Leaderboard

Popular Content

Showing content with the highest reputation on 08/24/2024 in all areas

-

3 points

-

Most MSers are probably familiar with the M20 that I picked up. It was listed here as a Free M20A in southeastern Wi. It ended up not being an A model but a straight 0-320 powered M20. I thought I would start a separate new thread to share bringing it back to airworthy. I’ll update this thread as I do the “ inspect and repair as necessary”, or IRAN. This will be probably a year long process to get it flying as my full time job is quite busy and I commute 5 hours home on weekends from Southeastern Wi. My plan is to get it flying, fly it a bit and then sell it. As much as I’d like to keep it long term, it’s just too expensive and I’m not willing to spend that kind of money when I’m done working full time in a year and a half. I’ll start updating this thread from the beginning to where the project is today. Thanks, David2 points

-

Put one on the gear.motor, too, for when you need to manually lower them.2 points

-

The one I have collared is the autopilot breaker. That would be the one that I'd need to pull "in a hurry" if I had runaway trim issue. Otherwise it seems that most scenarios would be more deliberate and slow.2 points

-

You don't want to aim for the numbers because if the wind changes (or you misjudge) and end up short, there is nothing you can do. But, if you aim at some point down the runway, you can slip or s-turn or deploy speed brakes if you have them or put the prop to hi rpm to increase drag.2 points

-

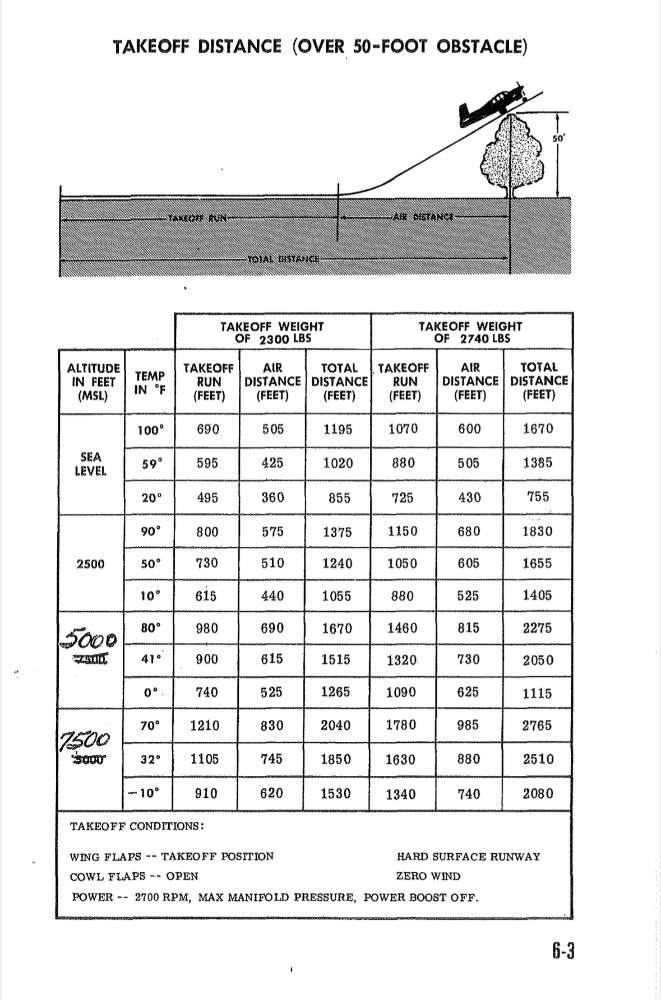

MGTOW ops are not necessary depending on empty weight. The differences in the weight of a mid body can vary by as much as 400lbs. I’ve heard lots of general claims about take off advantages of 3 bladed props, but I’ve never seen any data. I would be really interested to see it. I’ve always subscribed to the notion that losing weight (both pilot and plane) is the best way to improve takeoff and climb performance. Unfortunately, the Hartzell 3 bladed prop is 14lbs heavier than the compact 2 blade. In my view, light weight is a significant advantage in the relatively low powered segment of Mooney models (the 200ish horsepower group.) Looking at my book numbers, 440lbs makes a significant difference. On a standard day at 7500’, book take off roll numbers show that it takes 67% more runway to lift off at MGW of 2740lbs (1850) when compared to 2300lbs (1105’). An M20 with an operational weight under 2300lbs gives excellent take off performance. When under 2100lbs it has exceptional takeoff and runway performance for a cross country airplane.2 points

