Leaderboard

Popular Content

Showing content with the highest reputation on 12/17/2024 in all areas

-

I just voiced my opinion that it was not OK under any circumstances for a "safe drop-in" replacement fuel to cause damage to fuel tanks and paint that would cost tens of thousands of dollars to repair. While the damage can arguably be mitigated by new sealants and paints, I do not want to be the one paying for it. I am all for developing new, cleaner and better fuel, but it needs to be safe. Fuesl that causes deterioration of tank sealant is arguably not safe in my book. Of course, this is merely hypothetical as we do not have sufficent data to conclude with any reasonable degree of certainty tha the new fuel does, in fact, adversely affect the sealant and paint. George's post (now also missing) was very information and had some good points in it. Nevertheless, I am of teh pinion that indepenent testing done by somene else than the inventor/supplier fo teh fule is warranted here before the new fuel becomes teh only available optino for the piston fleet.5 points

-

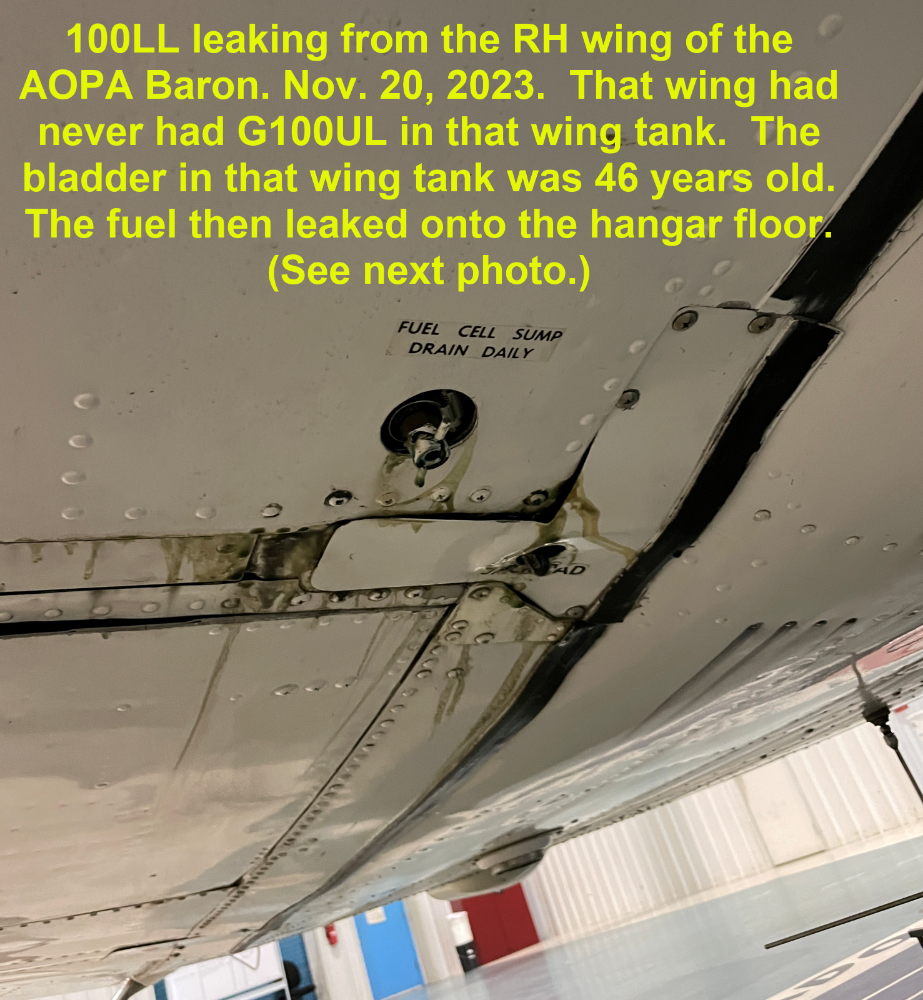

I copied George post here which was very informative at least for me on the history and chemistry sides. Especially for subject that is still under discussion while Avgas is “in transition” (I can understand why OP post on a specific aircraft gets removed, maybe request? or AvWeb story?) “Very much appreciate the discussion and the feedback, here. Please allow me to provide a response to some of the messages. 1) I am a big Mooney fan. Flew a 67 Mooney Super 21 for nearly 2,000 hours. Commuted to and from law school in Norman, Ok. to the family Ranch (100miles each way) on a daily basis for 3 years. 2) Part I - - Some aviation fuel chemistry history: A- During WWII fuels with very large amounts of aromatics were adopted. Arguably, the Air War would have been much more costly in terms of losses for the fighter aircraft without the introduction of aromatics to aviation gasoline. The fuel approved for D-Day was "100/150" - - and used a lot of different aromatic components; B- In the ranking of the levels of "aggressiveness" as solvents, the ranking starts (most severe) with benzene. Then add a single CH3 group and you get toluene. Yes. Paint stripper you buy at the paint store. C- Add a second Ch3 group and you get xylenes (three isomers - ortho, meta, & para) Xylenes are significantly less aggressive as a "paint stripper" than is toluene. <== THAT is important. Keep that in mind. D- Many fuel bladders were developed during WWII and are labeled "approved for aromatics" or something similar. If you look closely at some of the P-51s and other planes at Oshkosh, you will see a placard that states "approved for aromatic fuels." Part II - - Post WWII. A- We had "Green" 100/130 with LOTS and lots of lead. And even purple 115/145 (with lots of aromatics) At the end of the piston airline and going into the late 1970s and 1980s, the ASTM folks decided to drop the lead content and created BLUE 100Low Lead. Still lots of lead. But much less than GREEN 100/130. B- Some of the refiners had very good "aviation alkylate" (~ 70% of some 100LL fuel formulations) with relatively high MON values for that aviation alkylate (a less than pure form of isoctane). Those refineries could make 100LL with relatively low levels of aromatics (almost always "toluene" from the paint store). Maybe 10-20%. C- Other refineries (P66 at Borger, Tx, for example) had lower MON quality "aviation alkylate" and the had to use a LOT of toluene. I can show you detailed hydrocarbon analysis (GC-FID) test results for local (Ada, Ok. FBO) P66 Borger, Tx 100LL that has 29% toluene and another 4% of other aromatics for a total of about 33% aromatic content. 3) Fleet Experience during the transition to 100LL - - A-Starting shortly after the introduction of 100LL, with high levels of aggressive toluene, A LOT of Mooney, Piper, and other airplane owners that had aluminum integral fuel tanks (no bladders) began to leak fuel out of lots of rivet holes. That started a whole new business for G.A. with companies initially specializing in re-sealing those tanks. Later, companies developed retrofit fuel bladders for those problematic "integral fuel tanks". B- A big part of the problem was the aircraft manufacturers did an "inconsistent" (careful choice of words) job of applying the polysulfide sealant to the interior (rivets and seams) of the aluminum integral wing tanks as they were manufactured. [As we have learned during material compatibility testing, the devil is in the details when it comes to the proper application of sealants to fuel tanks. ] C) Over the decades, the level of toluene from most refiners has decreased due to better quality aviation alkylate, but some refiners - - for at least some production runs - - still (from looking at their data sheets) still have a lot of toluene. 