Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/2025 in all areas

-

Send me the two thousand bucks and I’ll see about it4 points

-

I'd never heard of this but it feels like there's a There there. There are little mineral solids in your vestibular system that sense linear and angular acceleration (otoliths). Some clinical maneuvers to treat spurious sensations involve repositioning these (Dix-Hallpike maneuver for benign paroxysmal position vertigo). So it wouldn't completely surprise me if a whack on the head wasn't salutary. Aside: I think Fourier analysis explains why whacking machinery is good... a spike impulse is a superposition of multiple frequencies, thus empirically exciting resonances of multiple unknown mechanisms. @EricJ please critique my theory D3 points

-

I have always joked that one reason I will never get a divorce is that hitmen are cheaper than lawyers. At some point, someone may find that fitting here, too.3 points

-

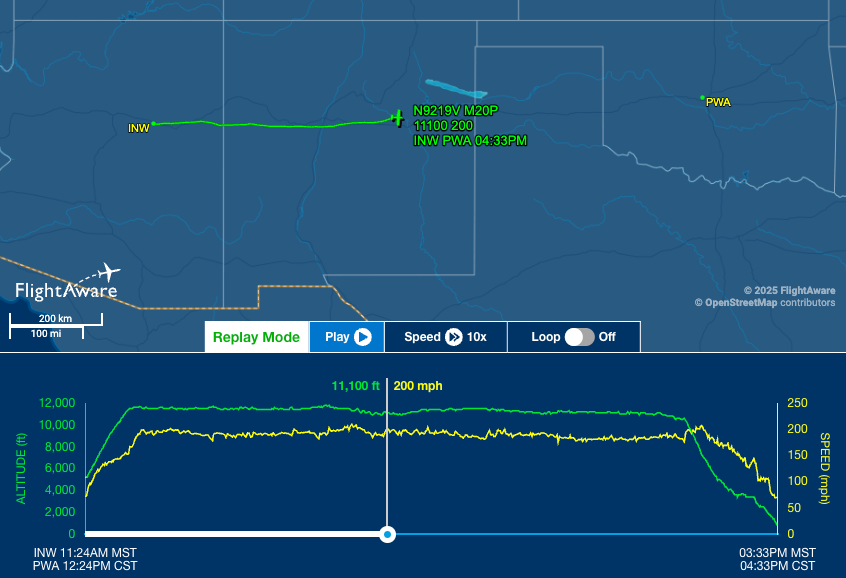

After owning my Mooney for about five years, my flights have more or less limited to California. This is the first time I took my Mooney across the country, or at least half way. 1100 nautical miles from California Central Valley to Oklahoma City with only one stops. 65.5 gallon total. Converted to statute miles, that's 19.3 mpg. Incredible flying machine. Of course 20+ tail wind helped a lot. At times, I was cruising at 180+ knots ground speed!!2 points

-

Thanks for the help all, its getting flown to another location on Monday and I'll have them give their opinion, but I'm providing the Heim bearings and theyre going to install them and swing the gear to get the door closure setup properly. I'll have them look at the hinges as well. I was able to find the heim bearings on ebay as they were available right away, but Lasar did have them as well (as well as the 550017-005). To clarify, I did use the term "ferry" more loosely than I should have, but the CFI does insist on flying it there with the gear down. Its going to a shop he recomended, so I'll see what they have to say. I appreciate the help of everyone here to get me flying again, and also save me $1000-2000. My CFI is fairly young, but he has 1600 hours and as the student I'm going to let him do what he thinks is proper (as long as its not costing me an arm and a leg when it doesnt need to). In regards to the existing Heim bearings, the wear is on all four bearings and its the ball being loose in the sockets. My Statesman is mostly original, and the last pilot that owned it was a bit of a cowboy in the fact that he'd just get in and go as opposed to giving it thorough inspections. I'm learning as well so this has been very helpful. I most definitely dont think the bushings are there based on my memory of seeing it so I'm ordering new bushings as well (550017-005)2 points

