Leaderboard

Popular Content

Showing content with the highest reputation on 09/16/2025 in all areas

-

When talking about no-back springs, it is important to distinguish between the two actuator manufacturers that Mooney used. There have been a number of documented failures of springs in GEC/Plessey actuators and I do not believe that no-back springs are available for these. The Eaton actuators (which confusingly were manufactured under several names) seem more robust. There was at least one (maybe two) documented failures many years ago causing Eaton to recall certain serial numbers which I believe is the source of the idea that there was a bad batch of springs. Probably some of these were never pulled and sent back to Eaton, but if they were going to fail, they'd certainly have done so by now. The spring is a wrap spring brake/clutch and it will wear in service. The chattering that Don Maxwell speaks of as a symptom of needing replacement is undoubtably caused by slippage of a worn spring. Outright failure is caused when the tangs on either end of the spring break jamming up the mechanism. I think this is a very, very unlikely event and I'm in no hurry to replace mine given the possibility of a maintenance-induced failure especially since there are now very few mechanics that have any significant experience working on these things. But, each owner will need to assess the risk and chose a course of action that they believe appropriate.4 points

-

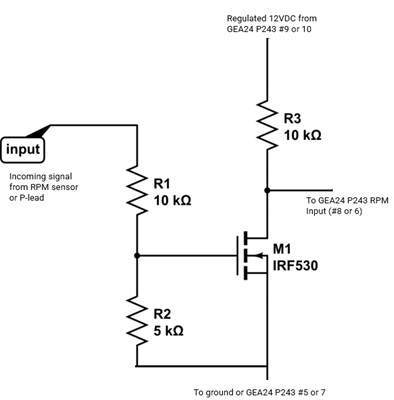

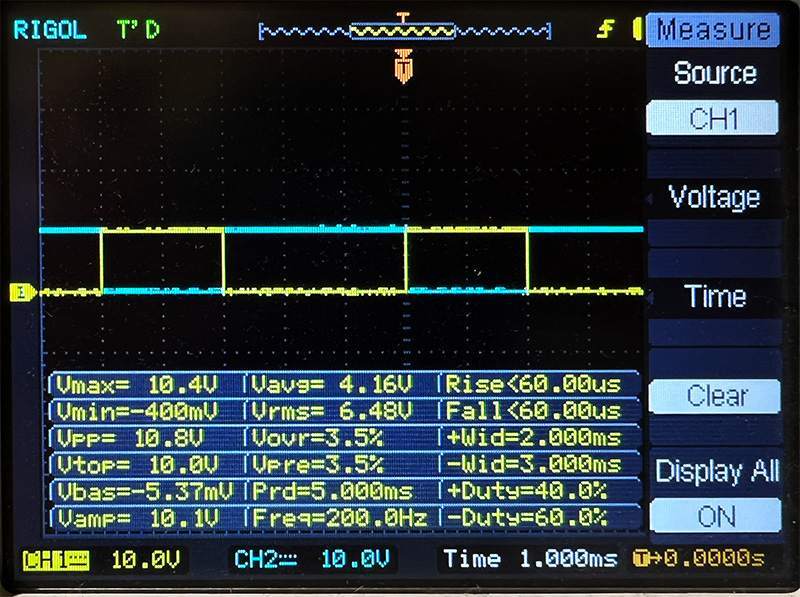

I realize that this thread is over half a year old at this point but I am following up in case anyone else runs into this issue in the future. After nearly a year, we have finally isolated the root cause and have managed to resolve it. The bottom line is, the RPM signal being sent into the GEA24 sensor adapter is a pulse signal, and the duty cycle of said pulse signal must be greater than 50% in order for the GEA24 to process it properly at higher frequencies (i.e. RPMs). In other words, for every high-low period in the signal, the signal must spend more time in the "high" state than in "low." Since my last comment on this thread, we have tried installing magneto filters, rerouting cables to avoid high-noise areas, swapped the GEA24, swapped the GI275, and even replaced the P-lead interface with the UMA T1A3-4 tach drive sensor (approved for GI275 EIS since July 2025) all to no avail. We tried all sorts of experiments, including rotating the tach sensor with a drill (to simulate the engine rotating), powering the EIS (GEA24 and GI275) with a regulated power supply, powering just the RPM sensor with the power supply, and even testing a Hall-effect RPM gauge from Amazon and hooking it up to the UMA sensor to verify it played nicely with the Amazon gauge (it did, beyond an equivalent of 5000rpm). Eventually, we removed the GI275 and GEA24 from the airplane and constructed a basic wiring harness in the workshop. We have an oscilloscope and signal generator, so we had the signal generator feed into the RPM input port of the GEA24 to emulate a sensor (with the o-scope monitoring it). After playing around with the waveforms a little, we found that the duty cycle of the RPM signal directly impacts the EIS's ability to properly resolve a valid RPM reading at higher RPMs. Duty cycle | Max RPM before fail | Failure mode 15% 1200 rpm Fluctuates, then drops to 0 30% 2400 rpm Fluctuates, then drops to 0 50% 4000 rpm Fluctuates, then drops to 0 70% 4000 rpm Red X 85% 4000 rpm Red X The above data implies that in any case, the EIS (as configured for a Lycoming 6-cyl direct drive engine) only goes to 4000rpm before failing the RPM, likely by design (a Lycoming spinning at 4000rpm is ... bad). However, we can clearly see that the RPM performance drops sharply at duty cycles below 50%. As a side note, this may explain Garmin's position of the magneto being "at fault" regarding the erratic RPM readings on select EIS installations. I haven't had the