Leaderboard

Popular Content

Showing content with the highest reputation on 12/03/2023 in all areas

-

I've owned my M20J for 24 years and have flown it for about 3400 hours, but that doesn't mean I have any immunity from rookie mistakes or that I'm out of beginner's luck. Last Sunday, when I started the plane to come back from Thanksgiving, the propeller blade hesitated a bit before catching. I made a mental note that my battery might be going. Today (Saturday), when I headed to the plane to shoot some approaches in actual, the propeller moved a couple of times very slowly. I decided to get a jump start and fly anyway, given that my alternator has been working well and that, should that change, my route would keep me within a few minutes of a landing, and there was also nearby VMC. Plane started fine with the jump. Shot the RNAV 29 into Petaluma and decided to make it a full stop and save about $17 on fuel compared to the price at my home base. Plane would not start after refueling. And the FBO couldn't jump a 24-volt battery, and they called the maintenance shop on the field and got no answer, and they called another mechanic who had no equipment to get me going. So this wasn't looking good, especially with a cross-country trip planned to begin with a flight to Window Rock Wednesday night (eventual destination is the Jacksonville (Fla.) marathon, which is Sunday, December 10). I ordered a new battery online with rapid delivery, and I was about to look up rental car options so that I could get home and then return to Petaluma once the battery was delivered. That's when I saw a pilot driving out the gate, and I figured I'd ask him if he had any suggestions. He did. He told me the mechanic happened to be on the airport working on a plane. I found him. He tried to give me a jump from a 24-volt battery, but that didn't work. Then he gave me a tow over to his shop and tried a 24-volt power unit designed for jump starts. That didn't work the first couple of times. Finally, he asked me to look at my EDM 930; the battery was fine. The problem was my starter, which appeared to be fried. There was nothing to lose from trying one more time, so we did, and it caught, and I made it back home. I am now cancelling my urgent battery order and putting in an urgent SkyTec order, instead. I'm lucky I (1) got the plane started, (2) found the mechanic at the field on a Saturday, (3) didn't have this happen at an unattended field or in the middle of my cross-country trip. And I'm an idiot for not having looked at my engine analyzer to learn that the reason the prop wasn't spinning had little to do with the battery. I should have guessed this earlier, considering the battery is only a year old. But my previous starter issues have been either that they wouldn't engage or that they wouldn't spin at all. I had no experience with a starter problem looking the same as a weak battery.4 points

-

So far, it sounds like you’ve successfully eliminated your battery from the list of possible suspects, but it doesn’t yet sound like you’ve proven that the problem is the starter itself. There are several other less costly components in play than a starter and it could also be that you’ve simply got a loose wire somewhere. Before you go through the hassles of disassembly required to remove the starter, I’d check the voltage going to the starter while it is being cranked to see if it is getting all the juice. Depending on the results of that test, you’ll know what to focus on, the starter itself of the wiring/solenoid between the battery and the starter. Good luck and let us know what you find the problem to be when it’s all fixed. Chuck4 points

