Leaderboard

Popular Content

Showing content with the highest reputation on 11/07/2024 in all areas

-

Also when you remove exhaust hardware that has not been removed in a long time, you may find more problems that require more work - slip joints, flanges, - or corrosion may conspire to induce problems like breaking a stud.5 points

-

Here is some more information after talking to live people: -- Lycoming technical support said that they agree that the AD is poorly phrased, in the sense that it appears to at the same time say that "any bronze particulates" should trigger a bushing inspection, but at the same time points you to the SB 480F which says that unless you find relatively large "chips" of bronze you can continue to monitor the situation. According to the tech person the only reason Lycoming asked the FAA to create this AD was to force people to be serious about looking at the oil filters and suction screens at each oil change (he said "you wouldn't believe how many mechanics out there do not follow these recommendations"). When asked how many engines failed due to bushings coming apart, he said he did not know. When I pressed and asked if it is more like 3 or like 300, he said he can tell me it's not 300. But, perhaps as a CYA move, he said that the way he reads the AD as phrased is that if you find even one tiny bronze particle in your oil filter, you are required to pull cylinders and check the bushings. And then, say, you fly it 50 hours, find another tiny bronze particle, you do it again. And so on. Love the FAA and their imprecise wording. -- I also talked to the final A/W inspector at Penn Yan, so a guy with a lot of experience. He said quite clearly that you should follow the guidance of the SB480F, and look for chips (>1/16" pieces) in the oil filter and suction screen. You don't find these, and maybe find a few tiny flakes, continue to operate as normal, per the SB. He also said that they did quite a few of the inspections required by the earlier 2017 AD, and only found 4-5 bushings that moved and needed to be replaced. He was not aware of any specific engines that actually failed because of moving bushings. So he was firmly recommending just watching the oil filter and the suction screen and be on your merry way. BTW, I do have the affected bushings, it was confirmed that when my engine was O/H-ed they put in Lycoming LW-13923 with a ship date of 08/2012, so smack in the middle of the affected range.3 points

-

It is not the cost of the parts, but the cost of removing the baffling, intake, exhaust and all 4 cylinders, removing the pistons from the rods, doing the test and putting everything back together.3 points

-

I also sent my gns 530w up there and they fixed my volume knob and refreshed all the other buttons and knobs at the sane time. Much cheaper than sending it to garmin.3 points

-

2 points

-

Indeed, GA suffers from a surplus of capitalism…what we need is greater regulation. That should do it.2 points

-

2 points

-

You could press the part into modeling clay, then use casting epoxy to create a new one. https://specialtyresin.com/products/tough-cast-65d-black?variant=45639252672747¤cy=USD&utm_medium=product_sync&utm_source=google&utm_content=sag_organic&utm_campaign=sag_organic&gad_source=1&gbraid=0AAAAAofNuf2L8hHM6Cbu-Eo4AXxeFduri&gclid=EAIaIQobChMIhNPU3IDLiQMVEiFECB3JehEuEAQYAyABEgLtuvD_BwE2 points

-

Take a look at the one used on the Pipers. With the right hardware it can work just fine.2 points

-

Ha that lack of easy access is way understated. Damn knuckle biting curing vocabulary expansion nightmare i tell you and make damn sure you have a new crush washer to go on there or the used one that’s on there now will leak and you get to clean that mess up until next oil change as there is no way you are going to swap that old crush washer for new before all the oil runs out.2 points

-

Yep Equity firms see us as a cash machine, and they know they can put nearly any price on their goods and we have to accept it because there isn't anywhere else to go. They will wring these providers out for every cent, until GA collapses or morphs into jets and uber rich hobbyists are all thats left.2 points

-

2 points

-

2 points

-

Are you willing to pay the $1k to fix it if it does? Mine has not popped open but when my neighbor’s ovation did pop open and cost him $1k to repair. That was enough incentive to lock my baggage door for every flight. Low effort to do with a low probability but high money loss if it does.2 points

-

After @kortopates raised this with me at my last PPP, I always lock it and I added it to the checklist. I know it is supposed to be an emergency exit, but I can’t find - and I did do some searching – any Mooney accident report where it was reported that it was used in this way. But I did find several that referenced the door opening in flight.2 points