opportunity to explore the magneto P-lead output on an oscilloscope but I suppose that different condensors/capacitors in the mag may directly impact the waveform, and in turn, the "duty cycle" despite it not necessarily being a clean-cut two-state pulse signal. Going back to the issue at hand, the UMA tach sensor, by construction, has a fixed duty cycle of 1/3, or 33%. Looking at the inside of the sensor reveals that the unit is nothing more than a wheel with a permanent magnet embedded somewhere in it, and this wheel rotates in close proximity to a PCB with a Hall sensor on it. Unfortunately this doesn't help the cause, but what can help is if the signal could be "conditioned" to an adequate format before being passed onto the GEA24. In this case, "inverting" the signal such that at 0V (low), the output is 12V (high) and vice versa, would effectively increase the duty cycle from 33% to 67% with minimal impact to the geometry of the waveform. There are several ways one can accomplish that, but ideally the "signal conditioning" circuit needs to (1) be reliable for long-term duty, (2) have fast switching characteristics, (3) be simple to construct (KISS method), and (4) be resilient to environmental variables like temperature and humidity. One possible method from this discussion is using a transistor, such as an IRF530 MOSFET, to drive the gate (or base in a BJT) to cause the transistor to conduct or cutoff between the drain (collector) and source (emitter): In the above circuit, the output signal is held at the MOSFET drain-to-source voltage. When the input is pulled high, the MOSFET starts conducting and effectively diverts the power passing through resistor R3 straight to ground. Thus the output voltage sees almost 0V. But when the input drops to a low voltage state, the MOSFET stops conducting and the output is virtually held at near 12V (assuming the GEA24 itself has a high impedance, which it does, so that only a minimal amount of current flows through it). I'm sure the real electrical engineers will hate me for the simplified explanation, but that's really the heart of the circuit. No circuit is perfect and the primary concern with this design is the MOSFET's ability to react quickly enough to sudden changes in the input signal. However, the IRF530 exhibits sufficient switching performance and testing with signals up to 13kHz (for the UMA T1A3-4 tach sensor which produces 2 pulses per engine revolution, that's equivalent to 390,000rpm) demonstrated that the circuit was still able to maintain a duty cycle of greater than 50% even with the imperfect rise/fall characteristics of the MOSFET. (Testing the circuit at near 13kHz. Yellow = input, blue = output) (Testing the circuit at 200Hz - equivalent to 6000 engine RPM. Yellow = input, blue = output) In the image above, the GI275 can be seen indicating RPM well above the 2200-2300rpm failure threshold I mentioned in my previous posts. In fact, this is near full power with the manifold pressure running well above ambient. Granted, the troubleshooting and testing here was all done with the UMA T1A3-4 sensor, which obviously works a bit differently than the magneto P-lead interface, so if anyone else is having issues and would like to keep the P-lead interface while implementing a solution, then a thorough review of the behavior and characteristics of the P-lead signal would be warranted.3 points

-

I just got the data from the county. KWVI sells, on average, 11,600 gallons of 100LL per month3 points

-

On the job training is the best learning. If you learn, you get paid; if you screw up, you're no longer employed.3 points

-

Found this listing on line. Don't know timeline if before/after the LASAR announcement. I think it is going to be a tough business. mooney.pdf2 points

-

2 points

-

We’ve logged over 30 hours this month, thanks to our trip out to Washington, and right now I’m sitting at 30 GB used. Only one more trip planned for this billing cycle, so I’ll be abandoning some GB once again.2 points