-

Mooney shifted from Dukes actuators to actuators made by Avionics Products Company (Denville, NJ) on the M20J starting with serial number 24-0378 in 1977. Avionics Products Company (Denville, NJ) was owned by Consolidated Controls Corporation (CONDEC) which was purchased by Chicago industrialist Farley in 1984. Avionics Products Company sold actuators to Mooney labeled under the name Avionics Products Company (Denville, NJ) Some are just labeled CONDEC - Consolidated Controls Corp. like the OP picture above. The acquisition went badly for Farley and Farley sold CONDEC to Eaton in May 1986. So in 1986 Eaton inherited Avionics Products Company actuators - they changed the labeling at some point to Eaton. I have seen some labeled with Eaton Valve and Actuator Div. (El Segundo, CA) In 1984, Libbey-Owens-Ford (L-O-F) acquired Vickers Inc., a leading maker of hydraulic and electrohydraulic systems, from the Sperry Corporation. (no relation to the Vickers PLC (UK). L-O-F combined Vickers with Aeroquip, which they had purchased in 1968 and renames it Aeroquip-Vickers In 1999 Eaton acquires Aeroquip-Vickers The Vickers Aerospace Actuators and Controls Div.is located in Grand Rapids, Michigan. There are Mooney actuators labeled with only the Vickers name (Vickers Aerospace Actuators and Controls Div.- Grand Rapids, Michigan) It is not clear if Vickers made any actuators before the Eaton takeover. More likely Eaton consolidated all Mooney landing gear actuator manufacturing in the Vickers division. However, the actuators labeled with "Vickers" do no say that they are a division of Eaton. At some point in the early 1980's GEC (UK) (that is General Electric Company UK no relation to US GE) also became a supplier of actuators made in Whippany, NJ GEC sold actuators to Mooney labeled with the name GEC (UK) Aerospace Inc. (Whippany, NJ) In 1989 GEC and Siemans jointly acquired Plessey PLC (the focus was upon the telecom and electronics businesses) GEC (UK) Aerospace Inc was dropped into a Plessey company with all the businesses that did not fit with the overall acquisition focus on telecom/electronics. Actuators were then labeled with the Plessey name only. The deal went badly (along with the entire "Dot-bomb" era) Things were sold off. I think the Plessey "Electro Mechanical Div" just atrophied away and shut down. Today Eaton is the "last man standing" in Mooney gear actuators for J and up.4 points

-

I got a cool picture sent to me from the avionics shop about 3 weeks ago (got a new 355 installed to compliment my 650), and they had what looks like Air Force 2 in the shop! So there's my plane with Air Force 2 (or some govt marked VIP mover gulf stream) in the background in a big hangar with white shiny floors and my plane is shiny in the front of the scene, And the avionics shop said "the men in black were jealous".3 points

-

A corroded inspection plate? They're not structural, so just take a scotchbrite wheel to it until the corrosion is gone, spray a little primer or prekote on it, paint it, and be done, no?3 points

-

Thanks. I got some smoke from the starter on the try just before the one that finally worked, and this says smoke is an "indication[] that the starter is in need of repair."2 points

-

The second half of your post is about rigging. 1/2 inch alerion droop on each side is common. Spec is 0 to 2 degree droop on the travel boards, With the gap tolerances in the rod ends they tend to ride up higher in flight and generally a little above the flaps..But the 1 inch difference in flight is not normal. However do not mess with the rigging until you fix the engine droop/alignment first. You will just be chasing your tail. There is static rigging and dynamic rigging. Since you are in the UK here are 2 excellent KNR Shoptalk articles that are clear and pragmatic. Also see the discussion in Mooney Flyer on page 8. As Clarence (MSC in Ontario) advised: Flight control rigging is not too hard. Locate and replace all worn and sloppy rod end bearings. All are essentially the same, lock the two yokes together with a straight edge across the control wheels. Adjust the lower center bell crank under the floor with the off set per the manual or install the rig pin per the manual. Adjust the left and right wing bell cranks per the manual by use of the wing push rod.. Adjust the left and right aileron short rods from the bell crank to the aileron for up to two degrees of droop in the static position, generally more droop for faster planes. Adjust the left and right flap up stop bolts to zero degrees as measured with the correct travel board. Test fly the plane. You should end up with aileron and flap trailing edges aligned at cruise speed with the ball centered. If not you will have to make small adjustments. (this is the "dynamic rigging" and may include adjusting {bending} the aileron tabs carefully) I never bend the aileron trailing edges with wide vice grips as shown in the manual. I use two long boards clamped to the trailing edge with many clamps so I end up bending the entire edge a very small amount and never end up with waves caused by vice grips. Clarence https://knr-inc.com/shoptalk-articles.html?view=article&id=75&catid=25 https://knr-inc.com/shoptalk-articles.html?view=article&id=106&catid=25 https://themooneyflyer.com/issues/2017-OctTMF.pdf2 points

