Leaderboard

Popular Content

Showing content with the highest reputation on 10/22/2024 in all areas

-

I honestly think they've overshot on this one. There are many out there, myself included, who were very much on the fence about whether the infant mortality unknowns of a replacement spring were better than the unknowns of an otherwise healthy spring with a lot of hours on it. And that was when the spring was selling for an eye-watering $1000 per unit. But at $3000 per unit, those of us who were already on the fence probably have our decision made easier.6 points

-

It looks like Lasar just ordered them from existing Mooney drawings/specs/part numbers and is marking them up. I'm reluctant to give them any credit for doing any engineering here.4 points

-

I will venture a guess that the airplanes that have worn gears or suffer an actual gear collapse have not been maintained properly for years. If the gears have been cleaned and regreased with the proper grease on schedule they will, in all, probability last as long as the airplane does. Running them dry is what causes the wear we see.4 points

-

The programing is actually easy once you realize that both pitch and roll have to be set up before any taxi checks. It is all contained in very detailed sheets (2) One for roll and one for pitch. Should read it through first to get familiar with the terminology You will also have to set up the TX ports (NEMA and 2 429s) on what ever GPS you are using so the Aero 100 can read what is being sent to it. 429s only needed if you want GPSS for IFR approaches. ALL the install info comes to you on a few engineering drawings. DON'T expect detailed photos like with the Cessnas installation. Little bits of install info are scattered about on the engineering drawings for each servo. READ the drawings and take notes several times before you start the install. You might have to adjust the roll servo connection to the aileron arm to get clearance so that it rotates about the ball joints The angle of connection is tight so bolt length and washers may need to be adjusted to get a good fit. (all allowed by reference on the drawings), The control head will be the easiest part to install. Buy a very good quality insertion/removal tool for the pins and do yourself a favor and buy 10 or 12 extra ones as you will screw up a few, Pay heed to my warning of buying GOOD wire strippers for 22 ga wires. The install will take you longer than you think as you have to think about every move before you do it. For instance the lateral placement of the roll servo although called out as a dimension at only one place on the drawing will leave you pondering just how to verify that dimension once in the wing. You will need a small angle drill for the roll servo bracket holes too boot. Getting the vertical placement of the roll servo mount hole in the span- wise stringers in the wing is an exercise in frustration to do it correct. You need to drill the servo bracket holes undersize first and then match drill the backing plate holes undersize and then install the bracket in the wing and match drill one hole in the stringer, cleco it to the stringer and then drill the other end of the backing plate holes. cleco that and then redrill all the holes to the correct size for matched hole drilling. Then you install the nut plates on the backing plates (again redrilled to the correct size for the screw clearance). This is the kind of stuff not called out on the engineering drawings which you will have to figure out for yourself. Location of the holes in the servo mount is the critical dimension. This is not a quick assembly LEGGO kit but it is possible to do IF you have the determination and skill set. You can download all the info on the BK website and read ahead before you order. Get very familiar with the paper work before you order if you want to install it yourself or with your A&P.4 points

-

Procedurally speaking, it could be done if the owner got a policy for it or if the buyer leased it first for more 30+ days. I've had people ask to do this before and I'm not signing an insurance company up for a day's worth of premium (that could be around $5 on a plane like this, including about 75 cents of commission to the broker after spending about $2-9 on DocuSigns and $3-$ to absorb an ACH fee) to take a risk of on flight. So I'd negotiate a minimum earned premium to do this. If the plane needs a special flight permit to get this done, the insurance piece might not get done at all. Older airplanes are being tough enough on the loss ratios without adding one to the mix that hasn't been flying for a tiny amount of premium.3 points