-

See 2 posts that Bob Krommer made to the Mooney List in December 2005: https://donkaye.com/useful-aviation-articles Needing to slip the Mooney on final usually indicates failure to have established a stabilized approach. There are times where a slip to final may be useful. I've had ATC ask if I could do a short approach when on downwind with no time to widen the downwind. A turning full slip (NOT SKID) in the landing configuration to final at 85 knots (no less per Bob Krommer) worked great. Don't do it with passengers. Or sometimes I've had a student misjudge the slope for the base turn and a slipping turn slightly above 85 knots solved the problem. I'm not advocating doing slipping turns in the normal course of events; just that its another item in your bag of alternatives.2 points

-

Adding to the M20 story, here are some pictures of the disassembly and moving from Gary Indianna to Waukegan IL, UGN. It took about 6 hours to disassemble by myself and the load the tail and tail one in my trailer. That was done on a Saturday. On Sunday I came back south and loaded the fuselage section on a 36 foot flatbed trailer with help from a friend. It was a fun drive around Chicago. This all happened pretty quickly as I received pictures and talked with the broker on a Thursday and when I asked how long I had to move it the answer was by the upcoming Sunday. Time to get moving.2 points

-

I've related this conversation before here on MS Had a private talk with Bill Wheat many years ago and he related to me that he tried numerous spins in the Mooney (IIRC short bodies) and on one he said it went to five turns and he almost didn't get out of it He swore he'd never do that again. Just a word to the wise from the preeminent Mooney test pilot.2 points

-

2 points

-

2 points

-

@ProtoFly when you trim for full flap landing (75-80mph), where do you find your trim at? My landing trim is exactly my marked take-off trim2 points

-

I've done some basic formation flying with another friend and a mega hour CFII (ATP, bla, bla, bla) guy doing the teaching. And I think I got pretty good at it. However... I would NEVER join any kind of large formation flying group going into OSH (or anywhere else). Sorry, I know a lot of guys get excited about it and the group doing it thinks they're doing the needed training and are covering their bases..... But with that many GA pilots of varying skills, the potential for something happening is VERY high. I'm somewhere around 2,600 hours and I still don't think I have the skills to partake in something like that. I'm not a military pilot and I don't fly formation mega hours a year. Just trying to fly into OSH single file and getting instructions causes many a pilot to blow it. Then you put them in a situation where they may not be able to turn left, right or either way.2 points