4) G100UL Avgas - - A- Uses a very high quality aviation alkylate (2-4 MON numbers higher than the alkylate used for 100LL) and then uses xylenes rather than toluene in order to achieve the 100/150+ octane/supercharge rating for G100UL avgas. The right choice of xylene isomers will have higher octane blending value than does toluene. Using "xylenes" also has the advantage of being less chemically "aggressive" than is toluene. But the high quality alkylate and the premium xylene isomers also "cost more" than the related components in 100LL. BUT - - there ends up being no lead. B- We did extensive material compatibility testing, including a whole variety of older bladders and a whole range of tests for sealants applied to aluminum. All of that supervised (in person) by multiple FAA engineers and managers and then later approved by the FAA. 5) The 100LL we have at the airport in Ada (typically Phillips from Borger, Tx) still tends to have a lot of toluene in that fuel. A- Late October of 2023, AOPA brought their 1965 demonstration Baron to Ada. Two freshly overhauled IO-520s. One fuel bladder was 46 years old and the other ~50 years old. They were supposed to have been replaced with new, prior to the start of testing, but the bladders were on "back-order". B- G100UL avgas was exclusively kept in the LH bladder and 100LL was exclusively in the RH bladder. C-Within 30 days, we noticed fuel "spots" on the hangar floor. Investigation - - we found fuel leakage and staining on the bottom of the RH wing - - which had ONLY ever had 100LL. See photographs. 6- Oshkosh, the leakage from the LH wing tank (G100UL Avgas) was ( based on Eagle Fuel evaluation) caused by pre-existing damage to the tanks and the gaskets associated with the access panels. (In addition, there were pin-hole leaks in both fuel bladders). 7)-G100UL Avgas is NOT a threat to normal aircraft paint. A- Embry Riddle did extensive certification testing of G100UL avgas. They used G100UL in their C-172s for over a year, at Daytona Beach. They had no evidence of any fuel leaks and they had zero staining on the wings. B- As part of our due diligence, wee have deliberately spilled a LOT of G100UL Avgas onto various painted components from the many Bonanza aircraft that come through the TAT shop for turbo systems. That includes LOTs of wing tips and the lower cowling access panels, both of which are removed and replaced (with tip tanks and newly louvered lower access panels.) C- Some of that has been allowed to dry on those painted surfaces and then the process was repeated. NO SIGN OF ANY LOSS TO THE INTEGRITY OF THE ADHESION OF THE PAINT. D- We have even soaked a couple of those side panels in G100UL for a week or more. The paint was fine at the end of that. E- What does and will happen - - is if you do not properly clean up the spilled fuel, and allow it to dry, it can and will leave a light tan stain on the paint. If you do properly clean it up, it will not stain the paint - - even after repeated spills in the same location. But, to date, we have never seen any evidence of any type of "paint striping" activity to any of the dozen or more aircraft parts that were removed from our customers Bonanzas and used as "test articles." See https://g100ul.com/dl/Refueling Hygiene G100UL Avgas.pdf F- An aside - - some of the recent crystal and graphene coatings improve the resistance of aircraft paint to any damage from any variety of 100LL or G100UL - - but that is not a cure all. See the link Refueling Hygiene! 8. So "what happened" on the bottom of the Mooney wings ? A- In one case, the sump drain appears to be leaking. Likely the fittings inside the wing are also leaking. B- In the other case, there appears to be some kind of leakage from inside the wing. Not sure from the photographs. C- Almost certain that old drain valve has a "nitrile" set of O-rings. D- The paint on the bottom of the wings has likely had many months of exposure to steady drips of 100LL. In California, probably with only ~ 15% toluene in the 100LL . . . maybe. E- No information about the age of the paint on the bottom of the wings, but from its overall appearance and the multiple rivet holes that are bare and which have lost their paint - - it is likely a they are rather old paint jobs. The paint on my personal Bonanza, N11RT is about 35 years old and it is in much better condition than the appearance of the paint (away from the damaged paint). F- It would be good to know the age of the paint for each of those two aircraft. 9. What to do ? A-There is a long standing FAA / maintenance bulletin (20 + years old ???) that tells mechanics that when they find fuel leaks or deteriorated fuel lines or gaskets or O-rings, they should replace those components with parts that are made from chemically resistant materials (viton, fluorosilicones, etc.) Those types of materials are specifically stated to be for use with a wide variety of fuels, including aromatic based fluids. A lot of mechanics have ignored that recommendation over the years. Last . . . 10. I would like to have the chance to borescope an older Mooney fuel tank that has not been converted over to a bladder. A- If anyone on this forum would like to bring their plane to Ada we can do that here. You might find it interesting. If you have the STC you can probably leave with some G100UL in your tank, if you want. I hope this information helps to bring some clarity and understanding to these issues that will be the subject of conversations during the transition away from leaded avgas.”5 points