-

I struggled with hot starts when I first got my F model. Mags were due for overhaul and the ignition harnesses were ratty; that said, cold starts were fine and my LOP mag checks per Savvy did not show any abnormalities so I was initially hesitant to blame the equipment and figured I was doing something wrong. Eventually did the mag overhaul and put in a set of Maggie harnesses when the plane was next down for maintenance, and everything got better. I spent a while agonizing over technique, but now agree with others that you should carefully consider an ignition problem rather than something you’re doing wrong in the cockpit. Just to add another technique you could try: I tend to shut down the engine between 1100-1200rpm as others have mentioned. When ready to start, don’t touch anything; if you feel compelled to do something, advance the throttle another eighth inch but leave the mixture and pump alone. Then start cranking. After a very short shutdown to refuel, it should catch pretty quickly without other intervention. If a couple seconds have gone by with no firing (common with a 15-60min hot start), I will slowly advance the mixture until it catches, while continuing to crank. When first trying this, figure on 2-3 real seconds of easing the mixture forward. It will start to catch a bit, and then as you go another half inch forward, it’ll actually start and run smooth (by hot start standards anyway). Over time, I got a knack for what mixture position runs smooth with this method, so now I advance more directly to that spot rather than a slow push through the stumbling-because-still-too-lean region. This is also the spot I push the mixture to during any other start attempt (cold starts or if it fires right up during the do-nothing phase of hot starting). I’ve flown just over 60hrs in the last 30 days (most if it concentrated in two busy weeks with multiple legs per day), mostly in 80-90deg heat, so did quite a few hot starts and didn’t have any tricky starts using the above technique. It’s usually started in under 5sec of total cranking time (either fires right off or it’s time to give it the appropriate lean mix), so not particularly hard on the starter. Sent from my iPhone using Tapatalk3 points

-

If you NEED one to make your plane airworthy, take what you can sell it for and subtract salvage price. Whether its the NBS, insurance, etc….at some point pilots will just sell their planes.3 points

-

There are many many threads on MS discussing the no-back spring. Basically, there’s a very small number of confirmed failures that resulted in gear-up landings, and the failures are mostly attributed to manufacturing defects in the springs themselves. The original bad batch was installed as original equipment from the factory, and at least one aircraft has had a failure in a replacement spring. The collective wisdom here I think is that your NBS is very unlikely to fail, and it’s probably low on the list of reasons Mooneys land gear-up. Don Maxwell has been paraphrased here a number of times saying that they can tell at annual if a spring is chattering during gear swing tests and that you’ll know well before it fails. And anecdotally, they seem to fail more often on retraction than extension (so you’re stuck with gear down, not with gear up).3 points

-

Ya know. We talk a lot around here about getting a PMA and DERs and such. Nobody wants to do it because it is too expensive. Well LASAR bit the bullet and spent all the money. Now they want to earn a profit on a very low volume item with high NRE. Be glad they are available.3 points

-

welcome aboard, the FIKI Bravo shines in mountain flying, typical cruise at FL190 30" 2300 RPM is 185 KT TAS at about 18.5 GPH, at climb power 34" 2400 RPM the Bravo will hold 600 ft/min at 120KT up to FL210, I typically do not go higher unless there is a need to climb above icing clouds, the critical altitude on the turbo is around 21,000 ft, key to longevity is CHT below 400, TIT below 1600, power reductions not more than 2"/min with synchronous fuel flow reduction to keep TIT in the mid 1500s, this engine really runs better with Tempest fine wire plugs and needs 25h oil changes, run conservatively the engine will make TBO, maybe needs a cylinder or two overhauled, turbo and wastegate tend to need an overhaul around 1200h. Overall about as good as it gets in a piston single, the Acclaim is faster due to its better cowl and propeller, the engine though has very different characteristics compared to the Bravo engine2 points

-

100% agree. Pretty sure my 1970 has the rich carb. The doghouse is in excellent condition. Has the Lasar guppy mouth closure, and we added adjustable cowl flaps a long time ago. I often have trouble keeping the hottest cylinder under 400 in climb out. It was worse when I was based in Arizona! Don't even want to mention what CHTs we hit in extended high-power, slow speed maneuvers simulating takeoff stalls. Those temps climb fast, but they sure do take a long time to cool back down. Enjoyed this thread. Going to the airport this weekend and will bring an extra tube of red silicone with me to re-do some of the older sealant. Can't hurt!2 points