-

I used ABS cement as it works perfectly with our ABS plastic, doesn't require mixing like epoxy, and results in a weld. Mine had been repaired with epoxy in the past and that failed but I'm not sure it was applied or what type; it looked like a rough, quick, and dirty repair. I learned a fair amount doing these repairs and intend to write it up once I'm done.2 points

-

Yeah, my interim plan of having a "brand new Champion Slick mag" to avoid the QAA issues is not such a slam dunk at this point. Doing SureFly as soon as possible.2 points

-

You should re-adjust the cam in the mag. If it is not properly adjusted, the dwell can be too short. Thus jacking up the pulse width. It is an easy adjustment to make and can be done without all the special tools called out in the service manual. You just have to buy a new screw. Spruce sells the screws for $5.2 points

-

I removed my wemac's to clean and repair them, two had lost their springs. It's a pain in the ass you need to cut them out of the headliner, drill out the rivets, then for reinstall rivet them back in, and use PVC cement to build back up the housing that holds them. If you do want to just mask them, an empty paper towel tube fits perfectly over them and provides a really nice invisible border.2 points

-

A 70 year old German machinist who taught me everything about materials, machining, engineering, CNC programming (even though he couldn't use a computer), how to hunt, how to be a man, never to back down from a fight but still remain humble, and when I should not make a sarcastic comment! Mike is still kicking today, over 90 years old. They simply do not make people like him any more. All hail the old timers!2 points

-

For years the only option for rudder trim was this: http://www.aerotriminc.com/id2.html Not a huge difference in price just to add the YD on the Garmin now.2 points

-

My wife and I just had this discussion on a flight Saturday. When we put in the GFC500 I didn't add the yaw damper, couldn't justify the extra cost. In cruise I typically stick my foot/boot in between the rudder pedal and side panel to keep it straight and not have to keep constant pressure with my leg. It would be nice to just let the AP do that work. I still might add it one day.2 points

-

Brett the owner of Lasar spoke yesterday, 9/12/25 at the summit and said they are taking over parts manufacturing at Kerrville and they have taken over the factory lease there. They’re implementing updated manufacturing processes and will be manufacturing parts in earnest going forward. I know there has been some negative comments about this deal but they are the only ones that stepped forward and put the money in the game. While some may interpret an increase in parts costs negatively, consider no parts availability. He also mentioned Lasar, as a Mooney parts dealer purchased close to 80% of all the parts Mooney sold into distribution. He also mentioned they would have direct and distributor sales channels. After listening to his presentation and engaging him afterwards my thoughts are a lot more positive. They also presented a concept called Mooney Phoenix they are working on where they’ll be taking trades and purchasing airframes and totally refurbishing them with all the latest technologies, interiors, paint and engines and offering them as an option for a “like new” aircraft purchase. It’s an interesting concept it will be interesting to see how it catches on. They are definitely investing in the continued life of our aircraft in a way nobody else is and the fleet will hopefully live on much longer with their investment.2 points

-

My home town had an old fruit of The loom factory with about 500k sqft. When the textile industry left there were no takers. it cost the city about 800k a year to do the bare minimum in maintenance. they were so desperate for someone to take it they offered huge incentives hoping someone would at least cover the expenses. it is not cheap to maintain that size facility.1 point

-

1 point

-

I meant to say spring CLIP. There are no springs inside the wemacs. The paper towel tube is exactly the right size to slip over, and is easy to hold while you’re spraying, then you can quickly move onto the next one.1 point

-

The previous owners were chasing speed. It isn't a huge problem, but a lightweight battery would help with not having to think about CG too much.1 point

-

It was at WestJet RAP in the MX hangar there, but I suppose it's possible they've moved it while they wait. I'm unfortunately back in Orlando so can't keep an eye on it directly.1 point

-

They had some delays sending me the empty crate so they haven't gotten it yet... hopefully next week!1 point

-

Some interesting updates to share, and the mystery deepens... I received a call from the Director of Product Support at Hartzell, which apparently owns QAA. He was aware of my prior case and had inspected that magneto at my old engine shop. He just learned about this latest case from my emails to my old engine shop, which they forwarded to him. He informed me that it is their opinion that there is nothing wrong with my engine or anything else related to my operation or the installation. He said QAA overhauled magnetos do not have 'overhauled' impulse couplings, but rather they always replace the impulse coupling with brand new OEM Champion impulse couplings. He encouraged me strongly to file a SDR with the FAA and to attempt to open a case w/ Champion directly, and that they would help any way they could from their end. He also suggested they were aware of a few similar cases, but this is the only known case of two failures consecutively. I got in contact w/ Champion's Quality department and promptly received a call from their Director of Engineering for the Piston stuff. He didn't really give me any new information but said he wanted to inspect the magneto in person while he is in Orlando next week. (I am having the magneto parts shipped to me) QAA apparently will also be sending a representative to be present. I also filed the SDR w/ the FAA... we'll see if there's any followup there. I think the Hartzell guy was going to make some FAA contacts aware of it. So obviously if it is in fact the case that these were brand new Champion couplings, that's pretty concerning.1 point

