Leaderboard

Popular Content

Showing content with the highest reputation on 06/03/2024 in all areas

-

I know some people here have much better machines, but my trip yesterday was an eye-opener to the capabilities of my E model. Took off from KRKS (Western WY) at 10am, and five and a half hours later landed at 91C in Eastern WI, crossing five states (WY, NE, SD, IA, WI). 993 miles non-stop at an average speed of 190 mph, burned 46 gallons of fuel at 13,500 feet. Of course tailwind helped (around 25kts), but I still feel amazing about it. I used oxygen all the way, and felt none of the fatigue I used to feel after flights above 10k. Here's a picture of one of the more spectacular buildups I had to dodge along the way.14 points

-

He was absolutely correct in this statement. However, he should have also pointed out that there is a lot of WRONG information from maintainers. That's why we have to verify what anyone tells us. Good for you to delve into this.6 points

-

5 points

-

What a pleasant time I had listening to all the details from the man himself. He is a new owner of a Mooney and took great care to tell me what an amazing plane it is. The plane had been flown 30-40 hrs / year for the last several years. He purchased the plane a few weeks ago and was getting instruction for his insurance. The engine is an IO360 with approximately 1000 hrs on it. He was flying with an instructor at approximately 3500 ft when the engine seized without warning. It is locked up. The propeller did not windmill at all. They found a nice place to set it down in a farmers field and there it sets. It is unharmed in any way except for the seized engine. They are waiting for it to dry out before pulling the engine.5 points

-

4 points

-

Thanks everyone. I agree 100% that the primary cylinder temp gauge is required equipment. My avionics installer disagreed after he threw out my functioning OEM temp probe with a supplemental EDM830 install. He also installed the crush temp probe I purchased for the EDM on the old gauge thinking it would read.He stated that if it is not in the TC it wasn't required. Said "there is a lot of WRONG information on forums". Now I have to fix his error to have a functioning cylinder temp indicator that is primary. Thanks again for replys. Hopefully they will help someone else someday. Scott4 points

-

CAR 3.675 Cylinder head temperature indicating system for air-cooled engines. A cylinder head temperature indicator shall be provided for each engine on airplanes equipped with cowl flaps. In the case of airplanes which do not have cowl flaps, an indicator shall be provided if compliance with the provisions of CAR 3.581 is demonstrated at a speed in excess of the speed of best rate of climb.4 points

-

The koch chart can also help where poh data doesn’t exist. This faa pamphlet is actually pretty useful: https://www.faasafety.gov/files/events/nm/nm09/2013/nm0951144/density_altitude.pdf3 points

-

OK, as the OP I feel obliged to respond to some of the comments. In the end I had to go to Driggs -- I was not aware of the fact that Jackson Hole has extremely limited overnight parking, which must be reserved well ahead of time. (They said 5 tie-down spots total.) Takeoff from Driggs was absolutely a non-issue. Much easier than a takeoff I did years ago from Fremont County (1V6) in a fully loaded Piper Cherokee 180 on a hot (90+ degrees F) day. 1V6 stands at 5450 feet. My POH only shows information for 5000 pressure altitude and 80 degrees F. But @Shadrach's table for an F helped. Thanks to all who responded.3 points

-

The OPP regulation is a very valuable path for owners like us in this situation. There is quite a bit of latitude on the "production" of said parts, and the owner does NOT have to literally make the part themselves. They only have to be involved with the specification and direction of the production, and only install them on their own plane. (ie don't make and sell them to get around PMA rules!) The specification can be as simple as "duplicate an existing part using the same materials and dimensions," and that is perfectly proper. In this case, the machinist friend can make a batch of them without worry and distribute to individuals. I would very much like to buy a set as well if you and the friend are willing. If he makes a batch, the price could be lower for everyone. If you want to create a paper trail, you could have anyone interested complete a simple form to create the specification and then everything is above-board. (This is how companies like MacFarlane handle making duplicate engine control cables or similar where they do not have a PMA!) If you need a scrap version for destructive test, I'd suggest talking to Maxwell or Top Gun or similar and see if they have any in their box of misc hardware that is used for show-n-tell.3 points