-

2 points

-

And, the last place I worked at would have charged $250,000. Both your company and mine would NOT be where to get something like this simple spring made.2 points

-

2 points

-

I thought that they were just buying a minimum quantity of the same old part through Mooney Intl? They aren't actually manufacturing these.2 points

-

$3,000 for a spring the size of your little finger. This is insane . And it still needs to be installed…more $.@PT20J is right. This is a good deal for Lasar. And of course for Eaton. It sucks for owners. Mooney must really be in dire straits if it could not scrape up any cash in order to get on this gravy train.2 points

-

I’ve been to about a dozen programs and still get a good deal of worthwhile ground and flight instruction D2 points

-

2 points

-

If anyone finds this thread in the future wondering if the Mooney Safety Foundation Pilot Proficiency Program (PPP) is worth it... Yes it is The all day ground school (we were scheduled from 7am to 4pm) was like a fire hose of information. I have pages and pages of notes from it I've barely digested. That's on-top of the training manual handed out at the beginning that we barely scratched. But let's talk about the flying. First off, you'll get your BFR and IPC checked off during your flights. But more importantly is the practical education, tips, and tricks you'll get flying your plane with an instructor. I've had tons of instruction over the last year working on my instrument rating, but let me tell you how crazy it was to get actual instruction on how to fly my Ovation. Highly recommend the program, and will be back.2 points

