Leaderboard

Popular Content

Showing content with the highest reputation on 02/13/2025 in all areas

-

This is one of the very rare instances where I consciously break St. Busch / St. Deakin's commandments. The safety consideration of not having to move three levers in the correct order in a potentially high-stress situation of a go around due to a bounce, "baby on the runway", or something else wins, in my humble personal opinion, over the cylinder longevity consideration. As a matter of fact, in the end of descent the cylinders are comparatively cool anyways.3 points

-

I would check the rudder balance after removing the servo. You should be fine with the cover patch.3 points

-

2 points

-

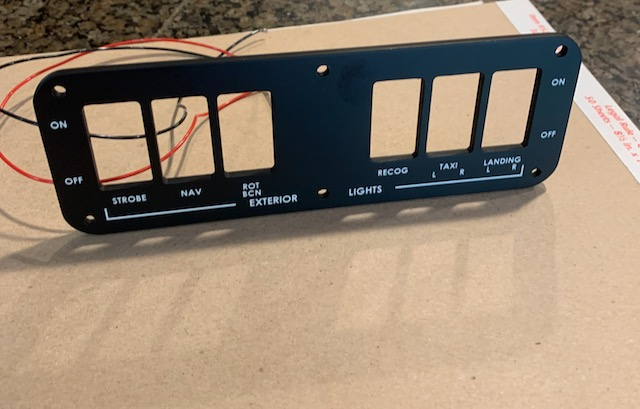

C&K 16amp SPST switches available at any electronics retailer (digikey, mouser,etc).2 points

-

I know this was touched on briefly by a DER for gears post but not specifically the path I took . My gears were not quite on their last leg but well used as the actuator motor was as well; so my A&P and I asked the engineers at Mooney if it was possible to engineer or draw engineering plans to install the whole electric gear retraction assembly including emergency gear extension from a model J/K or later for my F model. In our thought process this would eliminate the emergency hand crank and clutch, the inevitable gear replacement issue and the frequent inspection requirements of my F model. Similar to a DER this is not a group endeavor because it is based on each model type and is assigned to each aircraft serial number. The FAA had to approve and reissue the emergency extension section my of my specific Operators Manual. But having said that the ground work has been laid for a "better" retract system for our "vintage" Mooneys by Mooney. The process did take a bit of time and of course money, I did purchase a very nice entire gear retraction system out of K model and had to pay for Mooney's time and effort as well. So I'm not sure if this an answer to everyone's issues but I really think it will work well for we Vintage Mooney owners moving forward. I have to thank my A&P and the two gentlemen in Engineering at Mooney that helped us get things moving forward and through the finish line of Mooney and FAA approval. Now it is out with the old and in with the newer system.2 points

-

Sure thing! Let's just ignore 1500 years of history and the rules of English grammar, in order to possibly prevent offending highly-sensitized people. And if taking that step offends other people, well, they don't matter anyway. How do we ever determine which groups to avoid offending? Please note that there is no right to never be offended, and the very idea that there is offends me. So since someone will inevitably be offended, just follow the rules of grammar and offend fewer people.2 points

-

Well, my eyes are going and I can barely read the (copy of copies) performance charts out of the POH , so I had some down time and decided to recreate the performance charts for the aircraft (attached). Hopefully there are others that can use them, even though virtually everyone uses an EFB that has the performance date on them... V/r Matt Mooney M20E Performance Charts.xlsx1 point

-

I have been searching all forums and only read "it's not possible". Now I have it in my Mooney and it is working like a charm.1 point

-

The other thing is, how much fuel are you actually "dumping????????" You are at a very low power setting with very low fuel flow. Even doubling the fuel flow is not a lot of fuel.1 point

-

Compared to 1600-degree exhaust, I wouldn't be too concerned about any air that might pass by.1 point

