Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/2025 in all areas

-

7 points

-

Well, Starlink just made the decision very easy. We have Starlink at home, just received an email telling us because we do, we get a mini for free and when using roaming, 1/2 price on the monthly fee. No requirements for anything other than the low use $5/ mth fee and can roam whenever and for however long we choose. Terms are the mini is a rental at no cost so I won’t own the unit. I rather like this format, should allow for future upgrade at an overall lower cost than buying initially.5 points

-

Someone said that the silicone gaskets sometimes leak and other times they don’t. I have found that the key is cleanliness. I have even reused them and they work fine. Make sure the mating surfaces on the valve cover and head plus both surfaces of the gasket are completely free of oil film and then install dry and torque to 20 in-lbs (retorque during every annual). if you get a leak or one develops later, don’t just retorque because that very slippery gasket sitting on an oil film just promotes gasket migration and leaks. Disassemble, clean all surfaces and reassemble. You’ll be happy with the results.4 points

-

3 points

-

If one end of the tow bar is connected to the aircraft, the other end is connected to my hand. I am crazy zealous with this rule... if I need to check wingtip clearance while pushing, I will remove the tow bar, walk over to check, walk back and reinsert the tow bar. So far, so good3 points

-

Everyone needs to go back a few steps anytime they get distracted on preflight and also do a walkaround, at a distance, of the entire aircraft. Phone call interrupt your preflight? Go back a bit and do a walkaround. Prop strikes Tow bars and FBO traffic cones are *such* common claims. Old Republic (the insurance underwriter) even has branded "Tow Bar Removed?" embroidered keychain straps.3 points

-

Assuming that you have the cylindrical reservoir with the pipe plug at the top, the part number for the plug is 850009-000. It appears to be a standard pipe plug with a small hole drilled in it to vent the reservoir. I would call Frank Crawford at Mooney and see if he would share the drawing or at least tell you the size of the plug and the hole. I'm certainly not an expert on Mooney brakes but last year I did remove both master cylinders for rebuild and I replaced all the hoses in the brake system. So, I had all the plumbing pretty well opened. My A&P suggested opening the bleeders on both calipers and letting the system drain by gravity while occasionally slowly exercising the brake pedals. I ran about a pint of fluid through the system this way. Then we bled it bottom up with the A&P at the bleeders and me suctioning out excess fluid at the reservoir with a turkey baster. We did this until there were no more bubbles evident in the plastic line to the reservoir. It didn't take much and the brakes have been rock solid ever since.3 points

-

Just an update for everyone - it looks like after a few days of working with my hosting company they FINALLY a) admitted this was a problem with their top level DNS servers and b) they managed to fix the issues. I am not sure what exactly was wrong but it was something with the SOA (start of authority) DNS records for the domain and something that is outside of my control. So users that were not able to access the site with certain ISPs (Verizon and CenturyLink are ones I am aware of) should now be able to find our site again. This also fixed the email delivery issues we were having with Yahoo (and their subsidiaries like AOL and SBCGlobal) and Apple as far as I can tell looking at logs over the past 12 hours the emails seem to be going through now. If you do have any issues I would appreciate you letting me know by shooting me a message here at @mooniac58 Thank you for your patience! Craig3 points

-

2 points

-

I’m another who only has strobes and leaves them on at all times. Ive flown “big iron” with rules/techniques similar to what @Jackk suggests and they do make sense in some applications. However, for our small (and short) airplanes I think having a blinking light on the ground is more positive than negative. It also seems our strobes aren’t as bright as say a Gulfstream, but maybe that’s me. I definitely consider turning them off more at night as they can be distracting (especially to others), but without them, it can be hard to see the airplane even with all the other lights on. For example, parked in a runup with someone else taxiing in , I might leave them on until they are definitely lining up next to me and not at me and then turn them off. In the daytime, without fog or maybe snow, they don’t really bother me when others leave theirs on.2 points

-

Similar to others above, my ac came only with strobes, and they’re on from engine start to engine shutdown. (Tbh I just keep them on all the time, so if the master switch is on then the strobes are on.)2 points

-

Many Mooneys don't have beacons. The FAA has stated that the strobes gotta be on from startup to shutdown except when "it would be in the interest of safety to turn the lights off" https://www.ecfr.gov/current/title-14/chapter-I/subchapter-F/part-91/subpart-C/section-91.209 https://www.faa.gov/media/138212 points

