Leaderboard

Popular Content

Showing content with the highest reputation on 03/18/2025 in all areas

-

My understanding is that it's common for the GFC 500 to do a poor job of maintaining IAS during a climb in turbulence, even on other airframe types. For example my flying club has 5 Piper Warriors and sees that same issue. IMO, pitch mode is the right tool for the job in that scenario. I like to climb at around 100kts IAS in my J, so in turbulence I'll establish that, and then turn on pitch hold. Then just keep an eye on your IAS to keep it in a desirable range, and adjust pitch if needed. It's a much more comfortable ride that way. Even if the GFC 500 could do a perfect job of maintaining IAS in turbulence, it would still be doing significant pitch changes, and I think I'd prefer to just maintain pitch and accept the fluctuations in IAS.2 points

-

I have the original gain settings. It holds airspeed well in smooth air. It chases it a little in turbulence, but I have a hard time holding a constant airspeed in turbulence manually. I use PIT if it’s bumpy. Tightening the pitch servo bridal cables to max spec helped.2 points

-

Just swap your loosest push rods with your tightest, then swap your loosest rocker arms with your tightest. If you cannot get them in range, you will need to buy some new push rods. It takes a couple of hours to put all the pushrod and rockers together, measure them and swap them around. They usually get tighter when you rebuild an engine because when they overhaul a case they mill a bit off the parting surface and the case gets a bit narrower.2 points

-

The Lycoming Direct Drive engine overhaul manual is usually pretty easy to find for free on the internet, and it should have detailed guidance on what needs to stay together and what doesn't. IIRC things like the actual hydraulic lifter assembly may need to stay together (or not, I don't recall exactly), but it should be spelled out in the manaul. The pushrods aren't that big of a deal since they're selected during assembly using dry tappet clearance, which is pretty easy to do. You'll either wind up using all of the pushrods or need to order one or two. It's not ideal that everything is mixed up, but probably not horribly tragic, either.2 points

-

I carry a multimeter with me. When I was having these issues, I used it with the engine running to check steady voltage to the power buss at the alternator circuit breaker. That’s how I figured out it wasn’t the alternator. From there it was a matter of following the connections after the alternator circuit breaker. If the alternator wasn’t steady at 14 or so at the breaker, I would have started looking at the field wire or voltage regulator.2 points

-

Thank you everyone for your help. After a couple of missteps, we found the correct compression fitting to correct the problem. For our 1980 M20J, the following compression fittings worked from Aircraft Spruce. 261UB-04 - Brass Poly-Flo Fitting and MSC261P - MATCO Tubing and Fittings. MSC261P had both the nut and the original design of the plastic ferrule. I bought one of each, just in case. It turned out that the fitting back by the reservoir was also failing so the MSC261P went on the tubing/tee under the pilot's feet - in the same area where the electric boost pump is located and the 261UB-04 went on the fitting on the reservoir. Hope this helps someone.2 points

-

Don't forget the connections on the circuit breakers also can be loose. Someone a while back was chasing an alternator problem and showed how they checked voltage drop at every connection and just how much was lost due to high resistance/age in all the electrical connections Most of the Mooney fleet has circuit breakers and connections that have 50 years of age on them without ever being taken apart and cleaned. On another note- circuit breaker manufactures recommend cycling C/Bs occasionally. How many are out there that haven't been cycled in 50 years?2 points

-

@takair That is correct. It will follow LPV GPSS maneuvering but it has an altitude restriction of 700 AGL so no "coupled" LPVs down to minimums. Disconnect and hand fly from 700 AGL Its feed is strictly GPS so no VOR or ILS approaches are possible except one can us the "track" heading to fly a VOR/ILS down to 700 AGL. One could also us the altitude mode and manual descent control and capture down to 700 AGL- Might be easier just to hand fly those AND I will say (again)- If you can't fly an ILS you shouldn't be flying IFR. IF your flying entails LOTS of IMC down to mins or near mins spend the money and go Garmin If you are a VFR mostly pilot and your IMC is an occasional climb out or let down to 500 or more ceilings then the AeroCruze 100 will do just fine for you. If you are strictly a VFR pilot then the AeroCruze 100 is the PERFECT answer for a "cheap" autopilot for VFR flying. Its biggest feature for the VFR only pilot is the "One button push" to straight and level flight. As long as the A/P has power (whether or not it is in use) it will connect up and go straight and level with a one button push on the BLUE button panel mounted. This is the best safety feature that any VFR pilot can have and the FAA drags their feet in bureaucratic red tape and CYA in the approval of this safety device. They've been doing it for years and people die because of it.2 points