-

What we need is some of them nanbots to inspect the camlobes. Keep reedin' bout em in the magazeens. Heck, them nanbots could probly even repare those camlobes and fix other sh!t while we're flyin. Bout time aviation caught up with the modern world! Whare's Elon when we need him?2 points

-

Thanks for all the ammunition. During the IRAN they replaced the lifters and the camshaft. Valves and springs were reused. I will make sure lifter clearance is checked and we are replacing all the springs. Compression check would be interesting as well. I upgraded my savvy membership for additional support. Lousy problem but I’m learning a ton about engines! Sent from my iPhone using Tapatalk2 points

-

Just get DLC lifters and a new camshaft when you overhaul and forget about it.2 points

-

I had an old gray beard pilot tell me how to break vertigo. It sounded silly until one night I got the spins. I tried his method and it is solid. It completely cured it. When you get the spins, close your eyes, tilt your head back as far as possible, then whack yourself as hard as you can in your forehead then tilt your head down and open your eyes looking at your AI. Remember this. You will need it some day and you will thank the old guy.2 points

-

It always amuses me when I open a tank and see that nut plate slathered with sealant. The only leak point is through the rivets. Even sealing the shop heads is worthless. You need to seal the bottom surface and the rivets. Once the tank is opened up, it only takes a few minutes to drill out the rivets, clean up the nut plate and buck the rivets back in. The bottom surface needs to be sealed and the rivets need to be bucked wet with sealent.2 points

-

Sharing a video I really enjoyed and which helped me better connect some of what I read here to where it is on the engine. Being new to aviation, sometimes it's hard to follow the more seasoned members' explanations, but this video has helped me and hope it can do the same for other's in learning more about their engines. Happy viewing and have to love the Canadian accents!2 points

-

The “substandard methods” appear to have been adequate to resist all factors prior to now, which would seem to at a minimum diminish your assessment of what is adequate. if it withstood all chemical and environmental conditions before g100ul, why is it now substandard?2 points

-

As with most things like this there are a variety of opinions, but I can give my take on it. FAR 43.9 requires "maintenance" to be recorded in the aircraft records, and the definition of "maintenance" in FAR 1 includes inspections. So a 43.9 maintenance record entry for an "inspection" may just include a statement of items that were inspected on that date, and nothing more than that. How much disassembly was performed is not really a required detail, and many people lean toward making maintenance entries as short and terse as possible. If the "inspection" isn't a 100-hour or annual inspection done by an IA, or some other inspection required under Part 91, then there's no requirement for a discrepancy list or statement of airworthiness. Generally, 43.11 is only taken to apply records of 100-hour or annual inspections or other required inspections, although the wording says "any inspection performed in accordance with Part 91". Pedants may take that to mean more than it is generally taken to mean, which is why some people advise that a pre-buy not be described as an inspection. Maybe it's an "investigation" or a "look" or something, but "inspection" is fairly broadly defined elsewhere, so this is one of those areas that can become a conversational minefield. In 43.11(a)4 where it says "insert type", the options for "type" are generally "100-hour" or "annual". For the most part many pre-buy inspections are done without considering them maintenance or inspections and the only record is whatever report is given to whoever is paying for it. YMMV, consult carefully with whoever is doing the work as well as whoever is managing the records for the aircraft. The owner of the aircraft is responsible for maintaining the records, so their input in this area is important as well. Even when an inspection is an official 100-hour or annual inspection with a list of discrepancies, there is no requirement that that list is or becomes part of the aircraft records. The only requirement, per 43.11, is that the inspector "must give the owner or lessee a signed and dated list of those discrepancies." The list can be, and often is, completely separate from the usual aircraft records. It is then the owner's responsibility to manage compliance, per the discrepancy list, to have the aircraft returned to service. Many IAs cover their own liability interests by keeping a copy of the list, and some insist on entering the list in the aircraft record with the 43.11 inspection statement. If an owner has a preference on how the list is handled, that should be sorted out with the IA ahead of time. Individual mechanics and IAs will have their own opinions and practices in these areas, so it's always good to ask questions first to manage expectations.2 points