-

1 point

-

I think it would take someone watching movies to burn up 50GB. With our set up of BT audio muted when radios are receiving, no way you could watch a follow a movie with those interruptions, so 50GB goes a long way looking at internet pages and page scrolling.1 point

-

It’s a rapidly evolving market of different plans as the GA use case catches on. It does appear to be settling out. However, the price point hasn’t changed much as it’s always been in the $50 to $65 range. Now, as soon as you cross over the beach, it does get pretty spendy. I’ll be taking mine to the islands in November and that will require the Global ($$) Priority plan at $265 for the remainder of that particular billing cycle.1 point

-

1 point

-

1 point

-

We’re still referencing the master relay, correct? Mx Manual 106, pg 9-129. Original installation by the factory was manufactured by Cutler Hammer, pn 6041-H-231. Several used examples on controller.com, and BAS lists them on their website, also. https://www.controller.com/parts/search?PartNumber=6041-H-231&SearchType=Start I think Spruce sells TSO’d replacements… if you’re looking for a new one.1 point

-

1 point

-

Lovely!! For another flavor of Bay Area flying experience, may I suggest E55, 0Q3, and 1C9. Happy to fly formation!1 point

-

Yes. I was referring to Continentals. Lycomings are easy, get a holed rubber scientific flask stopper of the appropriate size, stick a piece of tubing through, put the stopper in the oil filler in place of the dip stick Here is my Continental solution: Use pourable flex seal to seize the tube in the funnel Funnel sits nicely and seals the filler bypassing the breather tube. Much easier than snaking up the breather line.1 point

-

how did you get that tail compartment so clean? did you do it? want to do mine?1 point

-

YD. When I am flying long trips it’s sure nice to have on those bumpy days, IMC too.1 point

-

Look on the BK website… https://aerospace.honeywell.com/us/en/products-and-services/products/cabin-and-cockpit/avionics/autopilots-and-indicators/aerocruze-100-autopilot#resources-tab1 point

-

1 point

-

1 point

-

Hey guys! With particular deference and respect to @Minivation @EricJ and @Will.iam posts, I join the crew of those benefitting from this forum. Thanks much! I'll add a couple of cents based on questions posed in the hope it helps others to follow: 1) Before dismounting switch (as noted, it's a PITA), I would suggest repeated spraying of copious amounts (4-5 second blasts) of contact cleaner (I used CRC QD Contact cleaner from Lowe's). I removed my switch, but I think my problem may have been solved by simply spraying parallel to and either side of the vane. This would "flood" the switch housing and, while I am otherwise in complete agreement with Will.iam above, it must have gotten enough spray into the housing that it travelled down the plunger hole and ungummed whatever was stuck. As I had already removed it, I paid special attention to the terminals (which did not appear to be corroded), so it's possible that this did the trick, but I don't think this was it. 2) if this doesn't work for you, I used these custom tools: standard 1/8" driver with extension, bit adapter and 5/16" nut driver bit for the top screw/nut and 5/16 box wrench taped to a screwdriver for the bottom nut. Don't forget to mark your switch position on the leading edge and on the switch before you attempt to remove it! My fix did not require any further disassembly beyond removing from the wing and spraying with contact cleaner. YMMV. Nothing else to add to the referenced excellent posts. Good luck and let us know how you did!1 point

-

Mooney probably doesn’t make parts under PMA. They will make parts under a production certificate. I would think Mooney will give authorization to Laser to order parts from Mooney’s vendors. I’m not exactly sure how that works from a regulatory standpoint. If the vendor’s parts are PMA, then there is no issue.1 point

-

Dropped off this morning. Went over everything with the shop. Excited to see how it all comes together!1 point

-

Where did you guys learn all this?! My middle school shop classes didn’t cover any of this and these days they don’t even have those limited classes!1 point

-

Service Bulletins are not mandatory for private use under Part 91. The no-back springs are very expensive to replace and do not have a significant history of failure over the history of their use in Mooneys, so most people don't bother with changing them. If your A&P insists on performing every Service Bulletin as though it's mandatory your ownership experience is going to be very expensive.1 point

-

I really don't mind spending a few shipping $s to get it to you to see if it works. For whatever reason there are no parts number on anything. Let me know and I'll work with you. DD1 point