-

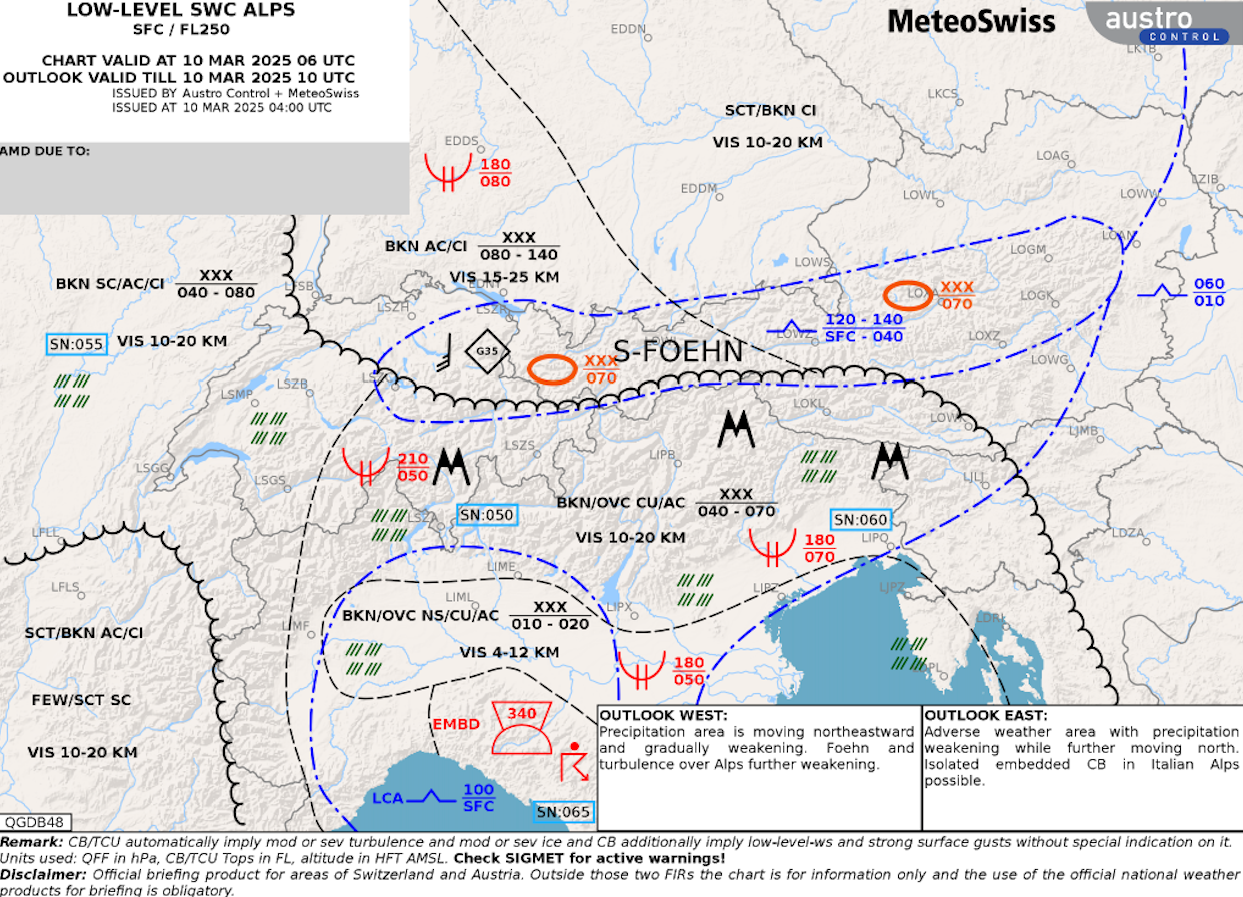

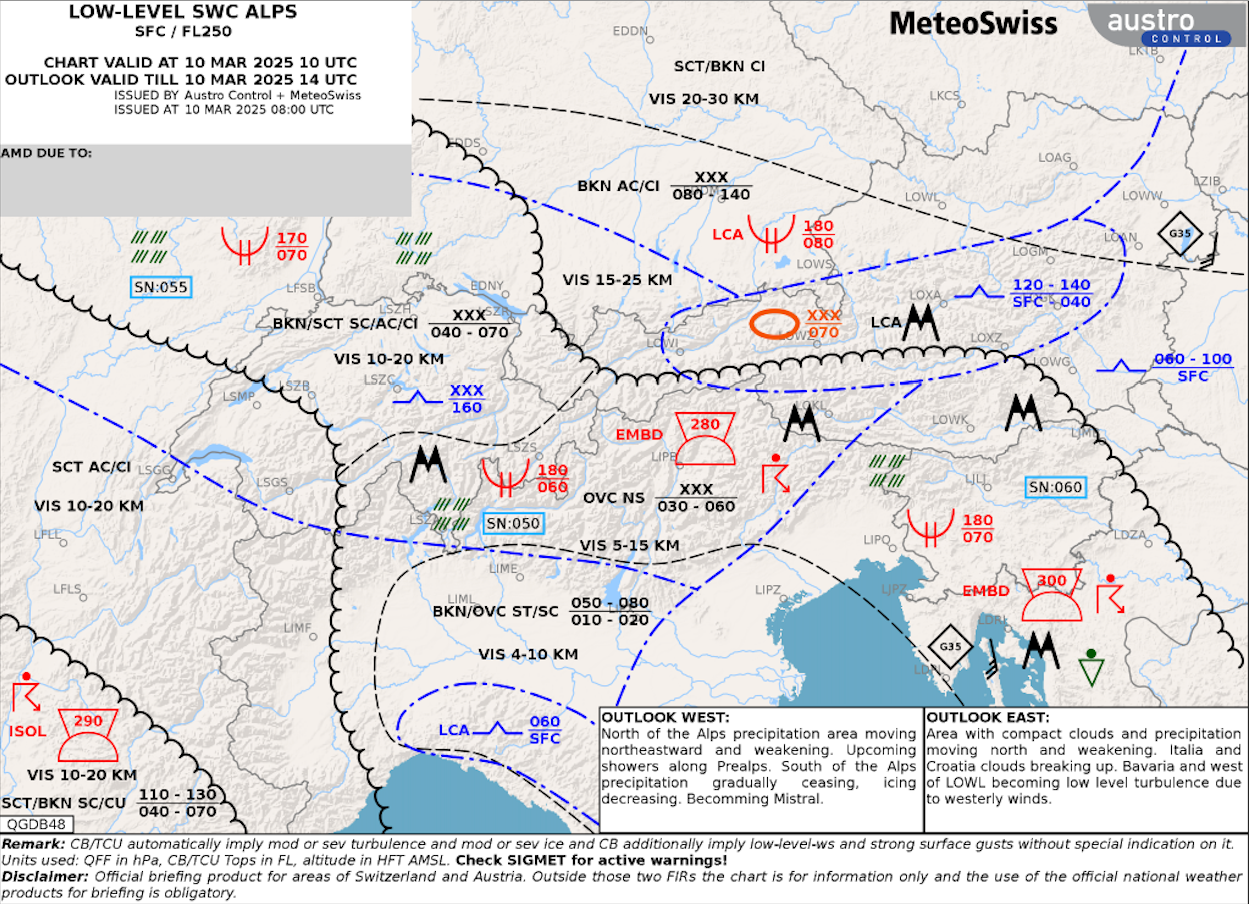

Thanks to the exceptionally friendly service at AustroControl, I was able to obtain copies of the LLSWC charts for the Alps, created through a joint effort between MeteoSwiss and AustroControl. For me personally, these charts — hand-drawn by highly knowledgeable meteorologists from Switzerland and Austria who truly understand Alpine weather — are the primary weather source whenever I’m planning to cross the Alps. The accident occurred at approximately 0820Z. The two available charts were valid for 0600Z and 1000Z, respectively. So, the situation can be seen as a kind of average between the two charts. The flight originated from LDZA (Zagreb, Croatia), located towards the eastern part of the chart, and proceeded northwest towards LJLJ (Ljubljana, Slovenia). There were strong winds over the Alps and the Karawanken mountain range (between Slovenia and Austria), with a prevailing southerly Föhn and associated mountain waves over the Alps. Cloud build-up was occurring on the southern side of the Alps — at 0600Z, cloud coverage was BKN/OVC between FL030–FL060 with tops above FL250. By 1000Z, the situation had worsened with overcast nimbostratus (OVC NS) from FL030–FL060, again with tops above FL250, along with embedded cumulonimbus (CB) and thunderstorms (TS). Icing was present between FL070–FL180, and snowfall above FL060. While skies over LDZA were still clear at 0600Z, a thick cloud layer had already formed over LJLJ and was moving northeast. By 1000Z, this cloud layer covered