-

Yup, narrow in the time domain is wide in the frequency domain and vice-versa (generally). So an impulse (whack) provides a broad-spectrum excitation. That's kind of what I was thinking about how it works, too, or it just gets the vestibular fluid moving enough to saturate the sensors so that when it settles down you're kind of reset or something.1 point

-

I'm glad you're posting someone else video... the title had me worried.1 point

-

And, also, there are some people where no physics, engineering, nor medicine are required to answer the question... only what your grandparents taught you: Yes, they need a whack on the head.1 point

-

You're certainly correct, and the points you make are not to be taken lightly. But what do you do if you live in the mountains, travel during winter, and work during the day? I would respectfully suggest that there are no absolutes with respect to these factors, just elements of a composite risk calculation. Remote areas with mountains and known flats (even if remote) are different from places with no flat areas anywhere vaguely within glide. D1 point

-

Except that is inserted in a tube that goes to the place you want to see.1 point

-

I kind of find it funny when people are worried it might be dark when they’re flying in low visibility conditions where you already can’t see anything.1 point

-

The Aircraft Spruce list looks to be really inaccurate. Both the states I regularly ship to are except from state sales tax on aviation parts - and both are on their list. Normally, I'd just eat the incompetency or lack of effort to know state tax rules. But when you're buying a $8K or $14K piece of equipment, it makes a big difference.1 point

-

Into the accessory case.1 point

-

Enjoy the adventure. I have great memories of planning (and often modifying) and completing long cross country trips to new places. Like so many things, others will have done more, and some others done less, so just value what it meant for you.1 point

-

Good point; maybe that's not the list I thought it was. In NC we are definitely exempt for parts if they are for an aircraft whose max takeoff weight is 2000lbs or greater. Shipping of those parts is still subject to sales tax. Spruce does a nice job of automating that at checkout if you just enter the tail number and max takeoff weight.1 point

-

1 point

-

And after that , go around the crankshaft up to the top from one end to the other.1 point

-

Victor was on my short list. There are some shops that I think provide a better engine standard than factory.1 point

-

Lycoming 4 cyl engines have 8 valves and 6 cam lobes, so two lobes actuate 2 lifters each. I wonder if those go out first?1 point

-

Gotta go dipstick tube. Put a group of engineering students together, with all of their materials and tools, offer a grand prize of a couple thousand bucks, making a tiny camera do a 180 and telescope a little further up wouldn’t be asking the impossible. I’ll throw down some prize cash.1 point

-

Nonsense. We have valve spring testers for this exact reason. Springs that are not healthy will absolutely show their signs. Bad springs will show up as an out of family curve. https://www.performancetrends.com/Valve_Spring_Tester.htm One common cause of broken valves in engines that run methanol and collect water in the oil. If the engine isn’t flushed or ran up to temp with pump gas rust can start to form on the springs and that little bit of rust can cause a fracture point for a crack to form. This is really common in drag racing applications. For an engine shop to say there is no way to NDT a valve is insane. So they are just slapping used or even new valves into an engine and hoping the seat pressures and heights are correct? That’s a great way to get valve float, piston to valve contact, valve seat recession, valve failure, or valve spring failure.1 point

-

Well, you can’t get to it from the dipstick hole in the case because you have to make 160° turn, go thru the slots where the case halves come together and get past the crankshaft and then you have eight lifters and six cam lobes to view. You can’t really go up through the drain port where the oil comes out because of the same issue, you have these quarter inch wide slots that are on the center line of the case halves that you have to go through and then go around the crank and then bend back towards the middle of the case to see the cam lobes. You can however, pull a cylinder off and you can see all of them pretty easily, but that’s the only way I know of.1 point