-

Your 5th para is exactly what I was trying to suggest. And when I said oil inspections I was being too brief and not specific enough; best to read the SB (I'll be looking at whatever I can for particles and probably sending the oil off for analysis too). Regarding your 6th para; I asked for an estimate from a reputable trusted builder. In CA it's $4500 to remove four cylinders and perform the press out test. Compare that to the FAA estimates. Sorry for begin too brief but Mooneyspace kept bombing; said too many users were logged in or something like that. Again, I'm no expert mechanic; just a retired DOD engineer / owner with time enough to investigate this issue myself and read the documents.2 points

-

The NTSB involvement probably didn't have anything to do with the pilot's statement. The NTSB investigates accidents which definition includes substantial damage. Note that the report lists the aircraft damage as substantial. A similar occurrence happened in June 2022 (Accident number ERA22LA319) where a M20J landed gear up in Charleston, SC due to a broken torsion spring in a Plessey actuator. The damage was classified as substantial because it ground through a structural tube in the belly much like this accident. The report picture of the damaged tube has the caption: "View depicting the damage to a tubular steel truss primary structure which required major repair and classification as an accident."2 points

-

Closing this out, after speaking with Hartzell several times, this is a known conflict on the IO-360 and they are not concerned about wearing through the boot. I’ve placed some silicone tape between the corner of the fuel fitting and the boot as well as compressing the boot against the starter body to lessen the contact pressure as much as possible. I’ll check it well during annual next April to ensure everything is still OK. I sure wish there wasn’t any contact, but it is what it is.2 points

-

And airways, RF leg support, programmable holds your AP will fly, visual approaches (many with GS) to virtually every runway in its database and improved VTF support on approaches (VTF includes the waypoints behind the FAF) and of course a much better moving map on the larger screen 750. And one of favorites: DB Concierge support with the FS-510! no more data card programming except for the terrain which is seldom updated anyway. Sent from my iPhone using Tapatalk2 points

-

2 points

-

McMasterCarr should have something what would meet your needs https://www.mcmaster.com/products/springs/springs-2~/spring-type~extension/1 point

-

@MikeOH there’s a 10%. I thought about putting a bid.. it’ll be around 80k sight unseen said and done. Doesn’t seem worth it1 point

-

I bought 2 new piper latches which worked well. Slightly smaller, but works.1 point

-

If the problem is a lack of model, I can make the CAD model for you in Solidworks. You provide me with detailed measurements of the part, and I can whip it up quickly. Then you can send that CAD model to xometry or other online source for printing. You would be responsbile to set tolerances, material used, and any other manufacturing items.1 point

-

Would really like to hear Lycomings thoughts on why the 2017 and 2024 ADs have different compliance requirements for the same P/N, particularly IF the defect is the same for the two populations of bushings. {Note: I was told by a reputable builder they've seen bushing move as well but so far not enough to make metal; I was also told some of the defective bushings were identified and rejected because they were too easy to hand press into the rod; I have a bit more gut confidence since my bushings were hand pressed into the rod.}1 point

-

I have one sitting on the shelf in my hangar from LASAR. It's just a short piece of round ducting, not rectangular like the original. My plane didn't have one when I bought it so I bought the boot, never put it on. My AP/IA mentions it each annual, but it's still just sitting on the shelf.1 point

-

Fly the airplane at cruise speed. Set the prop control to 2700 rpm. Land without adjusting prop. Turn the governor stop screw CW until it just touches the control arm. The screw is safetied with .020 lock wire and a jam nut. You might remove the lock wire before flight to avoid accidentally bumping the control arm. McCauley governors adjust about 25 rpm with each turn of the screw.1 point