the entire route from LDZA to Switzerland. Long story short — these were far from ideal conditions for flying directly from LDZA to Switzerland, even under IFR with TKS and additional equipment. (And remember — the flight was at FL095, which at least suggests it was filed as VFR.) A potentially better, though still quite turbulent route, would have been from LDZA north via Graz (LOWG) and Salzburg (LOWS) to Friedrichshafen (EDNY), but yeah, … Matthias For reference LLSWC Alps symbols2 points

-

Ironic, I’m on Delta flight to MSP to pick her up as I reply. The sub-zero temps in mid Feb to pick her up did not appeal to me. Cost? Just under 8 amu. Which (I think) came with some extras. My ‘63C has 48 gal tanks total fuel. In addition to the strip and seal, I asked Paul to take a look at the fuel senders. They worked, mostly, but both tanks had some intermittent ‘windshield wiping’ in the 1/2 to 3/4 full range. Paul replaced both senders with ones he had on hand that came out of a J model. No extra charge. I had expected to pay for overhaul of my fuel senders which were last done in 2008. I had removed the side upholstery panels before I left home so he would have easy access. Paul also did the Service Bulletin to upgrade the factory sump drain on the left tank, which was not replaceable on the early vintage Mooneys. The right tank had been converted to the screw-in drain before I got the airplane. But, to me, the biggest thing? Paul hangared my airplane from the first week in January until tomorrow (17 Mar), when I’ll pick her up. I don’t know if he’ll always have hangar space to accommodate in the future, but not sitting on open ramp in the dead of winter was a huge deal for me.2 points

