows what’s what. There are a number of cracked backplate threads on MooneySpace. Dynamic prop balancing can be beneficial, but caution is advised.1 point

-

For what it’s worth, my engine shop said they kept those parts purchase and receipt records for five years. You might be one of the lucky ones.1 point

-

There were three (3) STC turbo conversions of the J. Some turbo-normalized, some true turbocharged. Turbo Bullet, M20 and original RayJay (might be a ModWorks conversion). Which are you looking at? https://mooneyspace.com/topic/9340-original-rayjay-turbo-normalizer-v-m-20-turbo-v-turbo-bullet/1 point

-

It’s called a turbo bullet. There is a pretty good article about it. If I can find I will post it, but a google search should find it. they claim 200tas at 20k. That would be pretty good. the one listed now has 64 gallon tanks which may be limiting. The article said 25gph in the climb. But it seems like a worthy upgrade.1 point

-

Have you contacted Penn Yan? It’s a Part 145 repair station, so I would think it should have good parts traceability documentation.1 point

-

Mine started out pretty well balanced, so while the result was noticeable, it wasn't huge. Others see larger and more noticeable results. The guy that did mine said that some Mooneys are a pain because the long spinner backplates don't allow easy placement of the balance weight. I have a Hartzell Top Prop so the backplate is flat and the flywheel more easily accessible. So, depending on how the technician wants to apply the balance weight, that may or may not be an issue. Whether it makes a big difference or not will depend on how far out of balance your aircraft is to start with.1 point

-

1 point

-

There was one single follow up visit after surgery and no discussion about locking anything in.1 point

-

Yes, it's well worth it. Now having said that, everything is relative. You said your engine runs smooth, as compared to a number of other engines you've flown behind. My engine had the slightest vibration that I could feel, and dynamic balancing made it go away. But the other benefit is the improvement on reducing mechanical stress in your engine/prop combination. Less vibration yields less stress and less wear throughout the airplane, even vibration you can't feel in the cockpit. The best time to start that benefit is early in an engine's life, where yours is. The balancing process is pretty simple, and the setup takes more time than the measurements. An accelerometer and optical sensor are attached to your engine to measure engine vibration and prop position, and an indexing reflector is applied to the back of one blade of your prop. You run the engine up to a nominal cruise RPM and the computer calculates vibration in inches per second, and also calculates how much and where to apply offsetting/balancing weight (bolts/washers/nuts in varying combinations) on your flywheel to reduce the vibration. Stop the engine, apply the weights, and repeat until you're happy with the results. Here's a good introduction to dynamic balancing from Jeff Simon.1 point

-

Not sure if it was mentioned in the thread….but…IIRC….the price of the PMA cable is much more than the “owner” produced cable where you simply fill out the form to match what is in the aircraft currently. The cables are essentially identical, but they are building to your specs vs theirs… I suppose that limits their liability and also likely reduces paperwork burden. Give them a call about having a custom cable made….and I think the price might be more appealing. They make good stuff…1 point

-

I know. I know. I could buy a C8 Corvette for the price difference and be even happier.1 point

-

As far as the pilot swearing he put the gear down that’s not at all uncommon that someone is sure they did something but didn’t. particularly when it’s an action that’s always taken, they are sure they did, often remember specifically doing it. For example a Commercial airliner not putting flaps in the T/O position. There are even many examples of someone voicing an action on the check list, without actually doing it. No matter how experienced we are or how many ratings we have we are ALL subject to doing something stupid. I would say that it may even be more likely for an experienced pilot who usually flies something much more complex. They are more likely to become more complacent in a simple, slow airplane like a Mooney as opposed to the 737, Citation or whatever they usually fly.1 point

-

The absence of an IR doesn’t make anyone a “bad” pilot. It’s unfortunate that you interpreted it that way, because there was no malice intended. But it doesn’t change the fact, that the experience one gets during the training, would make any pilot better. I know I will always have places I could improve, and would hope we all feel that way.1 point

-

Just as an aside note- The Capt of that Valuet was a very close friend of mine. I gave her eulogy. She was a good pilot an a great person to know. Just one of several friends that are no longer here because of various accidents in this game we call "flying" It is the main reason why I sometimes become pedantic in my postings trying to stress safety and following the rules in aviation. It saves lives! Sorry for the drift1 point

-

I’d work on getting your instrument rating, by the time you complete that you should be insurable.1 point

-

Looking at your post-it makes me wish: wouldn't it be nice if the g3x had "power setting bugs"?1 point

-

I haven't looked closely at their head lamps, but I have been very happy with a number of other flashlights. https://www.olightstore.com/headlamps1 point

-

1 point

-

"Acceptable to the administrator" covers a lot of ground, and ACs, opinion letters, and other methods are often used to convey and clarify what that means. If fuel x becomes "acceptable to the administrator" to qualify as a particular "octane" or "grade" of aviation fuel, then there's nothing keeping us from using it and being completely compliant with the TCDS. The TCDS wording for fuel isn't very specific, and that is true across most TCDS for GA airplanes. Newer ones often tend to be even more vague than older ones, it seems. It seems to me it'd be pretty easy for the FAA to convey, through a number of means, that a particular fuel is compatible with the description in the TCDS. Maybe just an update of AC 91-33 would be sufficient. AC 91-33A says: The FAA does not regulate the distribution systems for either aviation gasoline or automotive gasoline. Nor does it regulate the specifications for either fuel. It does, however, approve the use of fuel to a given specification in an aircraft engine. So AC 91-33 says the FAA can approve the use of fuel to a given specification, which is really all that is needed.1 point

-

Sorry to hear about the relative’s broken hip. Difficult process especially as folks age. Your doghouse is probably in good shape. The difficulty is that there are often big holes that are hard to see and work on. When you get back home and you take off your cowling’s side panels, put a drop light inside the doghouse and turn off the lights in your hangar. Look under all four cylinders for light leakage that isn’t through the cylinder fins. Also look behind the doghouse, particularly where the upper engine mounts are located. There should be large felt pieces that seal up that area, but are often missing or messed up. Finally, put the light just under the prop and look forward under the engine to where the generator and starter are. Additionally- there is supposed to be rubber baffle material attached to the forward part of the doghouse, top and bottom, all the way around the front. It goes inside a small aluminum u-channel on the cowling. All of that rubber material should be present and nice and flexible. Also additionally- are the inter-cylinder baffles still in place below the cylinders? These are sheet metal that extend between the barrels of cylinder 2&4 and 1&3. Engine cooling isn’t really about airflow, it’s about the air pressure differential between the top of the engine (doghouse) and the area under the engine (leading to the cowl flaps). Since it’s a fluid, the air in the doghouse will follow the path of least resistance- which is often big holes around the starter, generator, oil pressure adjustment, and engine mounts. That lowers the pressure differential so less air is being drawn through the cylinder fins. To summarize the problem areas: - upper engine mounts - around and under the oil pressure adjustment - around forward parts of the generator and starter - baffling in the u-channel at the front of the doghouse - inter-cylinder sheet metal baffles below the cylinder barrels - other areas of the doghouse where it fits around the cylinders and case1 point

-

Your likely going to find that reworking your baffling is going to help a lot more than a cowl closure.1 point

-

I was told by Paul Loewen several years ago, the cowl enclosure did nothing to enhance speed or cooling. It was purely for asthetics.1 point

-

The original owner of my '94 J had some work done at Mod Works. The only Mod Works STC installed is the upper cowling mod to prevent cracking and it's worked well. Skip1 point