-

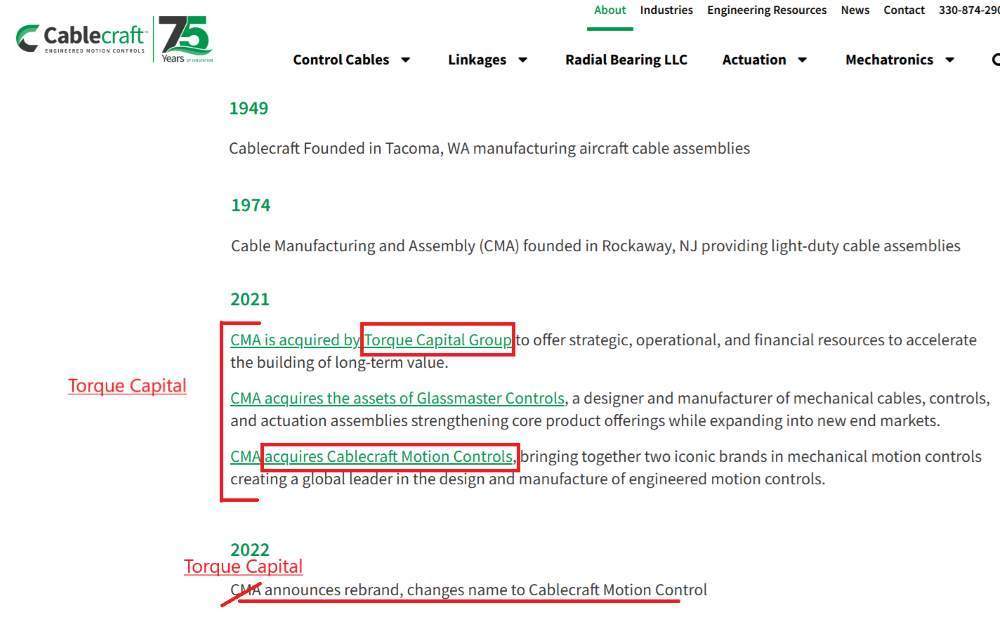

Torque Capital acquired Cablecraft and a couple other companies in 2021 and combined them. Torque's "investment criteria" is clear - "Typically control equity investments where we can actively partner with management to maximize returns". Partner with?...post Private Equity acquisition, the former company management is just a dog on a leash. http://torquecap.com/investment-criteria Vance Street Capital acquired McFarlane and a number of other aircraft part suppliers. When they acquired McFarlane they also announced that they were "partnering with" their target - complete BS - more like slavemaster and slave "partnership". https://vancestreetcapital.com/news/2021/10/vance-street-capital-partners-with-leading-general-aviation-pma-manufacturer-mcfarlane-aviation/ They formed Victor Sierra Aviation Holdings LLC (“VS Aviation”) to market them. They have 14 companies so far. https://victor-sierra.com/news-insights/1 point

-

This is just going to drive more and more OPP home-brew replacements out of necessity. If people are going to keep older airplanes flying, there won't be any other choice.1 point

-

You were looking to spend $80-85k as well as move down to a C Model. $60k for this plane, as equipped, is a very good price.1 point

-

Flew my Bravo into Fort Worth Alliance airport today. Winds were 160 at 24 gust to 34 knots. Luckily, that is straight down the runway. On final the airspeed kept oscillating +/-5 knots of my target airspeed. I decided to let the Garmin GFC500 autopilot fly the approach. I wanted to see how it would handle the winds. What an amazing piece of technology. It never deviated even the tiniest bit from course or glidepath. In fact, I started to get concerned the G3X wasn’t working right because I never saw any movement of the course or glidepath. It took me all the way to a 200’ decision height without the slightest deviation. I am such a huge advocate for the Garmin G3X and GFC500 suite of avionics. Amazing awareness and precision.1 point

-

These prices are not only here to stay, they will be going up and will never go down again. All of these manufacturers know they have us by the short and curlys, and they are going to pound us relentlessly. I don't know what the threshold is before our niche pushes back but they are intent on finding the limit.1 point

-

1 point

-

I can see it both ways. Enough damage to get an accident classification, but I suspect there are plenty of gear-ups like that which never make it to the NTSB because they are (ho hum, snooze) just another gear up. But when the pilot says they lowered the gear, it could take it out of the ordinary and into a safety investigation of “why did the gear collapse?” (I knew a pilot - also a CFI - who had a gear up sitting on the ramp. Initially claimed it happened on its own but came clean a few days later.)1 point

-

For the record, the B&C starters won’t fit the IO360s with the forward mounted fuel servo either. Too bad as it’s a great starter too! -Matt1 point