-

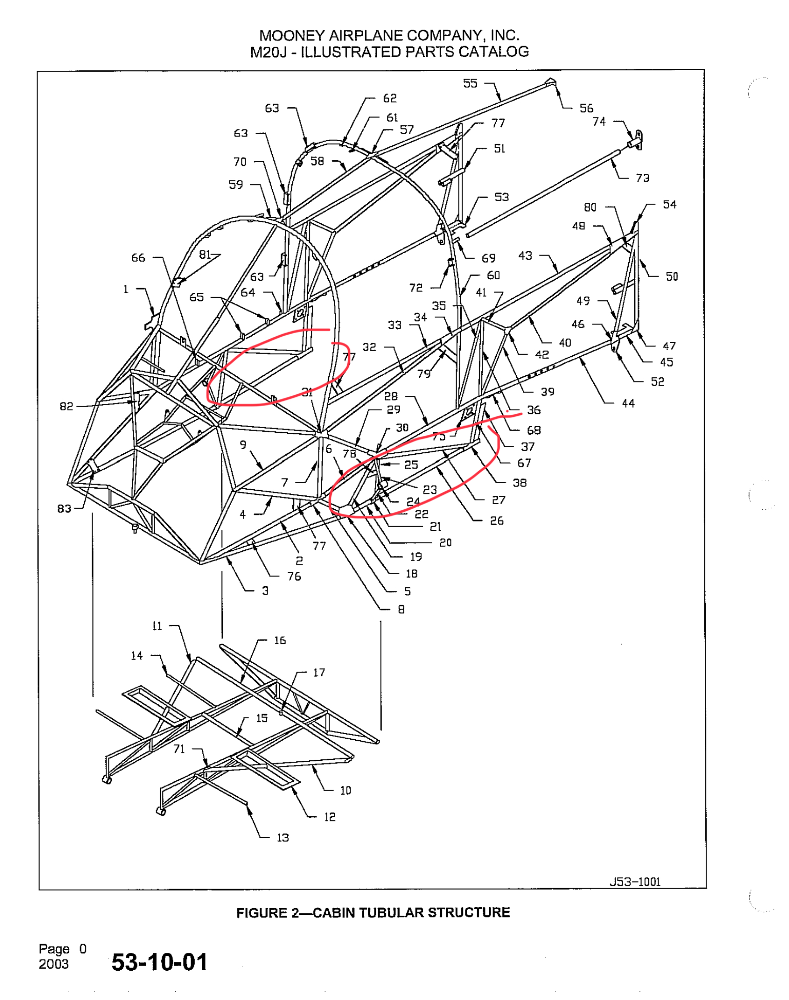

As a student pilot in the 1980's I swapped flight hours for fueling, cleaning aircraft and mechanics helper duties at the local FBO. One of the aircraft renters slid a wooden wing Mooney into the home runway without lowering the gear. The FBO AP/IA owner was a crusty old dog who relished in giving the FAA fits, so he drove to Texas from Idaho and bought a used wing from someone and mated the fuselage to the wing, which he never documented in the logs!. In the process the airplane was completely stripped down and one of my tasks was to sand off the zinc chromate off all the tubes before repainting them. The tubular chromoly fuselage cage reminded me of the funny car dragsters I worked on with my older brother and his buddies. Also it looked like the frame of the P51 models I built as a pre-teen. That was enough for me to realize the designers were interested in strength and protecting the passengers in the event of a crash. About the time the Mooney was ready to test out I acquiring my PP certificate (in the P and C brand aircraft), I got to do the taxi test runs of the rebuilt Mooney (my first time operating a Mooney) doing sequential ground runs up and down the runway and working out the known squawks. Finally the owner IA decided it was ready to go around the around the patch and I expected the lead instructor to perform the flight tests. To my surprise and (foolish) acceptance the owner IA said I could fly it around the patch for the first flight! I memorized the POH and recited it to him and over the objections of my instructor I performed the flight around the patch, left the gear down and noted that the left fuel cap was leaking! After that experience I knew all I ever wanted to own was a Mooney - strong, fast, sexy and efficient!2 points

-

Well, I have been flying a touch screen analog to the g1000. two 500txi a 750xi and 650xi. While the touch screen is convenient on the ground and occasionally in the air, I would happily give it up for some more buttons for input. its pretty difficult to hit some of those little touch screen buttons unless it is very smooth. I prefer the tactile feel of a keypad and buttons but I know I am an anachronistic village destroyer...2 points

-

I'm in Florida. I fly a lot of 1 hour trips to the keys, jacksonville, Tallahassee, etc. But I also fly to Atlanta, NC, and around 400 mile+ flights. **I have 102 hours in a 1989 J model within the last 11 months. I do plan to fly each summer to California, Montana, Colorado, British Colombia, etc., and to the same places on good weather days in the winter to ski. In my business I will have clients all over the country, and I plan on flying to see clients through the country during the year. Because of my widespread travel aspirations, especially trips out west in the summer in mountainous regions, I opted for the Bravo instead of an Ovation 2; a Bravo with long range tanks.... The Ovation 2 may be better suited for the 60-90 minute hops around Florida, but the Bravo is most likely better suited for 4-5 hours flights across the country; Montana, Idaho, mountains etc. Fuel burn on the Bravo? What will the fuel burn be at 160-170kts at 8,000 ft? What are your 17,500 ft fuel burns at different power settings?1 point

-

@rturbett Take another look at my Lower 48 map! I finally got around to checking off UT on our way down to the PPP in Ft Worth (KAFW). Great overnight in Moab, UT just because it was someplace we wanted to stay.1 point

-

Caution , that will allow the right mag to fire advanced and at low rpm. Damaging kick backs occur.1 point

-

Only two places it can go: out the breather or into the combustion chamber(s). Out the breather could be pressurizing the crankcase by blownby. Burning it would mean it’s getting past the valve guides or past the rings. Since this seems to have come on suddenly, something must have changed. I’d start with a careful examination of the cylinders. Sigh, with an airplane, it’s always something. Hope it’s something simple.1 point

-

it was in that ballpark, and they also replaced some or all of the membrane switches too, so it was a bit more. Still far less than G's flat-rate option, though.1 point