-

It's easy to be fearless when you're doing the work in Dugosh's hangar. The stuff isn't actually all that complicated but, I knew if I did get completely lost I had the resources I needed to get it out back together. Sent from my Pixel 6a using Tapatalk3 points

-

It's a type certificate, not an inventory of every legal requirement. The TC doesn't mention an altimeter or compass, either.3 points

-

I totally agree with everything you’ve said. However (), you know all too well that technological advancement far outpaces regulatory evolution. We live in a day and age when one can buy inexpensive instruments and be assured they will deliver precise, reliable information that is easy to read, download and share. I think there is probably room for a lighter regulatory touch here (as well as in other areas). If the goal of the regulatory body is to maximize safety, then regulators should be seeking to create a regulatory environment that facilitates maximal adoption of any well understood, reliable technology that contributes to safety of flight. I am not so sure that they’re doing the best job of keeping the end goal in mind. Experimental aviation provides a means to analyze and showcase areas where the certified, regulatory, framework increases safety and to also showcase areas where it generates almost no statistical difference in safety. If an area of the regulatory framework isn’t increasing safety…what is it doing? It certainly isn’t increasing availability and decreasing costs. The fatal accident rate in experimental aviation is much higher than certified. The precise stats might be fuzzy but the delta is large enough to be undeniable. More freedom granted and less regulatory oversight increases risk/decreases safety. However, I’ve not found a single instance where an experimental operator’s uncertified nav lights, strobe system, landing light or engine monitor contributed to their or anyone else’s demise. Regulators should be seeking to maximize the safety ROI from regulatory activities, yet there seems to be little interest in analyzing the areas where the FAA/PMA/TSO certification has no statistical effect on safety. I applaud the FAA for loosening the regs around AOA indicators. I would like to see that type of consideration more broadly applied. It would also be nice to see data on how many AOA equipped aircraft have been involved in stall spin accidents since the regs were relaxed.2 points

-

2 points

-

2 points

-

I have an original gear and original worm gear, they are getting scanned and drawn up, will let everyone know when it is completed as I need to get the original part back to the owner who was nice enough to loan it to me...unfortunately I have been unsuccessful finding a set of old, out of tolerance, gears for the destructive testing for the metalurgist2 points

-

2 points

-

You didn't say if you are replacing skins, but if you are, I'd check and see what they cost to get from the factory. I've found some of Mooney's parts prices pretty reasonable on parts it manufacturers. Some of those panels have stiffeners and by the time you cut up sheet metal and rivet stiffeners and drill all the holes in the right places, it might be easier to just get one from Mooney. Besides, making parts is about all that's keeping the factory in business these days and it's good if we try to support them when possible. Just a thought....2 points

-

I redid my panel at my last annual, it was a huge job. I've got a great relationship with my A&P/IA and they were willing to sign it off. It's really not all that complicated once you understand how it all interconnects, assuming you've got good technical aptitude. I'm mostly retired and like doing my own work mostly because it usually gets done faster than if I have to schedule someone else to do it and when scope creep pops up, and it always does with me, it's not really affecting someone else's schedule. It's also nice to know how everything works, I trust the airplane more now because I understand it all. There are 2 issues though, the first is obviously finding someone willing to sign it off. The other issue though, is that some avionics are only available to authorized dealers. I put G5s and an GPS 175 in my plane, if I'd wanted to do GI275 or G500 and a GTN, it would have been more difficult to get the equipment and STCs. Sent from my Pixel 6a using Tapatalk2 points

-

2 points

-

As part of the DVD package I send, I include a very important document that complements the video. I, also, send out an email that discusses how best to use the video. I have sent a number of copies of the video out by WeTransfer and separately send out the documentation along with the supporting email. It adds a separate step with regard to playing it. The .cdr file doesn't just automatically play like inserting it into a CD player. On the Mac it plays with "DVD Player" or on both a Mac or Windows machine it plays with a multimedia player such as "VLC". The video is not long (but each type of approach can be played over and over again), is not a polished production as many videos might be, but is different than any videos I have seen in that it was shot and composited to show in one picture the approach perspective from both the pilot's view and side view from the ground. Since it was made with tape, there is no prop interference and the unintentional but beneficial low alternator noise demonstrates the proper use of power in the approaches, ie, the less power changes the better. One other thing, I unapologetically included an unintended go around to show that, no matter what your experience level, when the unexpected happens, a go around can be started with a quick decision with no anxiety. Bottom line, the video can be sent out as a download.2 points