-

I think the best method would be to do all of the above. The hardest will be the intake, but not Impossible. The most important would be the crankcase. If you could make a manifold to move dry air through all three spaces, that would check all the boxes. it would be more fun to throw all that away and fly your plane at least once a week.1 point

-

Same - and one thing I bet a lot of people on here discovered: Once you learn how to properly maintain an aircraft, you can maintain cars to make them last virtually forever as well!1 point

-

Ag wise I think maybe back in the day when you bought a cheap surplus Stearman, paid cash and modded it and went to work bravery if you will was a thing. Nowdays if you use new new prices you can’t get an Ag plane for less than a Million bucks which is actually cheap once you consider it’s a 750 HP turbine, but especially once you get into multiple millions your getting insurance involved most likely as most can’t pay cash, so it’s become much more professional if you will, an accident prone pilot quickly becomes an unemployed one. In truth it’s sort of boring believe it or not, it’s hard work with very long hours, and usually seasonal. When there is work daylight to Sundown isn’t uncommon, and you usually get behind with weather and higher wind days factored in. This is an old Garrett Thrush, likely 80’s This is a GE powered Thrush which I Certified a couple of years before Retirement, unfortunately I believe GE has orphaned this engine. Both of these are small one man operations is South Ga. The small one man operators are more common than you might think.1 point

-

1 point

-

FWIW, your A&P will determine whether 337(s) need to be filed. I know of no regulatory requirement to file a 337 for this repair. There does not seem to be agreement among the relevant masses that a 337 is required to remove an STC, if this was installed with one, but you do hear that opinion a lot. Some argue that the original, pre-STC configuration is already approved, so if removing an STC restores it to an approved state, that's...already approved. I don't think many people file a 337 to remove a Brackett air filter (which requires a 337 on many airplanes). The other side of that is that the TC is altered by the 337 and altering it back requires another 337, for the record keeping if nothing else. I don't know of any clear regulatory guidance either way, just opinion. YMMV, your A&P/IA's opinion is the one that counts.1 point

-

For all the work involved, why not just replace the rudder? BAS has a bunch, you'd just need to have it repainted, which you'd need to do to your stock rudder anyways.1 point

-

We are basically one small ridgeline away from Mesquite, NV so we get a strong desert weather influence from the Las Vegas basin. 2900 MSL and as I write this it just stated the first snow in a year (very light). Quite pleased with the autopilot at this early time. Being a vanguard install some things needed to be figured out but overall for my needs (day, VFR ) it seems a perfect solution. Next week the weather will be better for my flying.1 point

-

I had the exact same thing happen twice on an Ovation I owned ten years ago. The fuel setup was checked by someone that knows the IO-550 intimately. We tested the Champion (massives) that we took out and all of them failed, with very high resistance. We ended up changing all of the spark plugs and it never did it again. If your fuel set-up hasn't been done by someone that really knows these engines you might start there. Although it wouldn't hurt to check the resistance on your plugs. On troubleshooting it's not always just one thing. Example, you might have been off for a long time on the fuel but your plugs were ok so it was working out. Now if the plugs are higher resistance it's to the point that you can't keep it running at low power settings.1 point

-

Thanks very much everyone! The first portion of the program is the power plant curriculum so I’ll roll my sleeves up for those areas. Several Continentals in the hangar but hoping to find a Lycoming somewhere in the mix.1 point

-

When I was a Test Pilot, flutter was one of the very few things that scared me, a good friend of mine (Dr Ralph Kimberlin) who literally wrote the book on small aircraft test flying and my Civilian Test Pilot mentor when he was flight testing the Aero Commander 112 got flutter that caused the aircraft to disintegrate, he got out, the flutter Engineer did not. There is a story why the Engineer was onboard of course, because that was uncommon and honestly he shouldn’t have been. Ralph passed away last Nov. https://www.fit.edu/faculty-profiles/k/kimberlin-ralph/ https://asn.flightsafety.org/wikibase/2731 People think, if I get into flutter I’ll just slow down, maybe, maybe not. North American Rockwell recreated the incident in NASA’s wind tunnel, time from flutter initiation to complete disintegration of the entire empennage was less than 1 sec. This aircraft had been dove to Vd several times with small issues occurring, what was different in this dive was Ralph had trimmed the elevator full nose down to keep from having to push so hard down, as is common on many aircraft only one elevator had a trim tab, this caused enough unbalance to trip flutter once it was initiated with a control doublet, a control doublet inputs forces very similar to turbulence and “excites” a flight control.1 point