-

The Omega transducer is a direct replacement for the Kulite transducer used by Mooney with Sigma-Tek gauges. According to the Service Manual Electrical Equipment Chart, your S/N has a "Mooney" cluster and transducer. Since the amplifier was made by IAI, perhaps the gauges and transducers are also made by IAI for Mooney. Anyway, IAI is still in business and does repairs. https://www.internationalavionics.com/ You might call them and see if they have information that would help you figure out what's going on with your setup. I might also contact the Mooney service department.1 point

-

I’m not sure anyone’s individual answer is all that relevant as I’m sure there would be some semblance of a bell curve; a small number of pilots might sell the plane rather than deal with it, a small number might shell out exorbitant money now to have one on their own shelf just in case, and everyone else will fall somewhere in the middle. FWIW I completely share your outrage that a spring can cost this much but we’re kinda stuck. As others have said, there’s always a chance someone wants to PMA it and take the business away from LASAR at a lower price but I’m not holding my breath. Unfortunately $3k is comparatively small in the grand scheme of flying one’s forever plane for years and years. Certainly on par or less than the cost of acquiring a different plane and working through squawks. Even though it’s a ridiculous number, I’m guessing the gears for my actuator will eventually cost more new. And I’d rather know there was an option on LASAR’s shelf. Sent from my iPhone using Tapatalk1 point

-

Yes the thought of the spring failing is fearful but then when you ask what is the worse thing that could happen, as there have even been reports if the spring failing when the gear is down and Don Maxwells comment of the gear giving noise chatter before it fails really starts to persuade me to pass on replacing the spring then throw on if the spring fails and i do gear up landing my insurance will replace the prop tear down the engine for inspection, i can than add some money to make it an overhaul, it really does not behove me to proactively replace this spring. True my insurance will go up for awhile i will have damage history on the frame but if I’m keeping this plane until i quit flying, that’s not that important. Laser has effectively priced this spring out to only the super worried or part 135 or commercial or the uninsured pilot. Everyone else will most likely take their chances given the excellent track record of the majority of springs that are still in service past their time. Sort of like running past TBO.1 point

-

Good choice of plane for the mission. You’ll want a FIKI bird, too. Foreflight performance plus subscription has a variety of performance profiles. Adjust cruise down by 5% for the TKS drag, and you should be spot on. Fltplan.com should have some free profiles as well. Cruise speed and fuel consumption alone are much less useful than the full flight performance profiles including climb and descent. -dan1 point

-

1 point

-

Back when I was a peak oil guy (I still am BTW) I would ask people what price gasoline would get to before they would stop buying it. Everybody looks at you funny and says “They can’t charge that much, I need my gas” Nobody would ever answer the question.1 point

-

I've got a 1990 J and it did not come with 2,900# from the factory. Previous owner purched the upgrade kit as the SN was about 20 off from having the increased GW as standard. https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://mooney.com/wp-content/uploads/2020/12/M20J-Gross-Weight-Increase-SL92-1-1.pdf&ved=2ahUKEwjeqezH9aCJAxUtLFkFHcE7G-0Q5YIJegQIFBAA&usg=AOvVaw0dsYZ3lkSYO2-zMHlgL_8a1 point

-

I will take the flap pump and actuator off you hands for a reasonable price. They’re not making any more of those.1 point

-

I have the engraver and I find it works just as well whether plugged in or not. So I got a pin vise handle and mounted it with a pin (coat hanger wire) shoved in with it. It is much easier to use and does a better job IMHO.1 point

-

It seems silly to replace by hours, it should be replaced by landings.1 point

-

BWA HA HA HA HA!!! They've got some moxie to call this 'deal' good news! In what world does a SINGLE piece of formed and tempered wire, in a lot size of 45, represent $115,875??? (And, that's at the 'bargain' introductory price!) Sorry there is just NO way I can believe an implied set-up charge that expensive can be justified for such a simple part. This is a 'bend over and take it' because we can price! Glad I've got the Duke's actuator....can't wait to see LASER's price for the gears1 point