-

It is all about certification/qualification to a known standard: proof that the device is trustworthy, if you will. The factory gauge system went through certification testing and was part of the Type Certificate issued for the aircraft. An aftermarket device monitoring all cylinders may well be a more accurate and better device but without proper testing and documentation the FAA says "no bueno". So, naturally, those companies that go through all the certification testing can advertise as "primary" and charge a hefty premium. Those that don't...well, you do get a better price! IOW, the FAA doesn't want you, the owner, to get to decide what is 'good enough' and I can't say I blame them. Welcome to aviation2 points

-

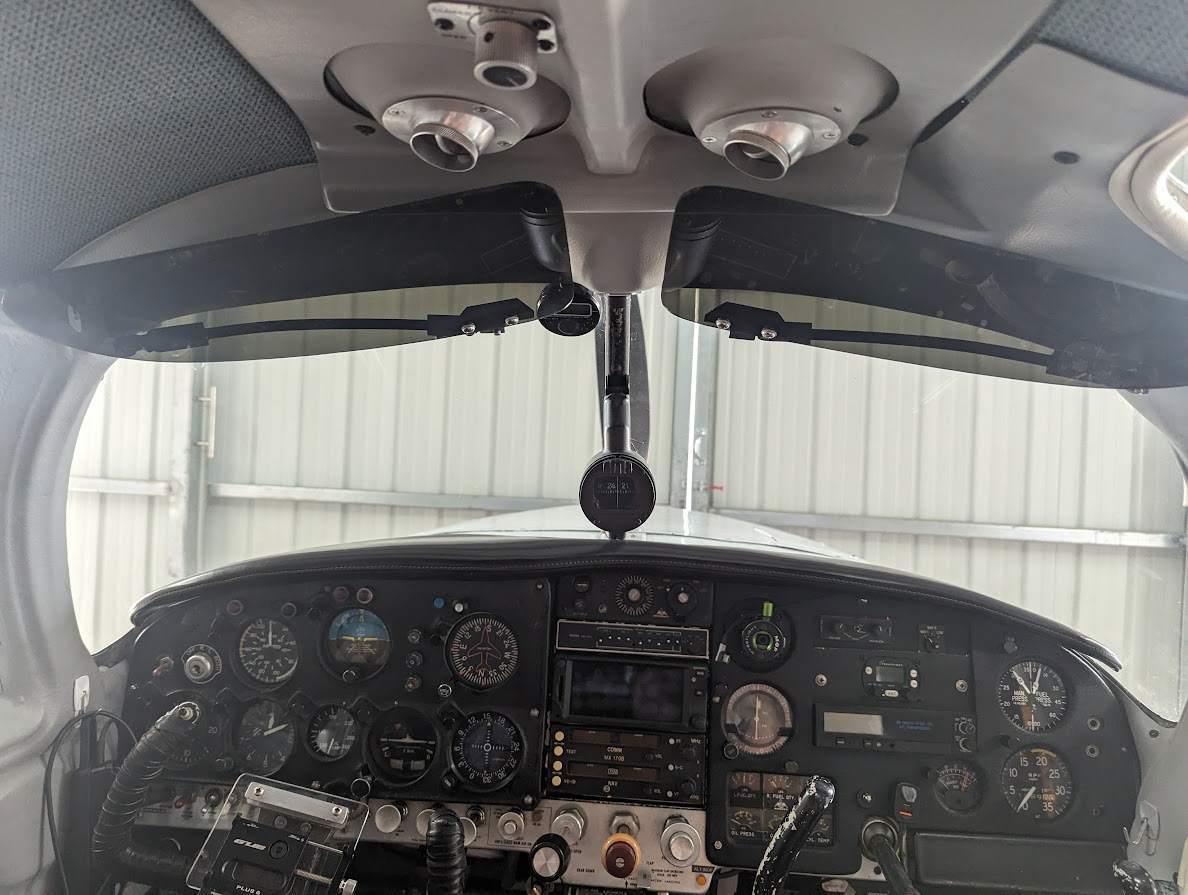

Ordered a set of visors from @DonMuncy My '66E had the center mount visor. Mr. Muncy fabricates a fully articulating visor with nicely sized hardware and smooth joints at a very fair price. I fabricated a very crude bracket for each side and used existing Mooney hardware to install to avoid any alteration to the plane. Hopefully my bracket will hold up over time. If not, I have no problem having paid Mr. Muncy a modest sum for his hand-made engineering. My Wemac baffles above are courtesy of @Utah20Gflyer's design. I built a vacuum forming machine and formed them from 1/16 ABS. Also copied @piperpainter's backseat mod w/ a slight twist. I guess it's time for me to confess that I've been lurking on this forum for a long time saving and compiling information. I have definitely taken more than I've given. I try to database any information that I might need in the future to repair or obtain equivalent parts to keep this plane in the air. And I can't quit buying up everything that comes available that I think I might need in the future. Why am i buying Brittain stuff from Bonanza guys? And why did I buy that lot of various early Mooney inspection panels? I save instruction articles such as @Shadrach's thorough course on hydraulic flap maintenance/overhaul or @carusoam's bullet points and I've saved just about everything @M20Doc has said. I do try to buy from the folks here. I ordered @donkaye's landing video. I have @takair's electric step conversion sitting in my hangar waiting to install. Picked up a battery charger from @OSUAV8TER shortly after I bought the plane. Anyway, I'm thankful for the folks on this forum and your willingness to share your years of experience and expertise. I fly out of a rural airport in the middle of nowhere in SW Louisiana. Without the information here, I will quickly run into something that will ground me. -David1 point