-

Yeah, the technique we were taught as student pilots often produces the same result.1 point

-

lol I’ve heard a few of these about silly gossip. This is an interesting one bc of the technical nature of the material. It listens pretty goofy. “It’s got a wingspan of over 36’. Holy cow! That’s longer than a bus!” It’s too early to listen into the G1000 section. Maybe after coffee.1 point

-

They identify as airmen, but the chromosomes don’t lie.1 point

-

1 point

-

Welcome, BrettD… Best option? McFarlane is the go-to for replacement throttle/prop/mixture cables. I think they’re even PMA’d for Mooney now, as opposed to an owner produced part.1 point

-

UGH! I wonder if that could be it. It sure fits the symptoms. My oil filter is NOT remote but I did note there are two different oil filter adapters and I THOUGHT I was careful picking the correct gasket. But I really only checked that the new gasket matched the OLD one when I was stopping an oil leak. Gawd that was a pain to R&R the adapter... I think I'm going to try the thermocouple on the oil cooler tank to see if it is even getting hot. If not, you may be onto the problem!1 point

-

Convoluted, however, these are your parts and they probably have nothing to do with the warranty claim, your relationship is with conti, call them first, see if they can get the parts, if not ask them who to call at hartzell, in parallel thereto call Main turbo in Visalia CA See if they can untangle the situation at Hartzell or can source the missing parts, I keep fingers crossed1 point

-

I'm strongly considering doing basically this same thing myself. Go to a school, get the cert.1 point

-

Don't know if this is your issue but might give you a clue. I fly a 231. The turbos are generally set up very rich and on final approach I generally need to lean the engine out to keep it from burbling. It burbles because the engine is overly rich but making very little power. If I lean it out the burble goes away. When I get to the tarmac and start to roll out I have to remember to put the mixture back in. During the final descent the engine can be very lean but won't quite because the descent is helping the prop and driving the engine. When the engine is no longer getting that help on the tarmac it can stop unless I enrich it. Hence varlajo's question. If you are intentionally lean during the final approach the prop can stop during the rollout unless you enrich the mixture. That is what you are doing when you hit the boost pump. Instead, just push the red stick in. Whether you are leaning during final or not, but boost pump gives you your clue. The engine stops because it is too lean. It was fine during the descent when the descent was helping the prop, but that stops when you are on the ground. Need more fuel.1 point

-

Alright, you guys have convinced me. I'm going to try with some thin CA glue instead. I'll mask both sides and make sure to use a needle tip. With the storm window open, there is just enough "give" if i were to push from the inside and apply glue from the outside, that the edge of the crack opens up ever so slightly. Opening it, applying a drop or two of glue, and then letting go might give just enough time for the glue to wick into the crack and help its appearance. The thin glue I have lists a working time of 3-5 seconds so I'll need to be quick.1 point

-

You’re always welcome Junkman! We’ve advanced our ADM and risk management quite a bit in the last few years.1 point

-

The rest of the world still knows where the Gulf of Mexico is. Let's hope the pettiness stays limited to the US.1 point

-

Looks like it’s ran its course (from the vent window to the outer edge of the window) We’ve always had luck with CA glue on cracked windows, it’s thin and should wick into the crack. If you’re worried about a mess you can tape along the sides of the crack, that would keep the glue contained. I’m guessing the crack relieved a stress in the window. You can also scrape any excess residue glue off the window with a razor blade. Also sometimes if your lucky the glue will wick in nicely and the crack almost disappears.1 point