-

Definitely remove and clean all connections, it’s more often the ground for some reason and don’t forget the engine to airframe ground strap. Even if it is the starter having good clean connections wasn’t wasted time. Actually now that I think about it for a sec, not having a deep voltage drop on the battery is an indicator of a poor connection, which could as has been said be in the relay. Connecting a multi-meter to the Starter and comparing its voltage to battery voltage during starting could be an indicator, but only if the bad connection is on the Pos side, if it’s the ground that check won’t show a voltage difference.2 points

-

The #4 cylinder on Peyton’s Mooney jumped back on today. Will wrap up the installation early this week and then the break in process can be done.2 points

-

Tower asks me "what happened to your paint?".2 points

-

The shaft with the roll pin is what you want to turn. Just push the tabs down with a screwdriver. Then rotate the shaft with your fingers till the vacuum is where you need it and then bend some tabs back up to hold it in place. I have found if you adjust the vacuum to the bottom of the green arc, your gyros last longer. And removing a gyro can make your vacuum high.2 points

-

2 points

-

Good lesson for sure. I feel like after we’ve had our plane for a while, I’ve had mine for ten years, we get a little complacent in thinking it has always worked, so it will always work. Sometimes I think I know it too well, and might suppose that something is minor or the airplane will still get me where I need to go when I should be looking deeper.2 points

-

The regulations are the key. I would go to school and focus on paperwork in a structured environment. Dugosh as far as I know isn’t splitting cases, doing their own mags, props, etc. That is all going to get sent out. At a school you will work on those things. School + part time at Dugosh would be the best bet.2 points

-

2 points

-

Recently I was cruising in smooth air in my M20C (Lycoming O-360-A1D) at 8500 ft on a cool clear day, enjoying unusually good performance (>150kt TAS) during a ~1 hour flight. OAT was 5 degrees C. Carb temp was 17F. The same engine roughness event happened twice, spaced 15 min apart. See below. I've provided traces of the only features that changed on the EDM900 monitor (1 sec sampling rate). Nothing else happened. Event 1: There was an instantaneous dip in RPM, then brief spike in RPM (no more than 50 either direction). The engine ran rough for ~10 seconds during this period before everything went back to normal. I reflexively enriched the mixture at the start of the roughness. There was a recorded very SMALL dip in oil pressure when it it started (1-2psi) but it's literally the only other thing that changed on the monitor during this time, so I show it here. Event 2: Same thing except it was even more brief in duration, and I did not touch the mixture knob or anything else during the ~6 sec or so of roughness. It resolved on its own. The rest of the flight was normal, as was my next flight. The monitor traces show no changes in EGTs during this time, so I doubt it's an ignition issue. The event almost felt like the timing slipped on one mag and then went back to normal quickly, but I don't know how that's possible. I have a Surefly left mag and a bendix right mag that is 150 hrs since overhaul . I did do a quick in flight mag check after the second event resolved, and that was unremarkable. I also wondered if there might have been a smidge of water in the fuel that ran through the engine. I did refuel before this flight, but the plane sat for at least an hour after fueling, and I did sump the tanks before getting going. I even wondered if it was a weird little windshear event that made the prop governor hunt for a few seconds- maybe the roughness I perceived in the engine was really in the air interacting with the prop; I didn't really notice any turbulence but I was hyper-focused on the engine at that moment. My only other thought was a prop governor / governor oil line issue. Can these lines have brief intermittent leaks near the prop hub? I have a ~4 year old pcu-5000. I have been noticing more oil in the bottom cowl for the last 10-20 hours, enough to put a couple of drops on the nose wheel after the plane sits for a week. There's more oil than previously on the air box, front of the carb, and the floor of the cowl. The rest of the visible engine including the accessory case and prop governor look bone dry. My A&P has been telling to consider changing the front crankshaft seal for the last couple of years given that it leaks a bit, and I am now thinking of getting to this in a couple of months at annual EVENT 1 EVENT 21 point