-

Selling my 1980 Mooney M20K 231, 3175 TT, TSIO 360 LB with 1425 TSOH, Recently Installed 4 repaired cylinders with new pistons and rings as well as one OH cylinder. CHT's within 50 deg or less now- 325-360 average) Aircraft flies POH numbers and speeds per Merlyn Waste gate and intercooler additions. Registration N888BC. Flies great including both RNAV and ILS approaches. No Fuel Tank Leaks! Prices Flight speed brakes Built in 76 cf Oxygen system New main tires Useful load 945 #'s Just finished annual and IFR certification I bought the airplane from a BT member through Neal Schwartz two years ago through BT and the plane hasn't disappointed. Avionics: -Garmin GTN 750 -GMC 35 Remote audio panel -GTX 345 -Garmin Aera 760 hardwired to GTN -AP- KFC 200 (works great and flies approaches very well -SL 40 standby radio and BK KN 52 Loc only -Aspen 1000 Pro Max EFD New 2024 -Artex 345 406 ELT -EI UBG 16 Engine analyzer. (two new probes recently) -Standby vacuum system Engine: -TSIO 360 GB to LB -TSOH 1425 -Turboplus intercooler -Merlyn Black Magic waste gate controller, Critical altitude increases to 22K -Air Wolf M20 Air-Oil separator -recently installed 4 repaired cylinders with new rings and pistons as well as one overhauled cylinder Propeller: -Factory 2 blade electrically heated -600 TSOH Log Books available via PDF on request Asking $159,950.00 US Steve 519 589 7034 sdawson630@gmail.com Located CYKF , Kitchener Ontario1 point