-

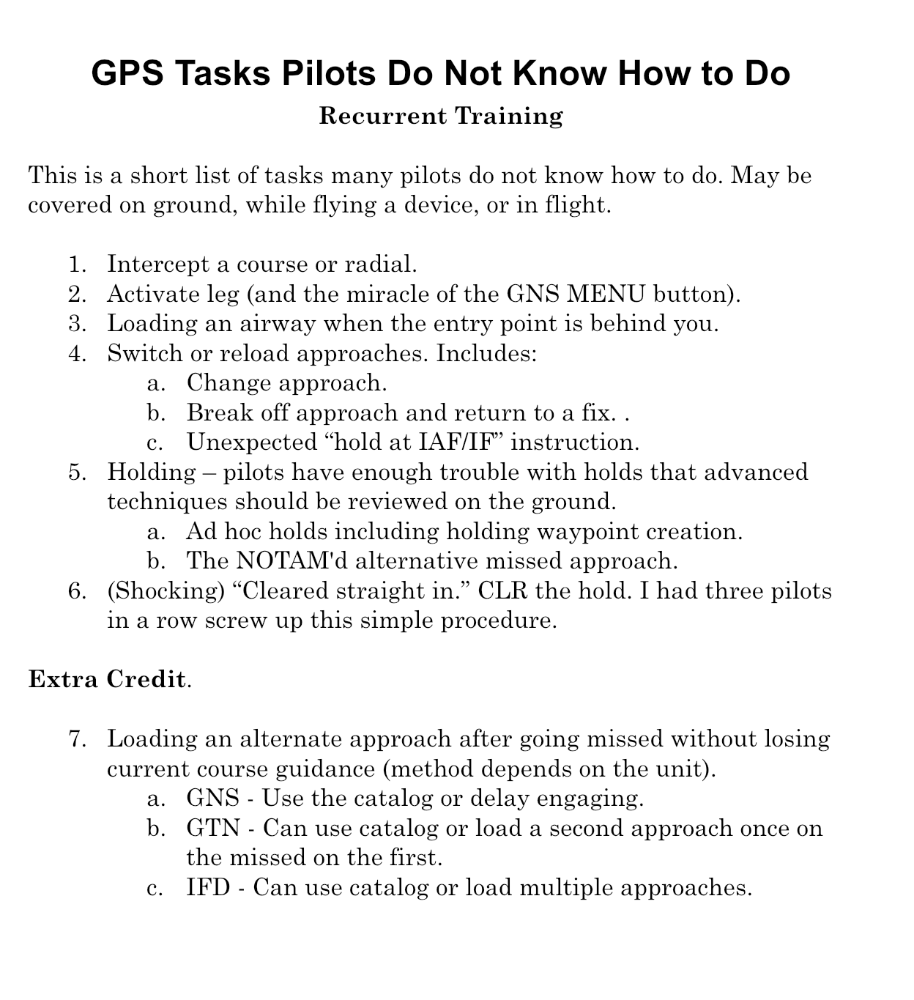

Levels of Learning per the Instructor's Handbook from lowest to highest: Rote, Understanding, Application, Correlation. Rote: Read the operator's manual several times. Understanding: Watch Youtube videos of the products you are interested in learning about. Application: Watch Youtube videos of the products you are interested in learning about with examples, read postings on forums such as this or Beechtalk, practice with Apps if there is one, and practice in your airplane. Correlation: Practice in your airplane in the real world with ATC throwing the inevitable curve balls at you. It happened to me today on a student's Instrument Cross Country. Except for the multimillion dollar simulators like operators such as Flight Safety have, I never thought much of inexpensive sims. If you're going to spend in excess of $100,000 for a modern panel upgrade, you need to spend the time and read the manuals from cover to cover--several times. While it may seem boring to some, most of the information needed to competently use the equipment is in the manual. And each of the manufacturers has their own design philosophy. Once you understand the philosophy, I've found that you can usually pretty quickly find a solution to a problem by going to the right menu. Finding the menu quickly is philosophy dependent. I do find it is challenging to learn many philosophies. I feel like I'm an expert in the Garmin world. Not so much in the Avidyne world, although I find I can get around pretty well even there, since the most used actions are fairly obvious. The more complicated actions in any of the worlds such as VNAV as an example, or loading Airways, which is device dependent, require a YouTube video, or an instructor who has "been there, done that". I have found that there is no substitute for practicing with your own avionics. If something doesn't go as planned, it's back to the manual for guidance, then back to the plane to try it out. Unfortunately, company support is usually worthless from my experience. These people seem to be trained to a level that is barely Rote. So set aside some time sit down in a cosy chair, and start your "Adventures Through the Manuals". You'll be surprised how much you can learn.1 point

-

The original airplane was built by North American Aviation and designated AT-6 (except the Navy called it an SNJ-3 and the Canadians and Brits called it a Harvard). AT was the designation for Advanced Trainer. After WW II, they were sold quickly for cheap as surplus. But then the newly-formed US Air Force discovered that it needed a trainer and it bought back several hundred (at much higher prices) and awarded North American a contract to update them. These were designated T-6Gs. I have a friend that owns a really nice T-6G and I have about 5 hours in the front seat. I've got another 5 or so hours in the back seat of an AT-6A mostly flown with an ex-Reno race pilot. If you think a Mooney stall is wicked - try a T-6 .1 point

-

I wonder... When some of the CARB standards were appied, a lot of excellent gas cans suddenly became "no longer gas cans" and you were instead directed to buy flimsy, overpriced plastic cans with ludicrously complicated theoretically-vapor-reducing designs. A lot of good cans were suddenly no longer approved. E.g. the Sceptre plastic cans used by the military among others. I got the impression that some cans sold as "not for fuel" could easily and safely be used for fuel, but others not. The whole thing was a great example of unintended consequences of well-meaning regulation. So it might be worth some legwork on materials, etc. my 2 cents1 point