-

1 point

-

1 point

-

I’m not a sheet metal guy. Aircraft Spruce lists an 1/8” structural rivet a full inch long. I think that would cover it. AN470AD-4-16 Then again, as my sheet metal troops used to tell me, a bolt will replace a rivet according to T.O. 1-1A-8.1 point

-

I believe that there are FAA-required inspections and there are informal inspections. Inspections required by regulation (for part 91, annual and AD mandated inspections) are maintenance activities and require appropriate logbook entries. An informal inspection such as a pre-purchase inspection is merely a professional opinion of the condition of the aircraft. It is not maintenance and there is thus no requirement for a logbook entry.1 point

-

My mechanic and I swapped a Delco Remy to a Skytec 149 NL outside on the ramp AOG in Tucson in ~ 2 hours (Bendix bushing blew up). We had limited tools and had to drop the lower cowl. No way I’m buying its an 8 hour job inside a shop with everything available.1 point

-

That was my next question is that block secured with screws and nuts or extra long rivets? They may be threaded for screws? There a Mooney item someone must have installed a set of them.1 point

-

I called around including to RAM aircraft which had been one of the few top shops I had gotten quotes from back in April and was my near finalist. I went with Penn Yan at that stage because of their equally excellent reputation, slightly better quote and also the fact that they are just 3.5 hours drive from my house in case I had the urge to check in on them plus similarly close to Weber the R&R shop. Well I remember that RAM had quoted me also an overhaul exchange price with reasonable penalties if the camshaft and or case had problems. I called them and explained my situation and they said they do have all the necessary parts in stock and they would honor the original concept of overhaul exchange. TSIO520NB's are a bread and butter engine for that shop, so they keep stock. And I called Penn Yan and they were so generous in their interest in seeing me land well and they understood well why I was not excited to go with an AirPower new or rebuilt zero time engine. So I signed to RAM and my engine will ship to them and this project will now become a RAM engine. And just as important, this engine will be spec'ed as I had wanted it in the first place again from a different excellent shop. And of course as is only fair I will pay Penn Yan for their time and labor I am in to it so far. I was already underwhelmed by the concept of a black box continental zero time engine which is just a paper work trick to call it zero time but it is only an overhauled engine from the continental shop with unknown parts. I was more so worried abotu their cylinder quality. Well now I know ... that zero time engine I was sporting had a camshaft put into it that was literally on its last overhaul legs since it had been ground down to minimum spec at that last overhaul and was now too narrow to consider grounding down further. So I am even less impressed by continental zero time engines than the already low opinion I had.1 point

-

I wonder if the AOPA legal plan will defend you in this kind of lawsuit.1 point

-

It's important you brought it up with them and also that you got the expletives out of your system before doing so. It's rather tricky when a mechanic or shop known for reliable work seems to overcharge. The number of qualified A&Ps available to help with our planes continues to shrink, and I tend to give the benefit of the doubt and prioritize maintaining any working relationship...unless they've done something willfully and egregiously fraudulent. Fortunately that has been confined to a single experience for me - charging >1amu for tightening an alternator belt - It was fortunate in retrospect that no punches were thrown by the shop owner and there is no lien on my plane after I refused to pay that bill. I definitely can't set foot in that shop again though...1 point

-

I just had all 4 rod ends swapped on my J. Order them new from LASAR. My shop took about an hour to install them, then another half hour to swing the gear and adjust them so the doors closed up nice and tight. Your CFI sounds a little, um... as though they need some coaching in the nuances of pilot decision making. The gear works fine, the doors close normally, why risk something like an engine failure after takeoff with gear that's stuck down? And why the ferry permit? Ferry permits are only applicable to aircraft with an unairworthy component. It's airworthy, and even if your CFI made the decision to fly it gear down (again, why?) you don't need a ferry permit to fly a retractable with the gear down. This, to me, is sounding some alarm bells about this CFI. Maybe you should be looking for another one. If the rods haven't yet been adjusted, there is no harm in retracting the gear like normal. Fly it to a shop who knows what they're doing, and have them changed in an afternoon.1 point