-

Actually only the Vintage Mooney’s use a shuttle valves. Mooney eliminated them somewhere between Vintage and Modern models changing to running the copilot brakes in series with pilot brakes. Standard Mooney brakes are no harder to bleed than any other GA brakes and best bled as instructed in the service manual with a pressure pot bottom up just like other GA aircraft. It’s the dual brakes that are bare to bleed that there is so much written about here in older threads including by myself. The reservoir plug is vented. i don’t no where to get a proper replacement other than salvage. Sent from my iPhone using Tapatalk2 points

-

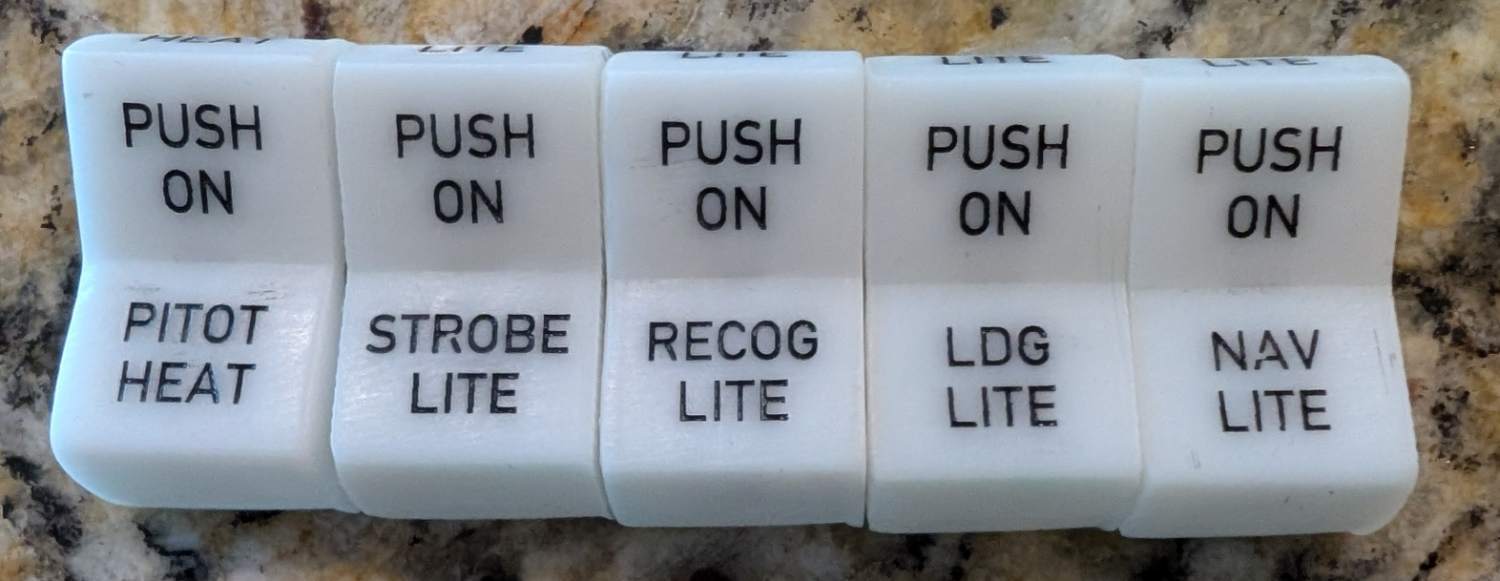

Scott - Not sure if you have the ETA or Klixon switch types but you may try @AH-1 Cobra Pilot or @redbaron1982 to see if they can help. I still have my ETA Boost Pump complete switch removed earlier this year during my avionics upgrade....let me know if needed. John1 point

-

1 point

-

1 point

-

Awhile back on Mooneyspace someone was torquing their silicone fuel sender gaskets and wondering why they were leaking. They were using foot pounds, not inch pounds and mutilating the gasket by using 12 times the force needed.1 point

-

If it's the upholstery on the inside of the door, call Aero Comfort and talk to Hector. https://aerocomfort.com/contact/1 point

-

Just get a small torque wrench, sometimes called a micro-torque wrench, that has a lower range of settings. They may be 1/4" or 3/8" drive, so pick one you like. This is the cheapie one at Harbor Freight, but they're actually pretty decent and definitely suitable for things like rocker cover screws: https://www.harborfreight.com/14-in-drive-20-to-200-in-lb-click-torque-wrench-63881.html1 point

-

1 point

-

1 point

-

Thank you everybody, yes my plug is solid, no hole, think airplane came with it SN 280, do not think it got swapped while I owned the plane, will bleed the brakes one more time over the holiday, got 3 or 4 qts 5606, two bleeder pots, all kinds of lines and fittings, bleed back and forth, one pot at the wheel caliper one pot at the reservoir, max 35 psi, the masters are parker hannifin 24D, I have a set of spares, will open one of them to understand the piston mechanism, think there is a check valve in the piston since the piston does not move over the supply port, fittings are tilted sideways, that is part of the problem, will take the back of the masters off to tilt fittings up and then pump by hand, think this is the fourth time I am doing this, somewhat determined to get it right now1 point