-

Well, it seems that the decision will be made for us by the government(s). The bureaucrats do not give a s^%$ about what it will cost us. They are only interested in checking the box that satisfied the environuts mandate. There have been more than few "new and improved" things that were forced onto the public that would not survive on the open market if it were not for government mandates or subsidies.4 points

-

4 points

-

I have had 92Q for about two and a half years. I really like the plane and it has been good to me. I have “caught up” on some maintenance/upgrades, new donuts, overhaul the mags, new flexible lines, new engine mount with the added gussets, got rid of some plaid headliner and not so nice blue carpeting, upgraded to J yokes, standard 6 pack layout, got the Brittian working, AV30 and JPI 830. But the one thing that has driven me crazy is the false third window. I always liked the “masked“ look on Mooneys. I decided to take the plunge and try to switch it up and add a “mask” and get rid of the rear fake window. I think it turned out decent, its not perfect but I am happy with the overall outcome. I used Spray Max 368 0031 2KRapid Fill Primer and Spray Max 368 0080 2K single stage topcoat. All in it calculates to about 4.5-5.5 oz to the weight of the plane.3 points

-

Two G5s won't provide attitude to your KFC150 autopilot. As @Rmnpilot mentions, you'll need a GI-275 with the autopilot interface to replace the KI-256 attitude indicator and another GI-275 to replace the KI-525 HSI. This will not only allow you to remove the vacuum pump(s) but will allow you to remove the remote gyro (KG102A) in the back of the airplane. If you have an early M20M with vacuum speed brakes you'll need the vacuum pump to run them.3 points

-

3 points

-

Most of the data that we have appears to be from a single source - the purveyor of the fuel. Don't interpret my concerns as a resistance to adoption of new fuel. I am all for improvement, but I also want some reasonable assurances, other than those made by the manufcaturer or government, that the change will not have signifcant adverse impact on safety and utility of my aircaft. In the ideal world, the market forces would determine the outcome, i.e, if the new fuel is better and safer than what we have, pilots will cheerfully adopt it and 100LL will go the way of the rotary telephone. I do not recall that the old phones were banned or that the govt would madate adoption of smartphones (by Apple or othewise). The market forces simply worked in favor of better products and consumer safety was not affected in any way (not getting into the theories of cellphones causing brain cancer here ). When it comes to fuel, the logistical issues with adoption of new products are much more complicated and thus it is more than likely that some form of government mandate will replace the current fuel and there will be little, if any, choice the consumer can make. Hence, I believe that the safety of the replacement product in such crcumstances needs to be tested with much greater scrutiny before it is unilaterally forced upon the public. While I aplaud George Braly and his team for developing the new fuel and I do not mean to imply in any way that his claims are false or unfounded, I am somewhat reluctant to blindly accept the claims without independent verification. The old proverb "Trust, but verify" comes to mind here.3 points