-

I think that's the crux of learning and training advanced avionics, GPS units, and navigators...There are a lot of procedures that you may not use regularly and aren't trained regularly. Some things are time critical, whereas others you can request delay vectors, or just put the unit in heading mode while you set things up. So the big question, is what's the "right" mix of simulation, Garmin Aviation Trainer knobology type computer work, and flight training. What items need to be included in an "Understanding your panel" guide book. What list of training tasks should be routinely exercised and understood. Even your basic steam gauge panel will have GPS Nav/Coms that require experience, understanding and education (and I've not yet flown a VOR approach that I thought would be my choice if weather was bad). Some of these tasks need to be trained with an instructor, but a lot of them are just process tasks that can easily be exercised in the air or at a desk chair. i.e. if you've never been asked to remove a hold do you default to "direct to" hold exit or do you just remove the hold by clicking on the hold and then remove, or do you try to reload the procedure and say "no" when it asks if you want to load the hold? @midlifeflyer I like your list as it's something that we all can work on independently as well as with an instructor.1 point

-

Absolutely. Problem is that Redbird doesn't even have full avionics fidelity with what it's emulating. So what you learn about the avionics is very surface, and some just wrong. The limitation is the underlying Prepar3d software. That #6 on my list? In at least two of the three cases, the pilots who busted their approach clearances spent a lot of time with a Redbird. The Redbird does not all you to clear the hold-n-lieu once it's there. The two busted their clearance in different ways. One said they never hear of clearing the hold. The other used the Redbird work-around. Don't get me wrong. It's still very valuable for many things. Development of good habits. Scanning. Understanding procedures. I did a session last week with a pilot in which we did the same approach three times to illustrate three different issues. But it's important to understand its limitations.1 point

-

I do practice landing within the white bars because it’s a nice reference. In my mind I pretend the beginning of it is the threshold. However, you’re definitely right, if I’m in a real situation and glide down to a 5,000’+ runway, I’m not aiming for “brick one”. 1000’ down will be a perfect outcome and 2 feet short could be a disaster (lights? Mud? Threshold?). It’s worth trying to be precise though as a 2000’ runway or field requires landing pretty close to the beginning and not short.1 point

-

There are small variations and very large sudden variations. Clearly, the engine won’t run on zero fuel pressure, so there is likely a bad connection. I would fix that. The smaller variations might remain if they are caused by vapor as is common.1 point

-

1 point

-

It's white, I don't know the exact brightness rating however1 point

-

Joey is an honest guy, go look at it. He knows Mooney1 point

-

I went with the G-5 backup for two reasons. 1) I like the square format better and 2) I already had it in the panel as a backup to an Aspen 1000 Pro. A friend just did a dual G-5 to G3X Touch and put the second G-5 on the right panel. Not including the WX500 (i purchased that directly), my panel was about $100K. It was probably more, but the shop I used believes that a quote is binding, except for changes made (adding the second G3X, etc). Many of us believe that a new product will come out (either G4X or G3Xi), and that it will not be a huge price to upgrade as there will be a market for used G3X Touch. My avionics shop owner is on an advisory board to Garmin and everyone is adamant that any follow on needs to fit the same panel cutout. For audio panel I picked PS Engineering. It was a close call, but they specialize in audio panels. And were very helpful and took time to go over things when I called when making the decision.1 point

-

(Since no one else mentioned it…) Don’t forget to pop the cabin door open. Suggest doing that earlier rather than later, especially if solo. Don’t want to be bobbling the plane around to reach over when you’re slow and close to the ground. if you’ve never flown with the door open, don’t worry. There’s so much wind force on it in flight that you couldn’t open it if you wanted to.1 point