-

For silicon my shop recommended medium loctite on the screws. I tighten around twice. First to 10 in-lb and then 15 in-lb on the second pass. If you keep going around and around with a setting of 25 in-lb you don't really get there because the gasket keeps compressing more and more until it is crushed. The light torque required for silicon is not tight enough to keep it from vibrating out without the loctite.1 point

-

Sort of particular to a Mooney. Go before you go. Make sure your passengers go before you go. No matter how fast or high we go the entire operation is slaved to bowels and bladders. Nothing worse than settling down on a long flight someone saying: On airliners, I've seen airborne returns for failure to preflight the waste tanks at great cost to company and passengers.1 point

-

There are so many airplanes getting glass cockpit upgrades that you can buy a nice United instruments altimeter with nice bright letters for less than you can get your old one repaired. And you will save a few hundred dollars by getting the newer one installed at the same time as taking the old one out.1 point

-

According to the IPC, some Bravos had shuttle valve on dual brake installation (s/n 27-0108 to 27-0143).1 point

-

I realize the question is not directed to me but since I had to go through two tries I can help. In my second try the only thing I changed was the SD card - i went from a 4GB to 2GB. The new 2GB card came formatted as FAT. I had to reformat it as FAT32. The CB that I pulled was GPS2. Good luck. Yariv1 point

-

One thing to consider is that in the west where you takeoff at 3500-6500 MSL that in the summer the turbulence starts low and moves up through the air mass as the day progresses, this means your time window of smooth air is narrow. So if you fly in the early morning you can go up to the normal 9500-11500 MSL and you have smooth air. Later in the day (10am-Noon) the air in that range is really bumpy but a couple thousand feet higher it is still smooth and also conveniently cooler. I’ve had some miserable flights at 11500 and 12500 staring at some clouds slightly above my altitude that I know if I climbed above them I’d be in smooth air. Unfortunately in the summer the climb rate to get another 3000 feet is pretty dismal. For example, earlier this summer I was flying from Spokane to Salt lake at 11500 and was getting bumped around which was making my wife and two of my kids very uncomfortable. I spent a while doing a series of zoom climbs and eventually got up to 13500. At that altitude it was nice and smooth all the way from WA to UT with the exception of the decent into our destination airport. Eventually it will get bumpy at 13500 and you might need 15500 for smooth air. No guarantees of course but this is how things generally work. Without a turbo you aren’t getting to 15500 in the summer. If It sounds like I have turbo envy it’s because I do. One other consideration is that if you want to file IFR there are many MEAs that exceed my naturally aspirated Mooneys capability, especially in the summer. My Mooney is fine if you respect its limitations, but sometimes I don’t like those limitations.1 point

-

To determine if the plug is the issue, you can just take the plug out and taxi around to check if the brakes are still soft. I seem to recall that my plug has a small hole in it.1 point

-

I wouldn't leave anything that isn't conforming to the type certificate on the vent in flight, drag or no drag. I think the takeaway is that plugs can be designed to fail safe rather than fail dangerous if you forget them (i.e. use a design that isn't 100% air tight) and that you should develop (and use!) a walkaround procedure to ensure you remove all ground covers from the aircraft before flight. Cowl plugs and tailcone covers are similarly dangerous if left on, but they are widely used with similar care.1 point

-

I get the correlation of the poll to the fuel vent thread. I took the poll as an expansion on the subject of ground safety devices as promoting safety awareness rather than a scientific exercise to measure what positive or negative outcomes can be established by their use. My takeaway from the tank vent thread was that a vent (or vent ground cover) could be designed that defeats insects, but allows the vent to function if the cover was not removed. Something along the lines of the little flapper pitot tube cover on my ‘62 Cherokee which used airspeed to function. But then, any additional induced drag by such a device would probably be rejected by the Mooney community.1 point

-

1 point

-

Perhaps, I get it. But I don’t think the object of the poll was to find out how many pilots are out there who have never made a mistake. Kinda like, filing an ASRS to report that nothing went wrong? I’m of the opinion that, if you’re in the game, sooner or later it’s your turn. Just don’t be chronic.1 point

-

After RTVing my replacement site guage into the hole as people have described, I allowed the RTV to cure, then I cleaned the area with alcohol and then cut a 3” circle of automotive Paint Protective Film (PPF) and installed it centered over the guage. Whether the RTV fails or not, that guage is not coming out in flight any more. Guaranteed!1 point