-

@Jetter2 Don’t think you’ll find your Cardinal faster than most well trimmed Mooneys and certainly not compared to turbo Mooneys. The M20K 252 & Encore strikes the sweet spot with fuel efficiency and speed per HP. The long bodies have larger engines and are faster but with higher fuel flow and weight. If a Cardinal RG is your jam, just go with it. No need to justify a decision that has big personal and some emotional aspects. Owning any aircraft is WAY better than owning none!! But don’t come to a Mooney fan website expecting to validate the conclusion you had when you first joined. We love our Mooneys here!3 points

-

I was just gonna post that link where it has a good description of why it's bad in a radial engine, but pretty much a non-issue on an inline or flat engine. Geared engines are another issue entirely, since gear lash, lubrication, etc., is an issue. I don't think any Mooneys have geared engines. That article also points out that lots of aerobatic aircraft (e.g., Bob Hoover's Shrike) spend (spent) lots of time with the props driving the engines and they don't seem to suffer for it. I don't think it's an excuse to abuse an engine, but I think it's not something to spend much time worrying about.3 points

-

The last 177RG was made in 1978. I don't believe there is such a thing as a turnkey 46+ year old airplane. If at that very moment in time that you buy it everything works, congratulations! Check back in a week and there will be something on your squawk list. That's airplane ownership. I'm not saying it has never happened, but in 40 years of following the market, although I've seen them advertised for more, I've never seen a Cardinal RG actually sell for $220,000. (Maybe I could see it if it was a 1978 model-last year-most desirable, zero time engine, TAT, Hartzell Trailblazer prop, new paint, Garmin glass with new autopilot, new interior, etc.) I wouldn't want my first airplane to be the most expensive example of that model ever sold. It's unlikely that the next buyer who has more experience will pay anywhere close to that. Someone may have paid $50,000 for the Tornado Alley Turbo upgrade on the Cardinal, and that may have added capability, but that doesn't add $50,000 in value. A legacy Cessna 182 (fixed gear) is a great airplane to build time in. It's a good step up from a 172 or Archer with a good margin of safety. If you buy it right, you can fly it and you'll get what you pay for it when you move up or stop flying. The maintenance costs are not crazy and they made enough of them that parts are easy to find.3 points

-

AJ with the S&C Bob reference from the wayback machine: FTW! Just stay out of the Trubulence! -dan2 points

-

I installed two GI-275s in my Bravo. Removed the entire vacuum system including the backup pump system in the avionics bay. All said and done, Gained 42#s in UL! And yes, G5s won't run the AP.2 points

-

Surprised nobody mentioned over-speeding on descent and the tails falling off so you end up UWOF. Very common Mooney problem. OP wisely wants a Cardinal RG.2 points

-

2 points

-

For sure! I have to avert my eyes It's like it's powered by two teams of hamsters with ropes and pulleys competing to see which side can get the gear leg up the fastest...and they aren't very well fed2 points

-

It seems like all of the cantilever-wing single-engine cessnas have ADs on the carry-through spars that are potentially very nasty and instrusive. All of the single-engine RG Cessnas have trouble with the gear power packs, but Mooneys arent especially problem-free in this area as well, although I'd argue better from a general maintenance perspective. We are blessed with relatively problem-free basic airframes compared to many. Everybody deals with corrosion, but so many other airframes have difficult ADs addressing basic things like carry-through spars, elevator hinges, elevator spars, wing attachment issues, etc., etc. It doesn't take a very thorough perusement of mooneyspace to discover that Mooneys are not especially problem-free, either, but there are an awful lot of common problems that we don't have.2 points

-

It depends what you're after. If it's speed and efficiency, the Mooney will spank the Cardinal 7 days a week. If things like big doors, top mounted wings, and tiny cargo compartments are important to you, the Cardinal is the way to go.2 points

-

It was posted by a passenger .... who might not be on speaking terms with the pilot this week2 points

-

I’m more than just skeptical. The airframe drag coefficient for a Mooney is .0173, the Cardinal is .0258. So unless the Mooneys engine/prop is unbelievably worse in efficiency than the Cardinal, the numbers are BS.2 points

-

2 points

-

2 points

-

I totally agree with you, and that's what I was saying. If the fuel have problem or potential issue we owners deserve to know, instead of being blindsided with a sudden fuel tank leak. I just thought if they made it clear to owners that their fuel will cause old sealant to leak, and we are not forced to use it, then it is fine. Then we can make an informed decision.2 points