-

Ancient, you say??? He's only midlife! But I miss the little Flight Guide book, it was certainly handy. Now I can't look up FBO details in the air if I decide to change my destination.1 point

-

envisioning how I’ve read that a factory reman is performed, they strip everything down, check it, throw it in a pile of good or not good, and then an entirely new engine is built of from a pile of random “good parts” I can’t imagine anything must stay together so long as they “check good”. A new pushrod and a new rocker, for example, just met each other on assembly. They haven’t even exchanged phone numbers before they start banging each other. just my internet guess1 point

-

Coming up on 2yrs on my reaseal from WeepNoMore and 0 leaks have come up. Also Paul is great to work with, accommodating, and the price isn't out of this world(think I paid $6600 in 2023 for my M20C). It was worth flying it from AZ to MN to have done.1 point

-

The FAA has a website for reporting SUP. They take the reports seriously. If one person wanted to make trouble, they would go after the one selling the unapproved parts. That would be the person who ordered them from Rochester. https://www.faa.gov/aircraft/safety/programs/sups Don’t shoot the messenger. I’m just telling you what the FAA told me at the IA refresher symposium two weeks ago.1 point

-

I am working on it. My preference is the 5-1792 dial with no screw tabs, but with an alignment key at the top.1 point

-

Of course it would. That is how they stay in business. As I stated once before, somebody needs to make a drawing, send it to Rochester with an RFQ. The RFQ should come from somebody with a business license. And if you don’t want to get the FAA on your case, you will need a PMA, or they will be unapproved parts. I learned the other day how serious the FAA is about unapproved parts. They consider people selling unapproved parts as criminals. They intend to send people sellling unapproved parts to jail. As much as everybody cringes at the thought of getting a PMA. Getting one for these dials should be easy. When I was restoring my Cessna, I bought gaskets and push rod tubes from Real Gaskets. I spoke to the owner a couple of times. I checked out his company on Google street view. It is in a shabby little strip mall out in the sticks. The whole place is about as big as a 7-11. He has hundreds of PMAs. If he can do it, it can’t be that hard. https://realgaskets.com1 point

-

1 point

-

I asked @blueontop that question once while doing a design study on a portable autopilot. He responded, “I don’t know. It depends.”1 point

-

1 point

-

The hotter spark on an electronic mag does a better job igniting the fuel-air charge, so you see little mag drop. Also, most report being able to run deeper LOP.1 point

-

The one thing that always irked my feng shui is since they are a system, why on earth is the "scoreboard" on the top of a G5 a different order than the G3X? Why would you not have them the same? At least the G500TXi and the G5 show the same: lateral mode / AP / vertical mode.1 point

-

They were. But there’s a reason the atlas is no longer being produced. Same reason those great little brown books of airport diagrams are gone.1 point

-

That's a little suspicious because it may mean that the other mag isn't turning off. Regardless of how good they are, there should be an rpm drop when either side of the ignition is shut off.1 point

-

Depends on if buying, selling, or just trying to get it running. You can measure the push rod lengths with the valve lash when the tappets are flat. You won’t have the normal seats and wear patterns on the valve train. However, it’s not the end of the world unlike rod caps or other rotating parts. I think with a little bit of mineral oil at break in it would run in ok. -Matt1 point

-

working on the same issue- turned off strobes, etc with no change. Pulled the alternator breaker and it completely went away with the clearest radio communication imaginable. Working with the mechanic to check all wiring, and likely put an inline filter. The alternator was just rebuilt, ( new brushes and a diode) but the problem existed before. Rob1 point