-

This sounds like a lazy mechanic who needs to make a boat payment. The rod end should be around $20, plus an hour or two labor. If a conversation with the mechanic doesn't resolve this discrepancy, then you need a different mechanic.1 point

-

Not sure how familiar you are with the documentation. Here is a brief summary of the process. Apologies if you already know all this. First, you must have the IPC for your airplane (Illustrated Parts Catalog). Here is one for an M20G in the Downloads area of MooneySpace, but you will need to be sure it covers the correct year and serial number for your airplane. Usually serial number is more important than year -- Mooney changed things more frequently than once per year. https://mooneyspace.com/files/file/176-m20-series-parts-catalog-1968-1978-2pdf/ As an example of how to find a part, in the illustration on page 142 (PDF page 134) one of the rod ends is numbered "29". In the list following the illustration, "29" is identified as p/n F34-14 which looks like an oem p/n and not a Mooney p/n. If they gave an oem p/n, you can frequently track it down on the Internet. That said, Mooney was not always precise with those oem part numbers, so some interpretation may be in order. A search for F34-14 yields an ebay advert which appears to identify a cross-reference part number (possibly a different oem), and sometimes those numbers can lead to further searches. The ebay advert calls it a "flap rod end bearing". Something like a rod end bearing may have been used in several places in a Mooney (or any other airplane) so don't get hung up on the suggested use -- it's the part number we are trying to match. In the end, sometimes you order what appears to be the right part but, when you get it, you find that it does not match the part on your airplane, and you start over. Finally, I didn't spend very much time on these searches, so you will need to verify these links for yourself. https://www.ebay.com/itm/256606874390?mkevt=1&mkcid=1&mkrid=711-53200-19255-0&campid=5338678874&toolid=20006&_xiid=256606874390%26customid%3Ds%253AGS%253Bgc%253Abe1913013cdd12343de9748fcf09209f%253Bpt%253A1%253Bchoc%253A1&customid=s%3AGS%3Bgc%3Abe1913013cdd12343de9748fcf09209f%3Bpt%3A1%3Bchoc%3A2&msclkid=be1913013cdd12343de9748fcf09209f https://store.vansaircraft.com/mw-3m-rod-end-bearing-bearing-mw-3m.html https://www.aircraftspruce.com/catalog/appages/aurorabrng.php1 point

-

The piano hinge fingers appears to have significant wear. When the doors are are wiggled the door hinge half will move fore and aft and it might be interpreted as bad rod ends. The slop in the hinge is not that big a deal but if you want to replace the piano hinge it's a standard part and not all that difficult to replace but requires match riveting onto the doors.1 point

-

@mhoffman An intermittent failure of the airspeed safety switch might produce those symptoms. One of the relays is in series with the landing gear circuit (in lieue of a squat switch). If you used the bypass button next to the gear lever, I believe that would have allowed it to go up... did you recall specifically trying that? These do go out from my experience and what I've read. Otherwise I would be thinking of something like a loose connector. But that's very a nonspecific contribution.1 point

-

1 point

-

Making two a side is exactly the plan. I plan 4 carbon fibre layers for each "side" to get the thickness right. Then, I trim the inside and bond it - for a total of 8 layers - at exactly the same surfaces as where the original part is riveted. I still have to decide on the vacuum bagging approach (low or high vacuum). In my experience, 70 - 80% of the work is in making the moulds. Since I have to make 4 (inside, outside times left and right), that mike take a while. I have experimented with a prototype (car fuel port lid) that was very similar and that worked splendidly. I'll keep you posted.1 point