-

Uh... negative... multi-engine training aircraft do indeed spend a whole lot of time with the throttle pulled back and the prop windmilling. Almost all OEI training is done with the "dead" engine actually still operating - it's either windmilling at idle, or operating at a very low power setting ("zero thrust"), because it's considered good risk management to minimize the frequency and locations under which an engine is actually feathered for real. Power off stalls require a windmilling prop. Vmc demos require a windmilling prop. Emergency descents are always performed with both engines at full RPM and idle power, in a high speed descent. This sort of work happens every day, so it makes it hard to buy into the idea that prop-driving-the-engine is a high-risk concern (hard to worry about "shock cooling" too, but that's a separate subject). None of that takes away from your data point on your buddy's RV-6 with the broken rings, though. And again, the acute risks of multi-engine training are high enough that long-term engine management concerns might be dismissed even if they're real. I'm just trying to understand the physics.2 points

-

Prop driving the engine was a bigger deal on radial engines because the situation that @N201MKTurbo described happens at the heavily loaded master rod bearing. It was especially problematic in the R-2800, I believe. It's not so much a problem in horizontally opposed engines. Somewhere I recall Lycoming warns against combinations of high rpm and low MAP (i.e., prop driving engine) on counterweighted engines because it can excite torsional vibrations that are outside the range of the counterweights potentially causing them to "detune" (which is a polite way of saying that they bang around on the pins until the bushings are damaged and then they no longer properly damp out the order of torsional vibration for which they were tuned).2 points

-

That's exactly why I'm asking for details. I'm a relatively fresh multi-engine instructor. The nature of the training requires allowing the "prop to drive the engine" on essentially every flight. Nothing in any multi-engine training material I've ever read indicates this is a concern. To be fair, the concerns of an immediate emergency/loss of control/crash are so acute in that environment that probably no one worries about the longevity of the engine. A neuron fired, and I remembered this article from AvWeb a long time ago: https://www.avweb.com/features/pelicans-perch-78-props-driving-engines/. It seems to suggest that the issues with the location of the oil hole in the rod journals, torsional resonance, etc. are "real", but do not rise to the level of an operational concern except in radial-engine (master rod) powered airliners descending at very high speed out of the flight levels for very prolonged periods of time.2 points

-

2 points

-

It’s not so much the oil holes on the crank rod journal because the loads on the rod are pretty low, but what is happening is that instead of having pressure on top of the piston pushing it down you have the crankshaft pulling the rod down and you have negative pressure on top of the pistons and you get ring flutter. It leads to broken rings and other things. Multi engine airplanes doing in-flight air shutdowns, and restarts don’t spend a whole lot of time with the throttle pulled back and windmilling until they are featheredor re-lit. And again, most of this is done at low speed and if the prop is driving the crankshaft at 100 mph is one thing but 150 or 60 miles an hour is something else. If you get on the highway at 60 miles an hour and jam your car into third gear it probably doesn’t hurt at all that much but if you shove it first, the forces are magnified. but generally speaking, you want positive torque on the crankshaft, and you want the engine pulling the prop, pulling the airplane forward, even if it’s just a small amount. In a four-cylinder Mooney, at high speed it’s probably around 18 or 20 inches, and at lower speed it will be less, like 16” and frankly, in the pattern if you’re going 100 miles an hour and you pull the power off and do a short approach it probably doesn’t matter all that much. But it’s at high speed where it does. I went for a ride in an Rv8 of a friend of mine and we flew around a while, and he had this habit of getting right up to the airport and then pulling the power almost to idle, and then shoving the nose down and the whole airplane kind of buzzed and had this flutter because of the air going through the prop air is disturbed because again, negative torque. He also seems to be getting about 400-500 hours on cylinders before he has to redo them, and the rings are always broken. Well, I have a theory as to why that’s happening.2 points

-

All the multi-engine trainers that routinely demonstrate windmilling and restart from the air driving the prop don't seem to have a problem. I suspect this is one of those things that is grossly overblown. Is there any manufacturer guidance indicating this is an issue?2 points

-

I love these threads. You like high wing airplanes, want to go 160kts, no retract time, don't like to suck O2, pleasure use only and you've got $200k to burn? Find a pponk'd 182 (of buy a good Skylane and pponk it when the time comes) enjoy 145-150 kts, cheap insurance and cheap annuals. Spend an extra half-hour each way, twice a year? Easy trade for the simplicity and capability of a 182 compared to turbo, deiced, retract anything. Nothing will crush your love for aviation like the running cost of an airplane more complicated than you need...2 points

-

175kts at 10gph is going to be something you only get while sucking the O2.2 points

-

I am older than you, but the same thing. I WANTED a top of the line panel to enjoy. When I finally sell the airplane, if I don't get what I put into it, so be it. I ENJOYED the plane for many hours and trips.2 points