-

You will have to experiment a bit, but the built-in MooneySpace search might work for that: https://mooneyspace.com/search/?&q=extensions&quick=1&author=PT20J&search_and_or=and&updated_after=month&sortby=relevancy &q=extensions (word to search for) &quick=1 (not sure what this does) &author=PT20J (restrict to Skip's posts) &search_and_or=and (restrict to author AND search word) &updated_after=month (last 30 days) &sortby=relevancy It's a little convoluted, but there is a way to get there with the regular user interface.1 point

-

1 point

-

Jake will treat you fair and very thorough, I was going to recommend him.1 point

-

1 point

-

I was very happy with Jim Fackler, http://www.jfdynamics.com/ I believe he is now out of Prescott, KPRC.1 point

-

That’s like mine from 25 years ago. The FSDO quizzed me for about 2 hours to make sure I knew what I was talking about, then said, “well, if Sam says you’re okay, you’re probably okay.” Then they signed my authorization to take the tests.1 point

-

As always with any adjustment, it's a good idea to determine that the gauge installed in the airplane is accurate by comparing it with a known good gauge before adjusting things. Vacuum regulators don't generally need periodic adjustment, so I might do some investigation, especially if the high vacuum indication is new.1 point

-

AP does not follow heading bug or follow flight director in heading mode or level wings with AP on heading mode off. On ground test does not turn control yoke in response to heading bug. FD operates normally. AP computer tests good. Planning to send to Bevan Aviation. Thanks.1 point

-

Short answer: polysulfide compound. Long answer: PR-1425 Class B is an aircraft windshield and canopy sealant. It has a service temperature range from -65°F to (-52°C) to 250°F (121°C), with intermittent excursions up to 275°F (135°C). This material is designed for fillet sealing of properly prepared glass, polycarbonate, acrylic and other aircraft sealing applications. This product is specifically formulated not to craze substrates. The cured sealant exhibits excellent resistance to UV and weather exposure. PR-1425 Class B is a two-part, dichromate cured polysulfide compound. The uncured material is a low sag, thixotropic paste, suitable for application by extrusion gun or spatula. This sealant has excellent adhesion to common aircraft substrates. It overlaps and isn’t easily removed as silicone, LEDs are suppose to last a long time, my mechanic put it on, so I assume he can remove it. He used it on my windows as well:1 point

-

Cabin leaks or no leaks, if he has the same set up that I have in my 67, he should have very high temp at the vent. Depending on mixture setting, mine measured between 155° and 175° at an OAT of 7°. At merely freezing OATs it’s pushing close to 200°. There is no ambiguity in whether or not the system is working properly…if it is, you can hard cook an egg with it.1 point

-

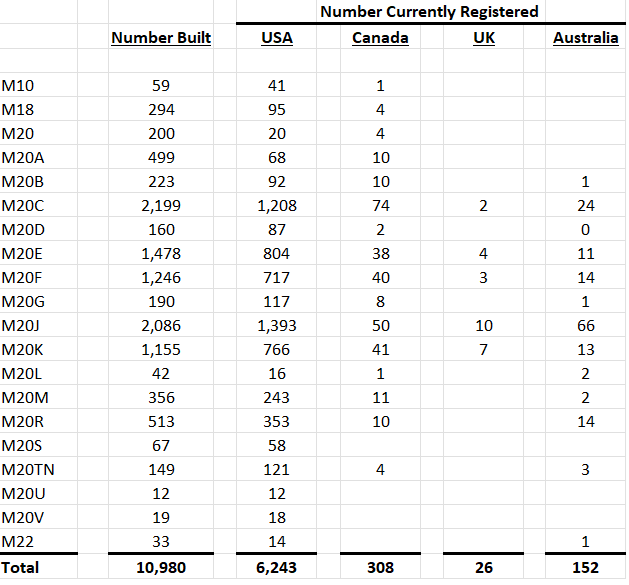

I think a lot of owners here are unrealistic about the entire parts situation. Time and time again many think there is a market for third parties to start building Mooney specific parts that are slow to come from the Factory. Many compare it to the classic car era of the 60's-early 70's (models which typically had sales in the 100's of thousands every year). Look at the numbers. The OP is looking for parts for a M20G. There are only 117 registered in the US and another 8 in Canada. And not all are airworthy and flying. The parts he needs from time to time may or may not be shared with other models. And as @PT20J says there were changes made in production of many specific models. Third parties like McFarlane will chase Cessna 172 because 44,000 have been built - and Piper PA-28 because 33,000 have been built in various flavors. Mooney? - that is a small market to gear up for.1 point