-

I don't have many details, but it appears the pilot was training and had a mechanical problem. Executed a safe emergency landing in a field. Well done! https://fox4kc.com/news/plane-makes-emergency-landing-during-practice-flight-in-clay-county/?fbclid=IwZXh0bgNhZW0CMTEAAR0vPvypyqmqUKGO0911MeaBg-nUqBGKKsrXrYzI4bVWtC_AbY1XDHNe0k8_aem_ARRhZd8Ht0HZrM15C6Dn4cxaRNrHiZSLh2Hpsz5erQ5Ivy5l9c9IU6LDI1c8CLh1PftmMEEUh1Ssx0URBPhXP48m1 point

-

Whatever you do, don’t spend the night! My wife and I were flying back from New Orleans a few years ago. The winds were howling in the wrong direction. I asked her if she would mind stopping and spending the night and we would fly home in the morning. She said “thank god, yes!”. So we stopped in Pecos and got the crew car and went into town. The only room we could find was in the Motel 6. The whole town was slammed with oil field workers. We quickly discovered that there are about 3 females in all of Pecos. Everywhere we went there were hundreds of eyes staring at her. Very bizarre.1 point

-

Right, en route VNAV and Smart Glide didn't work, I think everything else will. It's still way more capability than I have now, and I really like my Avidyne navigators. Sent from my Pixel 7 Pro using Tapatalk1 point

-

1 point

-

There are really no good options for this, although the one at the spar is further away, and there are less passengers in the backseat than the front.1 point

-

1 point

-

As I learned, if the gear leg has the stops, it's possible to break a stop clean off without denting a tube (or in my case, denting it so slightly that it wasn't easily felt.) If the steering is set up correctly, the first thing to limit travel is the rudder stops in the tail, followed by the steering stops on the nosewheel if you have them. At this point, there is still a gap of maybe 3/8" (I haven't measured it) between the leg tube (the weaker one that gets damaged) and the truss tube (the larger one that damages the leg). So, it's best to check out the stops if you have them. It's not too hard to kneel down and see them, or use a phone camera to photograph them. I also carry an inspection mirror that makes it easy to inspect such things and I carry a rubber knee pad like the kind gardeners use which also makes it easier to sump the tanks without grinding my knees on the tarmac.1 point