-

My practice, with electric gear: Gear comes down when the glideslope is one dot high, set descent power, then half (takeoff) flaps. I leave the flaps there and do not go full flaps unless I have broken out and a landing is assured. The plane lands just fine with half flaps or even no flaps. This is to avoid the high workload that comes with a full-flap go-around. If you have to go around from 75 KIAS with gear and full flaps, and you're trimmed properly for that (near full nose-up), the pitch-up action is very strong, so you have to do partial power, put in some nose-down trim, raise the flaps to half, let the plane stabilize a bit, raise the gear, more power, more nose down trim, raise the flaps. It's a lot to do while bumping around in the clouds in IMC near the ground, trying to fly a missed approach and not run into a tree you can't see. Leaving the flaps at half removes pretty much all the workload. You won't be trimmed as much nose-up. You just go full power, establish positive rate of climb, gear up, flaps up. I don't usually do touch-and-goes in the Mooney but my practice is the same for those. They're easy with half flaps, lots of work with full. It's good to practice full-flap go arounds because you may need to do one someday. Obstacle on the runway, someone pulls out in front of you, etc. But I don't want to do it in IMC. And if you're flying an instrument approach, there is pretty much always plenty of runway so landing with half flaps is fine. I also only use half flaps if the wind is gusting more than 5 knots or so. Really reduces the plane's tendency to balloon up off the runway in a gust. I have about 2 hours in a manual gear Mooney but don't think I'd do anything different.1 point

-

That's the reason why I spend some time on the runway resetting things on a touch and go. I'd be interested in hearing from anyone who flies IFR regularly on how they set up for an instrument approach and why plus whether you have manual or electric gear.1 point

-

1 point

-

1 point

-

In cruise flight with the trim full down, I used a spring scale to measure 40 lb of force required to fly level in my M20J.1 point

-

There have been a few threads like this one, and I always wonder what I’m overlooking. I usually take off with the trim set exactly where it was when I landed. It seems to work fine. No hard pulls, no wheelbarrowing. Don’t know what I’m missing.1 point

-

C model- fwd CG and trimmed on final at about 70 mph to the flare - When taxiing out for T/O it takes about 1/2 turn nose down for T/O trim to be acceptable for me. Many Mooneys have their pitch system rigged incorrectly. It takes jacks to level the airplane and correct tools to rig the pitch system correctly. Especially rigging the spring bungees for the correct elevator up position when the stabilizer is set to the proper LE down angle. Not many shops know how to rig the pitch system on a Mooney. Maybe I'll make a utube on it sometime. Just as a word of warning- IF the pitch trim is set full nose down on takeoff the nose wheel will never leave the ground. There's not enough elevator force at full up to lift the nose in that condition Several Mooneys have suffered this fate and run off the end of a runway at high speed.1 point

-

1 point

-

1 point

-

1 point

-

Exactly. I am sometimes overly anal (or anxious?) but I’ve been known to wash my windscreen after a trip before putting on the cover if the airplane is to be left outside. I don’t want the cover rubbing in those bugs!1 point

-

One thing to watch for, keep it as tight as possible when it’s on. Tight. It looks like good quality, but my bruces has zero wrinkles when on and doesn’t move in the wind at all. You don’t want it slowly rubbing.1 point

-

I have told quite a few passengers to randomly pull the throttle to idle while we are flying so I can practice engine out. So far nobody has done it....1 point

-

The big mistake was apparently doing stalls at only approx 2500’ agl. The minimum safe altitude for doing Mooney stalls is 5000’ agl - which is what we use at MAPA PPP’s. Falling leafs and any stalls shouldn’t be feared. A recent J model private student got very good at doing the falling leaf - so much so when he was practicing for the practical exam stalls he kept going into the falling leaf and i had to talk him out of it. But by pushing on the yoke aggressively till you feel light in the seat on any stall gets it’s flying again right away - just avoid a secondary stall by trying to aggressively to minimize altitude loss. Sent from my iPhone using Tapatalk1 point

-

A third option would be to ensure that the indicator and flap position match factory specs.1 point

-

With you and the instructor and no other (significant) weight in the back seats or baggage compartment, the CG will be forward. When the trim is run full up and full down to the stops, how do the respective markings line up then? I’m almost always solo in my C and set the trim indicator about one bar-width above the takeoff mark. When I have the back seats filled, it’s aligned with the takeoff mark. When solo, I also land with close to full nose-up trim.1 point