-

1 point

-

A little update and info for everyone. We just finally completed the installation of new engine and upgrade to 310HP. The process took nearly 12 months from decision to 1st flight with about 2.5 months downtime. We took the opportunity to replace everything including prop overhaul, new hoses, new exhaust, new clamps, etc.... Total cost was just shy of 6 figures ( I already had the prop) including an annual. All work was done at Gilmer Aviation in Pell City. Results were exciting - take off roll and initial climb out are excellent and top speed was 187 True (max power). A few things if anyone else is considering this: 1. Shop around for the STC. Prices range +/- $1000. We bought ours from JD @ Southwest Texas Aviation. He was excellent to work with. 2. We had a terrible time working with TCM and Air Power through the initial order process. It took months of calls and follow-ups to get the right quote. The people at Air Power were very knowledgeable and I feel the real issues were with TCM. However, 10 calls and no return is a problem. Once we wired the money to Airpower, we didn't hear from them again for 6 months until the engine shipped. After it shipped, they were very responsive and the core return was handled well. We replaced our G series engine with a IO550-N39. It was made new, but the factory would only sell it as reman. Part of the issue was that our aircraft has air conditioning and no one could figure out what exact engine would work as the G series we needed was discontinued. I believe for non air conditioning engines, the N8 is the best option. The N series has a tapered fin design so we had to modify the baffle plates (which is in the STC). 3. Steve Leary @stevenl757 and Bob Minnis were great help. Also had a couple conversations with Don Maxwell who was very knowledgeable about this process. Thank you to everyone that helped. 4. Acorn Welding for new exhaust was a disaster. They don't return emails, phone calls go unanswered and the parts they shipped didn't fit (not even close). We have sent everything back and it seems they will make it right. We had to install the old exhaust while we wait for them to get it right. Disappointing.... 5. I highly recommend Ricky Gilmer Aviation at KPLR. His new team member (Hugh) did all of the install work and it was outstanding! Hugh went above and beyond. I really can't say enough about how good their work is. Both Ricky and Hugh came from Epps and I feel fortunate to have them on our home field. 6. Was it worth it? As we plan on keeping this plane for a while, I obviously thought it was worth it. With upgraded avionics (G3x, GTN750, GFC500, etc.,, recent paint correction and ceramic coating, new 310 engine, I think 1051K is better than new and at less than 1/3 the cost. Comparing to anything else we could buy its the best value and performance available for our mission. Not sure I would go through the expense of just doing the STC to gain the extra 30hp. But if I was rebuilding or replacing the engine and prop, then sure I think it is worth it as an add on to that process. Pictures to follow - if anyone has any questions or is considering making this change, feel free to ask me any questions.1 point

-

I finished 95% of the old panel cleanup. The remaining wiring seen in the photo will stay. A couple questions for the group: First, panel mounting. Are there "standard" mounting brackets and avionics rails available for a new panel like this or will I need to have them fabricated? The avionics guy said vibration isolators are not needed anymore, citing Garmin avionics often don't work well with them. Is this the case? Second, some advice on lighting. I am considering a combination of LED bezel ring lights for the 5 round instruments and an LED strip light on the underside of the glareshield for an overall flood. I'd also like to have the toggle switches or switch labels illuminated. The original throttle quadrant/flap labels and compass are also illuminated with incandescent bulbs. Can these be converted to LED? Ideally, I would like the avionics and the instrument ring lights to be on one dimmer and the remaining flood/panel lights to be on a second. What would you recommend? Thanks!1 point

-

Ok, I will be the dissent here... My E flies nicely just barely lean of peak at 6gph, at varying prop speeds (2000 or 2400rpm, either way). I tend to get better speed at the lower RPM at low altitudes (close to Caron's speed, about 130mph indicated) when I operate this way at low altitude, i.e. close to sea level. The cylinders and oil are still warm enough to be healthy provided it is not a cold atmosphere in which case I would cruise with a higher power setting. If I am going somewhere any distance away, I will typically use more fuel/power... but for sight seeing or local flights where there is no destination, you can certainly enjoy C152 fuel burns at a higher speed in your mooney.1 point