-

Getting on the ground and inspecting the gear carefully is an important part of my preflight routine, and I think there is value in it. I'm not saying that it's the only (or even the best) way of identifying damage to the truss, but my intent is to be very familiar with what's normal, so I can easily identify when something is abnormal.1 point

-

1 point

-

1 point

-

A few pages back someone said "we can learn" from this. So what did us lowly "piston folks" learn? Adequately insure your plane in order to protect your investment from your own mistakes as well as the mistakes of others. If a third party damages your plane, don't expect them to have insurance or resources. If they do have insurance and resources that's great but don't expect it to immediately cover your costs. If you have willingly contractually agreed to name the City or FBO as an "Additional Insured", agreed to hold the City/FBO harmless (either completely or only with the exception of "willful" or "gross" negligence, to indemnify the City/FBO, and to waive subrogation clauses, then don't ever expect the third party to pay anything. And don't cook up some homespun version of what you think "gross negligence" legally should mean. If you have more money than sense (and like to flaunt it) then waste time and resources in order to personally file a lawsuit against the third party years after the incident and long after it has been repaired by your insurance company. Even if you win in court, don't expect to ever collect. Expect your insurance to deal with the incident immediately, repair your plane and to try to recover costs from the responsible parties over the longer term. Mooney N9391M, the M20F Executive, that was smashed by the falling gyrocopter at Oshkosh is a good example. You can have all the proof in the world, have investigation by NTSB, be fully in the right, win in court and still get nothing from the responsible parties. It is your insurance that will fix or replace your plane. Bent nose gear is harder to prove who was actually responsible. If I overnight somewhere where they move my plane and upon departure preflight I feel a dent in the nose gear truss, how do I prove that actual FBO did it? They may say "We didn't do that - you had the dent before landing. You are just trying to stick us with the cost of someone else's mistake". It becomes my word against theirs.1 point

-

Come to Lower Alabama in mid-July. Let's meet at KEDN the week before Oshkosh, and look at their weather station together. I'll be there at 19Z if you come.1 point

-

Not where I live. We call it "July," except when it's August . . . With occasional happenings in May, June and September. Three or four years ago, we reached 100° (with high humidity) every day in September. THAT was one for the record books!1 point

-

It's owned by Joe Kennedy of Kerrville, TX https://www.linkedin.com/in/joe-kennedy-b388b114 JOSEPH L. KENNEDY ENTERPRISES, LTD. :: Texas (US) :: OpenCorporates1 point

-

I think I might be confusing you. I apologize. AEROLaw at all times felt we could breach the GROSS negligence threshold. So that fact + my rule of life to fight evil whether is $.10 cents of $xxxx applies. As stated, that part is personal. But I am flying a Turbo fan, so there's the whole proof and pudding thing. LOL. $235k was repairs $50-$60k on loss of use was mechanical (e.g. receipts, mortgage etc...) $213k was expert witness. On the loss of value to an airplane with <20 hours on it. There were many many many more costs I incurred which did not claim. I was simply trying to get to zero. Hopefully I've explained the facts a little better for you. My ONLY aim here is to help the Mooney Community, not trying to win petty arguments of lean of peak or rich, I've got ZERO interest in that.1 point

-

And don't get me started on the one-sided contracts I read (or contracts that don't even use standard insurance language!)...In fact, on the backburner, I'm looking at developing an airport consulting program to keep GA airports both business friendly and consumer friendly.1 point

-

Hey, it’s an about flying a Mooney! https://generalaviationnews.com/2022/12/26/i-cant-believe-i-just-did-that/ -Don1 point

-

The new owner was getting transition training from a very experienced CFI. Engine just stopped mid flight.1 point

-

Depends on how the stat is computed, is it for instance percentage of all aircraft or is it biased by population size? For instance I think there are more Mooney’s than C-210’s, but perhaps as many 210’s are flown Commercially maybe their average usage is higher? If it were perhaps number per 1,000 hours flown it might be more representative? Be interesting to know percentage of Mooney gear ups due to gear failure. My personal take on it is my belief that there are many more low time Mooney drivers than other complex aircraft and that Mooney’s are often a pilots first complex over say the 210 or Bo crowd, and that maybe they forget more often than other type owners, or said another way maybe many Mooney gear ups are no fault of the airplane, where the 210 for instance usually is the airplanes fault. You know when a 210 drops its gear, you see them and the drag increase is substantial. Personally I don’t drop my Mooney gear until the white arc and at that low speed there really isn’t much difference. Long way of saying that as near as I can determine that actual gear failures in a Mooney exist of course, but are relatively rare. Example, I have tried to find out how many actual no back spring failures have occurred on an Eaton actuator that resulted in a gear up without much success.1 point