-

That's what I do for most takeoffs, along with Flaps Up. But when loaded up near gross, then it's Takeoff Flaps and align the marks. Check your CG with full fuel, no baggage and two adult males up front, you'll see why we put in a little Nose Up trim! But absolutely use the trim wheel. That's what it's for, so the plane will fly hands off.1 point

-

Weather/taxiing on grass during Osh (for any participant) could be a concern as there is typically weather that rolls through at some point every year. 2022/2023 had some crazy rain storms that passed through Saturday night/Sunday after the Mooney Caravan arrived. We found that quality outdoor tents were a nonissue, but the el cheapo Walmart special tents got turned into to flattened bath tubs! That year the Caravan vehicles and board went to the local outdoor store and picked up all the tents they had for the unfortunate fishies. This year rain rolled through and I think everyone was unscathed. It never lasts long, and the HUGE Caravan circus tent is a great place to congregate, drink a cold one, and chat with your fellow Mooney pilots as the bugs get washed off your wings. The taxi marshallers do a good job of placing cones on low spots and the grounds dry out pretty quickly as the remaining days are typically SUNNY. I still taxi decently slow/carefully, yoke pulled back to my chest, and they do a great job of rolling the grass smooth for the show. The three times I've been at Osh, I had no problem taxiing where I was being directed. We did have a pilot this year peel off after landing and go to general aviation parking area; he wasn't staying/camping at Osh but wanted to come with the Caravan. So it is possible to park somewhere else...although I think it's WAY more fun to camp beside your Mooney! Securing Aircraft: This is probably one of the benefits of the Caravan. You're surrounded by mass arrivals and I think that most mass arrivals are ahead of the curve in terms of Osh camping! These are the aircraft that usually have LED solar lights, cutting boards under the wheels, the Claw type tie downs, canopy covers, camp seating, etc. Given that most of the Caravan are seasoned vets, you can be sure none of the aircraft around you are going anywhere for most weather that would be coming through. I've found that the Claw is a great tiedown to use, works well, and easy to place and remove. Leaving Osh: Most pilots bring wooden or plastic cutting boards for the wheels; it distributes the weight over a larger footprint to keep from sinking into the grass as much. I picked up 3 cutting boards from Sam's that I reuse every year. Still, it takes more than just you to pull your aircraft out, but fortunately you have a whole group of Mooney friends to help make it easy! Food: The caravan always plans a group dinner every year under the tent. There are also several group meals that get planned in Madison as well as at Osh. Breakfasts are included Sunday - Wednesday under the tent each morning (part of the small Caravan registration fee). Lunches you are on your own. This year there were several that brought coleman stoves and we cooked out steaks or hotdogs. Food is definitely something that seems to get refined every year! At the clinic I attended there was one pilot who had some issues with feeling comfortable with engine management and trusting that his engine settings were fine (they were). But after a couple sorties with a seasoned safety pilot in the right seat he wasn't quite ready...and he wasn't signed off. But despite that there was never a problem with safety of flight, and that pilot has the opportunity to continue to learn and attend a future clinic to continue training. Hopefully as he improves, formation flight will gel and he'll join us. But if not, we still had a great time meeting another Mooney pilot and I'm sure he learned a lot in the process. Sometimes Formation flight may not be for you, but you don't know that till you try. If at any time a pilot feels unsafe, they can always call knock it off...for any reason. This is ingrained into the training both for your safety and the safety of others. BTW, we also have had a Beech pilot that joined that didn't get signed off. So it's not a gimme to get approved to fly in the Caravan. And if not for formation flying...how else are you supposed to get cool pictures!!1 point

-

Hi all, I stumbled on this old thread and thought I'd supplement with a video of me taking off from a 650m (2100feet) runway at MTOW, 3 POB. the 50feet clearance is pretty good too. YouTube video1 point

-

It is wonderful to have some postings again in the Caravan topic!1 point

-

Somebody designed a holder for a GATS jar. You use a small spring clamp to attach it to the nose gear, and it catches the squirt. My friend printed me one, but found the hole for the GATS jar did not fit, so he modified it. There is a guy at the airport is doing a small 3D printing Etsy store. Maybe I should get him the print file and he can make and sell them.1 point