-

True. The important point is that you need Garmin equipment to support the GFC 500 and sometimes people forget that when pricing the autopilot. I still believe the best setup is a G3X/G5/GFC 500 because this combination is one of the few Garmin configurations besides the G1000 that was actually designed as a system. It gives maximum redundancy, and the G5 is a great backup for an airplane without a vacuum system because it has a long backup battery run time. This is not to say that the TXi is not a great product because it is. And if I already had one, I would not replace it with a G3X when adding the autopilot. But, when starting from scratch, I weighed all the pros and cons and went with the G3X/G5/GFC 500. Lower cost, redundant ADAHRS, longer backuo battery life, older hardware.1 point

-

Oil pressure is decreasing as it heats up on the climb. MAP is decreasing as altitude increases. I am not changing mixture, throttle, or propeller controls during this time.1 point

-

I don't see any variation in my oil pressure or MAP when this happens. Blue is oil pressure. Red is MAP. When this happens I am climbing at roughly best rate. This does not happen in cruise, except when I enrich the fuel mixture after lean finding.1 point

-

Weep no more or wet wingologist east, they each do about one airplane per week, they recirculate the stripper with a pump, lots of know how in the process, Weep no more did my tanks 6 years ago, zero leaks, each of them have done thousands of tanks, their sealant never gets old on the shelf because of their high throughput, very hard job1 point

-

1 point

-

I think @PT20J posted a specific link as well, but something like this: https://www.walmart.com/ip/3M-Clear-Repair-Tape-1-88-inches-x-20-yards-1-Roll/462161976?wmlspartner=wlpa&selectedSellerId=101281679 I went to Grainger to get it but probably any hardware store will have something comparable. Gorilla brand makes a similar tape. There is regular and "heavy duty". I'm unsure of the exact difference but probably thickness or tear strength, so I would think either is good for this application.1 point

-

@gevertex My plane is in annual and I had some inkling the governor might need review. At last year's annual (MFSC) there was some variation after set-up and the manager told me it "might be getting tired". On some advice, I let it ride as the engine is de-rated from 2700 to 2500 rpm. The last several months I'd noticed some hunting of engine parameters, somewhat helped with mouse-milking the wastegate linkage (which actuator was overhauled last year). So, after some discussion with mechanics, on advice and statistics, this year I asked them to send it to a repair shop (West Coast Governor) for overhaul. Plane is about 1600 hrs and no log evidence of prior governor work. Heard back last week the governor "was in bad shape" and the estimate had increased. Currently trying to work the dance of parts shipment, timeline management, etc ("hey I need the plane, LMK if I can expedite things"). Don't have a full post-mortem or additional details. I figure it's parts going round-and-round and the macerator finally contacted the interferor and ground up some soft bits. Of course, these are just PP thoughts (hat tip @carusoam) . The local mechanic said they tend to prophylactically overhaul flight school/line service planes' governors sooner. Just a PIREP in case it helps. I know you had yours done a few years ago but who knows. There are apparently ways to bench-test these though I'm not sure everyone can. HTH David1 point

-

I did one of these on my C model. I located a nutplate with the screw, drilled from the bottom up, countersunk the hole through both of the layers, then riveted it in. I didn't take anything apart.1 point

-

1 point

-

Pack and flight plan wherever you are. Even at the run up pad if missing a chart. Cellular-Worth it.1 point

-

Nothing in that SB indicates you must overhaul it every 4 years, only when the engine is overhauled. There are periodic INSPECTIONS, but not overhauls. Big difference.1 point

-

You might also list it on ShareMyAircraft.com. I think I've gotten a number of inquiries from that. Also, if your airport puts out a newsletter, they may be happy to put an article in it (especially if you write it for them) about the club in formation.1 point

-

I think this would be sweet in any long body Mooney. It would also solve the impending demise of 100LL problem we are currently facing. If the price of mod would be similar to overhaul of a big bore piston engine, I think many owners would go for it. Unfortunately, the certification challenges would likely make such mod prohibitively expensive for most Mooney owners. If the price for experimental is around 100k, we could probably expect double that or more for certified aircraft.1 point