-

I wanted a boat that was above all comfortable and safe, hence the IP, over 40 and a boat is tough to single hand, an IP38 is actually 41’6” overall like most are measured. The code zero really woke it up in lighter winds, but an IP just isn’t a light wind boat, too heavy, but in 6 or so kts of wind and the motor ticking over at 1200 RPM my Autoprop would have her motor sailing at hull speed and burning less than a half gl an hour and charging batteries to boot. I carried four sails rigged, Main that was boom furling, Staysail that was my Storm sail too, 135% Genoa, and the Cruising code zero, cruising because it didn’t meet racing regs, but I was in no danger of racing my house. All sails were roller furling so I didn’t have to leave the cockpit for anything. Speed wise towing a dinghy really slows you down more than you would believe because your dragging the thing above it’s hull speed and forget passage making towing, in any storm the dinghy will at least flip and invert, and not unlikely you will lose it. Best on deck tied down, second best on davits. I wanted a big fast RIB and I didn’t have near the deck space for that so davits was it, but they gave me room for four 250W Solar panels, I ended up being about 45 ft overall, maybe 46. I miss cruising, if you have even the slightest inclination I say go, go now overwhelming majority wait too long and can’t. Don’t wait for the perfect boat, nobody needs a 50’ Condomoran, get a cheap 36’ boat and go if that’s all you have to spend, you’ll have just as much fun as the guy in the big Oyster, probably more really.1 point

-

Almost ready! Went to the shop today. The idea was to review all installation and do a thorough runnup and a quick test flight with the mechanic to review the GFC500 autopilot. All avionics working but we had a malfunction with the voltage regulator. Having it checked the next couple of days and see if we can fly the plane Saturday morning. However, we got to spend some time playing with the new screen. The G3X is indeed a very nice piece of equipment.1 point

-

And if you don't have the Lyc ship dates (or they've been disposed of after five years), you've got a practical choice to make. Recurring oil inspections for metallic solids or a bushing press out test for ~ $4500.1 point

-

I replaced mine a few years ago and it was half that. Capitalist owners doing capitalism at McFarlane. I'm told this is optimal for us. Unfortunately, they were also the OPP option, so maybe there's another cable fabricator somewhere?1 point

-

I’m sure glad I never wound up on our wonderful MS as a pilot that did something really stupid ! Maybe that’s why I stopped flying !!1 point

-

Don't you lock your rims away at night? Thats the main reason they fold up, right?1 point

-

1 point

-

I had that happen with the factory Eurostretch material on a 1997 Encore I had. I took down the headliner and took it to an upholstery shop, had them pull it off and re-glue it. It looked brand new when they were done. I think it was around $100 to have them do it.1 point

-

Here is a question for the APs around here. Is it possible to replace the bushings without taking the connecting rod out of the engine? My understanding of the mechanical process involved makes me doubt it is possible, right? Then how do you replace all four bushings in 4.5 hours, per the FAA? I would think the job requires splitting the case, which is (my guess) closer to 40 hours, even without counting the cost of taking the engine off the plane and reinstalling it... I really wonder how the FAA comes up with those numbers.1 point

-

This issue has been known to Lycoming for some time. The latest "ship date" listed in the AD (I'm still not 100% clear if these dates only apply to entire engines or also to the connecting rod assemblies) is Feb 2017. The Lycoming SB 480F Oil Servicing, Metallic Solids Identification After Oil Servicing, and Associated Corrective Action was updated 5/25/17. Lycoming SB 630A Connecting Rod Bushing Inspection After Cylinder Removal was updated 6/17/17. Evidently the bushings can loosen in service and either rotate in the rod or move out of the rod bore. Either movement can apparently cause them to wear and eventually fail. But apparently there have been some catastrophic failures leading to the AD. Based on the AD language, Lycoming and the FAA seem to believe that normal interval inspections of the filter media and suction screen will indicate an issue before it causes a failure. So, it begs the question: Where the filters in the engines that failed not being inspected?1 point

-

(g) Required Actions (1) At the next oil change or within 4 months after the effective date of this AD, whichever occurs first, and thereafter at every oil change until the bushing replacement required by either paragraph (g)(3) or (4) of this AD is done, perform a visual inspection of the engine oil filter, oil pressure screen, and oil suction screen (depending on the engine configuration) for bronze metal particulates. The actions required by this paragraph may be performed by the owner/operator (pilot) holding at least a private pilot certificate and must be entered into the aircraft records showing compliance with this AD Looks like logbook entries for oil changes just got a bit more verbose Sent from my iPhone using Tapatalk1 point

-

Just a quick flight past the Chicago skyline via the VFR flyway. Now just a minute from our sponsor, Ridge Wallet.1 point