-

The ice on the bottom of the wing is environmental icing. Icing from a cold soaked fuel into moist air. That is why you see MD-80s de-icing in Florida in the middle of the summer, until wing heaters were installed. With regard to being high on the approach, practice sometime with a safety pilot, gear down, flaps up, at best glide speed a full cross control slip. On a long body you can get about 2500-2700' FPM out of it. You can lose a lot of altitude really, really fast. I too had a problem with soluble water in the fuel in the winter. 99% pure IPA works wonders, but it is hard on the tank sealant. Make sure when you add it you are adding it in the fuel stream as you refuel. Do not just dump it in the tank because you will find your tank sealant wearing fast below the filler port. I have found 1 to 1.5% is more than enough. (Thank you Paul Kortopates)1 point

-

On my E, I wired the LHS into the green down light. If you put the gear down on downwind or before you put any flaps out the LHS will not say anything. At 200 feet and below, if the LHS is not sensing the gear down it will repeatedly tell you to check the gear. The landing height system is another tool in the toolbox that is quite useful. I have been using them in the Boeings I have flown for years. It will not stop you from an approach speed that is to high and proceeding to bounce on the runway so be vigilant for that. Getting a lot of landing practice is the best. In my 757 I new exactly where the tires were by the sight picture. Having the callouts were a great backup after a long day of 12 hours of flying and close to an 18 hour duty day. You can have a long day in any plane and the LHS is nice to have.1 point

-

Hmm. So because we study the issue in depth, the method of failure for classic resistance fuel senders is a loosening of the pivot at the sender body. this additional clearance needs to be accounted for as accurate contact pressure needs to be maintained between the beryllium follower and the resistance grid. Too much and the resistance grid wears out or the float doesn't fall onto the fuel surface and too little and there is intermittent contact with the grid - the latter is the source of windshield wiper fuel gauges. Rebuilt senders typically put in a new beryllium follower and resistance grid and do not address the pivot pin wear.... or corrosion pitting or security of the assembly. We get fuel level senders sent to us everyday - it isn't a good look let alone something to fly with. Your current senders when they and the aircraft was new - utilized tooling for the fuel senders that was accurate and maintained to produce a large number of relatively accurate fuel senders per year. For the aviation market - the tooling was brought out a few times a year for a replacement production run as the primary customers had moved on - I suspect that output quality for this tooling was neglected as well. It was a technology that was commonly used and common in its day but it was replaced wholesale 30 yrs ago So yeah we are more expensive - but we use aviation grade materials and practice. We set up what we do to be low volume and to hold accuracy for life despite that. Accurate fuel level at this point is proving to be the most effective way to prevent fuel related accidents. We and others in this field providing accurate fuel quantity in aircraft have yet to see a fuel related incident or accident aircraft. as I have been quoted - zero is a pretty impactful number.1 point

-

In Europe you will find tons of Mooneys on 1500 ft runways or less, primarily because lots of airfields are that small yet Mooneys are popular and operate in and out of there without any problems. Wangen Lachen (LSPV) has a 500x18m runway, which translates into 1640 ft. I've been there many times, no problem either in or out. There are quite a few Mooneys based there including a M22 Mustang and an Eagle which belongs to the local flying group. I've seen J, K's and others there. The original Mooney dealership in Switzerland was based in Bad Ragaz LSZE. Its runway is 1624 m long and 33 ft wide. For many years all Mooneys coming into Switzerland for sale (quite a few) passed through there. Shortest I know of that my airplane has operated in and out of was Helgoland in Germany, whose longest runway is 1570 ft long. It did operate out of there with 3 POB. The simple thing is: Open the POH and see what it can do. Take Off is rarely the problem, landing on short runways you have to get it right of course. But I would not hesitate to take my C model into 1600 ft provided there are no other factors like obstacles or else which make it a problem. I could not really make out the differences in those pictures due to quality. But there must be a quite fundamental change between the two which I am convinced has to do with a change in conditions or in the way calcs were done unless really a massive change in the construction has occurred which I believe it has not. Unfortunately Mike Miles is no longer with us, he would have known for sure. Maybe Bob Kromer can be found somewhere? He might have an idea.1 point