-

I'm lamenting that Mooney ownership doesn't have the capital or the prerogative to do a clean sheet with these guys, or someone like them, for a new 4/5 place Mooney, with a 'chute. They'd sell 800 aircraft a year, if they did. Instead of wasting time that won't exist for the piston-powered legacy fleet much longer on things like 100UL avgas, we should be pursuing certifications like this for both legacy and clean-sheet certified aircraft. We Mooney guys shouldn't be happy watching Cirrus take the lead on something like this (they never will push a turboprop equivalent for their legacy piston fleet, for obvious reasons). We should for our legacy fleet, for equally obvious reasons.1 point

-

They need to develop a larger one, with a full rated power of around 350 - 400 SHP. That way they can derate it to run better at higher altitudes. Hmm, I am thinking turbine Aerostar. But a turbine 252 would be very cool.1 point

-

The heat exchanger is typically called a "recuperator" and recuperates waste heat from the exhaust back into the thermodynamic cycle of the gas turbine. A land based gas turbine of similar size is from Capstone Turbine, and produced by the thousands since 1998, available today. That recuperator is very effective, doubling the total gas turbine cycle efficiency (from about 15% to about 30%), but very heavy, as it is land based. It proves the cycle out, but not aerospace ready. The cost of the recuperator is a major portion of the total system cost, just as it is a major part of the weight, not just an accessory. For aircraft, the recuperator effectiveness will depend greatly on size and therefore weight. Very difficult to make a solution that meets weight and cost targets. It is also a highly aggressive environment of massive thermal cycles from cold soak to +1000F exhaust temp on the hot side, plus a thermal differential with maybe 400F on the cold side. The exhaust gas is also highly corrosive at these temperatures, requiring fancier alloys (including Inconel 625 as a popular choice) Turb-Aero (https://turb.aero/) has a similar solution but with 2 spools like PT6. Also a long way from being availble for sale. -dan1 point

-

Look forward to speaking next week. Just so we’re clear on working “perfectly”.1 point

-

Oliver, There are a host of small issues that might be causing your problem. My sense is that everything was not perfect over the summer but was acceptable enough for you to think it was functioning properly. The symptoms of having air in the system are exacerbated by the cold. We had a particular harsh winter here. The last time I flew my plane it was in the low teens and the system performed flawlessly. It’s not the system. I will DM you my phone number. More effective to have a discussion over the phone. Thanks to @Ragsf15e for conjuring me. I’m pretty scarce around these parts these days.1 point

-

If you're going to do a complete strip and reseal and keep the airplane, get on the list and have Paul Beck at Weep No More or Edison at WetWingologists do it. Those two do them every week and they aren't learning on your airplane. They are each a Mooney flight away.1 point

-

Hi Don. I’ve owned my Bravo for about a year and a half and the guidance I have received from members of this group has been invaluable. 53 is the number works for me. I find that 2200 RPM and 31 inches is the sweet spot for my engine. I can get the fuel flow around 14 gallons per hour, TIT of 1600 to 1620 and cylinder head temperatures around 360°. Last week I was seeing true speed of 180 kn with this configuration. I tried to run at 2400 RPM and 29 inches of manifold pressure, I just did not like the way everything was running. I’ve downloaded and looked at the charts that you linked to. I understand what I’m looking at, but I cannot seem to find an adjustment factor for a live peak. They are all based upon maximum power. I come up with about 205 hp at 17,000 feet under conditions I was flying. 75% power. I’d like to know what that is on the side of peak, where my fuel flow is about 4 gallons per hour or less. Would you have any guidance or charts for this adjustment? Thanks Bill1 point

-

My shop does mine and I have a Surefly on the right side. But if I was sending out, I'd use Aircraft Magneto Service in Montana. https://www.aircraftmagnetoservice.net1 point

.jpg.5edc297a21cd7a4a03ff9d9407fb520b.jpg)

.jpg.18d76d9243b451cdd3c1a7326f8ca209.jpg)