-

connecting things isn't overly difficult, the g5 system is mostly connected with a number of 2 wire busses, can, arinc and serial. i had the whole thign wired up onmy bench in less than an hour. now snaking all that wire thru the plane while making sure it's all white and indistinguishable, thats the money maker. I really like the dynon setup, mostly a bunch off preconfigured 9 pin dsub connections between the dynon components,. oh yeah and they have the mounting shelves so most of it can go in as a unit1 point

-

1 point

-

1 point

-

Hope everyone got home safely. 7.0 Hobbs time for 1095nm, non-stop. SUPER smooth ride at 17,000. It was great seeing previous (I won't say OLD ) friends and making new ones. And putting faces with some names from online.1 point

-

67 M20F 1. Set 1200 RPM for 30 seconds 2. Mixture cutoff 3. Do not move throttle 4. Hot start - Crank and add mixture in when it catches Perfect start every time1 point

-

Thank you very much, guys! The flight home to Texas was uneventful and RJ performed very well. Very smooth engine, all the avionics are working. Performance was great. Whenever you see us somewhere (and we will be out and about a lot in Texas!), come on over and say hello! Maybe we can organise a Mooney breakfast or lunch sometime in Grand Prairie or Lancaster. That’d be nice.1 point

-

1 point

-

FWIW, the g1000 perspective in the Cirrus is a completely different interface than the mooney. The G1000 does feel counterintuitive when you first start using. It almost defies explanation, you just have to use it to understand. But it is logical, and once you understand how to manipulate it, it is extremely intuitive and capable. I am not trying to convince anyone to like it, but aside from flightstream, there isn't really anything to upgrade to, it already has it all in there.1 point

-

1 point

-

Get a Sensorcon. Then you'll know! https://sensorcon-sensing-products-by-molex.myshopify.com/collections/carbon-monoxide-meters?srsltid=AfmBOoqMEIgnwco1gX22n91VWCOVxxoZqHyHJECrdDLT2i1aklkGFuuQ I have the less expensive model, works great. The Mooney is good, truck heater is good, no leaks around the oven or gas log fireplace.1 point

-

An unprimed IO360 should start in 20 blades whether hot or cold. Given that yours does not, I would suspect something else is going on. 20 blades after a 10 minute stop makes zero sense. I flew my aircraft to North Carolina early this week to support disaster relief, repositioning on the field three different times before departing. Times between startup buried between 10 minutes and 30 minutes.. The airplane started every time without prime I have been flying this engine for more than 20 years and the only time I’ve had the kind of symptoms you describe are when there’s an ignition problem. @PT20J Skip gives good advice and information above. What is a “gear clicker“ and what does that mean in terms of throttle position? An eight Mississippi prime is an awful lot. If I primed that long on a normal cold start, I would surely hear a bang from the exhaust when the engine fired. I use a four second count with throttle open. I might do closer to eight seconds if it’s freezing or below, but I’d probably try six first.1 point

-

In my experience with various carbureted and injected Mooneys, C and G models always have hotter CHTs than E and F models despite having slightly lower C/R. IO360 operators start get concerned when their CHTs climb to levels that many O360 operators would be tickled with. The factory jetting appears to sub optimal, especially on the earliest models. No one cared before engine monitors. However, now that we have them, it easy to make comparisons between models. I don’t know that it translates into more frequent cylinder work for than the carbureted models. Everyone has been conditioned to be uncomfortable with CHTs >400°. There are many C model owners that have put lots of time and effort into their baffles and seals but still struggle to keep CHTs < 400°. Many have take off EGTs in the 1400s. With a CR of 8.5:1, all take off EGTs really should be no higher than about 1300° and preferably less to be rich enough. No matter how perfect the baffles and seals, any cylinder that is < 200° ROP at full power in the climb is going to run hot. If it’s running < 150° ROP, it’s going to run really hot.1 point