-

I've discussed parts sales with a few MSCs and most are unenthusiastic about selling parts to owners. First, Mooney doesn't provide a discount from MSRP, so MSCs all have to set their own markup which means they have to deal with owners shopping multiple MSCs for the lowest price. Second, there isn't enough money in parts sales to make up for the time on the phone helping an owner figure out what part they need. Then, there is the fact that owners frequently order the wrong part and when they return it, they grouse about Mooney's restocking charge. Only LASAR seems to have enthusiastically gone after the parts business, but that was with the previous owner and now the inventory seems to have dwindled and the markups have gone up on the parts they order from Mooney. Mooneys were pretty much hand built with a lot of changes over the years. So you really need to have the Illustrated Parts Catalog (IPC) and read it carefully because the part number for a part on your airplane might be different than one aircraft serial number before or after. And sometimes the IPC is wrong. So, when the MSC asks you for a part number, it's kind of a test. Does this owner have any idea what they really need, or are they going to order the wrong part and complain when it doesn't fit? And if you don't know what you need or can't figure it out, then they would prefer you work through a mechanic that knows that stuff so you don't waste their time because they are short handed and have a hangar full of airplanes that need servicing.1 point

-

Actually, the best way is to buy them from Mooney. Because if you get them from Mooney, Mooney will update them for free. Why is this important? Because some years back, Mooney stopped revising the documents because revisions require FAA approval. So, with limited staff and money, they stopped doing revisions and just scanned them all into pdf files which Frank Crawford adds comments to as part number or effectivities change without rolling the revision. Theoretically, the notes are just being gathered for the next revision which will never occur. So, there is absolutely no way to know that whatever document you download from the web has all the current updates. Better to get an update from Mooney once a year or so.1 point

-

You might also check the duct that goes from the NACA duct on the passenger side to the defuser behind the radio stack. There is a little elbow at the inlet that adjusts the valve. It need not be open in cold weather. The caulk you cleaned off was likely a dab of RTV. Perhaps you might reapply in a more “slightly” manner.1 point

-

When I push back into hanger bar stays on. When I pull out bar comes out and into baggage. When I fuel while traveling bar is used to tow to tiedown and then into baggage.1 point

-

The owner is age 87 or 88 according to an online database. I will note two things, one of which may be unrelated to this accident: - Please make sure go arounds and Stall avoidance are part of your recurrent training, and even moreso as you age. - for your safety, please remove sheepskin seat covers if they’re *at all* in the way of your manual operation of the trim wheel. I don’t care if you have electric trim.1 point

-

Hey folks, thanks, but I have to confess I am not putting alot of thought into this because as of Friday, I have an all new engine with an all new fuel system if no one caught that. It does not matter to me whether there was a problem with the old one or what the cause might have been. We did do some work on the fuel system over a period of years, including one complete rebuild when I first got the aircraft, and the installation of a new pump at one point, and the only effect that had was to shorten the time I had to run the fuel pump to get a stable fuel pressure. The only point I was trying to make was that filling the fuel lines is the first most important thing you can do to make any start work. Don't know what diagnosing my now-gone old engine has to do with this thread, which is about engine starts. Tried the old start technique on the new engine for the first time today. Worked great.1 point

-

I would definitely re-think your post. Of all of the owners on Mooneyspace I would put @jlunseth in the top ten of knowing how his airplane and engine, and of all of the M20K 231 owners I would put him at the top of the list on the TSIO-360-GB and LB engines. I'm nowhere on either list even though I owned an '83 231 and a '97 Encore. He may not be stating it in a way that you understand, but in following his posts since 2011 and looking back at the posts he's made since 2009, he knows his airplane and his engine very well.1 point