-

Here's a solution for all you folks that live in California but seem displeased with the state: https://www.nbcnews.com/news/world/denmark-should-buy-california-petition-trump-greenland-rcna1918061 point

-

The good news is that as of two days ago, Notice to "Airmen" has been reinstated. Gone is the term "Air Missions".1 point

-

Could not care less what they are called, so long as the info is relevant and accurate.1 point

-

I use Air Hawks on the nose because I was based the first 7 years at a field without taxiway, so every takeoff and landing had a 180 turn. In 17-1/2 years and 1000 hours, I've replaced the.nose wheel three times, and the mains once. Note that none of them were new when I bought my Mooney. Mains are Goodyear Flightspeed I; the -II and -III are designed for much higher weight and runway speeds well above Vg, and they cost much more, too.1 point

-

1 point

-

I thought likewise. The only thing dumber than the original change is changing it back. Change it to something descriptively neutral, like Aviation Notices, or Air Safety Notices, or Aviation Information (AI!), or something useful like that. They're under pressure to be efficient, so they have to hit the higher priorities first.1 point

-

1 point

-

I thought the original change to 'Air Missions' was a dumb waste of time and resources, and equally a waste of time and resources to change it back to 'Airmen'. Fix the system.....1 point

-

They can call them whatever they want as long as they get them working and stop these stupid outages1 point

-

Well, now all the drone guys don't have to read them any more. I feel safer already!1 point

-

No experience at MDW but I prefer to travel IFR, especially when going into bigger airports. I think it makes coming into their airspace easier, I get an automatic Bravo clearance, and I'm treated the same as GA VFR traffic once I report the field in sight but I never expect a tight pattern. They're used to bringing in big iron and seem keen on giving me a long final but want 150 knots till 5 mile out. I think a tight pattern would actually work best but that's not how things are done. Leaving, since it's a short flight, I may just head south VFR and climb once outside the Bravo. I know you're going away from home but you'll be in control of your routing and get home just as fast. I always find it more difficult to leave from an airport under a Bravo than just about anywhere else. I've never had a flight plan issue but I tend have to wait for an IFR release. I've had to wait up to 30 minutes but ATC involved supervisors on their own to get me out after 15 mins or so. I don't like to be stuck down low but sometimes it's the way to go.1 point

-

The letter pretty much says that they haven't tested it, and they also explain why they haven't. They also say that they are concerned because of testing that has been done by two other OEMs that have shown concerns with use of the fuel in their airframe due to tank sealant issues. They explain that they haven't tested G100UL because they (like most responsible industrial players in technology fields) participate in collaborative development, or "coalition participation" as they call it, to develop interoperational issues and standards development. They specifically cite PAFI and EAGLE as forums that they do support for these reasons, and that the STC path specifically does not follow comparable processes. Having been in industrial standards development myself, and also having done a lot of technical due diligence on small innovating companies for capital investment purposes, this is pretty much how industries solve these kinds of problems together. In standards development, things only move forward if there is agreement among the various participants that something has merit to proceed. Often small startup companies participate, and sometimes they contribute heavily to a standard development if their input has merit as agreed on in the group. Contributions from large companies get scrutinized as well and also have to get sufficient support from other participants to move forward. Having personally been on all sides of that many times, I can tell you that this is an excellent process for weeding out bad ideas and assuring that whatever gets left in the standard has been thoroughly analyzed by many sides of the relevant industry and market players. Consensus support from competive elements in a working group says a lot about the viability of the result in the marketplace. The other side of that is the lone "innovative startup" who thinks they don't need (or don't want, or won't be able to survive) the scrutiny and critical review of the other players in the standards body. I've seen this many times both from within standards development as well as in technical due diligence for investment. There are many such companies, and they usually have all sorts of "good answers" and "data" for why they will be successful and why their stuff is better than anybody else's. They also usually have at least one charismatic promoter (often the founder) who has already managed to sell it through several rounds of funding already, and wants more from you or your client. It is a very familiar playbook that has played out many, many times in many industries. Think Theranos if you want an example of a particularly egregious and well-known case. So players in large industries, particularly large players with big markets, or markets that are sensitive to field failures (like aviation), are generally unwilling to switch to a new key technology (like a fuel formulation) without a consensus-style development process. This is because history has demonstrated numerous times that doing so is almost always not a good idea, and that consensus development nearly always does result in a good solution. So it is not the least bit surprising the Textron has not tested a fuel formulation developed by a single (inexperienced) company outside of a recognized collaborative body. The other fuel formulators with more industry experience have elected to follow the PAFI/EAGLE/coalition path because they know that that'll get a good result with broad industry (and usually also government) support.1 point