-

1 point

-

Personally I don’t like keeping tow bar attached when not in use. I understand why some do it, and tow bar used as a chock seems okay. But my habit is when the tow bar is on it’s in my hand and when not in my hand it’s off will save a LOT of damage. It’s happened to a local pilot. I also have the habit of putting my tow bar, cowl plugs and pitot cover in the back where the pilot can see them. I’ve looked over my shoulder to verify them more than once. Reassuring to see them before the key goes in the ignition. ** the above are my habits and not trying to convince anyone else what they should or shouldn’t be doing.1 point

-

Starlink allows me to refresh my Foreflight in flight at flight levels. I can also use live satellite data feeds, and other data feeds like live webcams via the Windy app for my destination. Can also make WiFi calls, etc from flight levels. I don't mind it on my dash, Bravos don't have much visibility anyway1 point

-

I have a 64 M20E with a RayJay. I live in the Midwest flat lands and the only mountains I fly over are the Appalachian and Smoky which don't really count as mountains compared to the Rockies. Having said that, after about 7K feet we all see our max power start falling off and climbing at 500 ft per minute much less a IFR required ft per NM case becomes harder if not impossible. The RayJay is just like a second throttle. Start dialing it in and you get your MP back. I have never flown over 10K but with my setup, I can get 28" MP at 10K if I wanted. Pretty impressive. The key is to have a really tight system so you don't loose the extra air out through leaks. I do have to pay attention to cooling higher up and with the RayJay engaged. I notice about a 20 deg F oil temp increase and CHT's push 380F. I also give up LOP above 8K and go ROP to help with cooling. I will some times run 25/25 at 8K or 9 K if on a long cross country. Otherwise I usually don't engage the turbo and cruise at 65% power but my AP tells me I am not helping the engine and should run it harder. -mark1 point

-

The descent rate suggests this engine was still producing power. In some ways, a rough or failing, but still running, engine complicates the ADM process: will it hold together long enough to return to IWS? If the engine is producing no power and cannot be restarted, then you have only to pick a place on the ground to put the plane. -dan1 point

-

There are a number of limitations on the RayJay turbo installation on the M20E. There is an article on the installation of that system on M20E written by Kerry McIntyre @ KNR Inc., Evanston, WY. Search his website for the list of his articles and it is in the May 2000 MAPA Log publication. Practically speaking any turbo aircraft has numerous advantages over their normally aspirated versions. I have flown routes similar to yours for 20 years as I am based at KGEG. I have utilized several Mooney models (E, G, J, and K) and found that the turbocharged K model is best suited in all aspects for the routes I fly. Feel free to PM me if you want any more additional information on your consideration. Jeff1 point

-

The 99s were started by Amelia Earhart after she was turned down for membership by the Quiet Birdmen (QBs) Its a good organization and they paint compass roses on airports all over the country just for costs incurred,1 point

-

Another year has "flown" by. I flew it back from NJ to TX 4 years ago today. This last year I've done a few things to it: 2 Mid-Continent Dual USB ports, one with the 100w power for the Starlink The Area760 and GDL52 are now wired to ship's power. A Flightstream 210 has been added so that I can transfer flight plans from a portable to the G1000 and vice versa. And we can't forget about the Switch Guard from @Flyler Everything has been added for a portable A/C - The PlaneAC, which can be taken in and out In my first couple flights with that, as it pulls an amazing amount of air in, I am now going to have to work on getting my door seal tighter to avoid Carbon Monoxide being pulled in. I had to do that on a previous Bravo when I added the PlaneAC back in 2021. I end up doing an Inflatable door seal and it took some time to tweak the installation to get it sealed up tight. So I might have to talk to @tomgo2 again : )1 point

-

Rudy’s Aircraft Instruments. They overhauled my ASI. Very nice people, quick turnaround and reasonable $$.1 point

-

To make a long story short, I'm the last man standing that actually wants to buy something now. Before, I lost the vote. Now, I'm the only vote.1 point

-

Good eye noticing that. https://www.aircraftspruce.com/catalog/appages/atcontrollocks-mooney.php#productMainImage or https://airplanethings.com/product/control-saver/ I was going to say that's where the espresso maker attaches but I figured I better not . . lol1 point

-

Even 2k doesn’t seem bad for a part to keep a ~80k airplane going another 25 years.1 point

-

AMS3320 we stock several colors and three different thickness For fuel / oil AMS3325 Flurosilicone We base our products on quality, not cost1 point

-

Install dry silicone with fiberglass 25/27 Inch pounds the reinforced material cost five times more than non . ams3320.0931 point

-

1 point

.thumb.jpg.ae084ff98f2eda1b3f595ed45b9592c9.jpg)