-

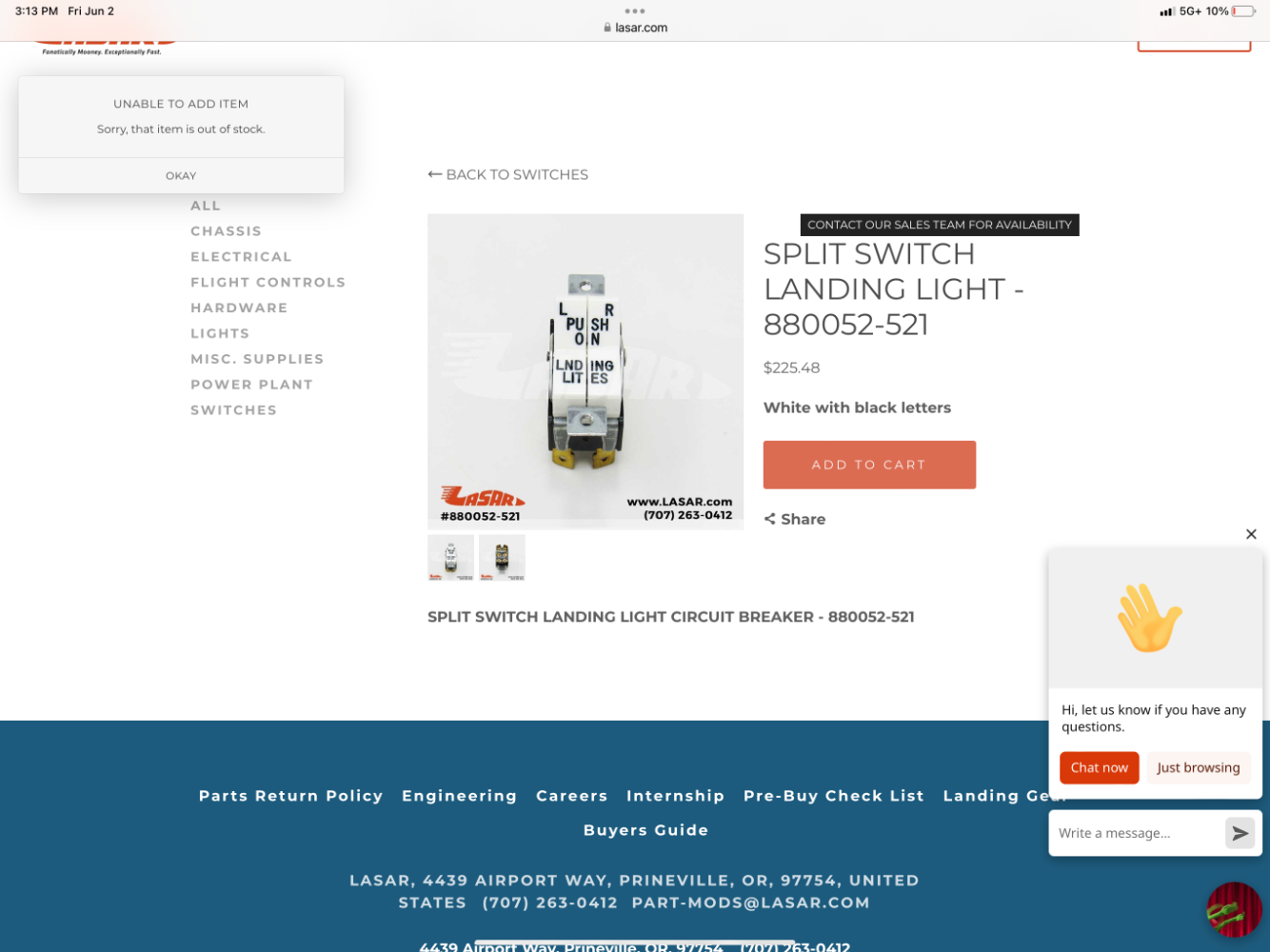

We have a 1993 M20J. The landing light toggle switch (left one is frozen in the off position, right one works fine). It was working fine. Don’t want to force it. 1. Any suggestions of what may be wrong. 2. I see some people had switches available back in March. Does anyone still have one? 3. Anyone have a part number? Or suggestion where to buy? Aircraft Spruce? Sensata? Assuming Lasar does not have. Thanks Kim1 point

-

I may have one from a salvaged 78 M20J message me if you are interested.1 point