-

What great videos! Thanks for sharing Marc. Was very nice to see one's own plane's arrival in awesome formation. And the takeoff from MSN, lead organization, masterfully crafted by Clippy. Incredibly Great experience!1 point

-

His nose would of been broken immediately upo exit of the aircraft. Some are slow learners and apparently need to have a "moment" to learn.1 point

-

Correct. Why should I pay depreciation when somebody else will? Same analysis, I don't want or need most new car features. I have my iPhone for times I need nav help. My cars aren't so old as to not have all the creature comforts. While I realize 'it wasn't a quote', it should be representative of reality. It started at $20K, then you posited $30K...if it gets to $40K (which I think is closer to the truth for what you listed after install and tax) that's pretty much 100% more than the original 'for $20K' you could... Just to be clear, if that's what you enjoy spending your money on then more power to you! My issue has been with the 'you should' because 'it's safer'....the implication being I'm an unsafe pilot simply because I won't upgrade. (Not saying YOU said that)1 point

-

My light panel for the overhead had become warped and the backlighting was not working. A little investigation revealed it was an electro-luminescent panel powered by an AC inverter in the overhead. I checked the inverter power output and it was good. Further investigation revealed several interesting facts. 1. The life span of these panels is about 2000 hours and since the panel is continuous power, if the airplane has more than 2000 hours, the panel is near EOL. 2. The inverter is simply glued in the overhead with RTV 3. There are two type of switches and panels. The MM makes mention of only the newer panel where all switch/breakers except the landing and taxi light switches snap into and are retained by the EL panel. (The taxi and landing lights are simple switches with CBs on the main electrical panel) The older type panels have the switch/breakers mounted on an aluminum plate and the EL panel is attached to the aluminum panel. Here is a picture. As you can see my panel is warped which occurs at EOL due to excessive heat build up from the AC power. You can also see the cutout in the aluminum panel to allow the landing and taxi light switches which are retained by screws in the overhead. So I decided to replace the panel. Mooney part # 150085-005. I knew it would be expensive, but hey...I got a new interior and I want it all looking good. Called LASAR. They said it was $773.00. Okay, but..........no stock at the factory. When could they get one? "Get back to you". One month later.....crickets. So I did what I was prepared to pay someone do. Hunt up a panel. Then I thought, if I buy a used one how many hours before EOL? Unknown. So I investigated more. I found a company called Fronpanelexpress.com. They can make an aluminum one, powder coated. You design the panel with their software off their website, upload the file and it gives you an immediate quote. $164.00. Nice but it was not back lighted. I considered post lights but was concerned about glare. If someone is still interested I have the CAD file that you can use, drop me a line if you want it. THEN, I found a company called Nimbus Aviation at FXE. nimbusaviation.com They specialized in EL panels and are a part 145 repair station. They asked for pictures and said, $475 plus shipping. Sounds good, so I sent them my old panel. What I got back was a complete new EL panel with an FAA 8130. Here it is: So it appears these are the go to folks now for these panels. I was willing to give the factory my money but no one wanted my money.1 point