-

Very much appreciate the discussion and the feedback, here. Please allow me to provide a response to some of the messages. 1) I am a big Mooney fan. Flew a 67 Mooney Super 21 for nearly 2,000 hours. Commuted to and from law school in Norman, Ok. to the family Ranch (100miles each way) on a daily basis for 3 years. 2) Part I - - Some aviation fuel chemistry history: A- During WWII fuels with very large amounts of aromatics were adopted. Arguably, the Air War would have been much more costly in terms of losses for the fighter aircraft without the introduction of aromatics to aviation gasoline. The fuel approved for D-Day was "100/150" - - and used a lot of different aromatic components; B- In the ranking of the levels of "aggressiveness" as solvents, the ranking starts (most severe) with benzene. Then add a single CH3 group and you get toluene. Yes. Paint stripper you buy at the paint store. C- Add a second Ch3 group and you get xylenes (three isomers - ortho, meta, & para) Xylenes are significantly less aggressive as a "paint stripper" than is toluene. <== THAT is important. Keep that in mind. D- Many fuel bladders were developed during WWII and are labeled "approved for aromatics" or something similar. If you look closely at some of the P-51s and other planes at Oshkosh, you will see a placard that states "approved for aromatic fuels." Part II - - Post WWII. A- We had "Green" 100/130 with LOTS and lots of lead. And even purple 115/145 (with lots of aromatics) At the end of the piston airline and going into the late 1970s and 1980s, the ASTM folks decided to drop the lead content and created BLUE 100Low Lead. Still lots of lead. But much less than GREEN 100/130. B- Some of the refiners had very good "aviation alkylate" (~ 70% of some 100LL fuel formulations) with relatively high MON values for that aviation alkylate (a less than pure form of isoctane). Those refineries could make 100LL with relatively low levels of aromatics (almost always "toluene" from the paint store). Maybe 10-20%. C- Other refineries (P66 at Borger, Tx, for example) had lower MON quality "aviation alkylate" and the had to use a LOT of toluene. I can show you detailed hydrocarbon analysis (GC-FID) test results for local (Ada, Ok. FBO) P66 Borger, Tx 100LL that has 29% toluene and another 4% of other aromatics for a total of about 33% aromatic content. 3) Fleet Experience during the transition to 100LL - - A-Starting shortly after the introduction of 100LL, with high levels of aggressive toluene, A LOT of Mooney, Piper, and other airplane owners that had aluminum integral fuel tanks (no bladders) began to leak fuel out of lots of rivet holes. That started a whole new business for G.A. with companies initially specializing in re-sealing those tanks. Later, companies developed retrofit fuel bladders for those problematic "integral fuel tanks". B- A big part of the problem was the aircraft manufacturers did an "inconsistent" (careful choice of words) job of applying the polysulfide sealant to the interior (rivets and seams) of the aluminum integral wing tanks as they were manufactured. [As we have learned during material compatibility testing, the devil is in the details when it comes to the proper application of sealants to fuel tanks. ] C) Over the decades, the level of toluene from most refiners has decreased due to better quality aviation alkylate, but some refiners - - for at least some production runs - - still (from looking at their data sheets) still have a lot of toluene. 4) G100UL Avgas - - A- Uses a very high quality aviation alkylate (2-4 MON numbers higher than the alkylate used for 100LL) and then uses xylenes rather than toluene in order to achieve the 100/150+ octane/supercharge rating for G100UL avgas. The right choice of xylene isomers will have higher octane blending value than does toluene. Using "xylenes" also has the advantage of being less chemically "aggressive" than is toluene. But the high quality alkylate and the premium xylene isomers also "cost more" than the related components in 100LL. BUT - - there ends up being no lead. B- We did extensive material compatibility testing, including a whole variety of older bladders and a whole range of tests for sealants applied to aluminum. All of that supervised (in person) by multiple FAA engineers and managers and then later approved by the FAA. 5) The 100LL we have at the airport in Ada (typically Phillips from Borger, Tx) still tends to have a lot of toluene in that fuel. A- Late October of 2023, AOPA brought their 1965 demonstration Baron to Ada. Two freshly overhauled IO-520s. One fuel bladder was 46 years old and the other ~50 years old. They were supposed to have been replaced with new, prior to the start of testing, but the bladders were on "back-order". B- G100UL avgas was exclusively kept in the LH bladder and 100LL was exclusively in the RH bladder. C-Within 30 days, we noticed fuel "spots" on the hangar floor. Investigation - - we found fuel leakage and staining on the bottom of the RH wing - - which had ONLY ever had 100LL. See photographs. 6- Oshkosh, the leakage from the LH wing tank (G100UL Avgas) was ( based on Eagle Fuel evaluation) caused by pre-existing damage to the tanks and the gaskets associated with the access panels. (In addition, there were pin-hole leaks in both fuel bladders). 7)-G100UL Avgas is NOT a threat to normal aircraft paint. A- Embry Riddle did extensive certification testing of G100UL avgas. They used G100UL in their C-172s for over a year, at Daytona Beach. They had no evidence of any fuel leaks and they had zero staining on the wings. B- As part of our due diligence, wee have deliberately spilled a LOT of G100UL Avgas onto various painted components from the many Bonanza aircraft that come through the TAT shop for turbo systems. That includes LOTs of wing tips and the lower cowling access panels, both of which are removed and replaced (with tip tanks and newly louvered lower access panels.) C- Some of that has been allowed to dry on those painted surfaces and then the process was repeated. NO SIGN OF ANY LOSS TO THE INTEGRITY OF THE ADHESION OF THE PAINT. D- We have even soaked a couple of those side panels in G100UL for a week or more. The paint was fine at the end of that. E- What does and will happen - - is if you do not properly clean up the spilled fuel, and allow it to dry, it can and will leave a light tan stain on the paint. If you do properly clean it up, it will not stain the paint - - even after repeated spills in the same location. But, to date, we have never seen any evidence of any type of "paint striping" activity to any of the dozen or more aircraft parts that were removed from our customers Bonanzas and used as "test articles." See https://g100ul.com/dl/Refueling Hygiene G100UL Avgas.pdf F- An aside - - some of the recent crystal and graphene coatings improve the resistance of aircraft paint to any damage from any variety of 100LL or G100UL - - but that is not a cure all. See the link Refueling Hygiene! 8. So "what happened" on the bottom of the Mooney wings ? A- In one case, the sump drain appears to be leaking. Likely the fittings inside the wing are also leaking. B- In the other case, there appears to be some kind of leakage from inside the wing. Not sure from the photographs. C- Almost certain that old drain valve has a "nitrile" set of O-rings. D- The paint on the bottom of the wings has likely had many months of exposure to steady drips of 100LL. In California, probably with only ~ 15% toluene in the 100LL . . . maybe. E- No information about the age of the paint on the bottom of the wings, but from its overall appearance and the multiple rivet holes that are bare and which have lost their paint - - it is likely a they are rather old paint jobs. The paint on my personal Bonanza, N11RT is about 35 years old and it is in much better condition than the appearance of the paint (away from the damaged paint). F- It would be good to know the age of the paint for each of those two aircraft. 9. What to do ? A-There is a long standing FAA / maintenance bulletin (20 + years old ???) that tells mechanics that when they find fuel leaks or deteriorated fuel lines or gaskets or O-rings, they should replace those components with parts that are made from chemically resistant materials (viton, fluorosilicones, etc.) Those types of materials are specifically stated to be for use with a wide variety of fuels, including aromatic based fluids. A lot of mechanics have ignored that recommendation over the years. Last . . . 10. I would like to have the chance to borescope an older Mooney fuel tank that has not been converted over to a bladder. A- If anyone on this forum would like to bring their plane to Ada we can do that here. You might find it interesting. If you have the STC you can probably leave with some G100UL in your tank, if you want. I hope this information helps to bring some clarity and understanding to these issues that will be the subject of conversations during the transition away from leaded avgas. Regards, George Braly gwbraly@gami.com2 points