-

I spoke to Greg at Advanced Aircraft and he's confident we'll sort it out no problem. Thank you for all of the info and insight! Now on to the oil cooler1 point

-

Well after about 4 months we are done... My M20C had its heart transplant and I am now running an IO-360-A1B instead of a carburated O-360... which translates into a 20Hp more horsepower. The engine swap was more complicated than expected. Mainly because I had to procure many of the parts that were needed. I had to get a new electrical fuel pump, a new exhaust... But lets start: After getting the engine and reading the STC I realized that I needed a new cowling and engine mount, in addition to a new electrical fuel pump and throttle, mixture and prop cable. Not a problem. Ebay, McFarlane and Aircraft spruce got me everything. The work started and first hurdle: the side panel I had from my M20C did not fit with the new cowling... my AP worked around it and fixed it and made them fit. Then little issues came up that became huge problems, such as the cables don´t fit exacly as expected and we need to find a way to make them fit... Did I tell you that my AP is great? Next hurdle: Baffles... where can I get a new (used) set of baffles... The old dog house did not work... So I had to go out there and find used baffles. I was lucky and found a full set in ARGENTINA.... I was able to get them and had them shipped. Then, the STC states that you have to move the battery box to the back of the plane. Easier said than done. After looking at the cables my AP said that it would be better to change all the cables... So I ended up purchasing an insane amount of cables, connectors etc. But now I have a brand new electrical system (plus new alternator and regulator...). The only thing that is still not 100% is the RAM air door. The STC states that you can use the carb heat cable, but I am not convinced. So I decided to order from McFarlene the RAM air cable. I installed a set of GAMI injectors, new ignition coils too. In parallel I also changed my autopilot to a Garmin 507 and swapped my ASPENs for a G5 and ad G3X touch. Finally after learning how to start a flooded fuel injection engine, I flew the airplane this weekend. It is great! Did it make sense? in hindsite: No. The costs I incurred were absurd. It would have made much more sense to sell my M20C and buy a M20E. But then... you get attached to your machine... so would I do it again? after flying the plane... most likely: yes... Oscar1 point

-

1 point

-

1 point

-

@carusoam seems to really enjoy the 310 upgrade in his O. He may have some pointers to offer.1 point

-

Trivia, but seating height doesn’t change much with height, height very much is in leg length. The AH-64 we had to sit at “design eye height” so that the system that measured exactly where you were looking would function properly and only a few inches of vertical seat adjustment allowed for over 95% of all adult males to work, covered I think at least from 5’2” to 6’6” at least. Of course there is always the outliers. A C-210 has a large amount of headroom as do several other designs, but of course taller cabins come with increased drag.1 point

-

1 point

-

Fly it a lot this year. My C ran $3100 in 2007 with 62 hours, -0- complex and a temporary certificate, along with several refusals to insure. With 100 Mooney hours at renewal, it dropped to $1600; now with IR and 500+ Mooney hours, I just renewed with Phoenix for $1000 with participation in FAA Wings and a recent MAPA PPP. First year required 15 or 20 dual including 5 instrument because I used a Mooney-experienced instructor whom they approved, otherwise it would have been 25 dual plus 10 solo. Be glad that rates have come down the last two or three years. Make good use of your dual time. Travel around, visit places you've never heard of. Land on runways that slope up, slope down, have humps or look like ski jumps while you have that CFI beside you. This will prepare you for traveling on your own. Learn the procedures, study the performance charts, and fly the numbers ±20 feet and ±1-2 knots. When you can make good landings at strange airports with unusual runways and unfamiliar ground references, then you will be ready to roam the country.1 point

.thumb.jpg.f39e537dd674d888af6c81b433677d6d.jpg)