-

I really appreciate all of the inputs on this topic. The article about landing a Mooney reinforced a lot of what I have been told. My one "complaint" with GA aircraft ownership relative to this topic is the lack of "truth data" regarding the flight characteristics and OEM provided operating techniques (all relative to what I am accustomed to with military aircraft operations). I feel certain that the lack of data and recommendations is due to the OEM's concern for liability (not unfounded) if they provide detailed recommendations that someone claims leads to a mishap. Bottomline, missing this information leads us all to essentially acting as test pilots and having to discover for ourselves the "right answers." Unless you find a CFI that is experienced in your type/model/series aircraft, they may not have the capability to teach you safe techniques for your specific aircraft. So, relying upon the best data as recommended (POH) and the best "consensus" on technique, I went out to discover for myself some numbers. Here are the numbers I captured in my flight today (stall warning, Vso, 1.2xVso and 1.3Vso - all in MPH): full flaps (65, 61, 74, 80), takeoff flaps (68, 63, 76, 82), no flaps (74, 68, 82, 88). All of this data was captured at 3000' MSL, gear down, level flight, about 15" MAP and roughly 2500 pounds. Each stall was taken to a true "break" and not just airframe buffet (occurs about 2-3 mph prior to the break). First note is that the aircraft stalls in an incredibly predictable manner, no bad behavior (stall tone, then airframe buffet, then a nose beak with only a small roll off that is easily countered) and recovery is very controllable with almost no altitude loss. I then performed a series of circus landings using the technique recommended from the article: approach at 1.3xVso and cross threshold at 1.2xVso, idle power and a smooth roundout. No flap landing was not dramatic and when flown on the numbers above was very straightforward (resulting in the aforementioned higher nose up attitude), same story for takeoff flap (I can see why there are a lot of folks who prefer this configuration as their "normal") and full flaps was definitely more predictable and controllable using these numbers and this technique (however, as mentioned, it results in a flatter attitude but comes with the benefits of the shortest landing rollout). Conclusion, previous to today, I was carrying 4-5 mph more than necessary as I was flying at 1.3xVso all the way to roundabout. Slowing to 1.2xVso across the threshold was a game changer. Given the 13mph buffer between 1.2xVso and stall, I feel "okay" about this technique, but sure would love it more if Mooney had provided the test flight data and recommended techniques to go along with my test flight.... Hope everyone has a great day. Fly safe and fly happy!1 point

-

No idea how standards were developed for 5G but I seriously doubt that the standards were set using the "lowest common denominator", the lowest requirement. If big bore Lycoming and Continentals and other high-performance engines are the critical path, then the standards should be set to meet them. It shouldn't be "let's get together and set standards for a fuel that we call "100" but really only satisfies the "94 fleet". i.e. "marketing hype". Let's all hope that it works for the more demanding high performance engine segment. But they should have been testing this in 520's. 550's, 540's, 580's Turbo and NA from the get-go. Not "Announce 100R ASTM - Great Success"....oh but we forgot to test it in engines that actually need 100. - and "Stand by for about 2 years while we begin testing"1 point

-

Valid points. Do you have anything helpful to the fleet to add? The Chinese did contribute. They also spent a substantial portion of the cash on the composite trainer only to drop it at the 11th hour. Long and short of it; what are your options. I will embrace the Lasar group and support their efforts until they give me a reason not to.1 point

-

PIREP: It worked great on a round-drip from NC to NYC with the regular $50/month roam plan. I have a 28V bus and bought these for power: Cable: https://www.amazon.com/dp/B0DS6YX58K Power adapter: https://www.amazon.com/dp/B0CZ7BL16W You can get a dedicated power cable that plugs right into the cigarette lighter port. But I need to also charge my ipad, so having at least one extra USB port is handy.1 point

-

with Starlink now competing, they may be more flexible on renewal pricing. I'll see in a few months. -dan1 point

-

Hmmm . . I'm still paying $30 for XM on my G1000 and a trip I took from Texas to Minnesota and back over the past ten days that confirmed my reason for having it. It is so much better than ADS-B weather. What plan are you on that's $18?1 point

-

Having fun here… Can I watch funny cat videos? Starlink - YES XM - NO. Can I FaceTime with my granddaughter at 10,000’? Starlink - YES XM - NO. Can I scroll Tik Tok videos? Starlink - YES XM - NO. Seriously, I think you’re asking about radar latency and it would come down to finding a low-latency website. According to what I have been able to find, radar.weather.com is touted as having real time radar data. However, funny cat videos are enough to seal the deal for me.1 point