-

I would want to have, in my scan, an AI that's failing and tumbling in IMC while my autopilot is following it.1 point

-

Lollll. Show me a single example of this very common problem. “An old timer once told me” does not count. I’ll be waiting but I suspect the troll goes back under the bridge!!! alright back to the prime topic. Anyone with a Cardinal RG, you are hereby challenged to a race. Apples to apples. I will travel 200nm to meet. We pick an airport and a GPS waypoint. Takeoff 1 minute after the other. Time to the waypoint. Let’s go!!!!1 point

-

I will add the another harsh reality, I have seen these projects get stalled, and the result was money put into an airframe that is now diassembled, parts scattered, and even further from airworthiness. Be prepared to do the job all at once. Have the time and money allotted before starting anything like this. IMO, like many others, if you have the money for the total project, buy the airworthy plane you can afford instead, and start flying now. -dan1 point

-

1 point

-

1 point

-

it's ridiculous, I could have gone to AOPA, I could have emailed the airport manager, I could have reached to the FSDO, I could have posted on X and I could have posted on Linkedin (find me there)...I didn't...I emailed GAMI and let them know and message the forum to let everyone know. Now I am really going to be up in this unless that thread resurfaces1 point

-

I rarely fly my G650 because honestly the ease of entry, exit, and overall space of a Mooney is just better. I like my F but reading some of these posts, wow….1 point

-

Not sure exactly where @Cody Stallings shop is but it’s that way and he’s a straight shooter. If it ain’t leaking, there’s a school of thought that say leave it be…1 point

-

Thanks for the reply. And THAT ALL, is my problem with winter flying, I never know which cloud will have icing and which won't. Even forecast can be very wrong. I have one of my worst icing on a day with only moderate icing forecasted (Canadian GFA literally paint any cloud above freezing level as moderate icing). And also had experience of picking up ZERO ice in forecasted severe icing. I think you guys down south have better icing GFA but I'm not so sure how much I want to bet my life on that either, with a airplane without TKS, even when it is just for the purpose of punching throwing a layer. Considering the limitation of single alternator and single pump, I think a reasonble way to fly a non FIKI TKS bird is to never get into something too deep. If it is icing in one specific altitude it'd be mostly ok to climb or descend through it since the likelyhood of alt or pump failure at this unfortunate time is pretty low, and even if it does fail it's not to hard to get out of icing before things get out of control. Please tell me if this is a stupid idea. I've heard Caravan pilots in my company says TKS works like wonder, much better then phnumatic boots. I'd like to believe them. But the plane I flew also have boots and they work like wonders. I had picked up two inch of ice on one approach and didn't even notice any performance degradation. But then there's also ATR with boots and powerful turbine engine that seemingly fall out of ice like drunk birds... Very airframe specific I suppose.1 point

-

Yeah, I was not seriously suggesting that a Malibu is comparable - I was just trying to point out that “winning the lottery” should be like an order of magnitude more ambitious than “the thing I can afford to buy right now”1 point

-

1 point

-

I have done winter trips with Clean, TKS, FIKI, Boot…there is so much grey in these capabilities depending if you are climbing, descending, cruising and how much VFR above/under “Known ice” is somewhere between actual clear ice splashes (10kts speed loss every 1min) and forecast of moisture bellow freezing level getting (where you can fly 10h), so at the end of the day, it matter of how much time you have versus how much time you need Pilots wants simple answers, * Known ice = IMC < 0C * FIKI: go flying vs Non-FIKI: no flying * Jets: go flying vs Piston: no flying The reality is much more complex of course To add more more grey: “your equipment is proportional to airspace and airport complexity”: in busy ATC system and airspace, you should not fly if you can’t take some heat (wrong choice) and be fully equipped for that, otherwise, you are getting into the way of those who are equipped From FIKI certification, one can see it’s more about redundancy than effectiveness, however, empirical evidences shows that they cope more than +10min, even some clean wings can last +10min Look at Appendix C to Part 25 (Part 23 as reference as well), to see just how limited FIKI certification is, you will see that the maximum droplet size contemplated is 40 microns...smaller than a human hair...so if you can see the droplets you are in conditions beyond which FIKI applies; if I recall the distance correctly, if the cloud you are in is stratus and extends more than 17 miles, you are once again outside of FIKI standards. All FIKI certification buys you is time to escape (10min at best), not permission to continue.1 point

-

Someone spent a whole lot of money on that Cardinal. In my experience, no airplanes do “book numbers” in cruise. Most doesn’t even make book, but may get real close if you are wringing it out and flying it like you stole it. That being said. The relative embellishments of them all still make them more or less accurate in comparison. Aviation is completely discretionary, and it’s expensive, so why not just get what you want? I would be willing to bet any turbo Mooney is faster than that cardinal at the same altitude and fuel flow. So for the sake of discussion let’s just say the cardinal is 10kts slower. On a 500mile trip that’s only about a 15min difference. 500/160= 3.125 hours. 500/150=3.333 hours That is not worth buying a plane you don’t like. I do say do the math on gpm as well as gph though, it can make a big difference in considering fuel burn. And as @dkkim73 said, using a conserver is a game changer for o2, or it was for me. I think if you compare apples to apples in appointments, age, engine time avionics etc, you get more bang for your buck with a Mooney. But as others have said, everything is a trade off, and the money is not the only factor.1 point

-

1 point

-

Damn, I got scammed: I would 1/ sell the beloved Mooney and 2/ get Cardinal that go 175kts at 10gph I would then fly that Cardinal at 130kts at 4gph on it's Carson speeds ! I now have to stop thinking about that 252/Encore, I am on the market for the Cardinals You have less problems as you only have to do 2/1 point

-

I would beg to differ. It is most definitely not fine if fuel that is billed as a safe drop-in replacement of the existing fuel would cause damage to tanks and paint, potentially forcing unsuspecting owwners to pay tens of thousands of dollars for repairs. While we arguably do not have enough data to reach any definitive conclusions on this issue, the concern I have is that we may not have a choice if the govt will force the switch to G100UL before these issues can be conclusively resolved. Yes, the damage can arguably be mitigated if you throw enough money at it, but I would prefer it not to be my money, i.e, having to pay for resealing of tanks and repainting of plane because I am forced to use a fuel that is too aggressive on sealant and paint.1 point

-

1 point